Online overhaul and refractory material transportation system for independent hot blast furnace and overhaul method

A technology of transportation system and hot blast stove, which is applied in the direction of furnace, lining repair, furnace components, etc. It can solve the problems of spherical vault collapse, large amount of demolition, and long duration, so as to avoid accumulation blockage, reduce construction cost, and improve The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

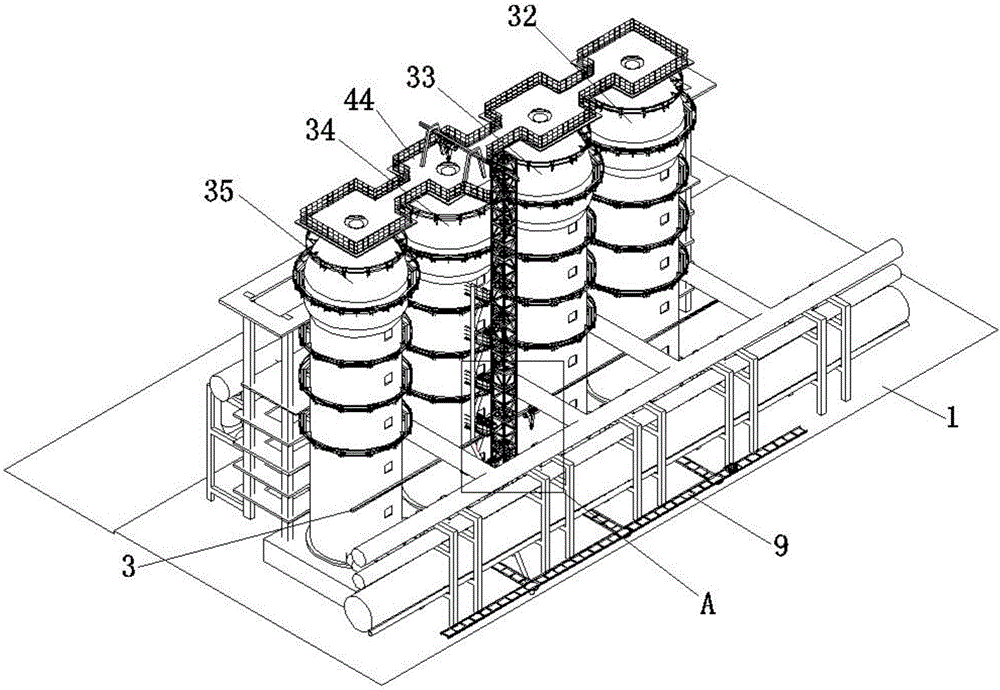

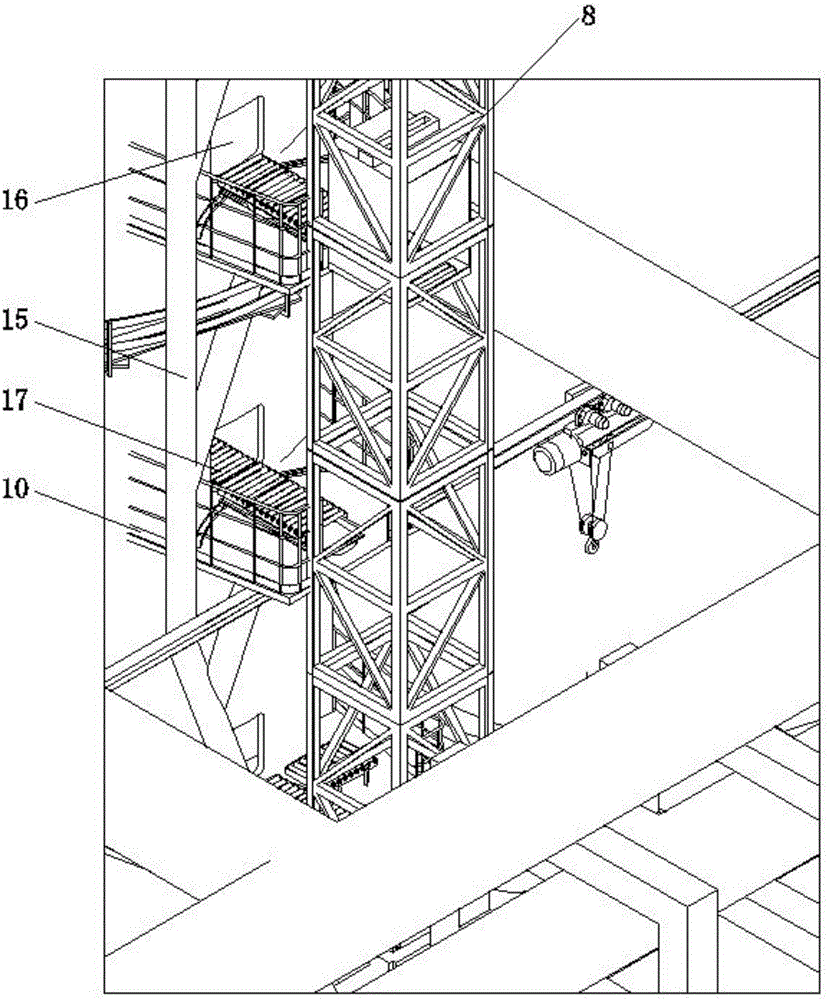

[0045] Such as figure 1 and figure 2 The shown online maintenance and refractory transportation system for the independent hot blast stove includes an external transport device located outside the hot blast stove and an in-furnace hoisting device located inside the hot blast stove.

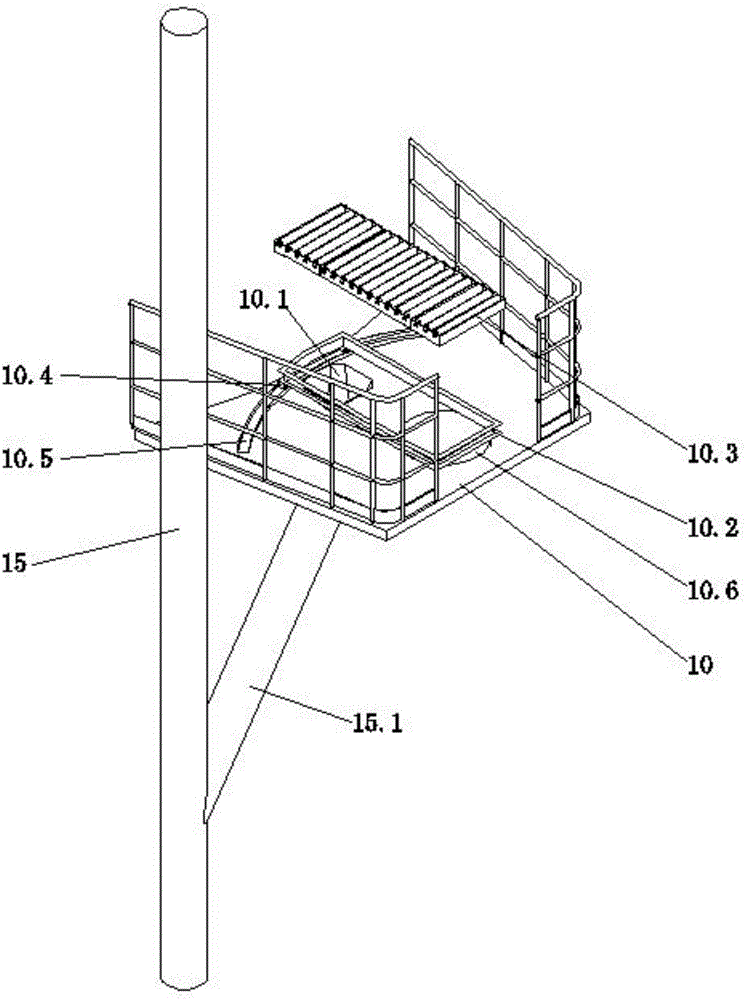

[0046] Such as Figure 5 As shown, the transportation device outside the furnace mainly includes a construction plane 1, a construction platform 10, an auxiliary vertical transportation mechanism and a vertical transportation mechanism 5, and a construction platform 10 is built outside the construction hole 16 of the hot blast stove, and a construction platform 10 is built below the bottom construction platform 10. A turnover platform 2, an auxiliary vertical transportation mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com