Water conservancy river channel silt removal device with silt and water separation function

A mud-water separation and dredging device technology, which is applied to mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., can solve the problem of not setting filters, reducing the space required for storage, and operating difficulties and other problems, to achieve the effect of facilitating collection and cleaning and preventing accumulation and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with specific embodiments. This embodiment provides detailed implementation methods and specific operation processes on the premise of the technical solution of the present invention.

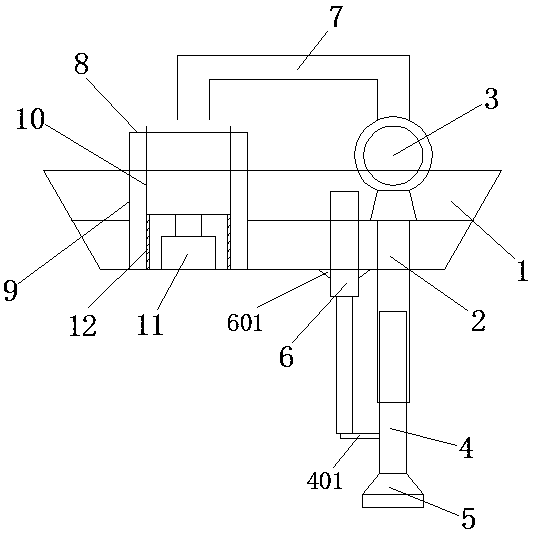

[0012] As shown in the figure, the present invention is a water conservancy river channel dredging device with mud-water separation function, including a dredging ship 1, a dredging pipeline 2 arranged at the bottom of the dredging ship 1 and a dredging pipeline connected with the dredging pipeline 2 Pump 3, the sliding sleeve at the bottom end of the dredging pipeline 2 is provided with a telescopic tube 4, the bottom end of the telescopic tube 4 is provided with a dredging suction cup 5, and the side wall of the telescopic tube 4 near the bottom is provided with a fixing plate 401, and the dredging ship 1. A telescopic oil cylinder 6 is vertically arranged on one side of the adjacent dredging pipeline 2. The telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com