Lifting type sealing and anti-blocking guide chute

A lift-type, material-guiding trough technology, applied in the field of material-guiding troughs, can solve the problems of increased stock of material-guiding troughs, increased work intensity, material blockage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

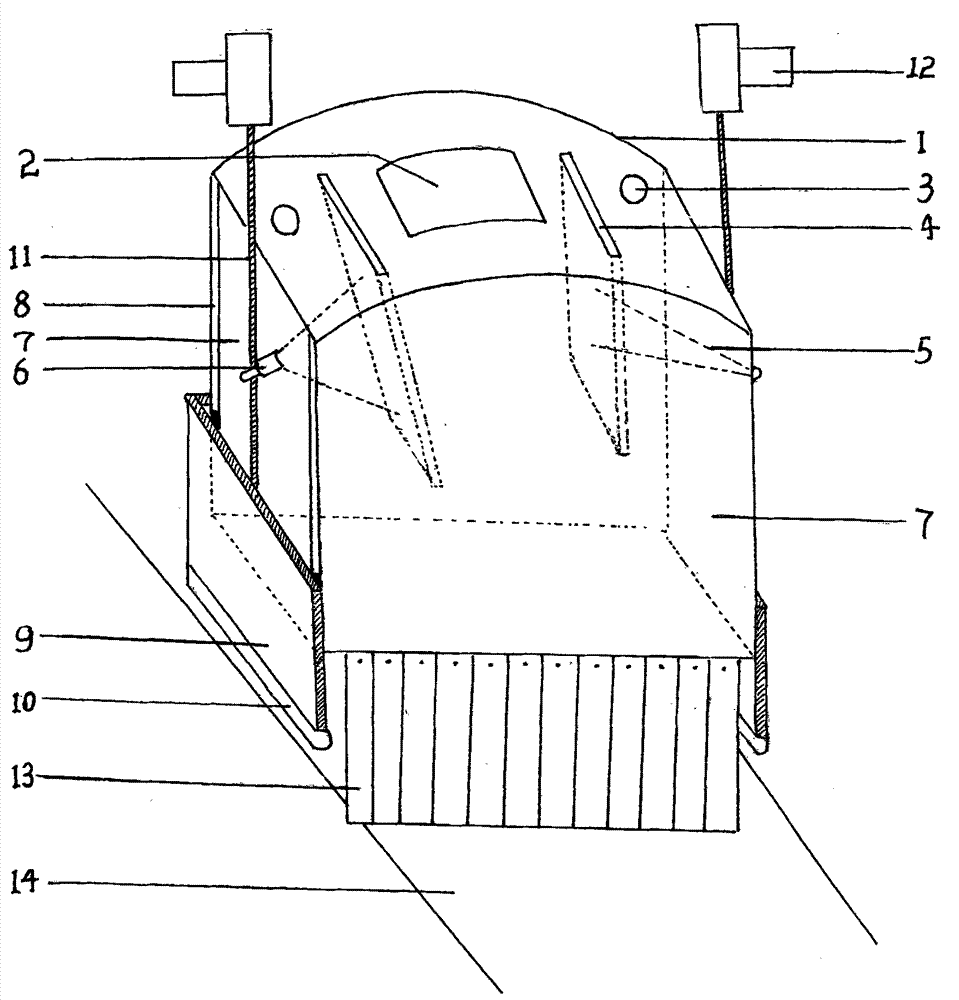

[0007] A lift-type sealed and anti-blocking guide trough, including a trough body (1), a discharge port (2), a spray nozzle (3), a buffer plate (4), an adjustment rod (5), an adjustment bolt (6), a fixing Baffle plate (7), sliding track (8), movable tank body (9), sealing strip (10), pull rod (11), driving device (12), dustproof curtain (13), material receiving belt (14), The top cover of the tank body (1) is arc-shaped, and the top cover of the tank body (1) is provided with a blanking opening (2), a spray nozzle (3), and a buffer plate (4), and the buffer plate (4) is adjusted by The rod (5) is supported, and the outer wall of the tank body (1) is provided with an adjusting bolt (6). (1) Sliding tracks (8) are set on both sides, and a movable trough (9) is set at the bottom of the trough (1). Baffle plate is formed and is a few characters shape, and pull bar (11) is established on the movable tank body (9), and sealing strip (10) is established at the movable tank body (9) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com