Novel glass powder sprayer and working method thereof

A powder spraying machine and glass technology, which is applied in the field of glass manufacturing, can solve the problems of complex structure, high price, and failure to solve the hidden danger of powder compaction, so as to achieve the effect of uniform powder spraying and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

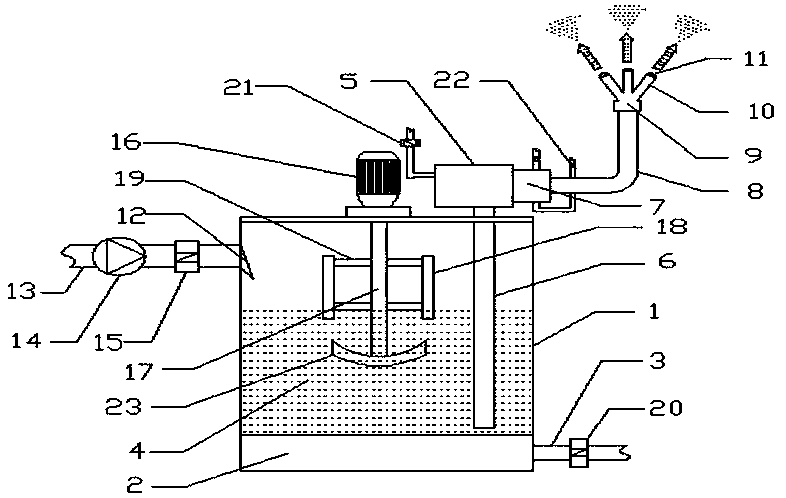

[0027] Such as figure 1 , a new type of glass powder spraying machine, including the frame (not shown in the figure, the frame structure is not protected here, it only needs to meet the layout of the factory site), and it is also fixed on the frame by bolt connection. The fluidization device, the vacuum generator 5, and the powder distributor; feasible, the vacuum generator 5 selects a Venturi vacuum generator 5; the fluidization device includes a fluidized powder storage box 1 and is arranged The base 2 below the powder box 1 is feasible, the base 2 and the fluidized powder storage box 1 are integrally formed, and there is a hole for the fluidized compression pipeline 3 to pass between the fluidized powder storage box 2 and the base 1; The base 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com