Cast-in-situ bored pile grouting device and construction method thereof

A technology of bored piles and grouting devices, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as the influence of the forming quality of foundation piles, easy to touch steel cages, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

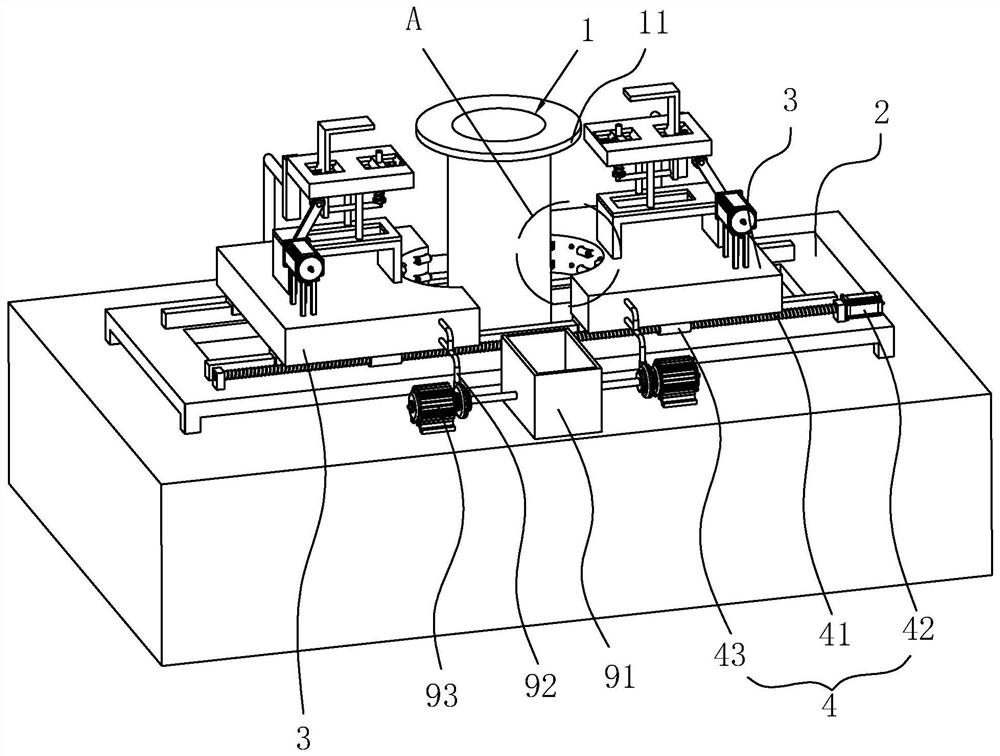

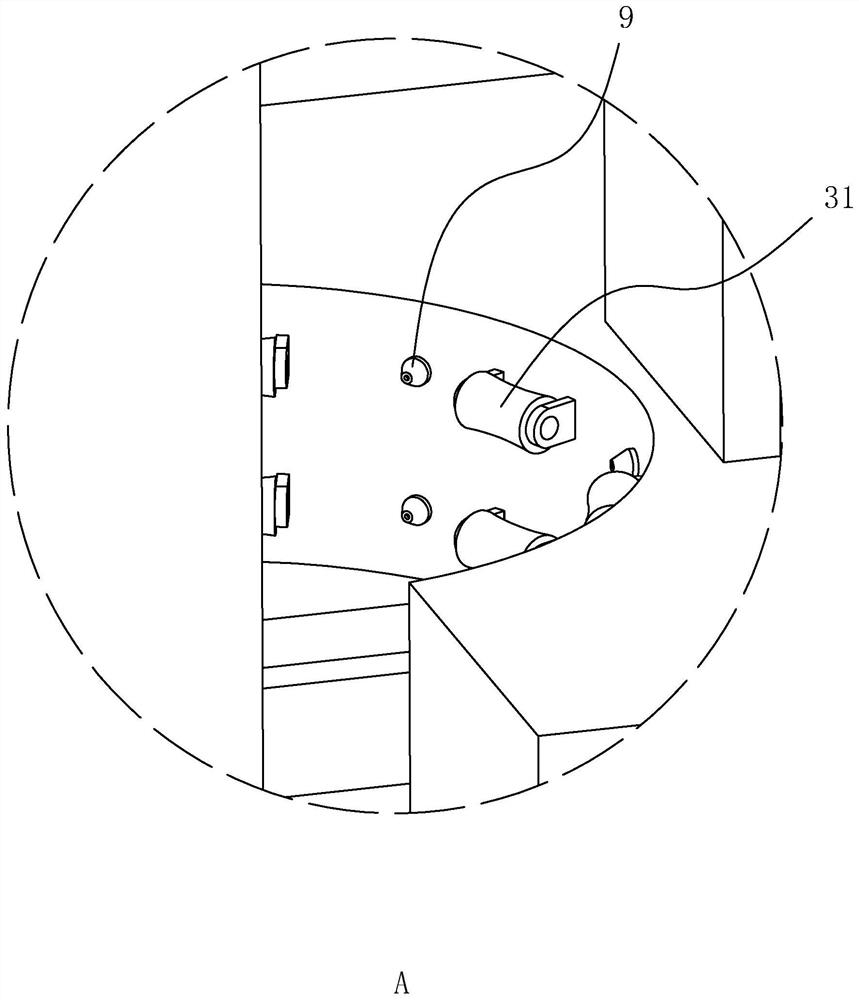

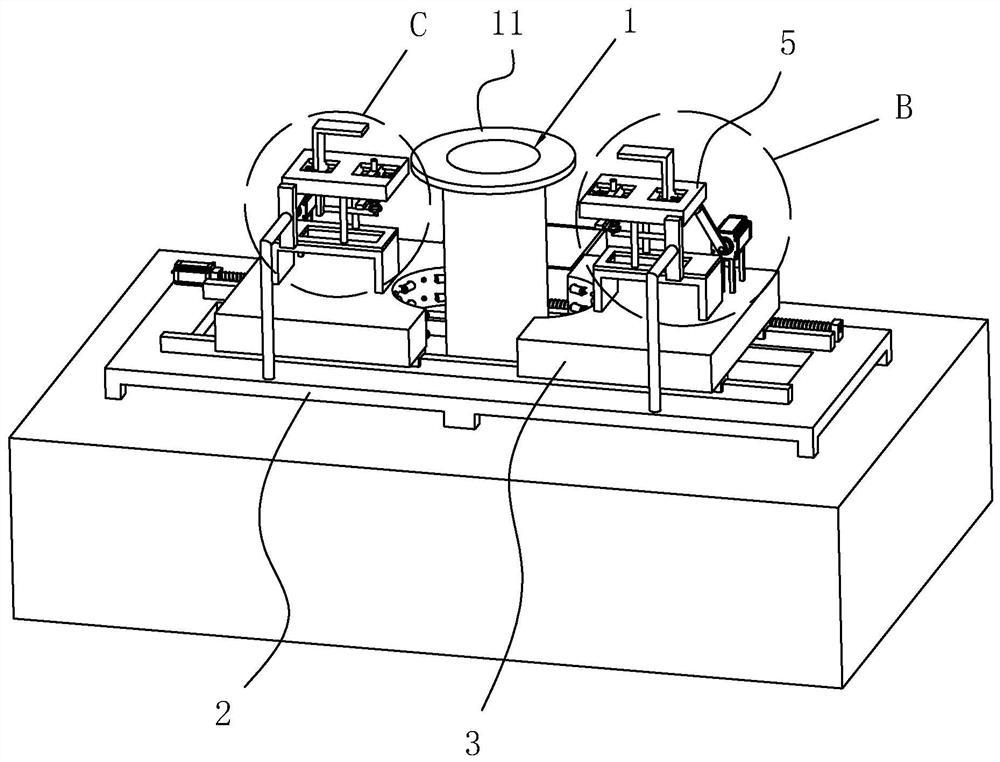

[0041] The following is attached Figure 1-5 The application is described in further detail.

[0042] The embodiment of the present application discloses a grouting device for bored piles. refer to figure 1 , including a frame 2 and two sliding seats 3, the frame 2 is placed on the ground at the position of the hole 1 of the foundation pile, the middle part of the frame 2 is hollowed out, and the hole 1 of the foundation pile is aligned with the hollowed out position of the middle part of the frame 2. On the top wall of the frame 2, guide rails are respectively bolt-fixed on the two side edges in the length direction of the frame 2, and the two sliding seats 3 are all slidably installed on the guide rails. The two sliding seats 3 are respectively located on both sides of the hole 1 of the foundation pile on the frame 2 , the sliding directions of the two sliding seats 3 are on a straight line, and they move symmetrically and reversely on both sides of the hole 1 .

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com