Patents

Literature

96results about How to "Dust evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

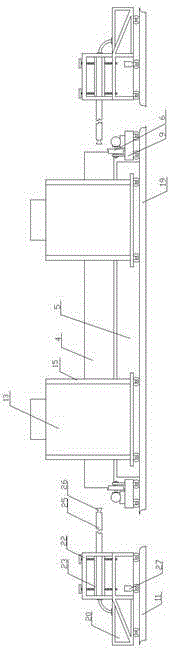

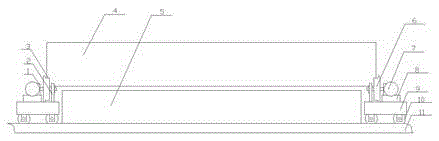

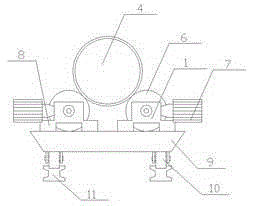

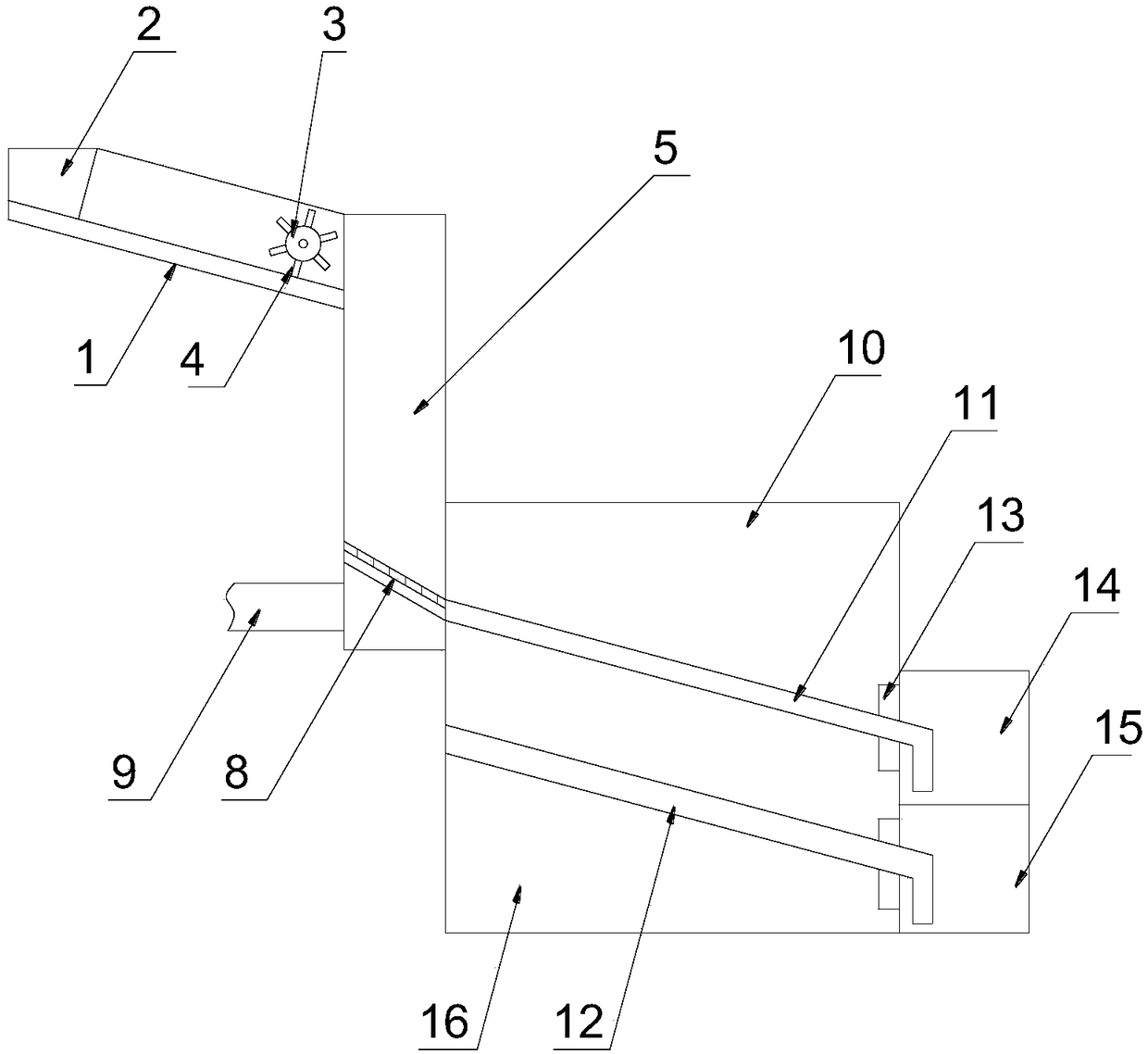

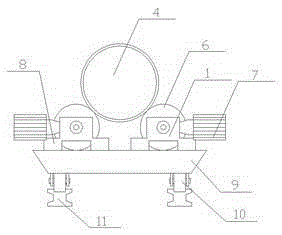

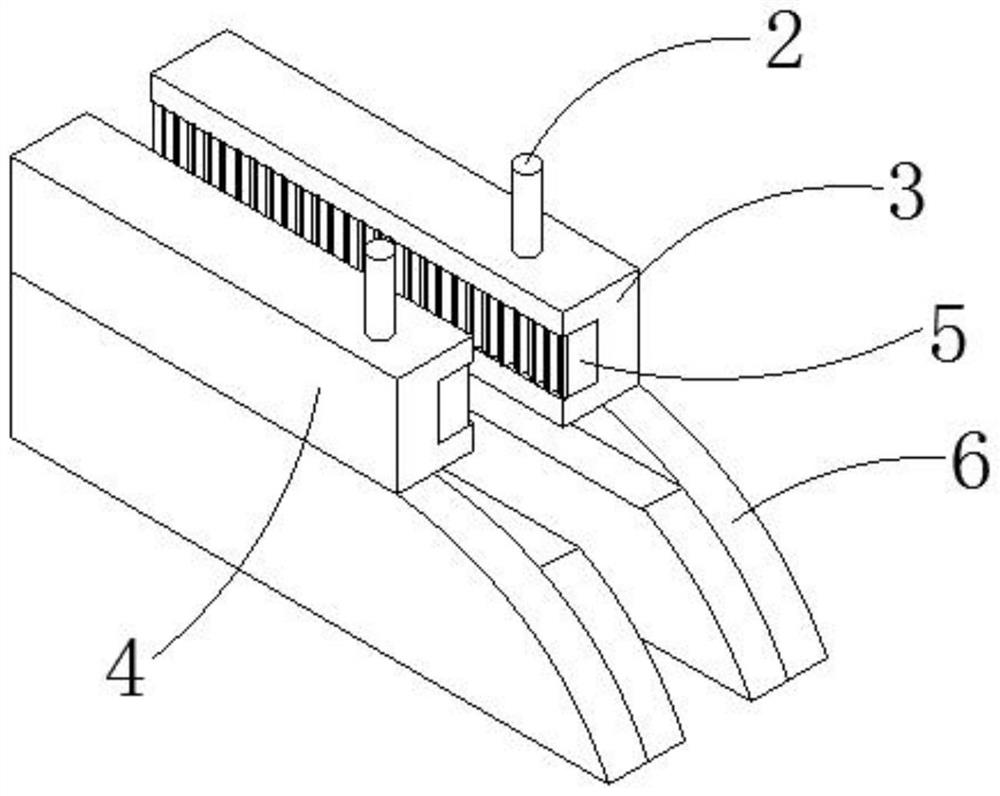

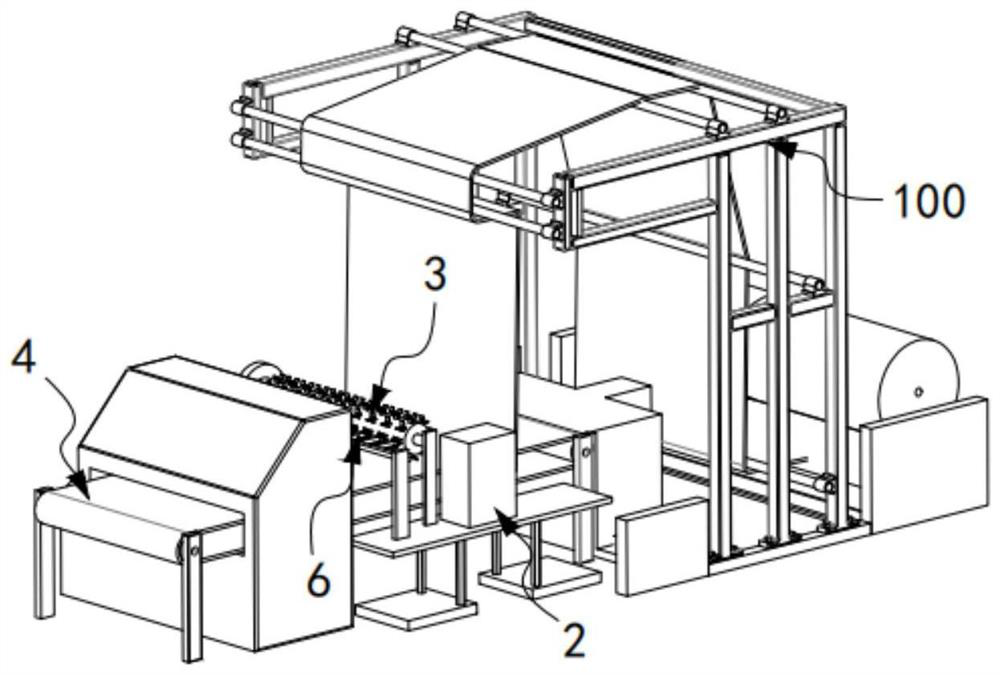

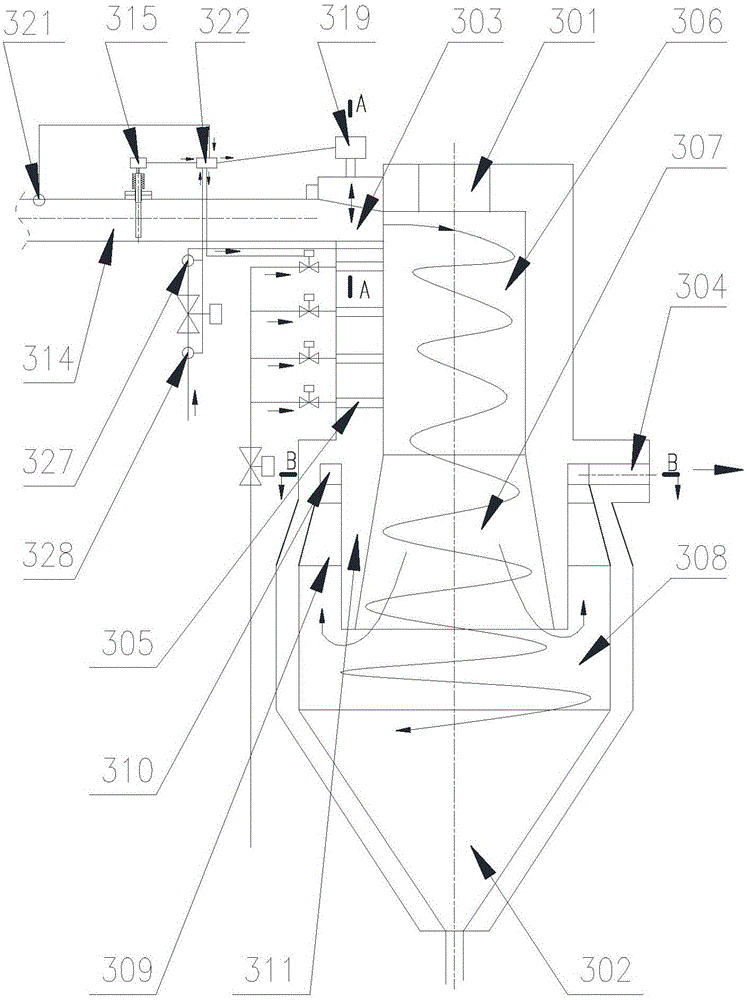

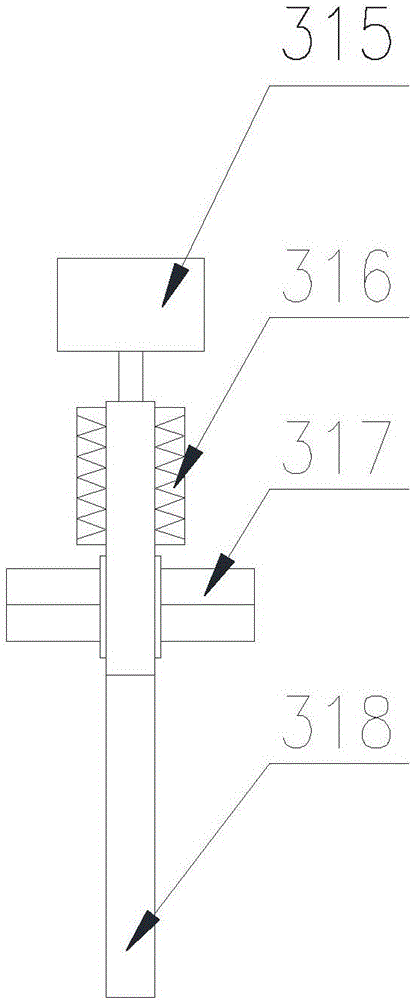

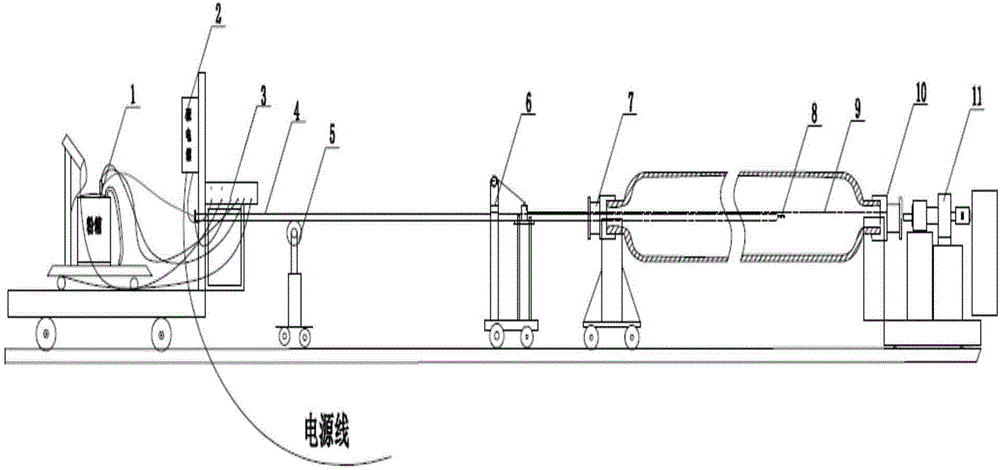

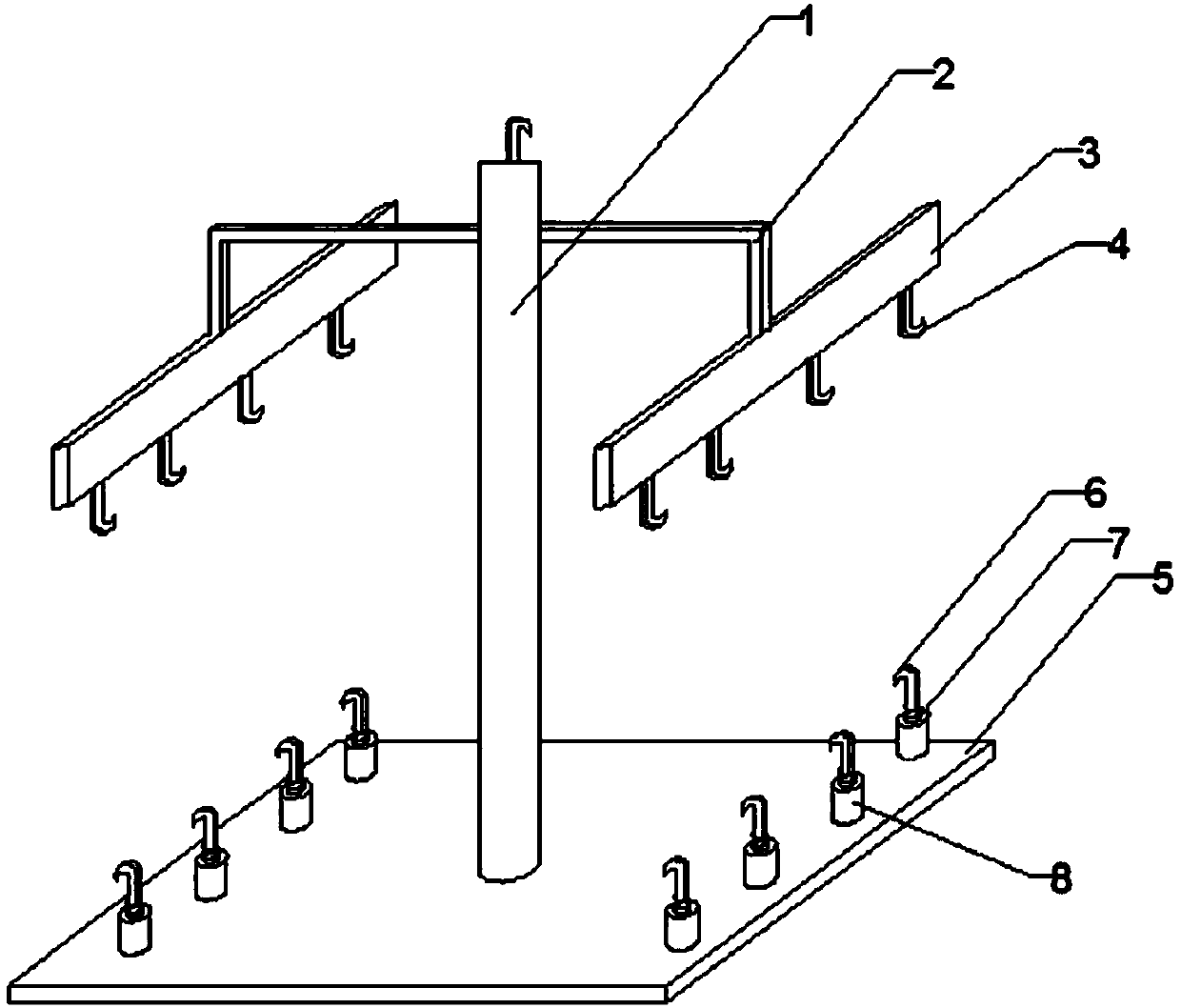

Synchronous spraying and curing processing method for pipelines arranged in parallel

ActiveCN105413978AIncrease profitAvoid vibrationSpraying apparatusPretreated surfacesMedium frequencyMaterials science

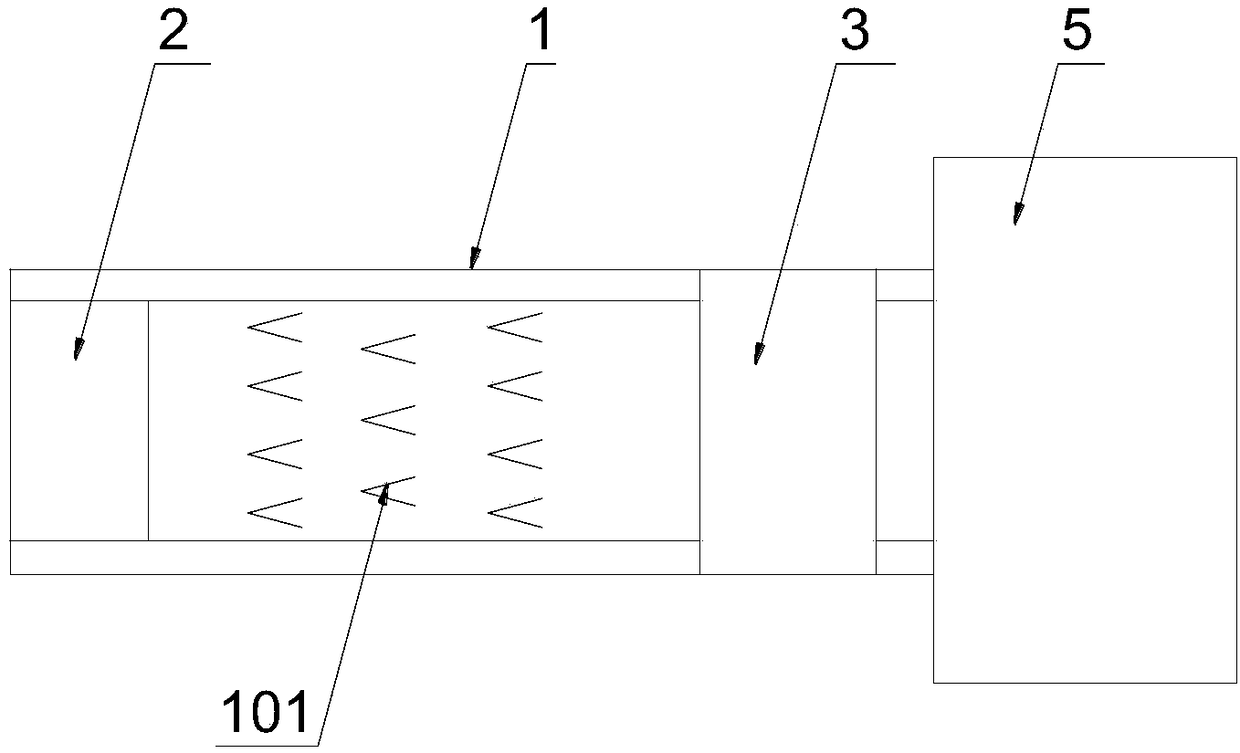

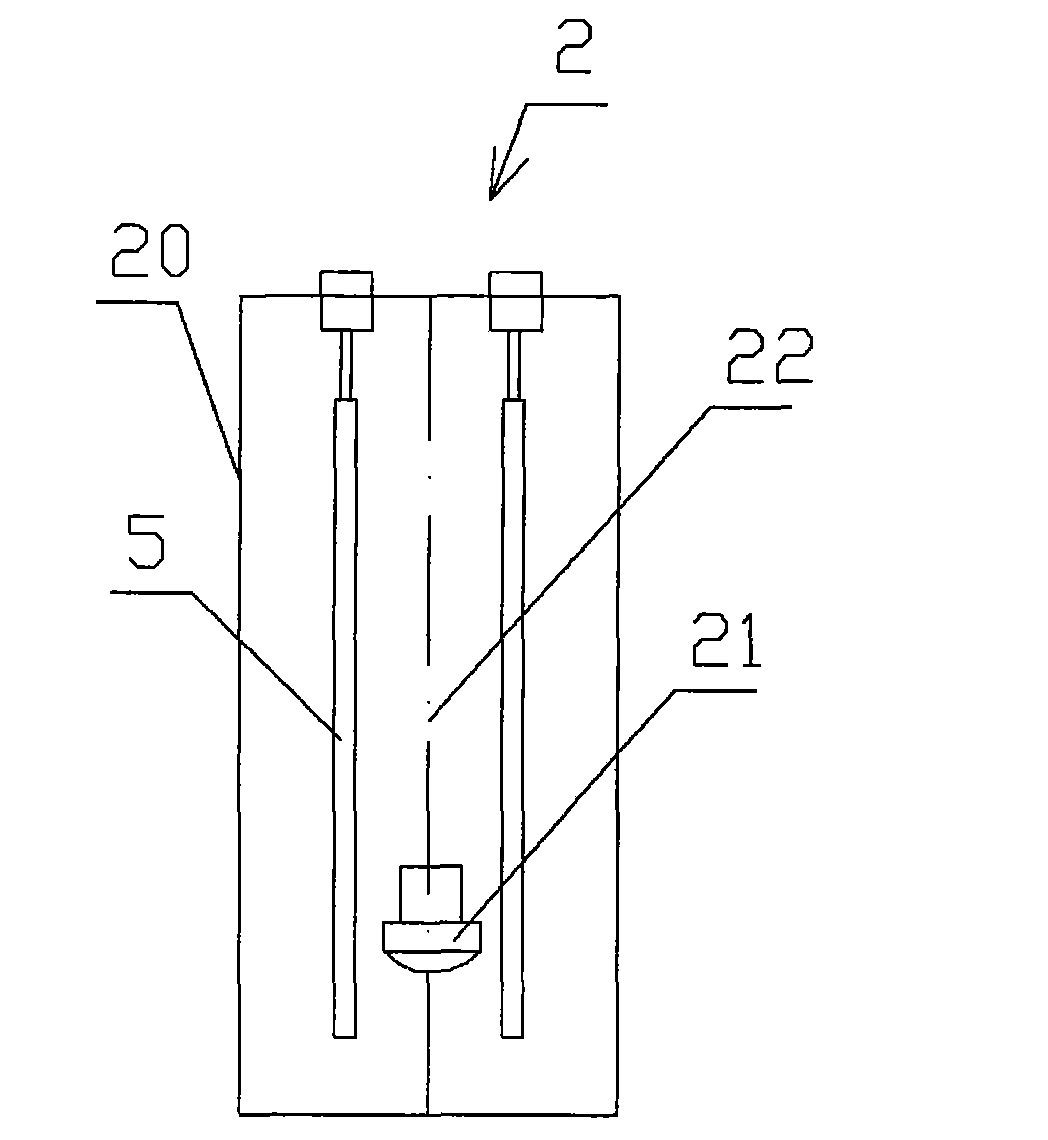

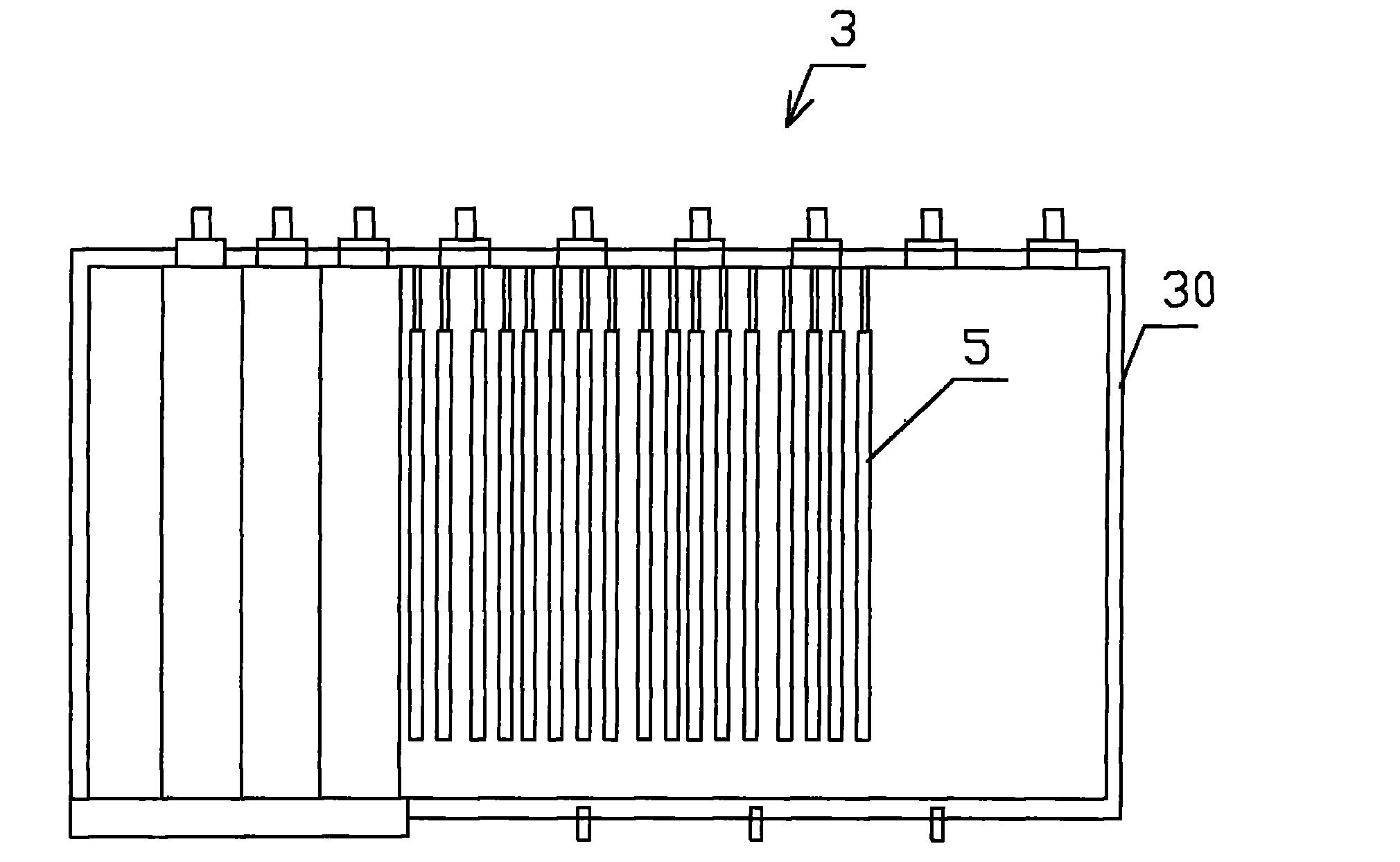

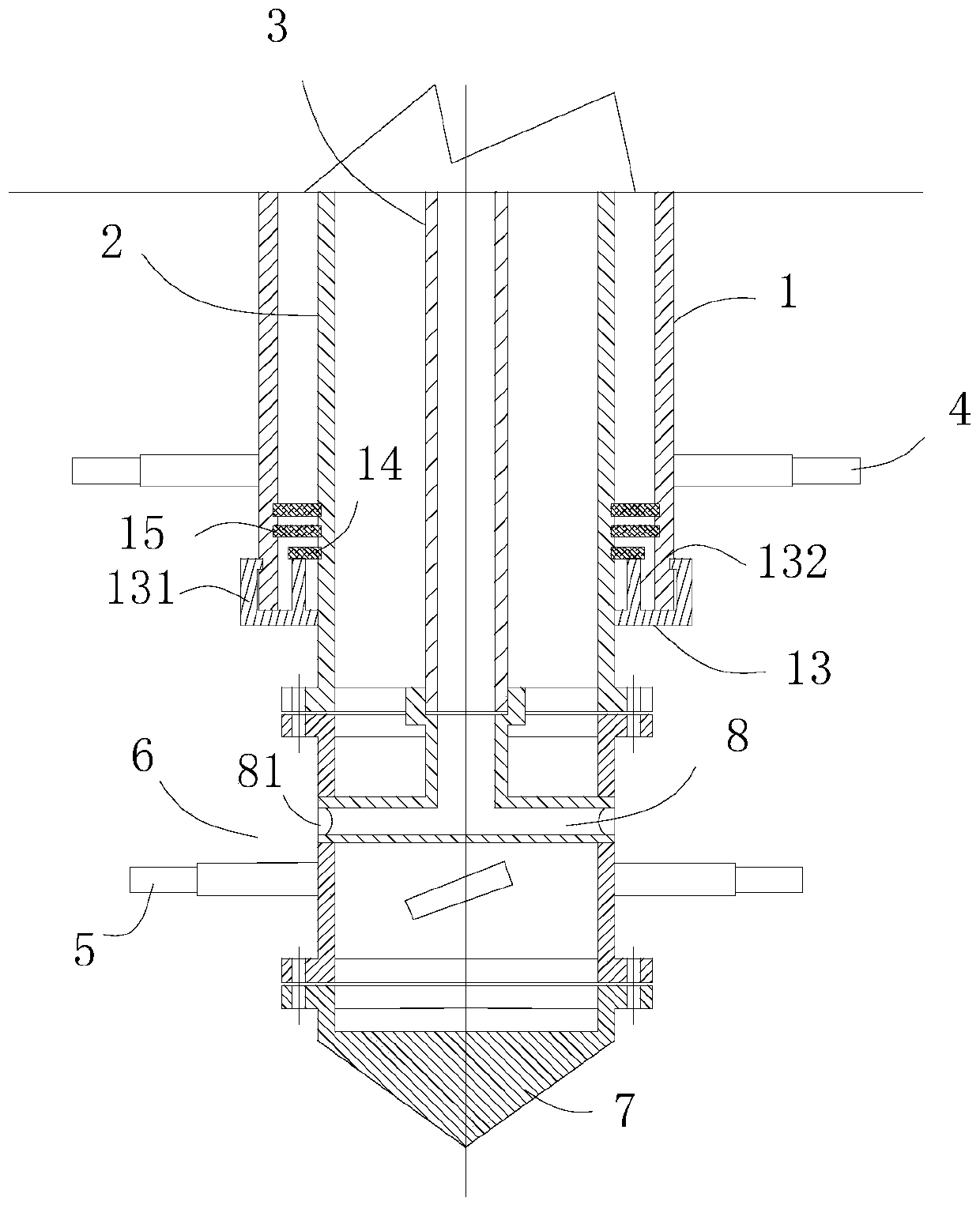

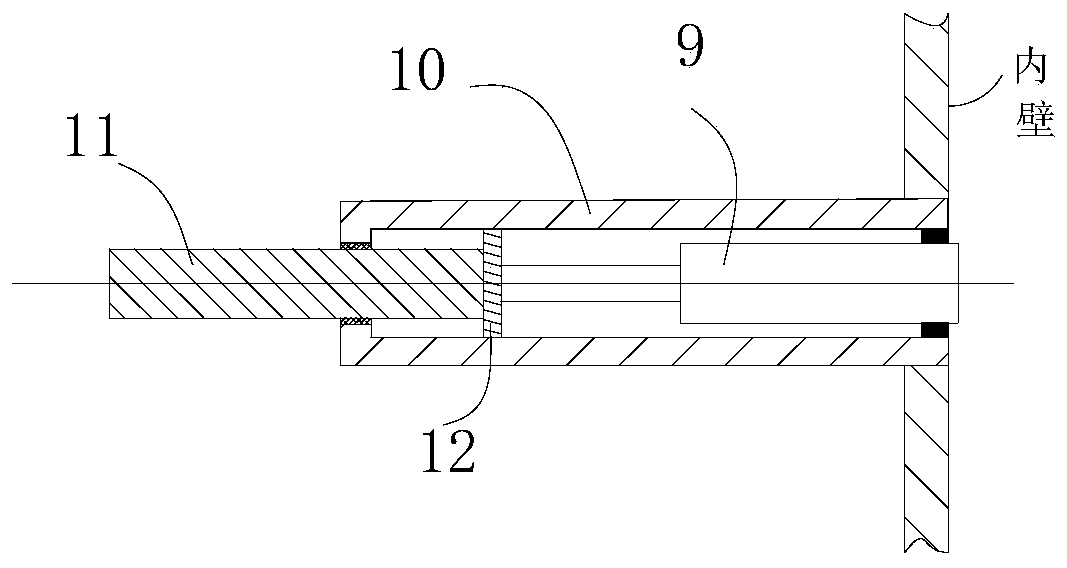

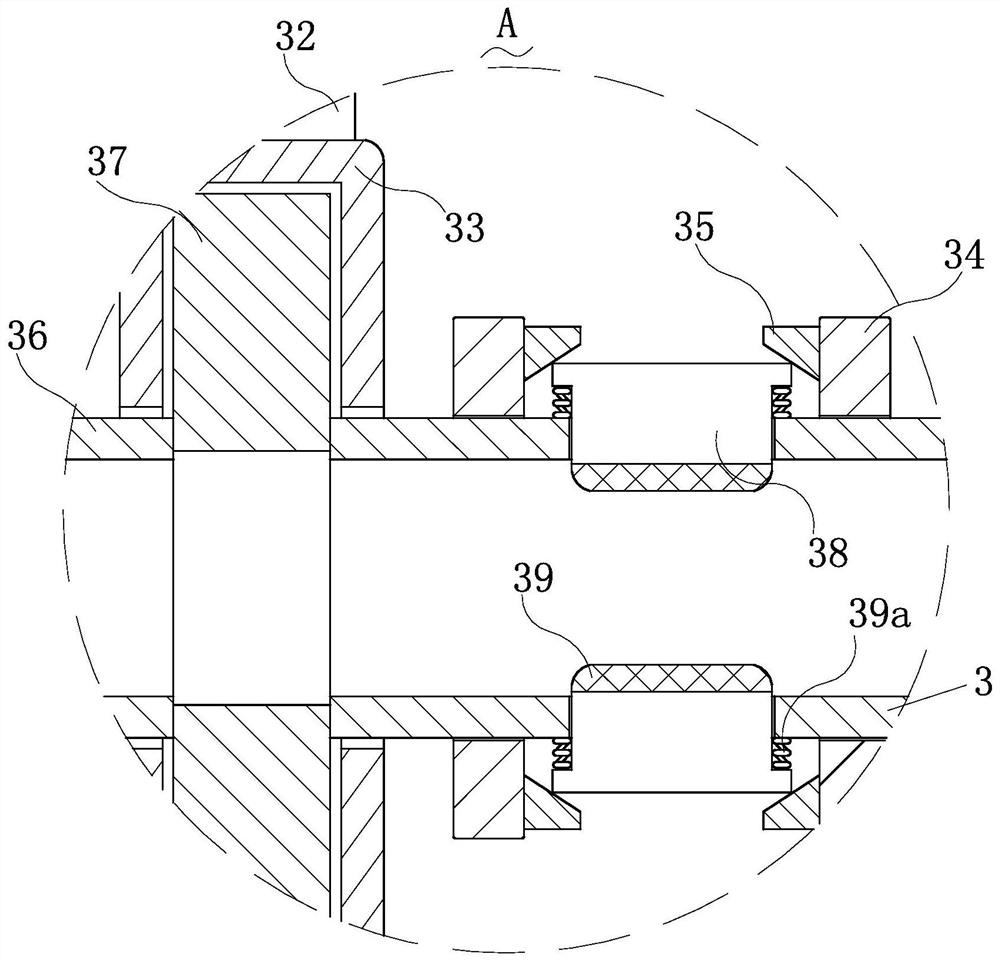

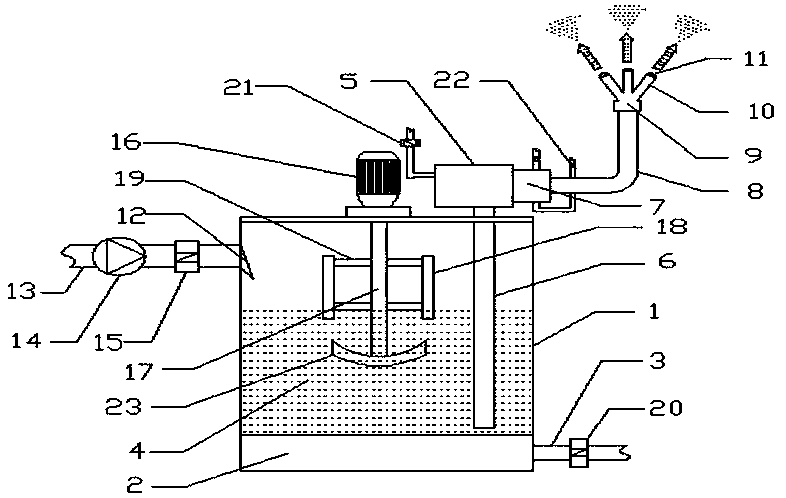

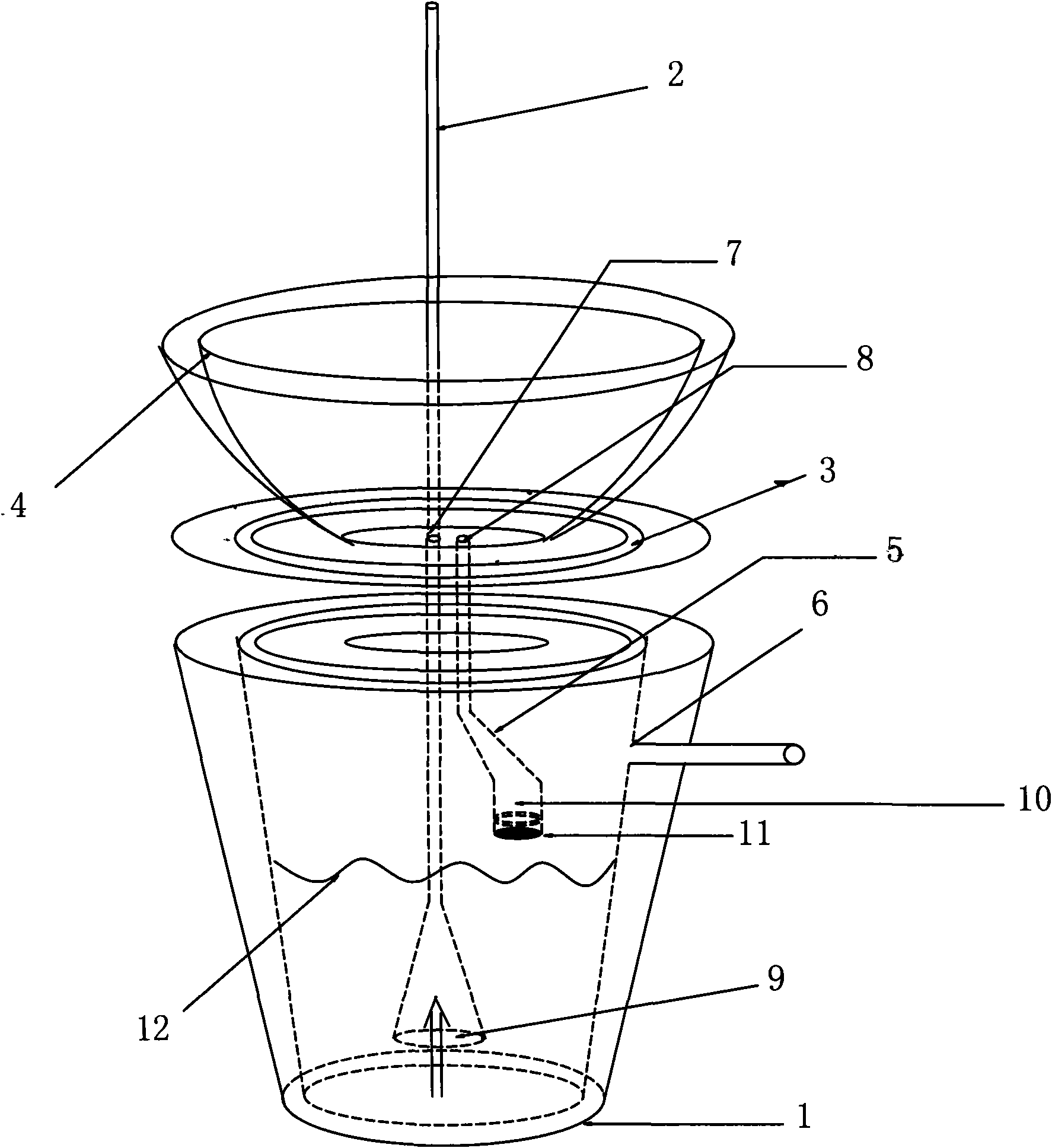

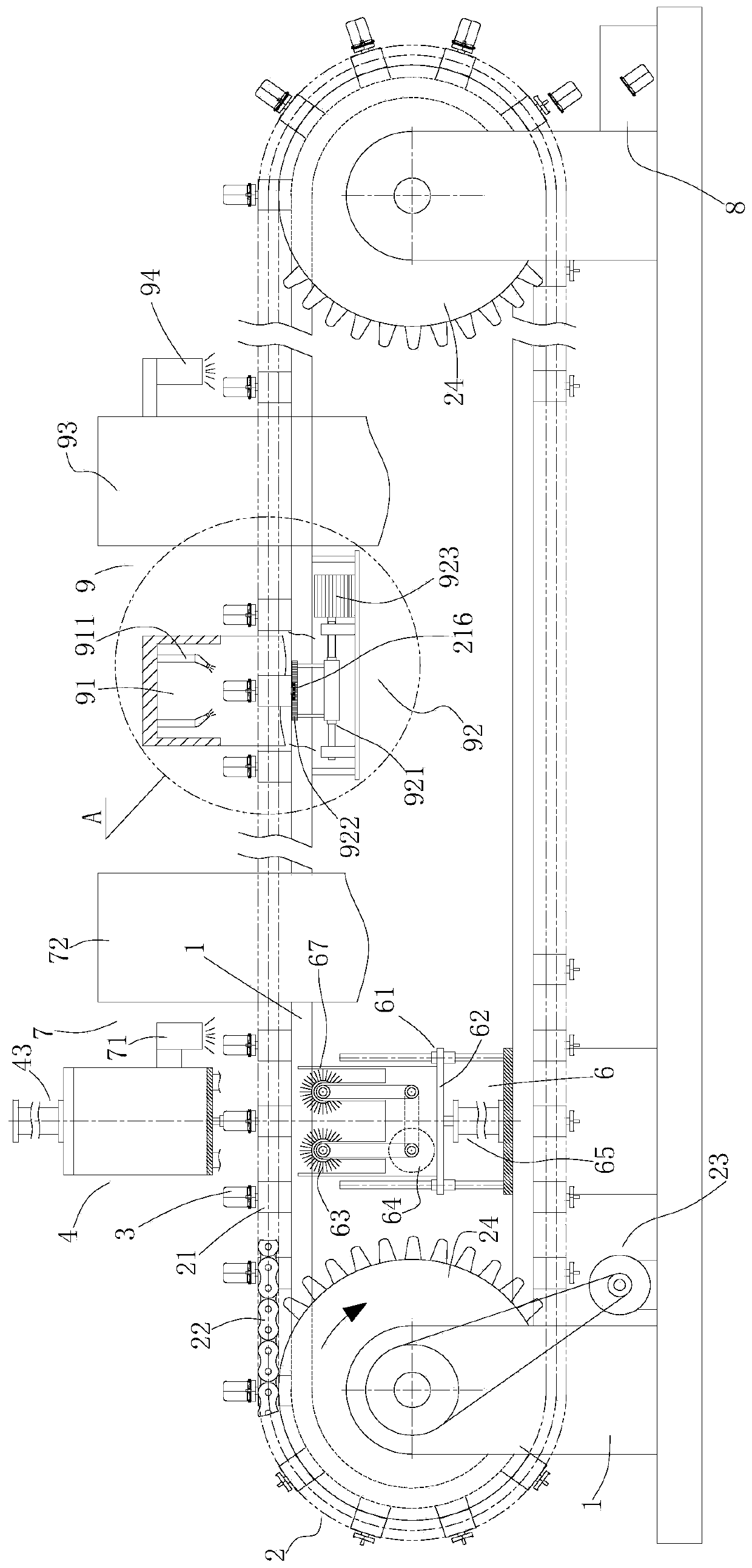

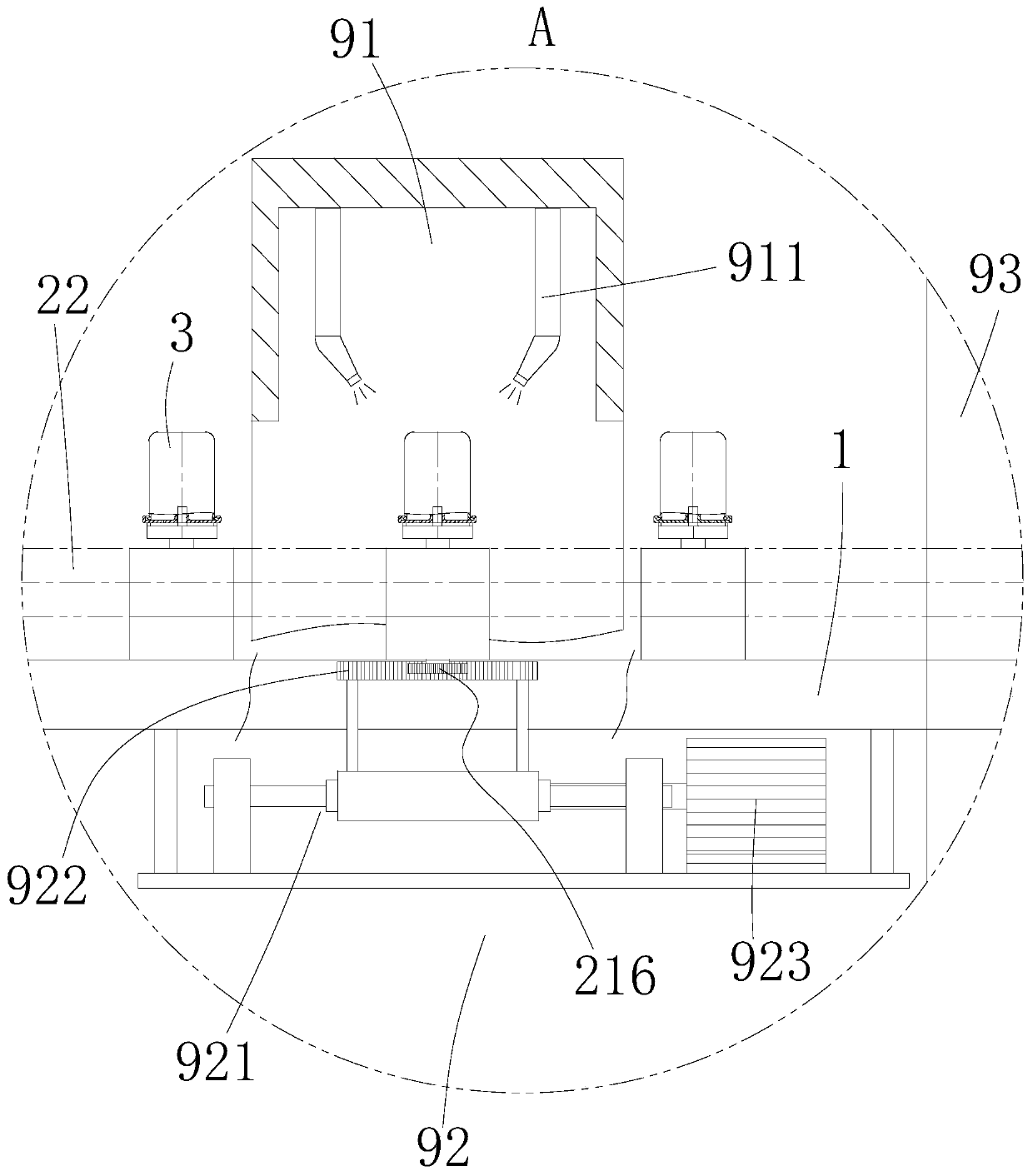

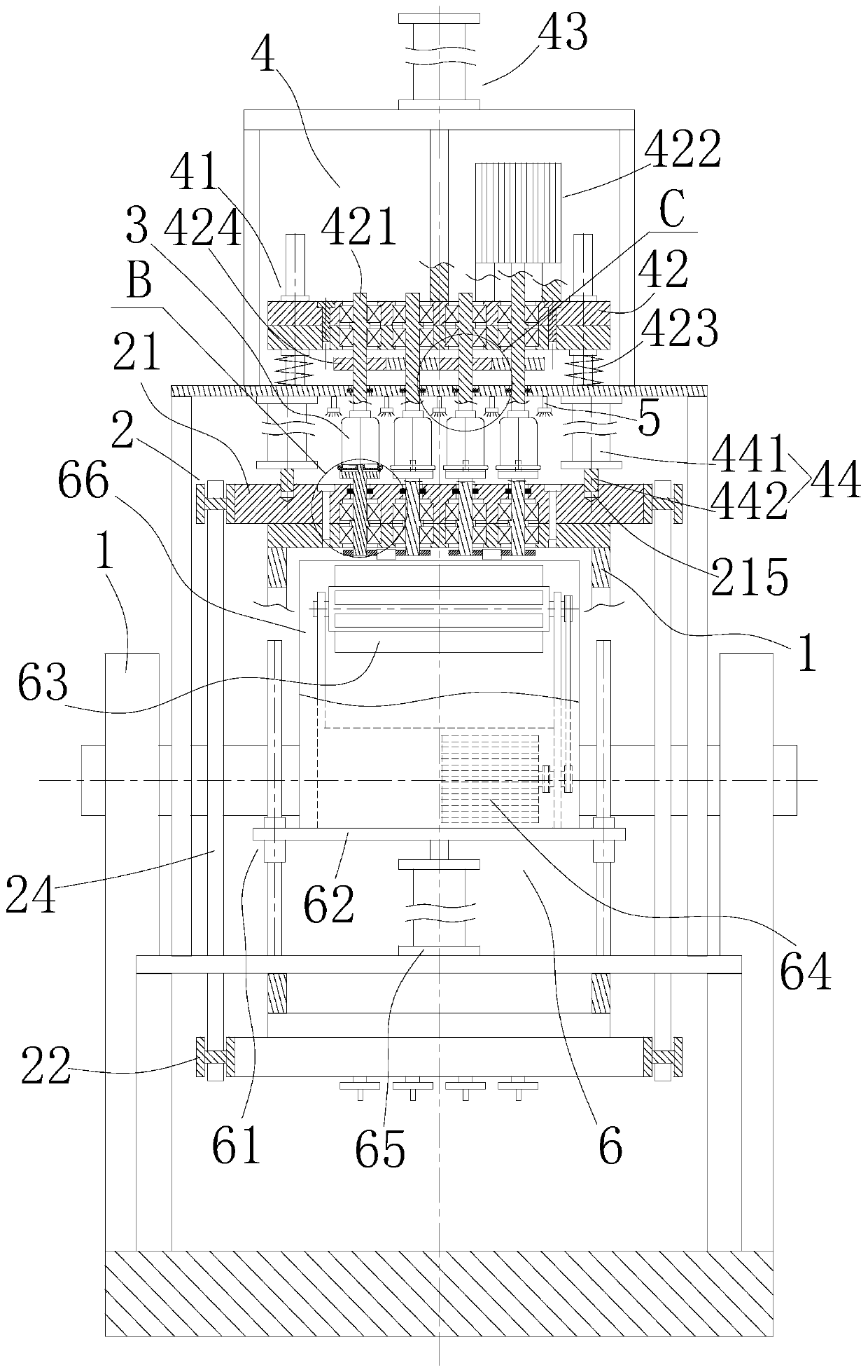

The invention discloses a synchronous spraying and curing processing method for pipelines arranged in parallel. The method includes the following steps that A, steel pipes are thrown into an acid pickling pond to be subjected to acid pickling for removing rust; B, the steel pipes subjected to acid pickling are cleanly flushed through clear water and then are dried for standby application; C, the steel pipes obtained in the step B are subjected to medium frequency heating; D, the interiors and the exteriors of the steel pipes are subjected to synchronous plastic coating through an electrostatic spraying method; E, heating and curing are carried out, and the pipelines are moved side by side before being cured; and F, natural cooling is conducted. In the step D, the plastic coating operation is carried out through an electrostatic spraying line, and the electrostatic spraying line comprises a steel pipe conveying device, an external spraying device, an internal spraying device, a powder recovery device and a pipeline side-by-side moving device. The method is simple, using is convenient, and production efficiency can be improved; a spray gun can be prevented from vibrating, powder is uniformly sprayed, and the powder utilization rate is high; the pipelines do not need to be lifted repeatedly and can be moved side by side.

Owner:青岛豪德博尔实业有限公司

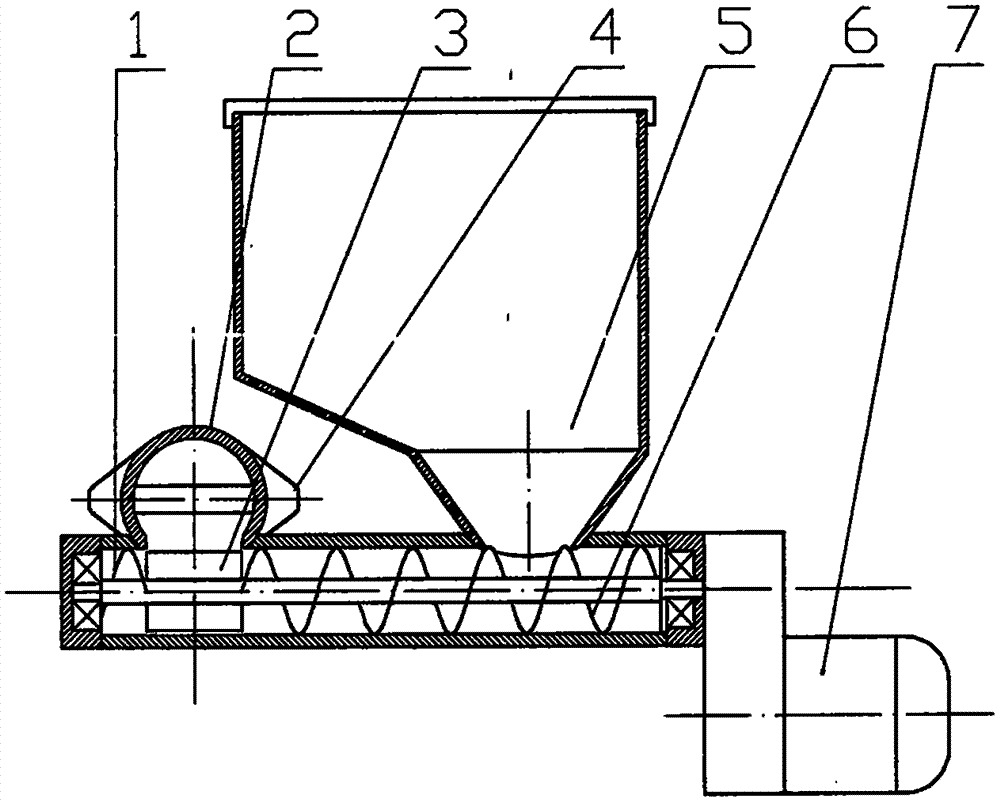

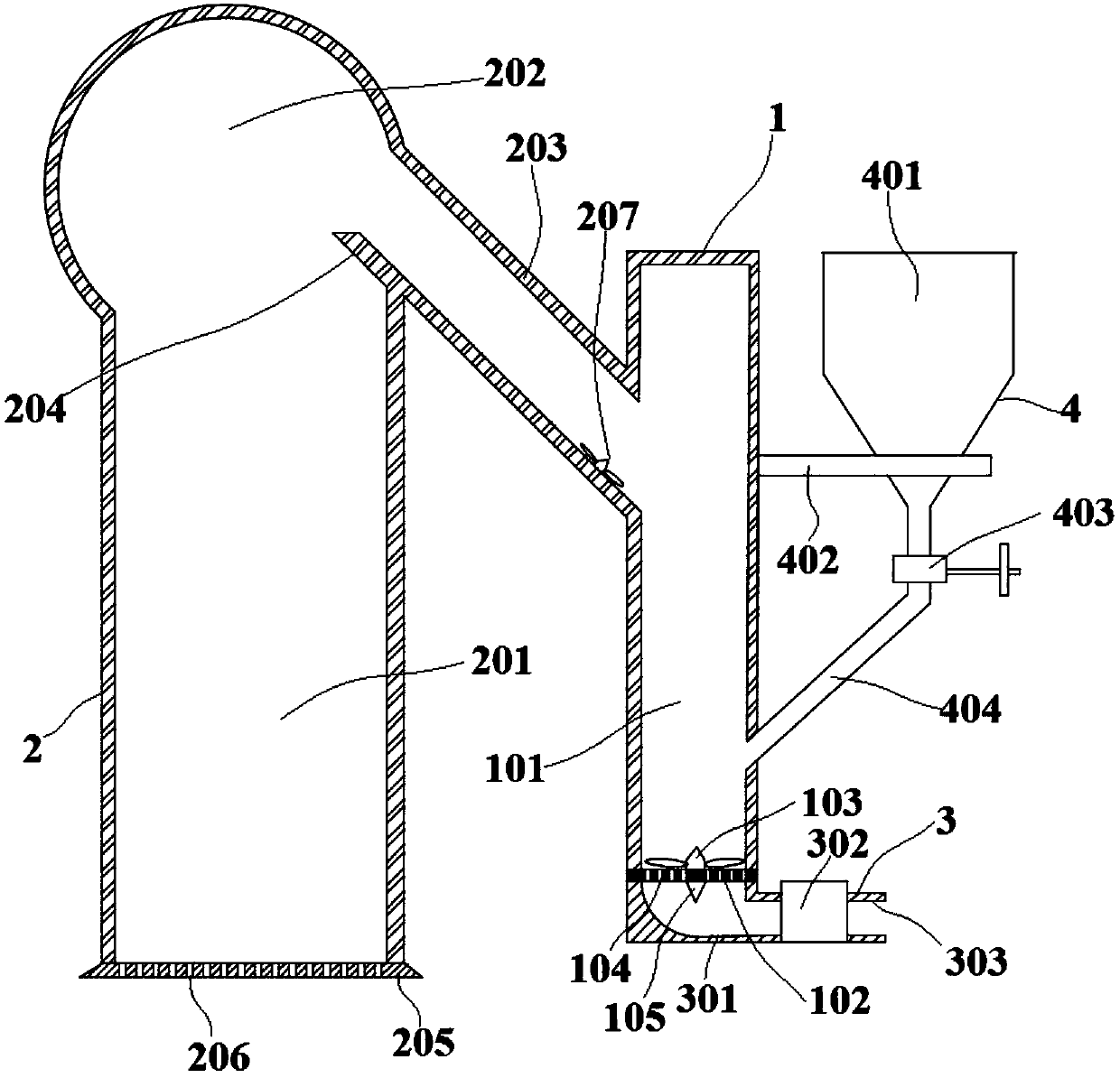

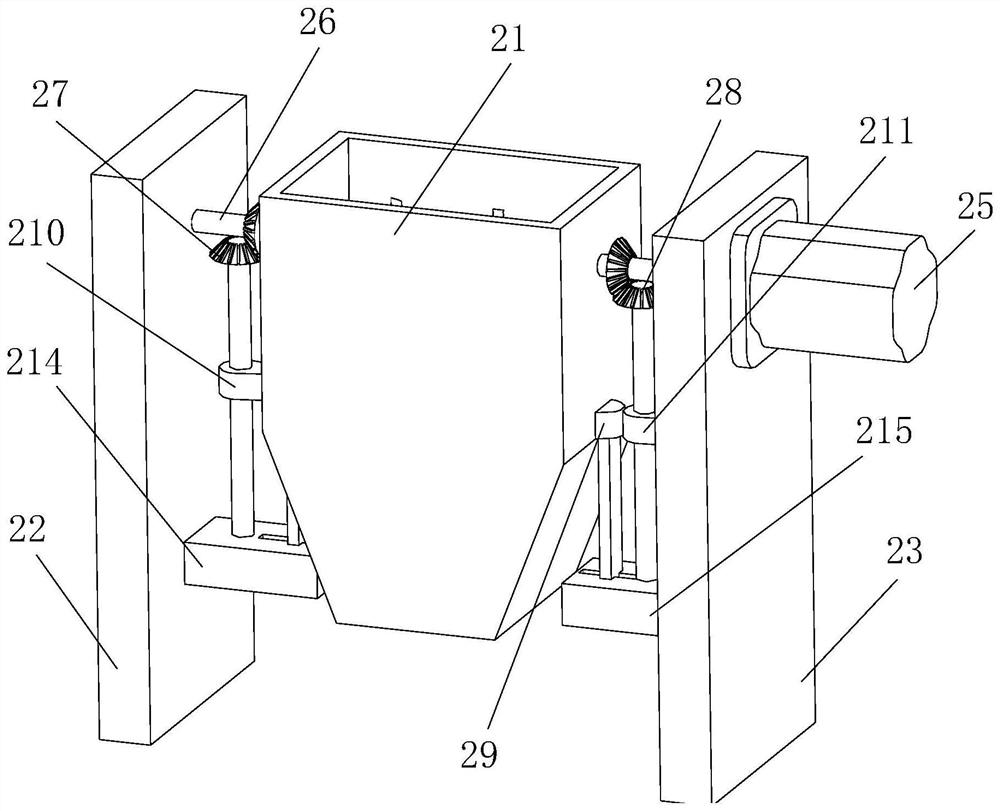

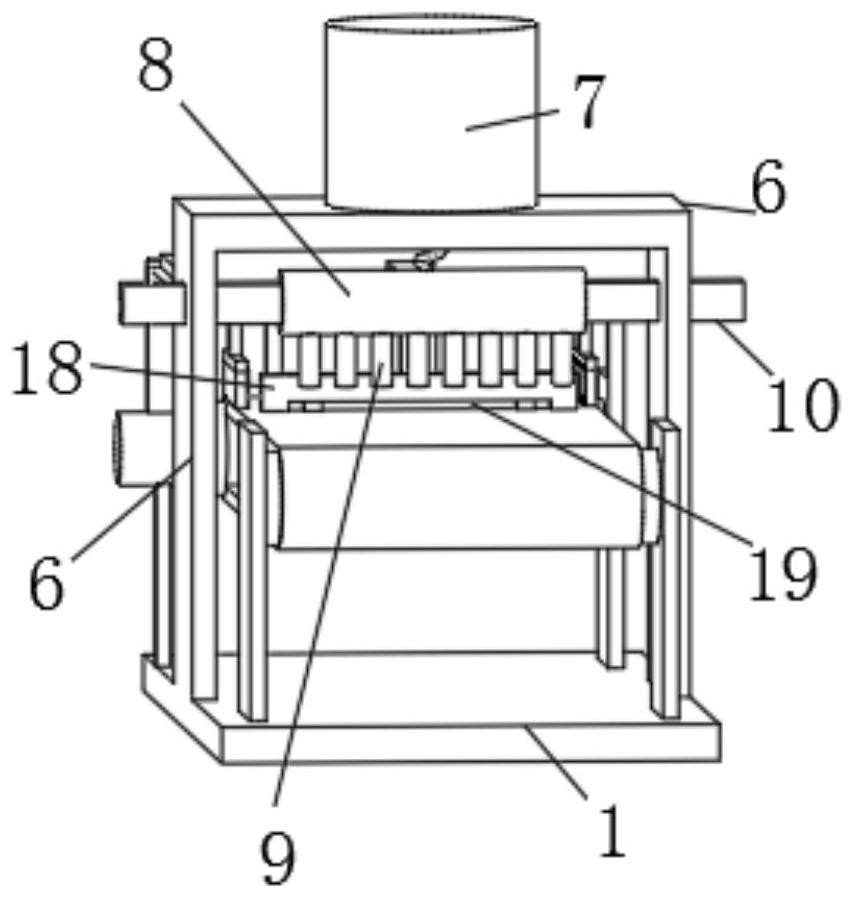

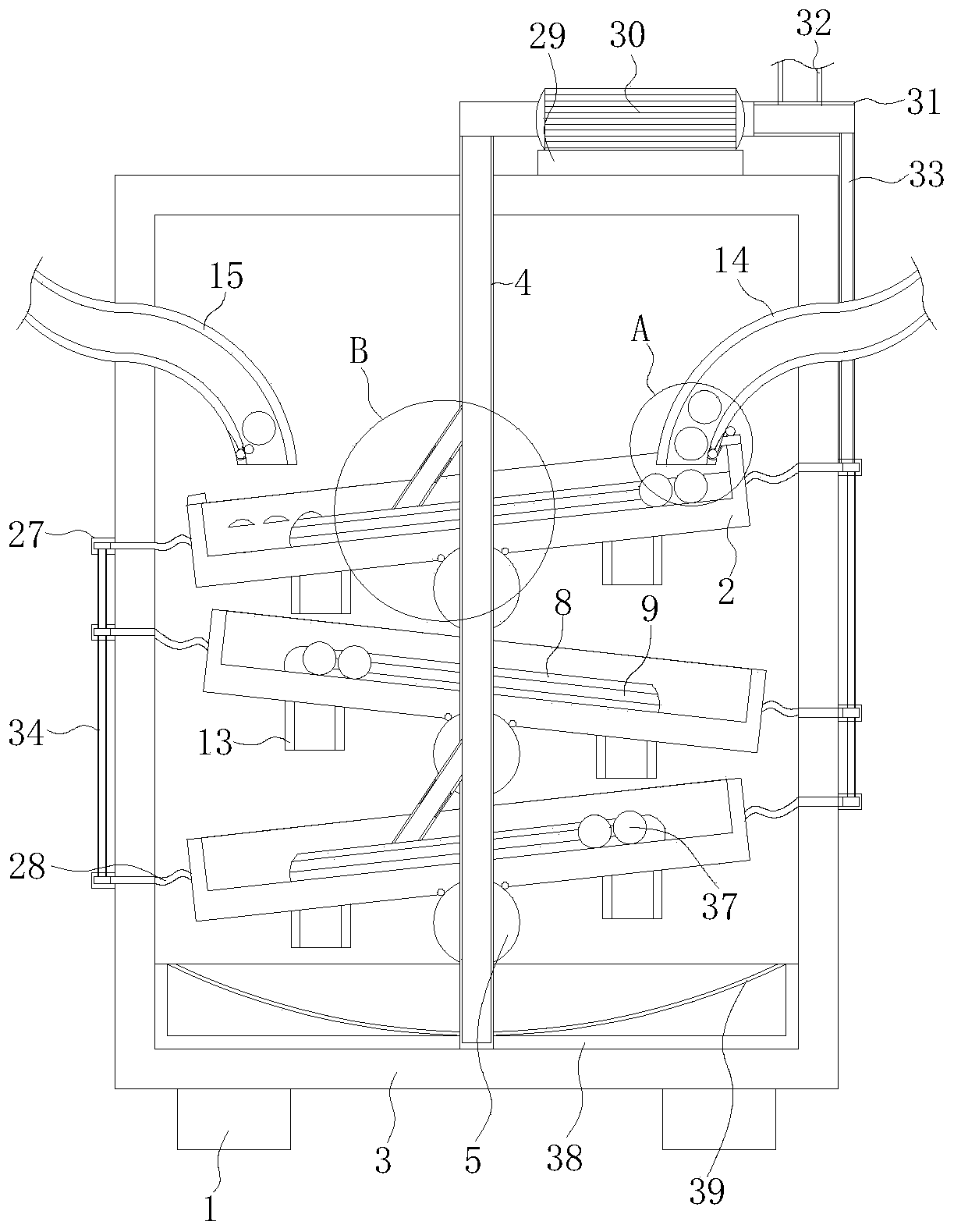

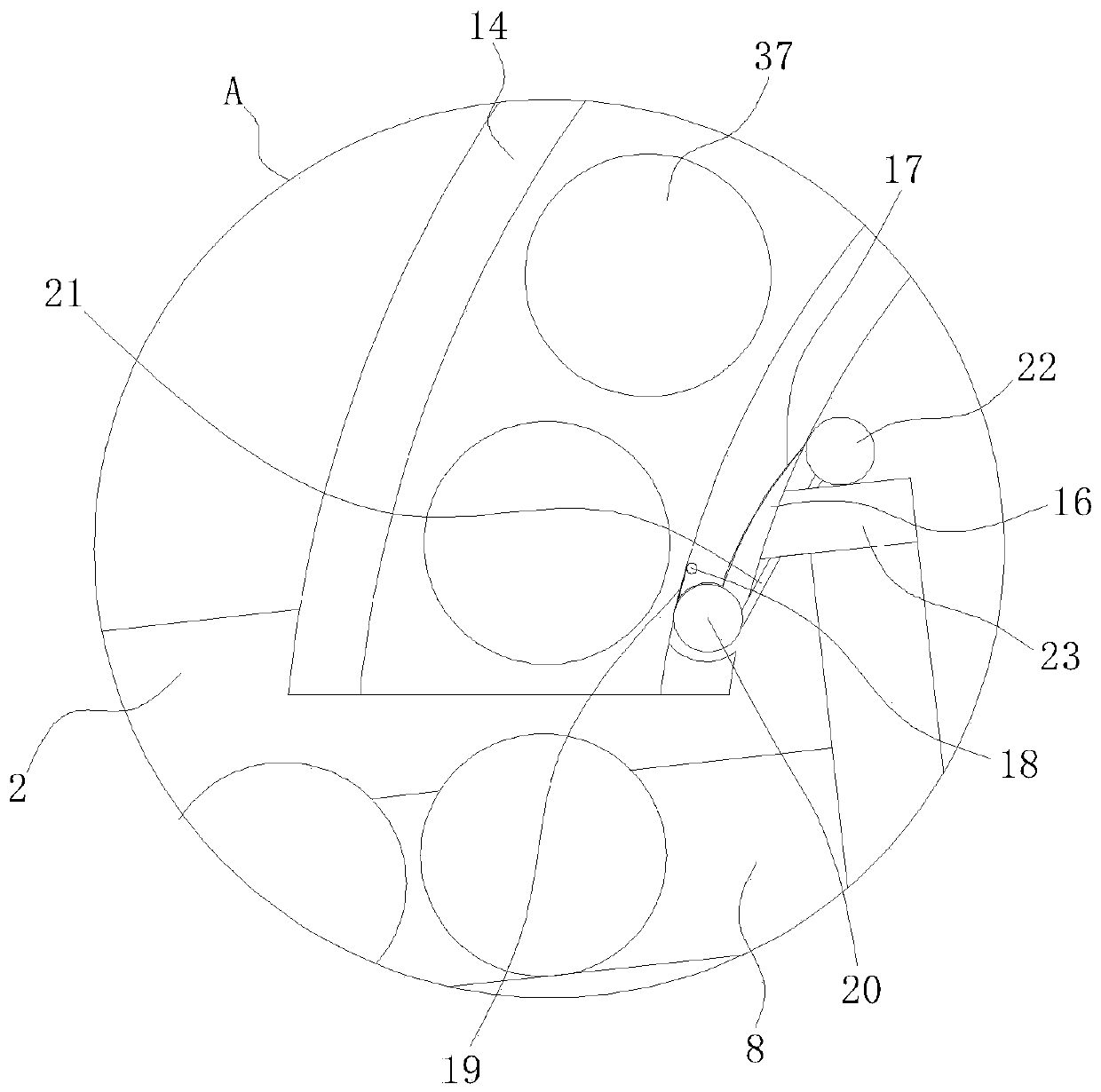

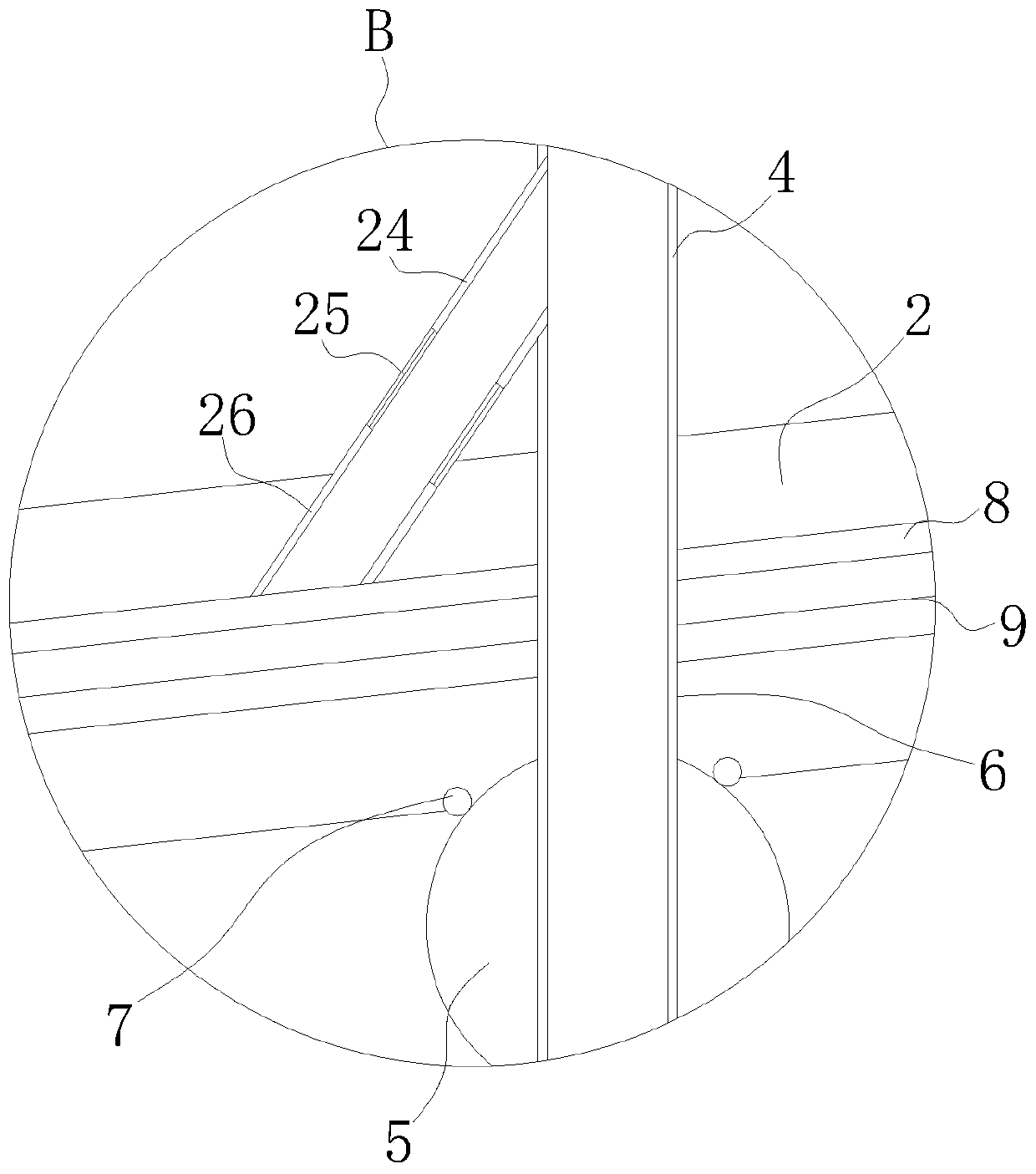

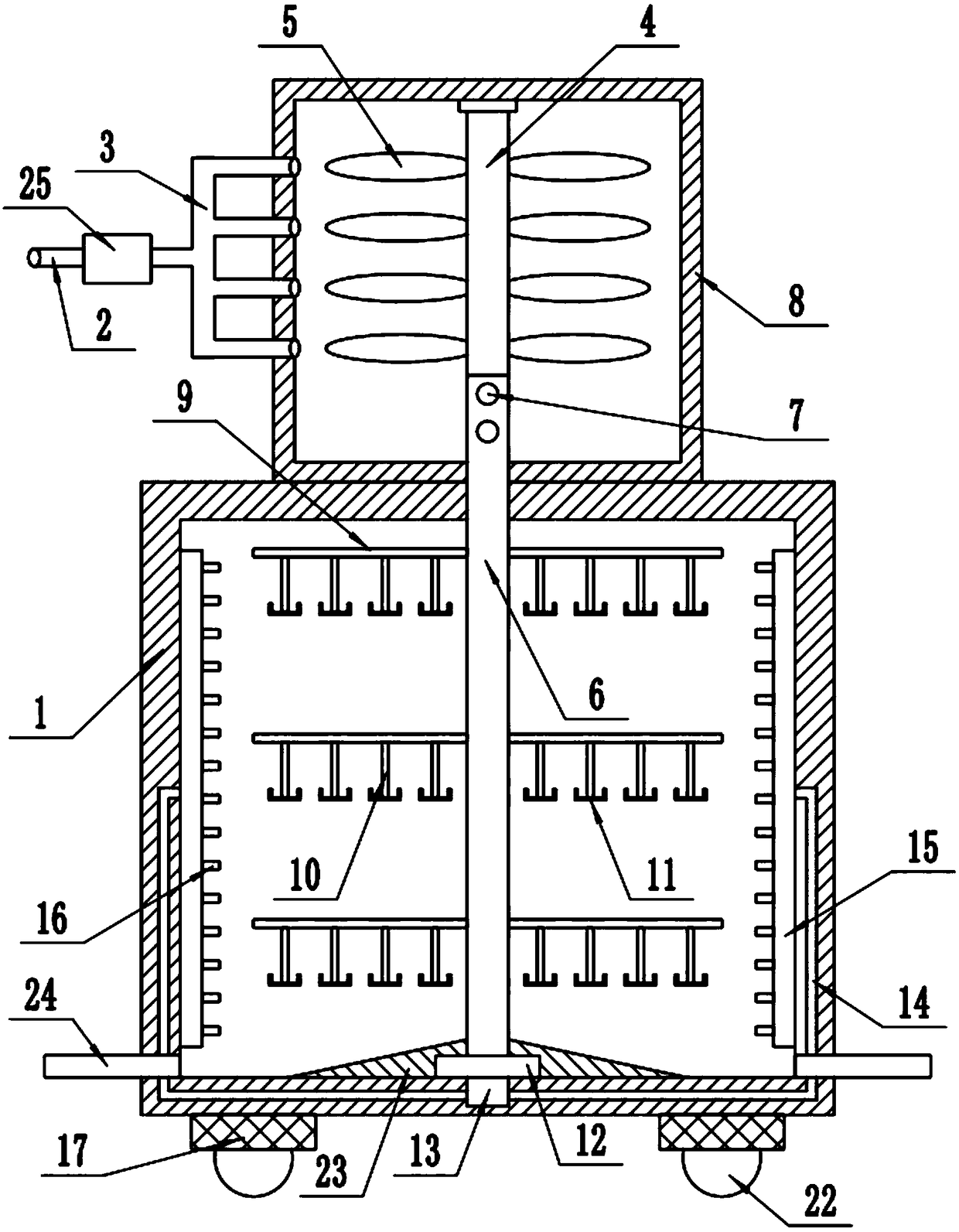

Uniform-feeding rice impurity removing equipment

InactiveCN108339751AGood dust removal effectAvoid reprocessingSievingGas current separationEngineeringWaste management

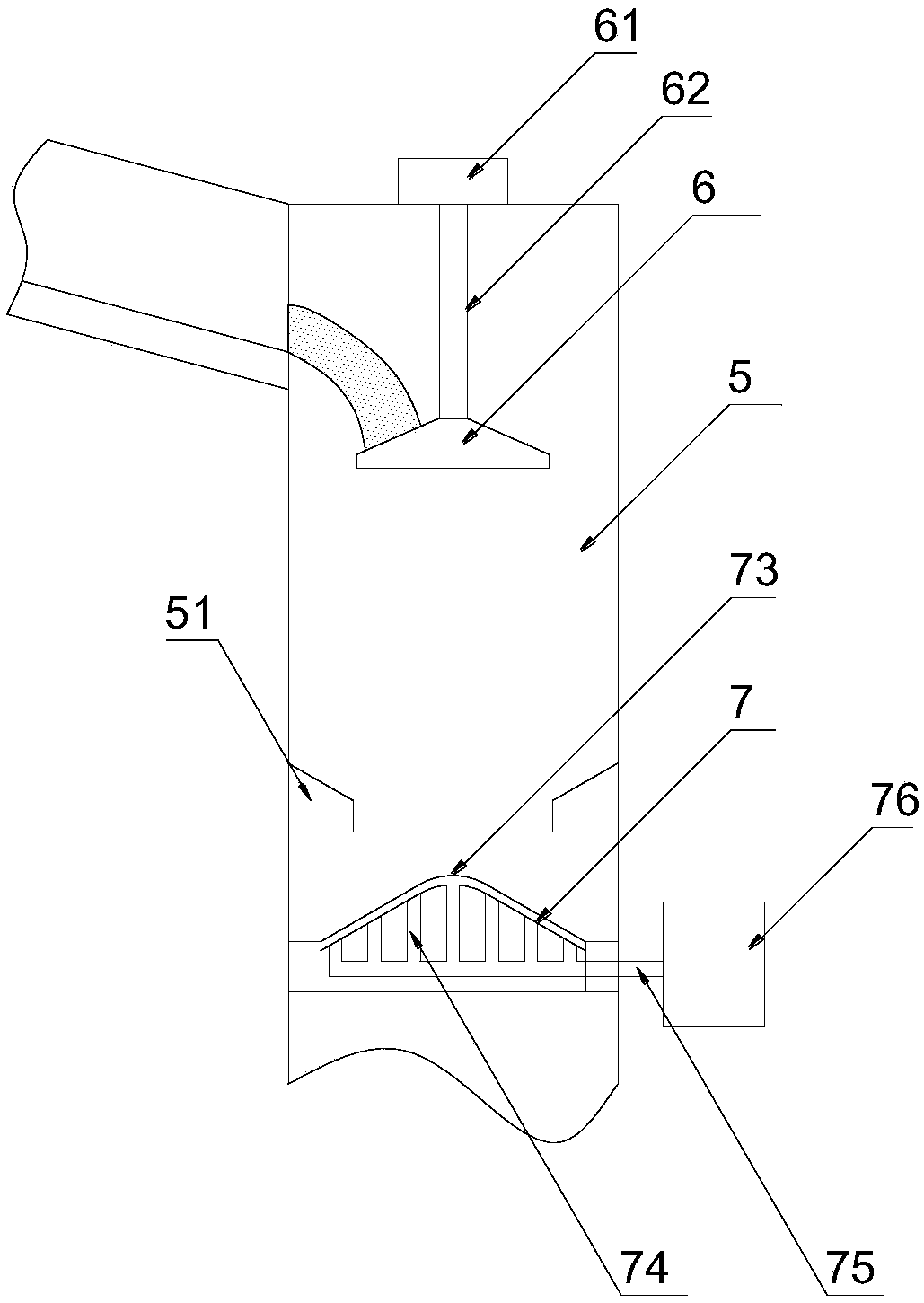

The invention discloses uniform-feeding rice impurity removing equipment. The uniform-feeding rice impurity removing equipment comprises a feeding plate, a discharging channel, a dust removing assembly, a case, a first vibration screen, a second vibration screen, a recovery box, a rice box and a waste box. The feeding plate is provided with a rotating roller, and pushing plates are uniformly arranged on the periphery of the rotating roller. A motor is installed on the outer side of the top of the discharging channel and drives a scattering disc through a rotating shaft, and the scattering discis located below a feeding inlet of the discharging channel. The dust removing assembly is installed on the lower portion of the discharging channel and comprises a dust removing disc, a filtering net, an air suction pipe and a total air pipe. A discharging outlet of the discharging channel is connected with a feeding inlet of the case, and the discharging channel is arranged close to the case sothat a partition plate can be connected with the first vibration screen. The waste box is placed on the bottom of the case and located below the second vibration screen. According to the uniform-feeding rice impurity removing equipment, rice is fed uniformly, impurities such as sand grains and dust in the rice are removed effectively, and the stone removing effect is good.

Owner:滁州广洋湖米业有限公司

Manufacturing method of epoxy resin pipeline

The invention discloses a manufacturing method of an epoxy resin pipeline. The manufacturing method of the epoxy resin pipeline comprises the following steps that A, a steel pipe is put into a pickling tank to be subjected to acid pickling and rust removal; B, the steel pipe subjected to acid pickling is washed through clear water and dried for later use; C, intermediate-frequency heating is conducted on the steel pipe obtained in the step B; D, epoxy resin powder is sprayed to the interior and the exterior of the steel pipe synchronously through an electrostatic spraying method; E, heating and curing are conducted; and F, natural cooling is conducted, plastic coating work is conducted through an electrostatic spraying line in the step D, the electrostatic spraying line comprises a steel pipe conveying device, an outer spraying, an inner spraying device and a powder recovery device, and an extension pipe which is arranged on the inner spraying device and used for being connected with an inner spraying gun is of a hydraulic-driven telescopic structure. The manufacturing method of the epoxy resin pipeline is simple; using is convenient, the occupied area of a production line can be reduced, production efficiency is improved, vibration of the spraying gun can be avoided, powder spraying is even, and the powder utilization rate is high.

Owner:青岛豪德博尔实业有限公司

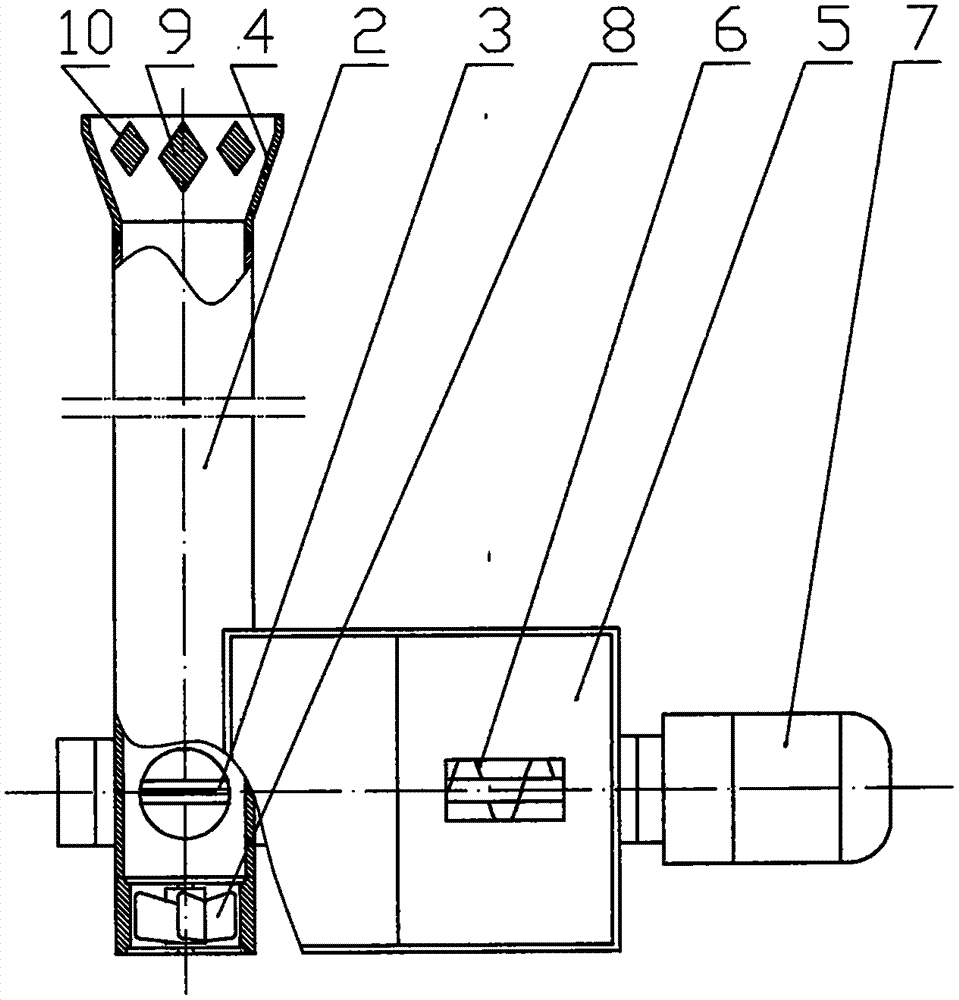

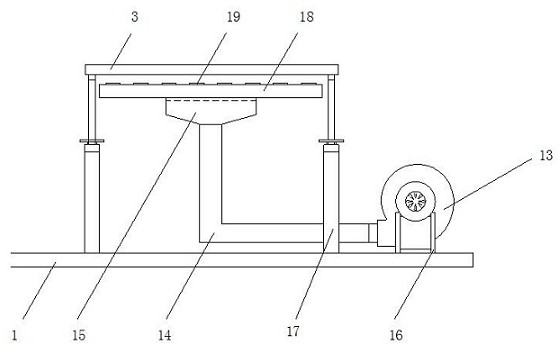

Disinfecting powder spraying and scattering machine for silkworms

The invention discloses a disinfecting powder spraying and scattering machine for silkworms. The disinfecting powder spraying and scattering machine for silkworms comprises a powder hopper, a draught fan and a spray pipe, wherein the draught fan is arranged at one end of the spray pipe; a feeding packing auger is communicated between the draught fan and the spray pipe; the input end of the feeding packing auger communicates with the powder hopper, and powder spraying blades are arranged at the output end of the feeding packing auger; a feed-back packing auger is arranged at the outer ends of the powder spraying blades; the powder spraying blades are positioned at the position of the communicating joint of the feeding packing auger and the spray pipe; a nozzle is arranged at the other end of the spray pipe, an opening of the nozzle is flat, and a shunting partition block is arranged inside the nozzle. By adopting the disinfecting powder spraying and scattering machine for silkworms disclosed by the invention, the dosage can be stably controlled, and the powder is sprayed uniformly.

Owner:吴华

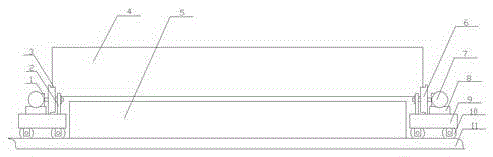

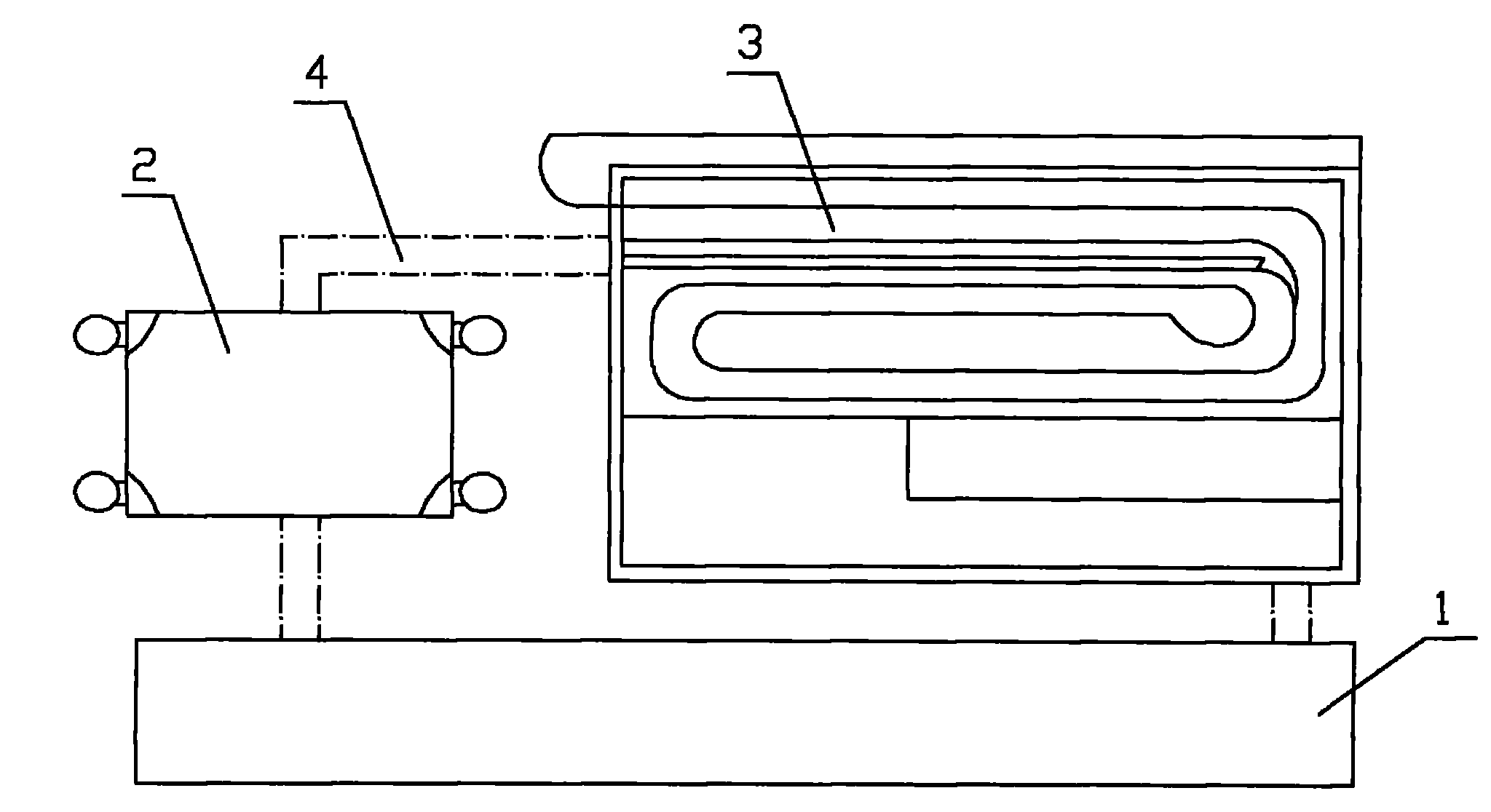

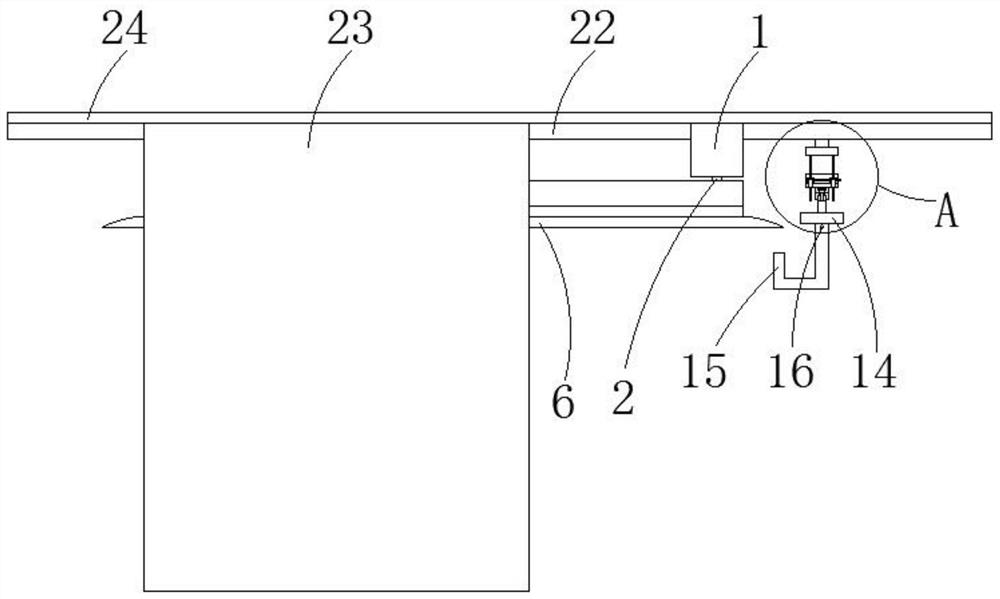

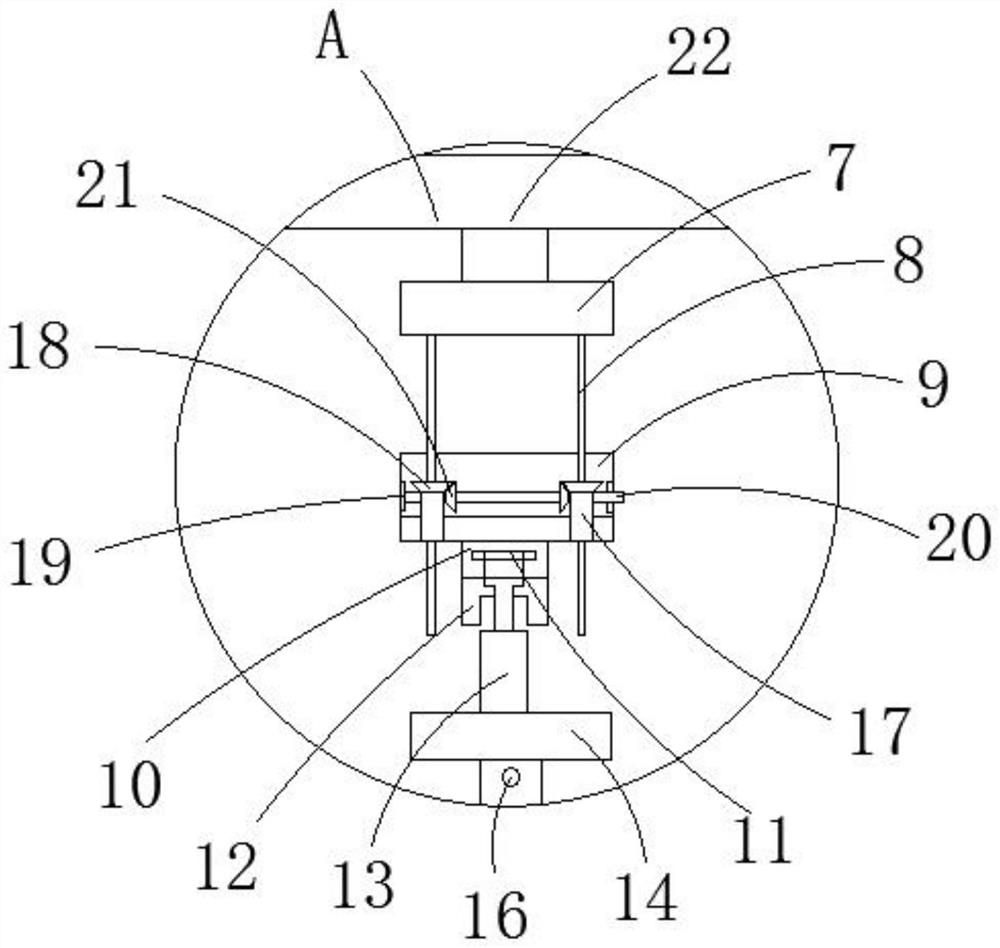

Vertical automatic coating production line of aluminum profile

InactiveCN102161022APowder evenlyGood running stabilityLiquid spraying plantsPretreated surfacesPre treatmentEngineering

The invention discloses a vertical automatic coating production line of an aluminum profile. The production line comprises pre-treatment equipment, coating equipment and drying equipment, wherein both of the pre-treatment equipment and the drying equipment are connected through a conveyer belt; a drying passage shell of the drying equipment consists of a gum sealed plate layer, an inner rock cotton layer, an air heat-isolating layer and an outer rock cotton heat-preserving layer from inside to outside; and a workpiece is vertically hung in the coating equipment and the drying equipment. Through the production line, the aluminum profile is automatically coated without human labor and is uniformly powdered; rotation is not required in work; the stability is high; and the surface layer temperature of the equipment is at most 5 DEG C more than the environment temperature.

Owner:ZHEJIANG MINGQUAN INDAL COATING

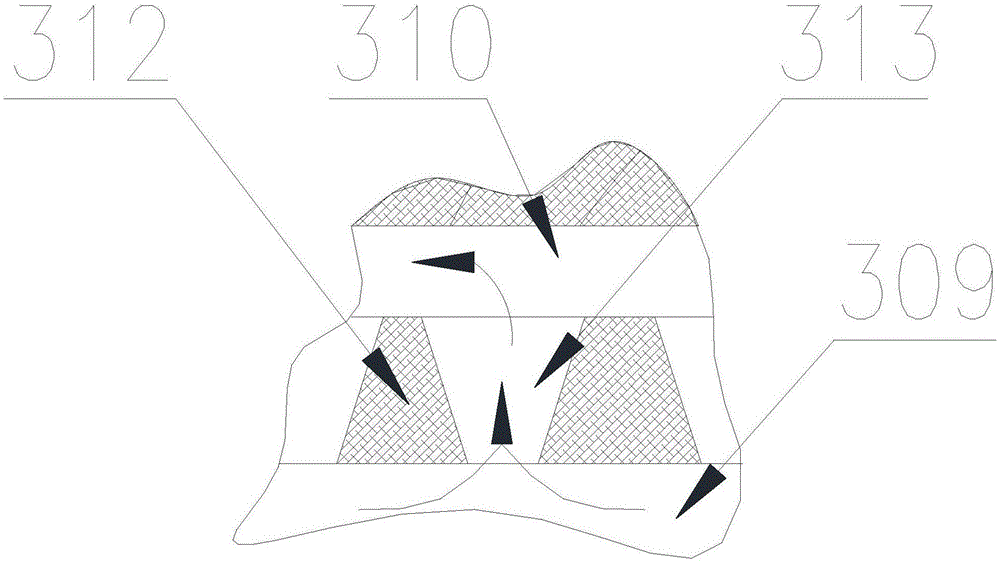

Cross-section-variable drilling tool for cement mixing pile

InactiveCN110080685AEasy to assemble and disassembleEasy to cleanDrill bitsBulkheads/pilesHydraulic cylinderStructural engineering

The invention relates to a cross-section-variable drilling tool for a cement mixing pile. The cross-section-variable drilling tool comprises an outer drill rod and an inner drill rod which are concentrically and coaxially arranged, a conveying pipe is arranged in the inner drill rod, outer drill rod blades are arranged on the lower portion of the outer drill rod, a spraying rod is connected to theend of the inner drill rod through a flange board, an inner drill bit is connected to the lower portion of the spraying rod through a flange board, a jet pipe is installed on the upper portion of thespraying rod, inner drill rod blades are installed on the lower portion of the spraying rod, one end of the jet pipe is hermetically connected with a conveying pipe for conveying a jet medium, jet orifices are formed in the other two ends of the jet pipe respectively, each of the outer drill rod blades and the inner drill rod blades comprises a fixed blade and a movable blade, the movable bladesare slidably connected with the outer drill rod blades, the other ends of the movable blades are connected with a hydraulic cylinder, the hydraulic cylinder is fixedly installed at one end, close to the inner wall of the outer drill rod or the spraying rod, of the fixed blade or directly installed on the spraying rod. The cross-section-variable drilling tool has the advantages of being simple in reducing structure, good in sealing performance, easy to control, high in adaptability and convenient to replace and clean.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

Glass duster

The invention discloses a glass duster and relates to the technical field of glass dusting equipment. The glass duster includes a powder spraying device; the powder spraying device includes a powder spraying cavity, a powder spreading board, and a first motor; the inner surface of the powder spraying cavity is provided with the powder spreading board; a first motor is fixed on the surface of the powder spreading board; powder spreading holes are formed in the surface of the powder spreading board; a spraying tube is fixed on the peripheral side of the powder spraying device; an air conveying pipe is fixed on the other end of the powder spraying device; and a feeding device is fixed on the peripheral side of the powder spraying device. The invention has the advantages of uniform powder spraying, simple structure and moderate price through the dust spraying device, the powder spraying tube and the air conveying pipe, and solves the problems that a glass duster is complicated in structure, high in price, high in maintenance cost, high in failure rate, requirement of flowability of powder is high according to a powder sending mode, and the glass duster is prone to being blocked.

Owner:安徽蓝博玻璃有限公司

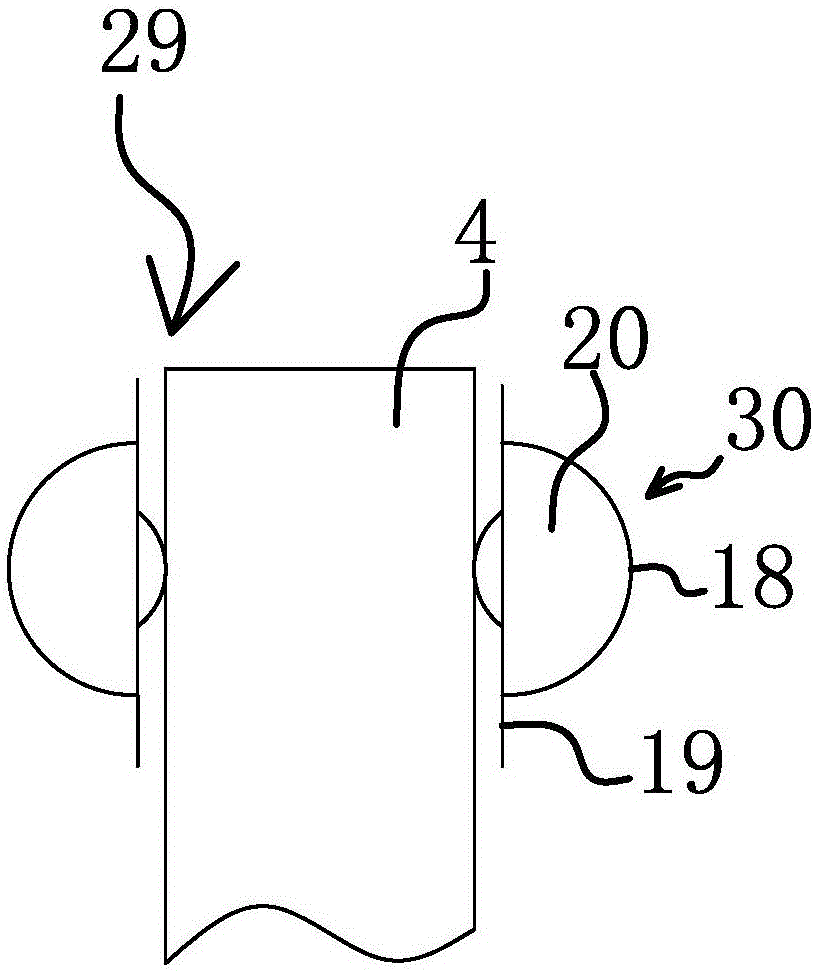

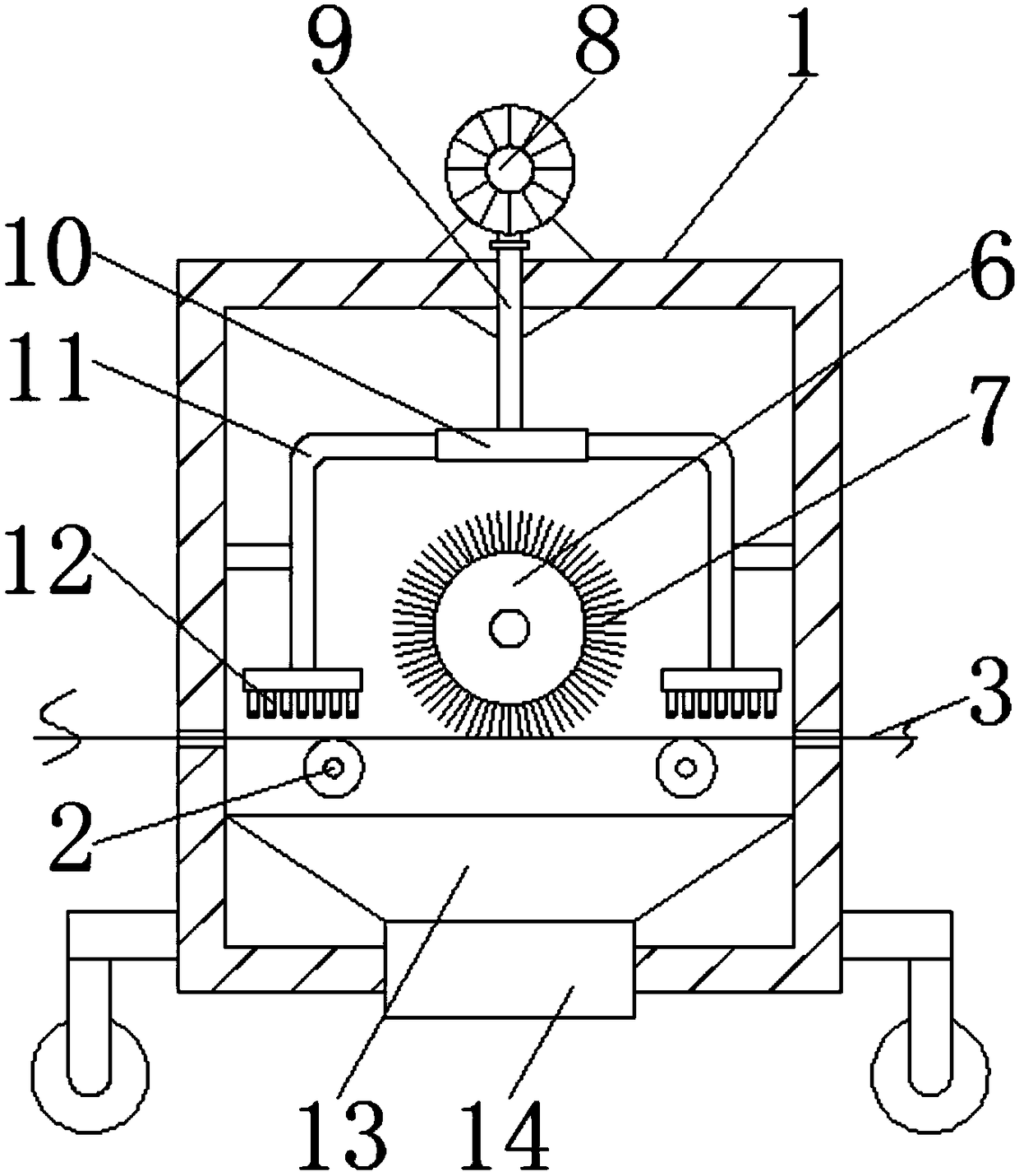

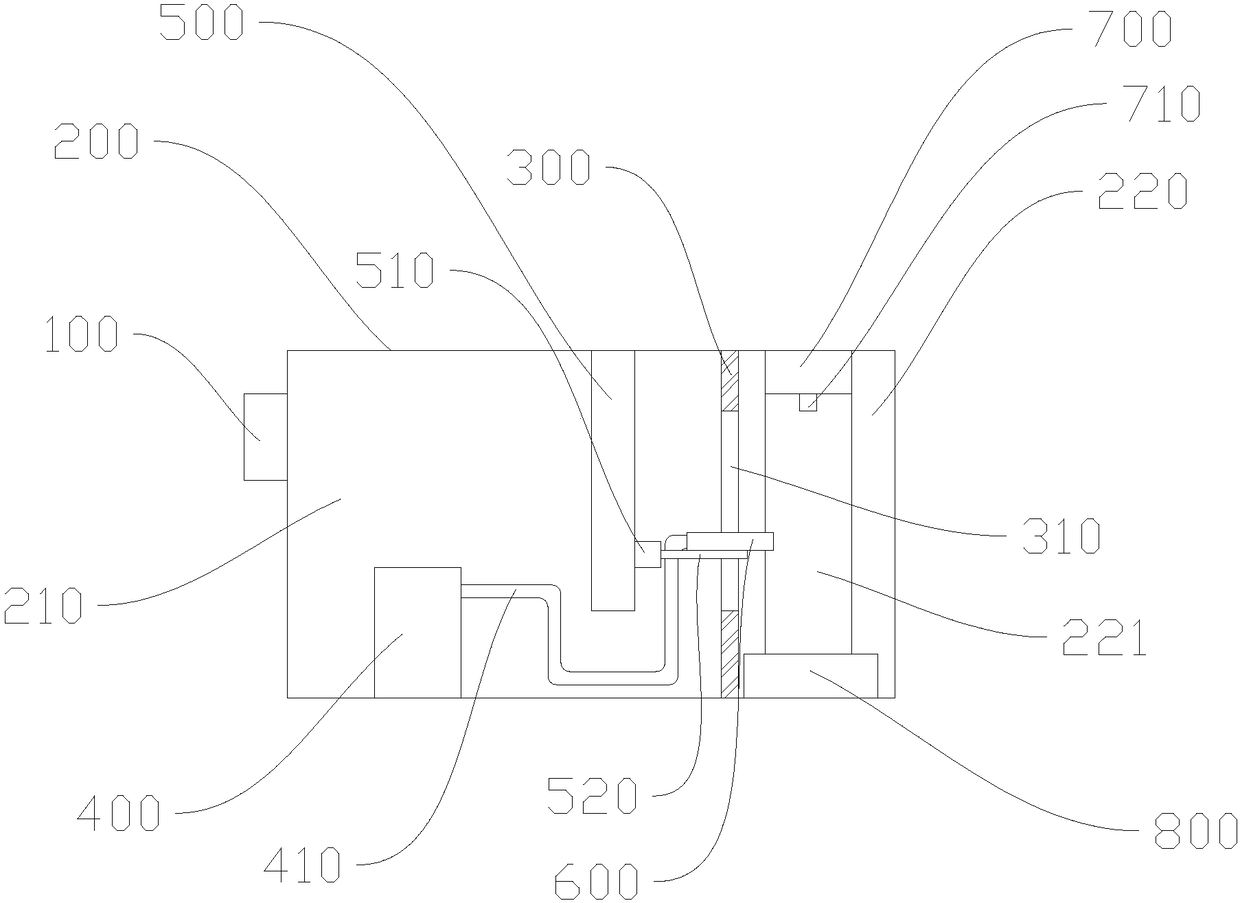

Clamping and dust removing device for power cable processing

InactiveCN112157036AAchieve cleaningDust evenlyDirt cleaningCleaning using toolsPower cableDust control

The invention discloses a clamping and dust removing device for power cable processing. The clamping and dust removing device comprises a box body, a dust removing mechanism, a fixing frame, a fixingdisc, rotating rings, pressing rings, a cable inlet pipe, a bearing, pressing plates, brushes, pressing springs, discharging openings and a driving mechanism. The clamping and dust removing device forpower cable processing has the beneficial effects that the driving mechanism is powered on, the cable inlet pipe rotates, when the cable inlet pipe rotates, the brushes at the bottoms of the two setsof pressing plates arranged in the annular array sweep a cable moving in the cable inlet pipe, the two sets of brushes actively rotate, uniform dedusting of the cable is achieved, and the dedusting effect is improved. Cleaned dust falls down from the multiple discharging openings in the side wall of the cable inlet pipe, the two sets of rotating rings are rotated, the distance between two opposite brushes located in the cable inlet pipe is adjusted, and when the two opposite rotating rings rotate clockwise or anticlockwise, the two opposite pressing rings move oppositely or reversely. Therefore, cables with different diameters can be cleaned.

Owner:王勇

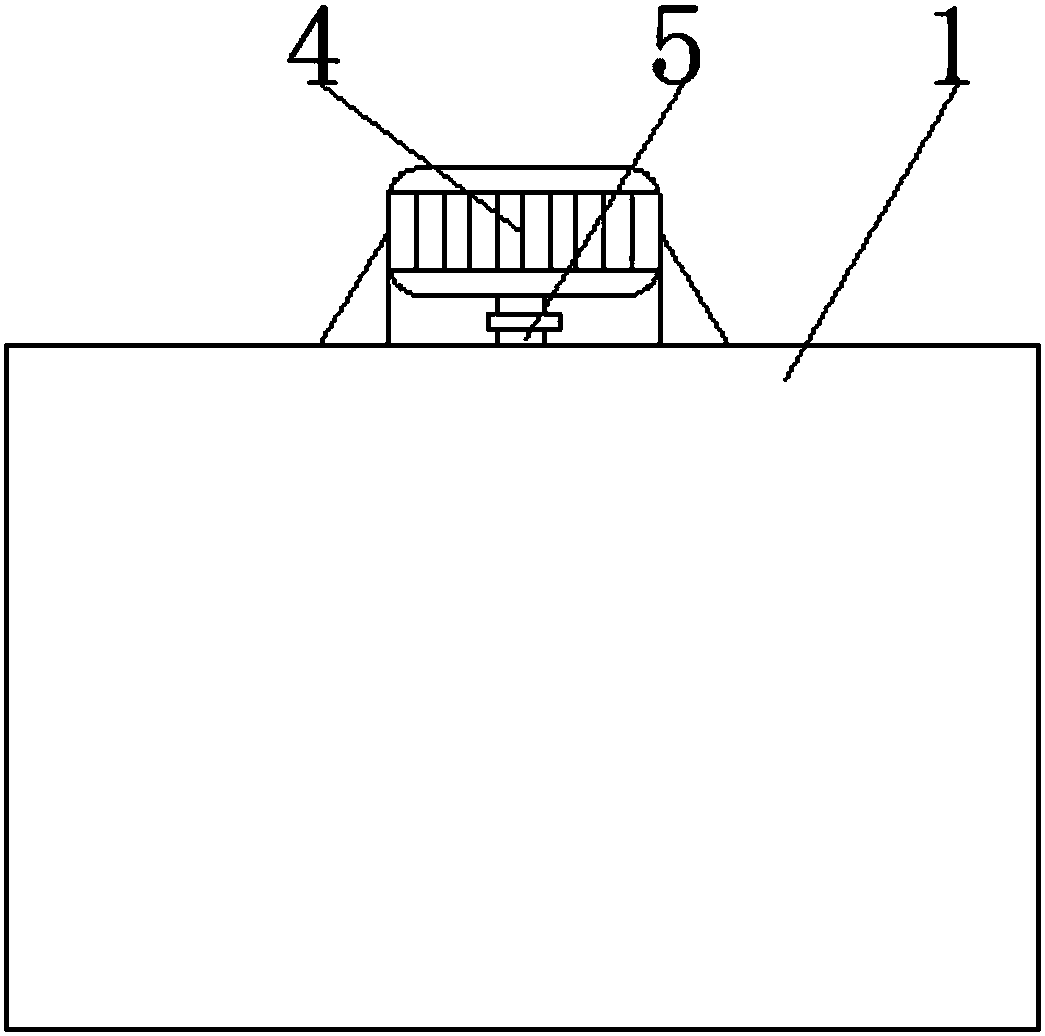

Novel glass powder sprayer and working method thereof

PendingCN109678355APrevent accumulation and cloggingPlay the role of self-cleaningEngineeringDistributor

The invention provides a novel glass powder sprayer which comprises a rack and further comprises a fluidization device, a vacuum generator and a powder distributor that are fixedly arranged on the rack, wherein the fluidization device comprises a fluidization powder storage box and a base arranged below the fluidization powder storage box; the base is internally provided with a fluidization compression pipeline; the fluidization compression pipeline is connected with an external compressed air pipeline; the fluidization compression pipeline is communicated with the fluidization powder storagebox; glass mold-proof partitioning powder is stored in the fluidization powder storage box; and a suction connector is arranged at the lower end of the vacuum generator and connected with a powder suction pipe in a sleeving manner. The invention further provides a working method of the novel glass powder sprayer, which particularly comprises the following steps: S1, opening a fluidization valve for fluidization treatment, and S2, turning on the vacuum generator, and conveying the fluidization powder storage box into the vacuum generator. The novel glass powder sprayer uniformly sprays atomizedpowder to the surface of glass through spray heads, is uniform in powder spraying, stable and reliable and reduces cost.

Owner:NANTONG VOCATIONAL COLLEGE

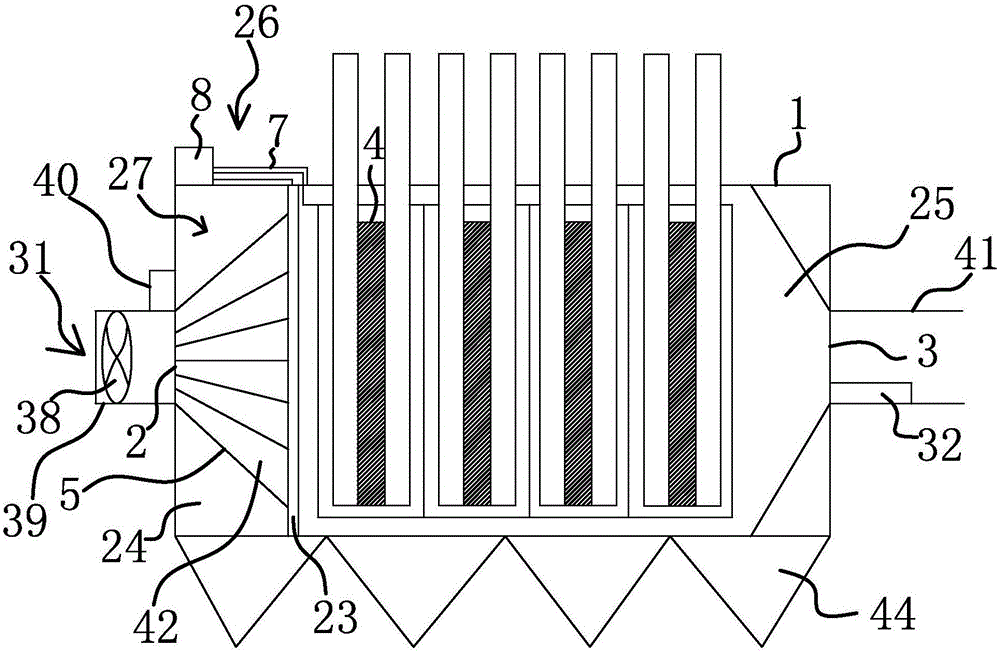

Electric dust remover

ActiveCN106622664AImprove work efficiencyReduce adsorption pressureCombination devicesExternal electric electrostatic seperatorEngineeringFog

The invention belongs to the technical field of environmental protection, and particularly relates to an electric dust remover. The invention solves the technical problem of bad dust removal efficiency and others existed in the prior art. The electric dust remover comprises a box body, wherein the box body is provided with an air inlet and an air outlet; the box body is internally provided with a clapboard, and the clapboard divides the box body into an air inlet chamber connected with the air inlet and a dust removal room connected with the air outlet; a discharge component is arranged in the dust removal room, and a cathode plate is arranged in the dust removal room; an air inlet shunt structure is arranged in the air inlet chamber; a smoke pretreatment component is arranged on the air inlet shunt structure, and a cleaning component capable of cleaning smoke dust attached on outside of the cathode plate is arranged in the dust removal chamber; the cleaning component is provided with an anti-dust structure for preventing smoke dust from spreading to the air flow in cleaning; a fan component is arranged on the air inlet, and the air outlet is provided with a smoke fog alarm. Compared with the prior art, the electric dust remover is high in dust removal efficiency.

Owner:浙江万源环保机械科技有限公司

Automatic hardware powder spraying production line capable of quickly changing color

InactiveCN112403736AEasy height adjustmentSimple structureLiquid spraying plantsGear wheelPowder Spray

The invention relates to the technical field of powder-spraying production lines, and solves the problem that powder cannot uniformly injected onto processing parts by using a powder spraying machinewhen parts are processed on a conventional powder spraying production line, in particular to an automatic hardware powder spraying production line capable of quickly changing color. The automatic hardware powder spraying production line comprises a fixed device and a conveying plate, wherein a connecting rod is fixedly connected to the bottom of the fixed device; a long guide rail and a short guide rail are fixedly connected to the bottom of the connecting rod; racks are fixedly connected to the inner side walls of the long guide rail and the short guide rail; limiting blocks are fixedly connected to the bottoms of the long guide rail and the short guide rail; a square-hole bearing is rotatably connected to the inner side wall of a circular clamping block; a circular shaft sleeve is fixedly connected to the bottom of the circular clamping block; a square-head circular rod is rotatably connected to the interior of the circular shaft sleeve; and a gear is fixedly connected to the bottomof the square-head circular rod. In a using process, powder can be uniformly sprayed onto the surfaces of processing parts, so that the aims of reducing the labor cost and improving the production efficiency are achieved.

Owner:佛山市明图涂装设备有限公司

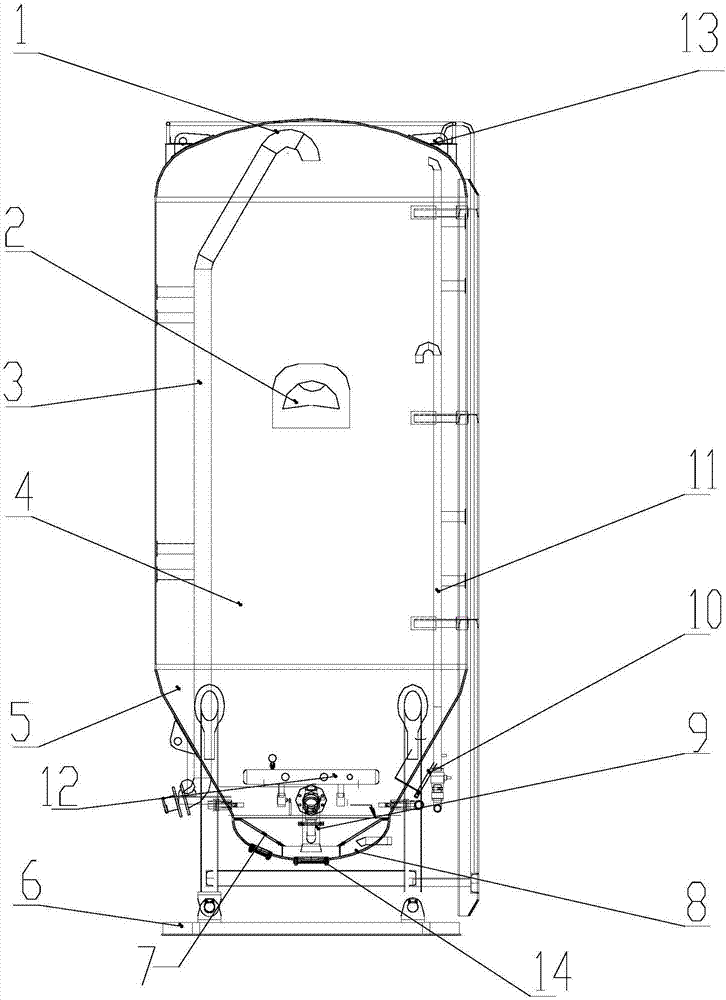

Novel vertical ash storing tank and using method thereof

PendingCN107499746ASolve the problem of ashImprove work efficiencyConveyorsLarge containersEnvironmental engineeringAir chamber

The invention discloses a novel vertical ash storing tank and a using method thereof. The novel vertical ash storing tank is composed of an elliptical head, lateral hanging lugs, an ash inlet pipe, a barrel, a conical head, a base assembly, a lower gas chamber, an ash outlet pipe, a manhole assembly, a deflation pipe, a main gas chamber, elliptical head upper hanging lugs, and an ash removal opening. A net-shaped oblique gas chamber is arranged at the bottom of the lower gas chamber, the ash removal opening is composed of a straight pipe and a horn-opening-shaped pipe, the ash inlet pipe is composed of a bend and a straight-through pipe, the bend is welded to the upper portion of the straight-through pipe, and the ash inlet pipe is provided with a fixed-connecting plate. According to the novel vertical ash storing tank based on the structure, ash falling is fast and uniform, pressure in the tank can be greatly lowered, the service life is prolonged, use cost is lowered, and labor cost is correspondingly reduced.

Owner:CNPC BOHAI EQUIP MFG

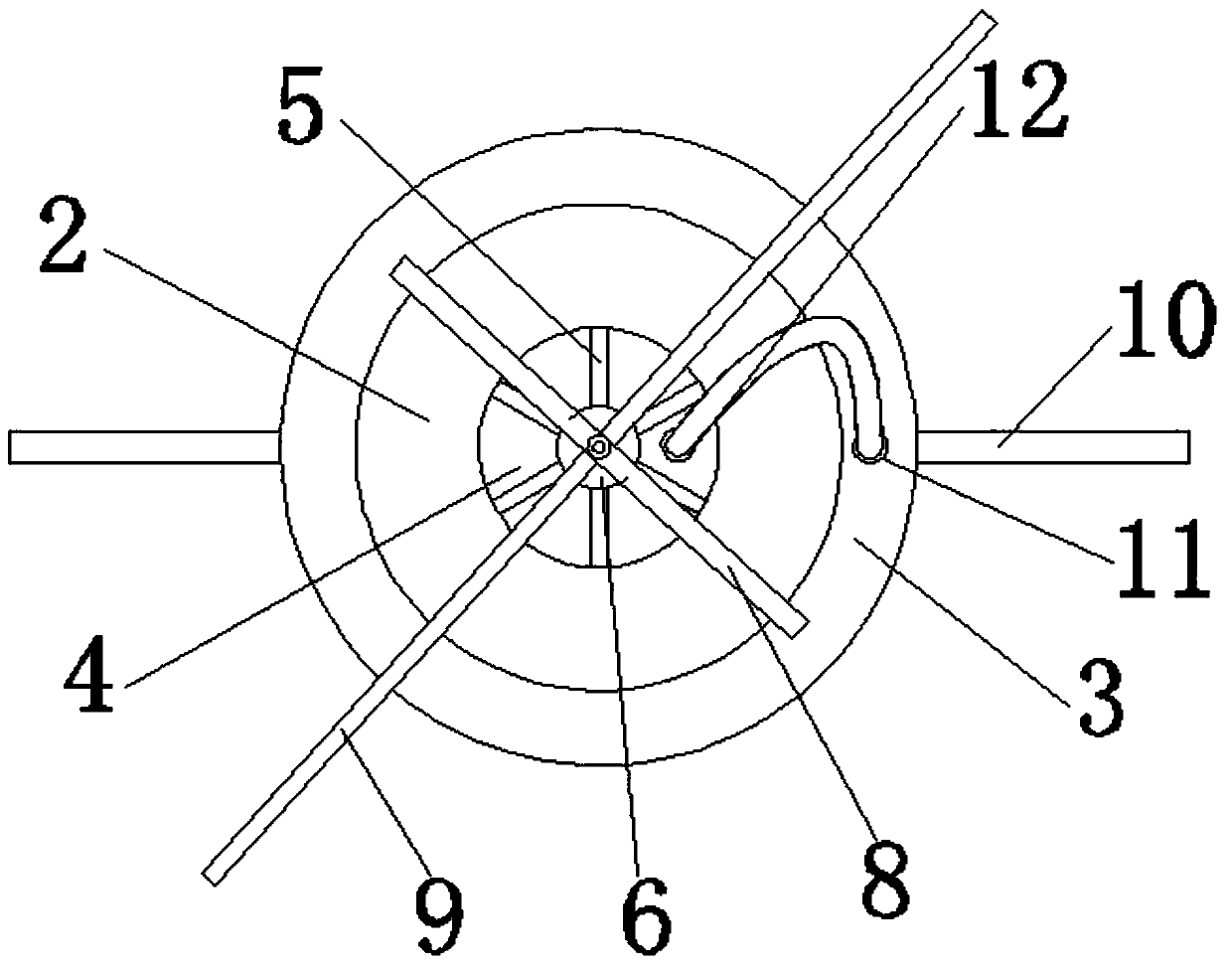

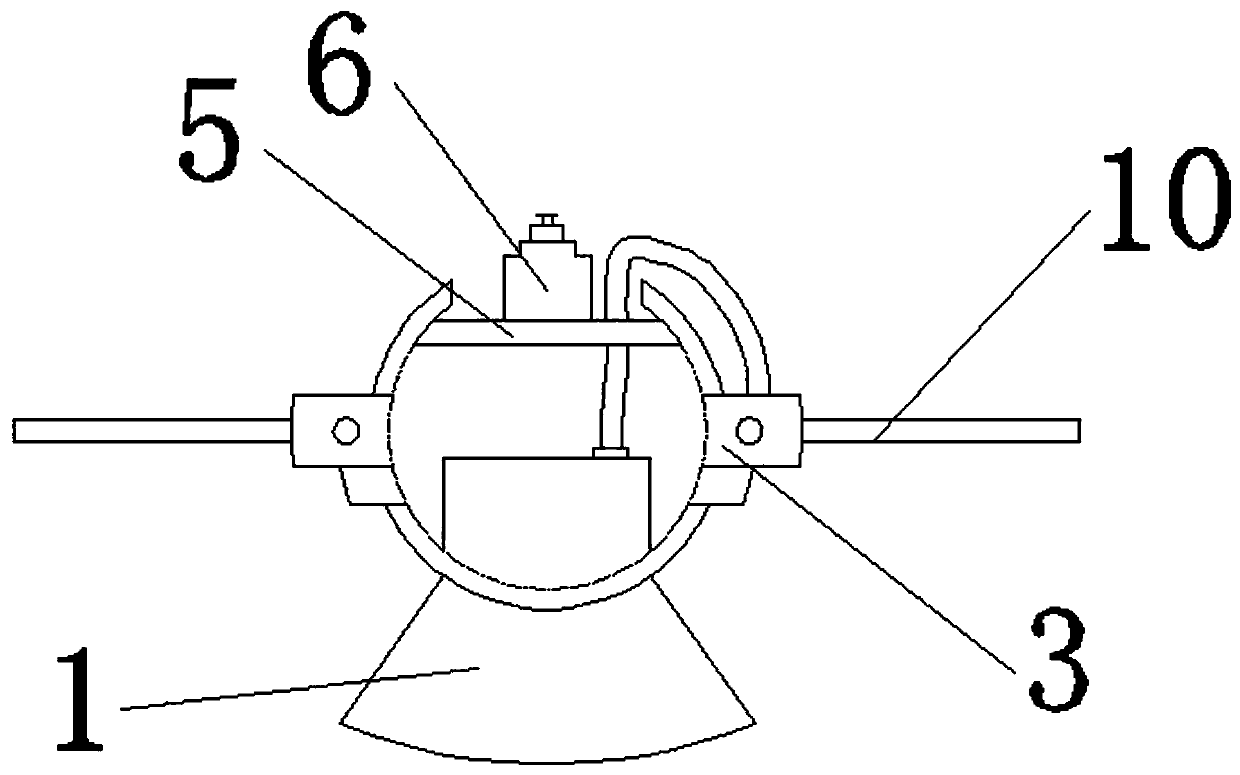

Adaptive nozzle

ActiveCN109701340ASave human effortEfficient use ofUsing liquid separation agentSelf adaptiveWater resources

The invention relates to an adaptive nozzle. The adaptive nozzle comprises a nozzle for discharging water, a hollow spherical sleeve is arranged at the tail end of the nozzle, a limit ring bracket sleeves the periphery of the spherical sleeve, the upper end of the spherical sleeve is provided with an opening, a fixing bracket is arranged in the spherical sleeve, the middle portion of the fixing bracket is provided with a shaft seat, the shaft seat is provided with a rotating shaft, the middle portion of the rotating shaft is provided with a steering sail blade, the upper portion of the rotating shaft is provided with an inclined sail blade, and an included angle between the orientations of the steering sail blade and the inclined sail blade is 90 DEG. The adaptive nozzle can adapt to the wind direction and spray water against the wind to reduce sprayed water mist from being blown away by the wind, and the adaptive nozzle can automatically change the angle of the water spray against thewind to automatically adapt to the power of the wind without real-time adjustment by an operator, so manpower is saved, water resources are efficiently used, and wastes caused by blowing away the water by the wind are avoided.

Owner:金华伏安光电科技有限公司

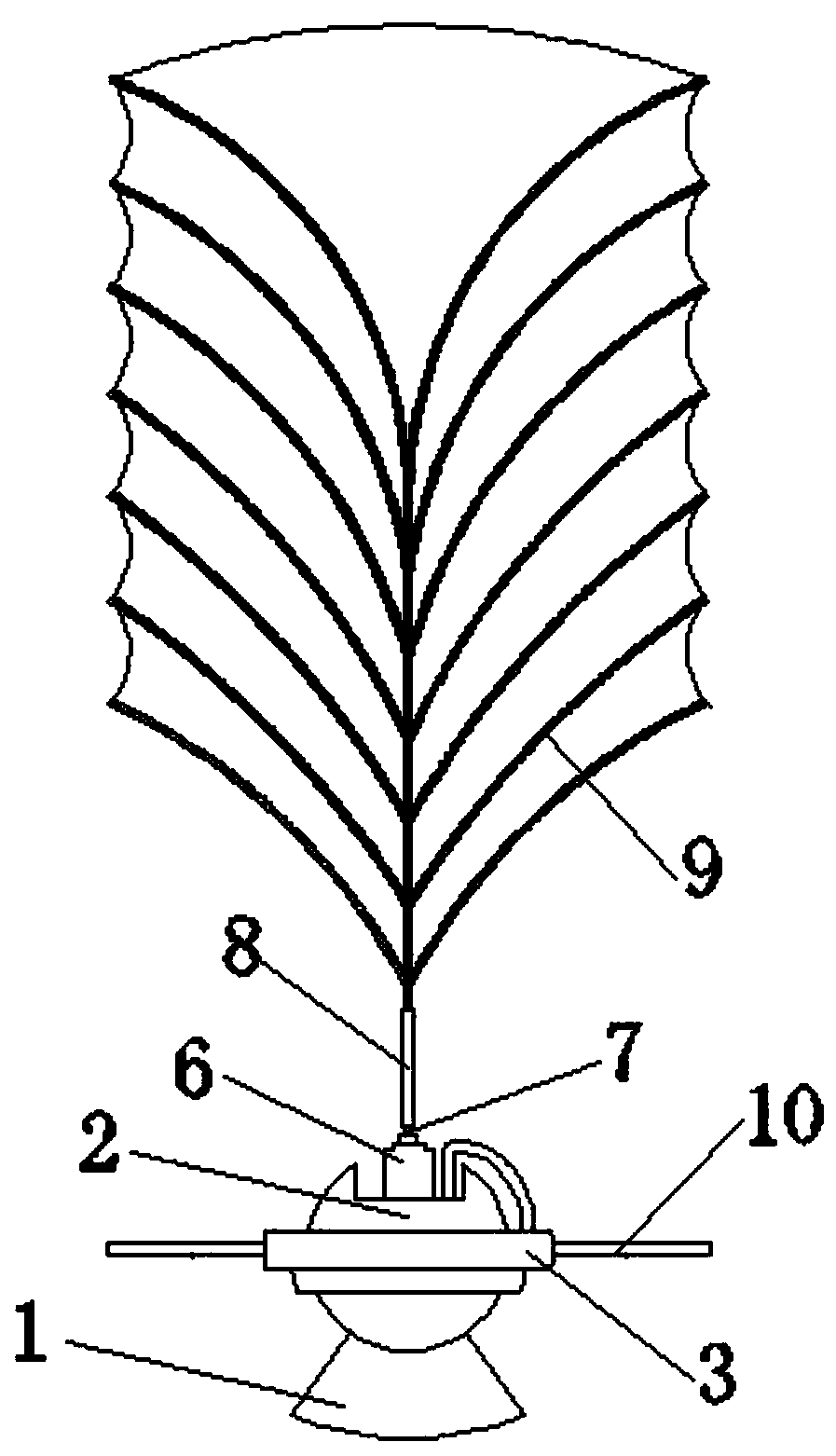

Special artificial pollinator for wheat breeding

InactiveCN107047281ARealize automatic powder sprayingSimple structureAgriculturePlant genotype modificationPollinatorPowder Spray

The invention discloses a special artificial pollinator for wheat breeding. The special artificial pollinator comprises a powder collection device and a powder spraying device, wherein the powder spraying device sleeves one end of the powder collection device; the powder collection device is connected with the powder spraying device through clearance fit; a spray head is arranged at the other end of the powder collection device; powder spraying holes are uniformly formed in the spray head; a push rod is arranged at one end of the powder spraying device; a rotating shaft is arranged in the push rod; a push plate end cover is arranged at the other end of the powder spraying device; one end of the push rod is vertically connected with one end of the push rod end cover; a motor is arranged in the push rod end cover and connected with the rotating shaft; rechargeable batteries are arranged at two sides of the motor; the motor is connected with the rechargeable batteries; a control button is arranged at the other end of the push rod end cover; and the control button is connected with the motor. The special artificial pollinator is simple in structure; and the rotating shaft is driven to rotate through the motor, so that automatic powder spraying of the powder spraying device is achieved, and the special artificial pollinator is convenient to operate, high in pollination efficiency, uniform in pollination, low in cost and simple and convenient in preparation.

Owner:王秀芹

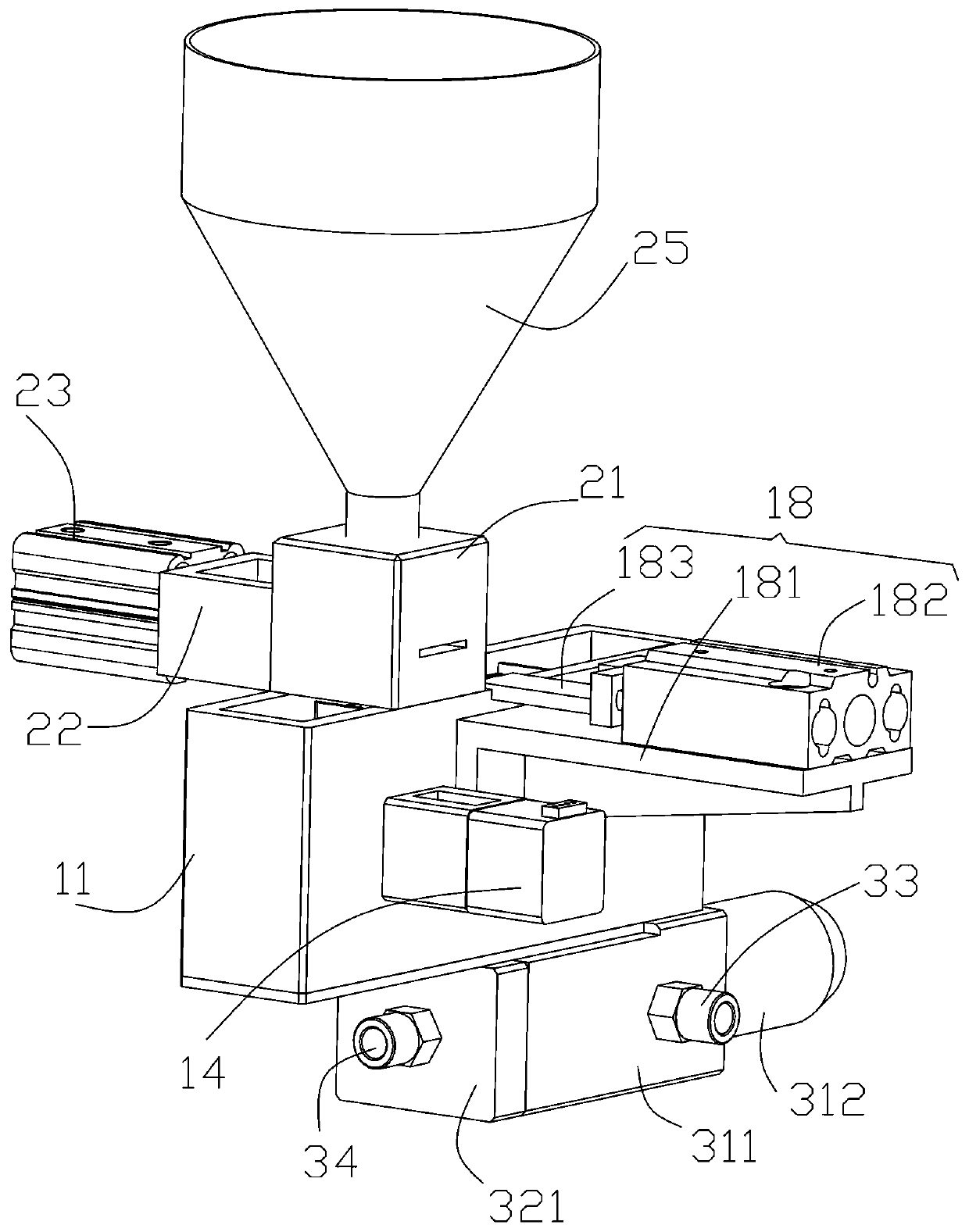

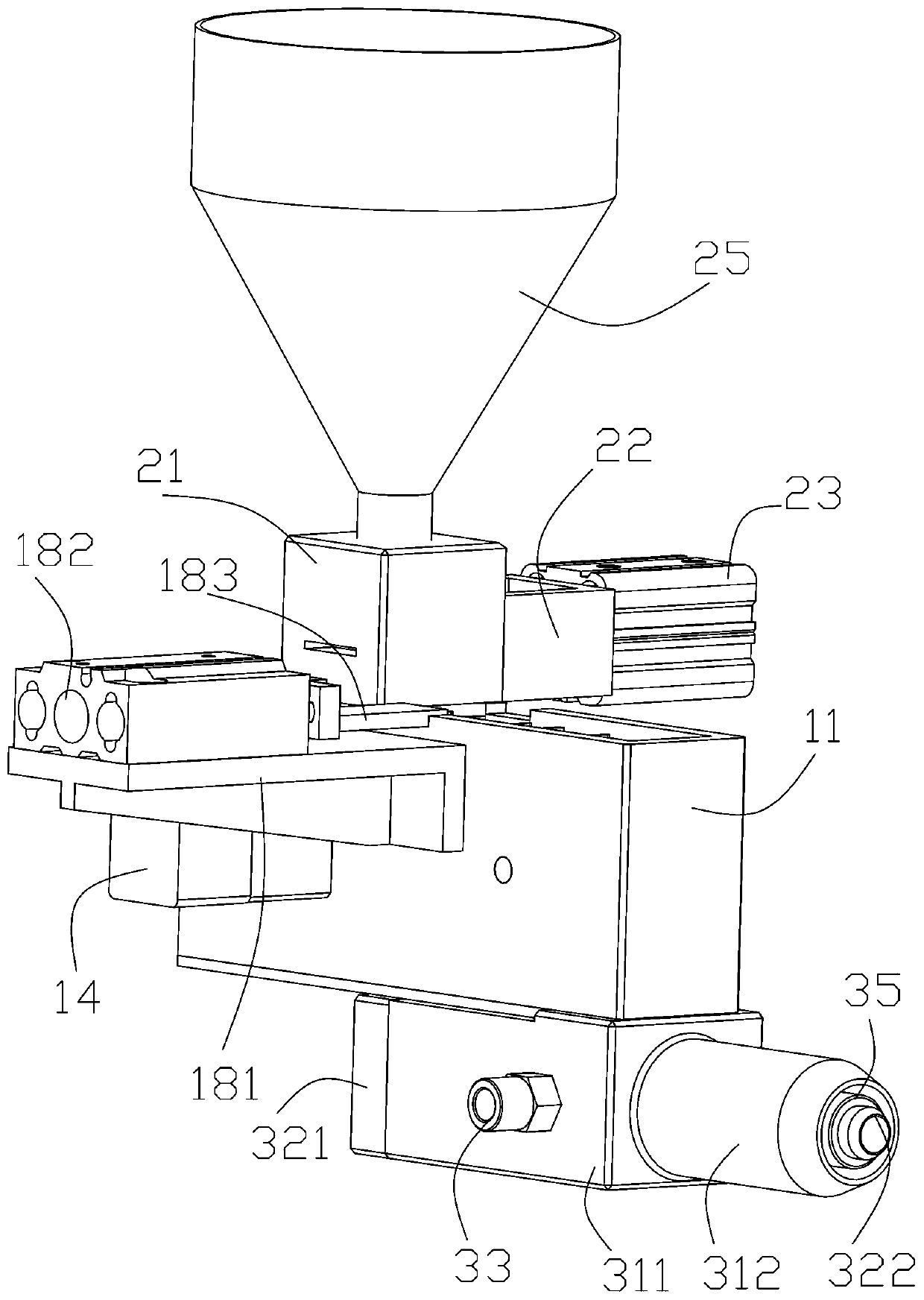

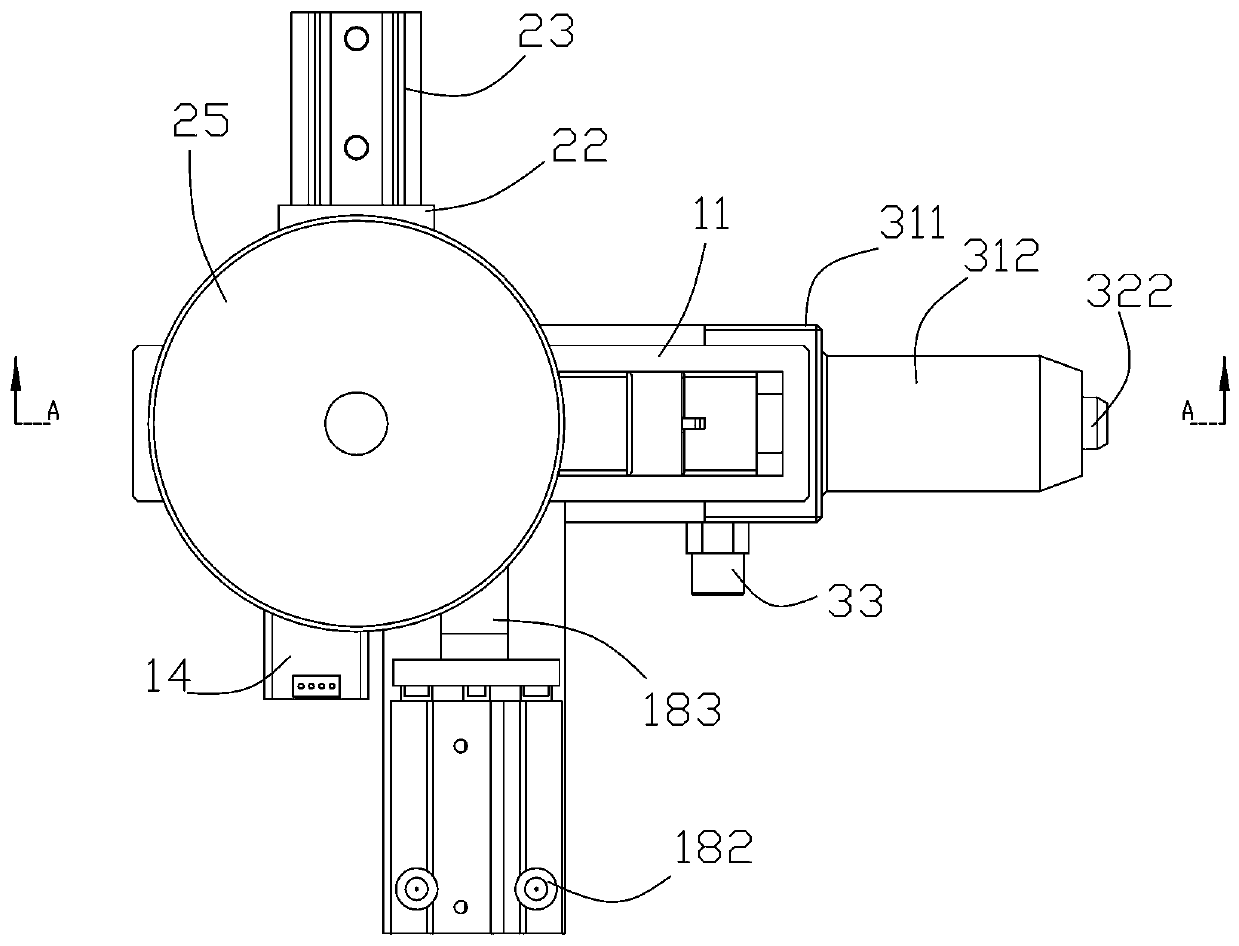

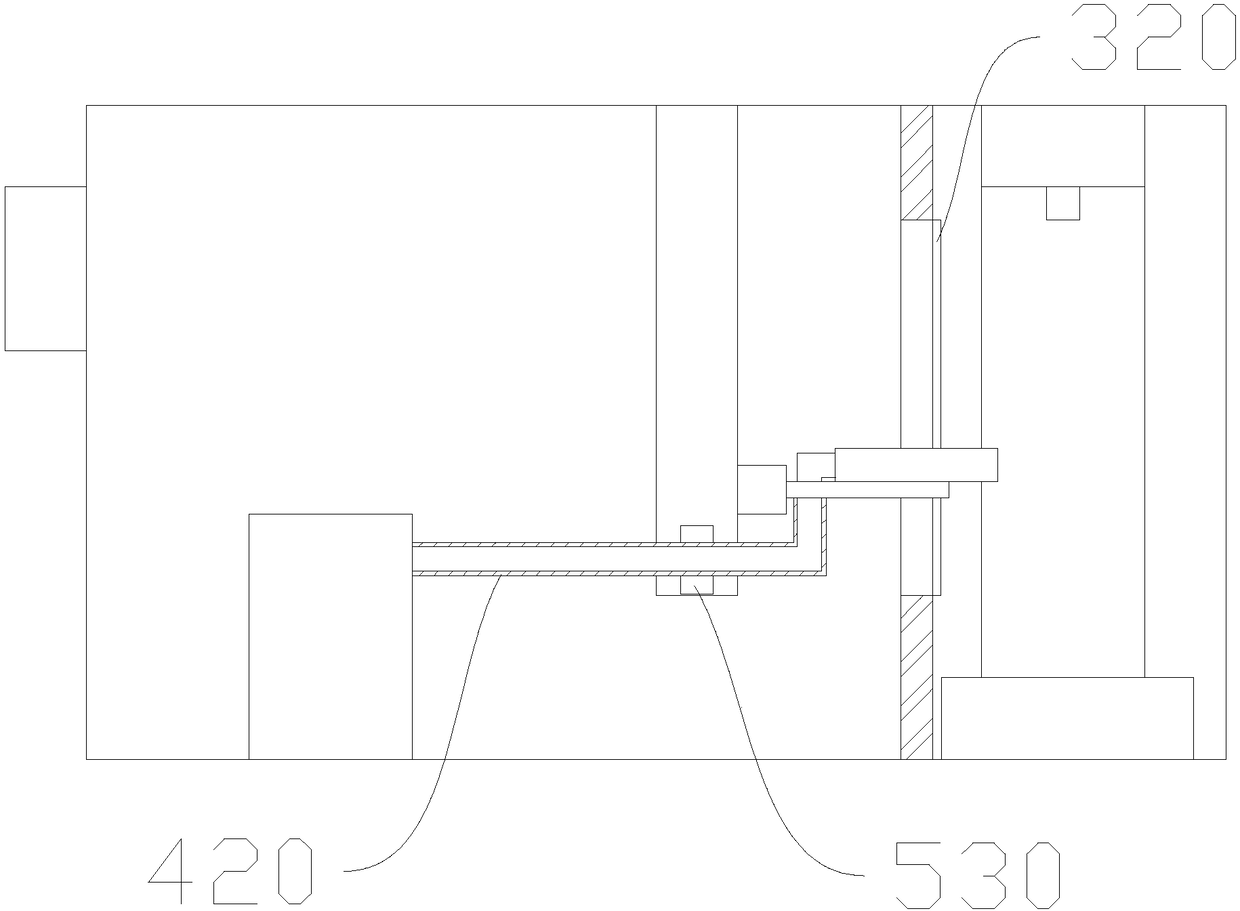

Material hanging type automatic wax injecting and quantitative powder spraying mechanism

The invention discloses a material hanging type automatic wax injecting and quantitative powder spraying mechanism. The material hanging type automatic wax injecting and quantitative powder spraying mechanism comprises a feeding device, a quantitative powder feeding device and a wax injecting and powder spraying nozzle; the wax injecting and powder spraying nozzle is used for spraying powder and injecting wax liquid into a mold; powder materials enter the quantitative feeding device through the feeding device; the quantitative feeding device communicates with the wax injecting and powder spraying nozzle; the quantitative powder feeding device comprises a belt wheel support, a driving motor, a driving belt heel, a driven belt wheel, a transmission belt and a material scraping part; the driving belt wheel and the driven belt wheel are both connected to the belt wheel support in a shaft connection manner; the driving motor is connected with the driving belt wheel; and the transmission belt is provided with powder feeding grooves at intervals, and the material scraping part is arranged on the belt wheel support. According to the material hanging type automatic wax injecting and quantitative powder spraying mechanism, due to cooperation of the feeding device and the quantitative powder feeding device, it is achieved that powder is quantitatively fed to the wax injecting and powder spraying nozzle, and therefore a quantitative powder spraying procedure is completed, manual operation is not needed, the work efficiency is greatly improved, powder spraying in the mold is uniform, itis avoided that due to the fact that manual powder spraying is not uniform, forming of a wax mold is affected, and the qualification rate of wax mold forming is increased.

Owner:昕致潮贸易(深圳)有限公司

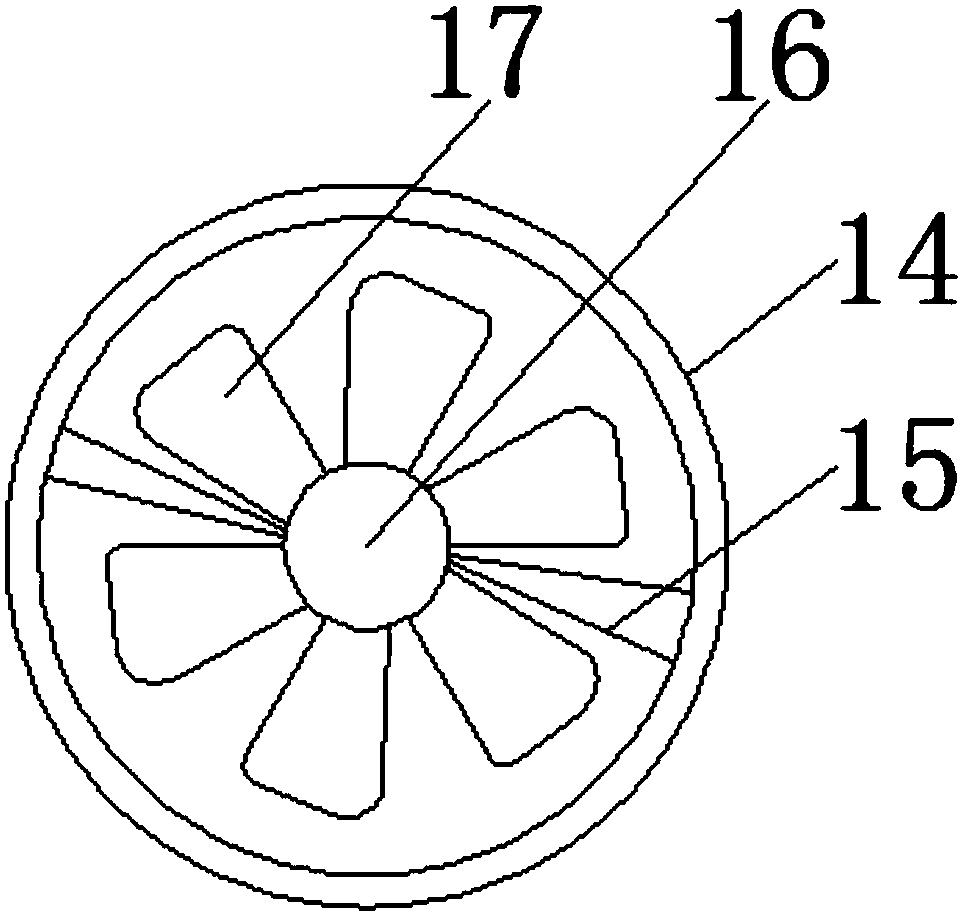

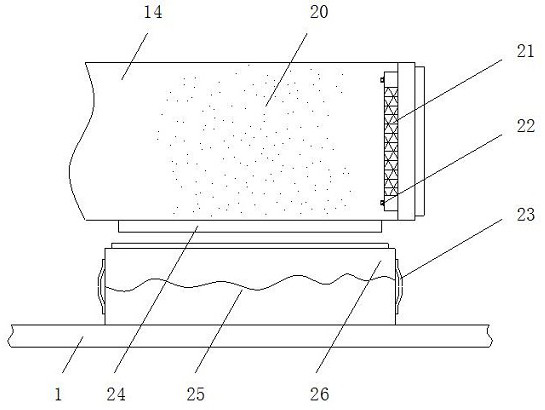

Dust removal device for cloth printing and dyeing equipment

InactiveCN108486848ADust evenlyReduce reworkMechanical cleaningPressure cleaningEngineeringUltimate tensile strength

The invention discloses a dust removal device for cloth printing and dyeing equipment. The dust removal device comprises a tank body, wherein through slots are formed in the bottoms of two sides of the tank body, roll wheels are arranged at the bottoms of two sides of an inner cavity in the tank body, and cloth matched with the through slots for use is arranged at the tops of the roll wheels; a motor is arranged in the center of the rear side of the tank body, a rotating shaft is fixedly connected to the front side of an output shaft of the motor, the front side of the rotating shaft penetrates through the tank body and is sleeved with a rotating disc, and a hairbrush is arranged on the surface of the outer side of the rotating disc. By virtue of the cooperation of the motor, the rotatingshaft, the rotating disc, a blowing pump, a connecting pipe, a tee joint, a venting pipe, a spray head, a funnel-shaped communication pipe, an exhausting fan, a fixed rod, a rotation shaft and fan blades, the uniform dust removal of the cloth can be realized, so that the dust removal effect of the dust removal device is improved, the problem that an existing dust removal device is poor in dust removal effect, the cloth rework number of times of a user is reduced, the labor strength of the user is reduced, and the dust removal device is worthy of popularization and use.

Owner:叶青

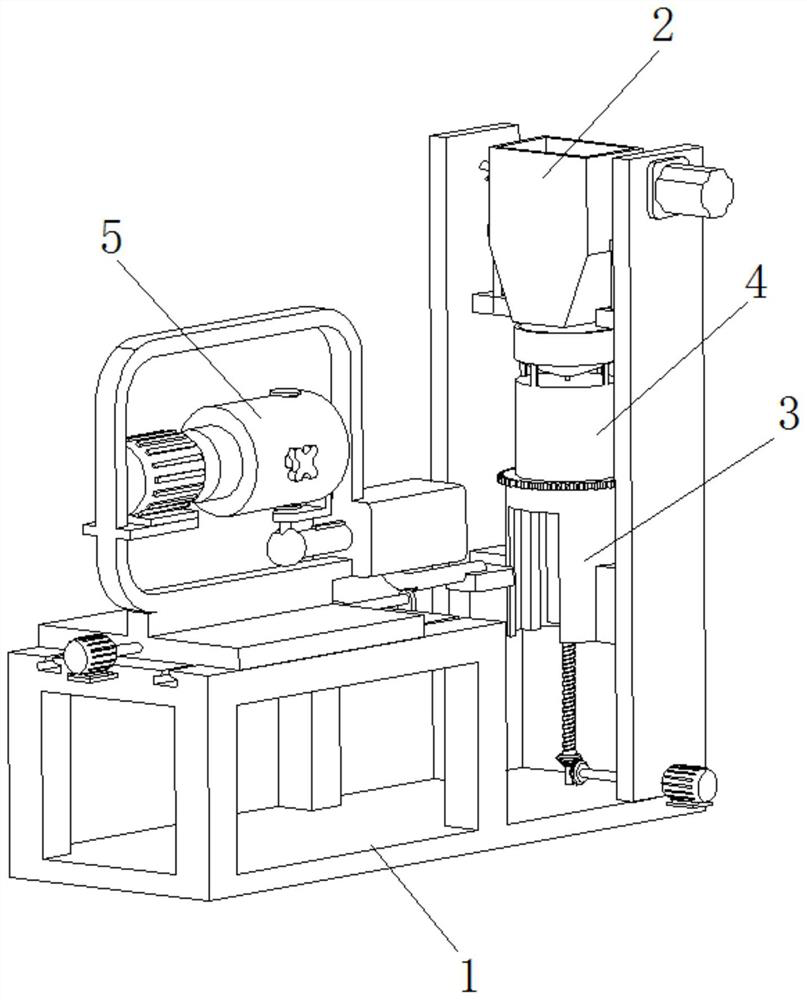

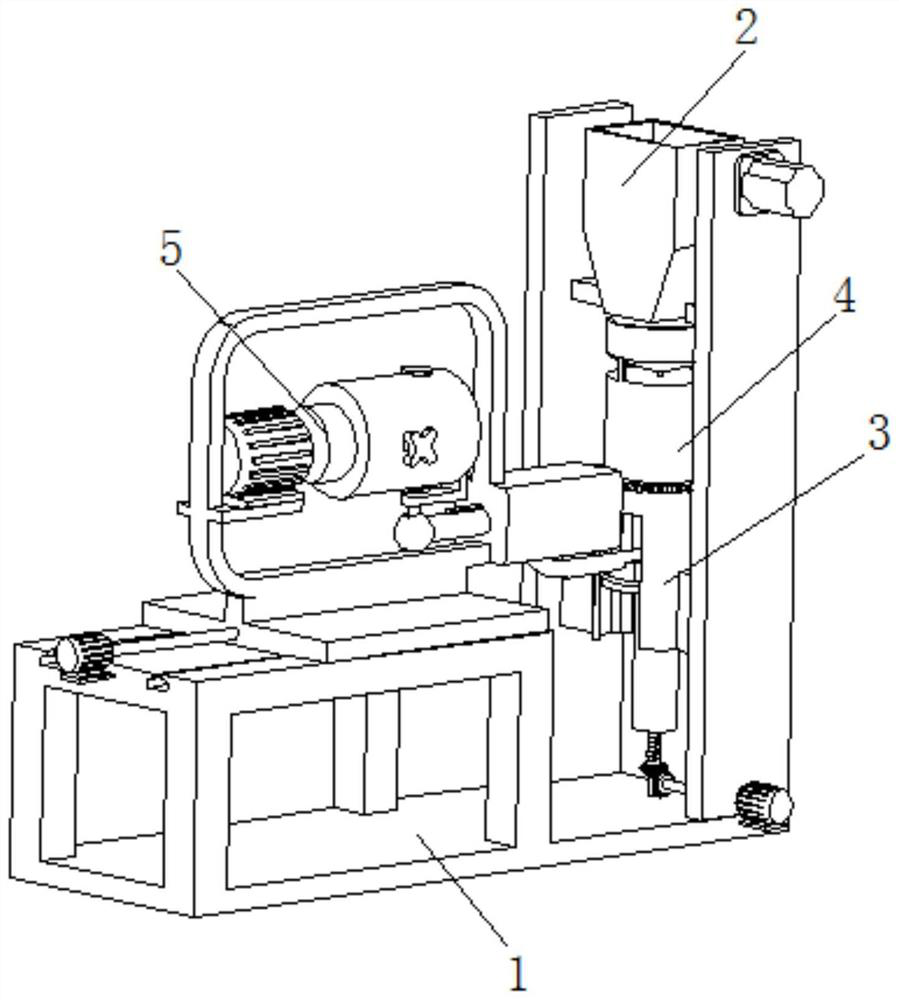

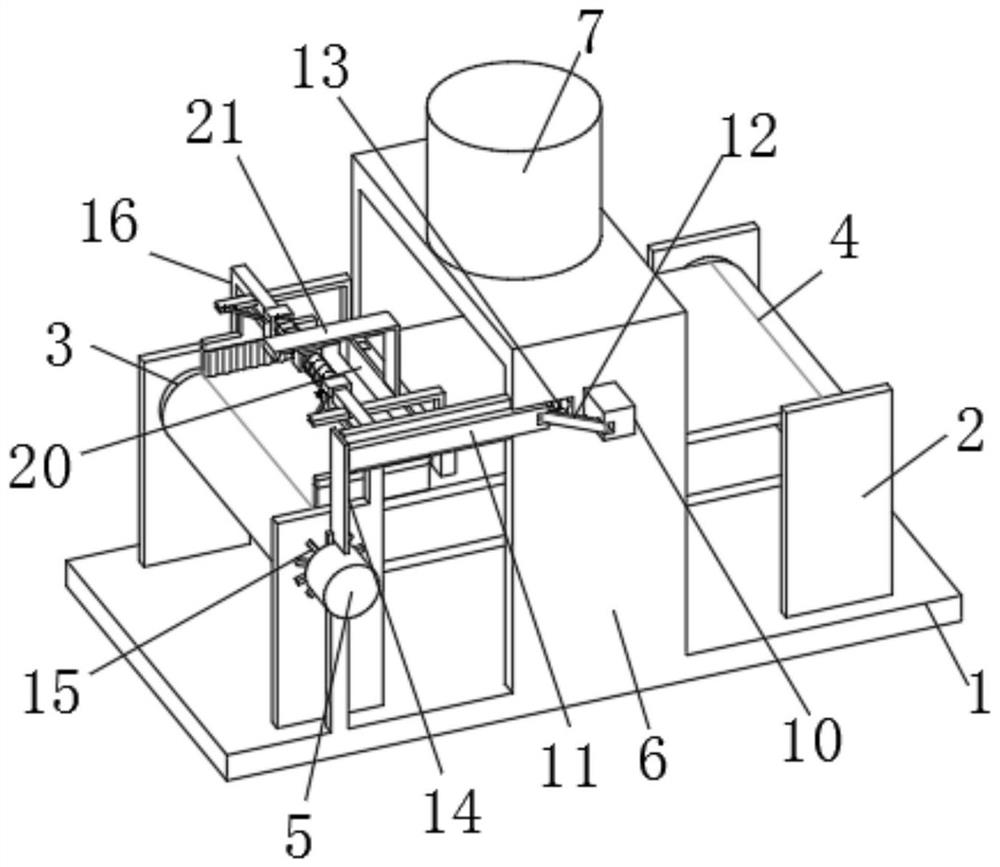

Powder spraying system for special ceramic production and powder spraying process thereof

The invention discloses a powder spraying system for special ceramic production and a powder spraying process thereof. The powder spraying system for special ceramic production comprises a base, and powder filtering equipment, feeding equipment, powder spraying equipment and powder scraping equipment arranged on the base; the powder filtering equipment is arranged on the rear side of the top of the base; the powder filtering equipment is used for filtering aluminum oxide powder to prevent the influence on the powder spraying effect due to mixing of large particles in the aluminum oxide powder;the powder spraying equipment is arranged on the rear side of the top of the base and located at the bottom of the powder filtering equipment; the powder spraying equipment is used for receiving thealuminum oxide powder filtered by the powder filtering equipment and spraying the aluminum oxide powder to ceramic; the feeding equipment is arranged on the rear side of the top of the base and located at the bottom of the powder spraying equipment; the powder scraping equipment is arranged on the front side of the top of the base; and the powder scraping equipment is used for scraping the powderon the feeding equipment after work to prevent the situation that the finished product effect of special ceramic is affected when the special ceramic is borne next time due to the fact that too much aluminum oxide powder remains on the feeding equipment.

Owner:贺强

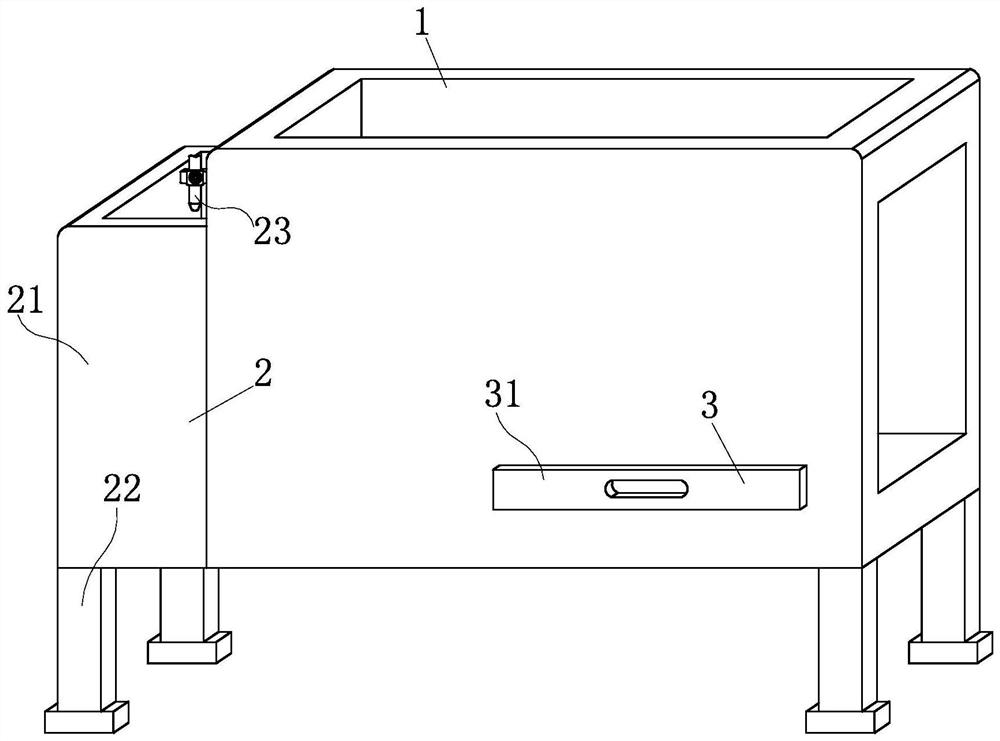

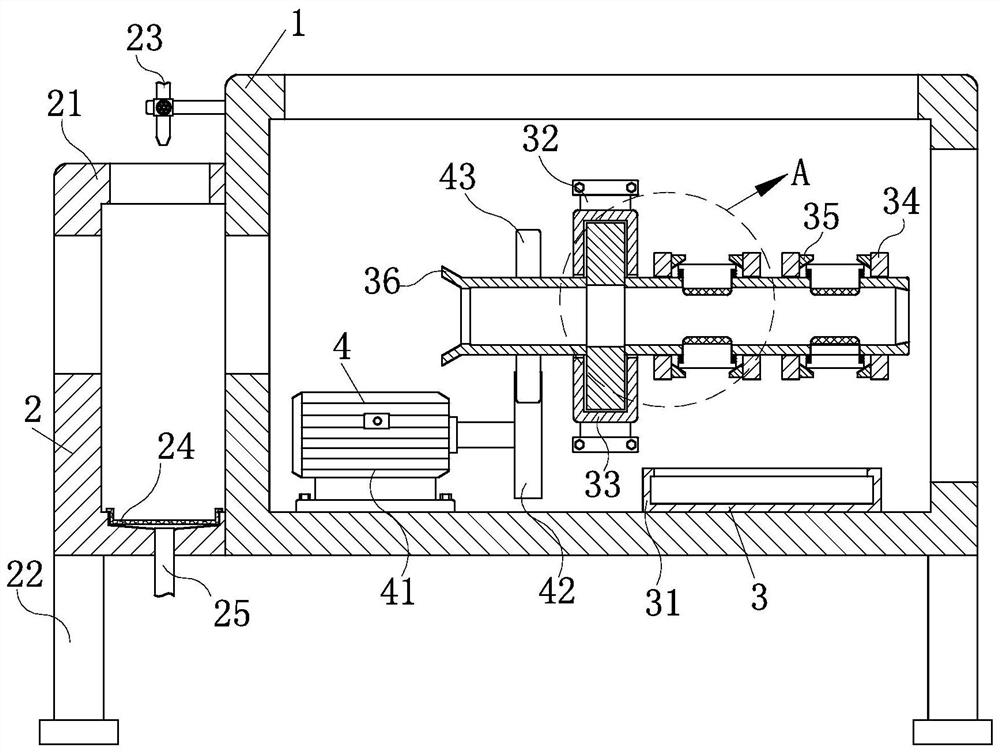

Automatic powder spraying device and using method thereof

The invention provides an automatic powder spraying device and a using method thereof. The automatic powder spraying device comprises a controller and a powder spraying room, wherein through a partition plate, a powder spraying cavity and a channel cavity are formed in the powder spraying room; and a conveying chain is arranged at the top end of the channel cavity. According to the automatic powder spraying device and the using method, a hardware product can be hung on the conveying chain, a second motor can be controlled by the controller to drive the conveying chain for transmission, the hardware product can be conveyed to a powder spraying zone, a first motor can be controlled by the controller to drive a sliding block to slide up and down, a powder spraying gun can be controlled by thecontroller to uniformly spray powder onto the surface of the hardware product along with the up-and-down sliding of the sliding block when the hardware product passes through the powder spraying zone, and the redundant powder can drop into a recycling box; after the recycling box is drawn out of the channel cavity, the redundant powder can be recycled; by use of the automatic powder spraying device, the problem that the manual powder spraying efficiency is low can be well solved; and furthermore, the powder can be sprayed more uniformly, the redundant powder can be recycled, and the environmental pollution can be avoided.

Owner:惠州市国丰达五金制品有限公司

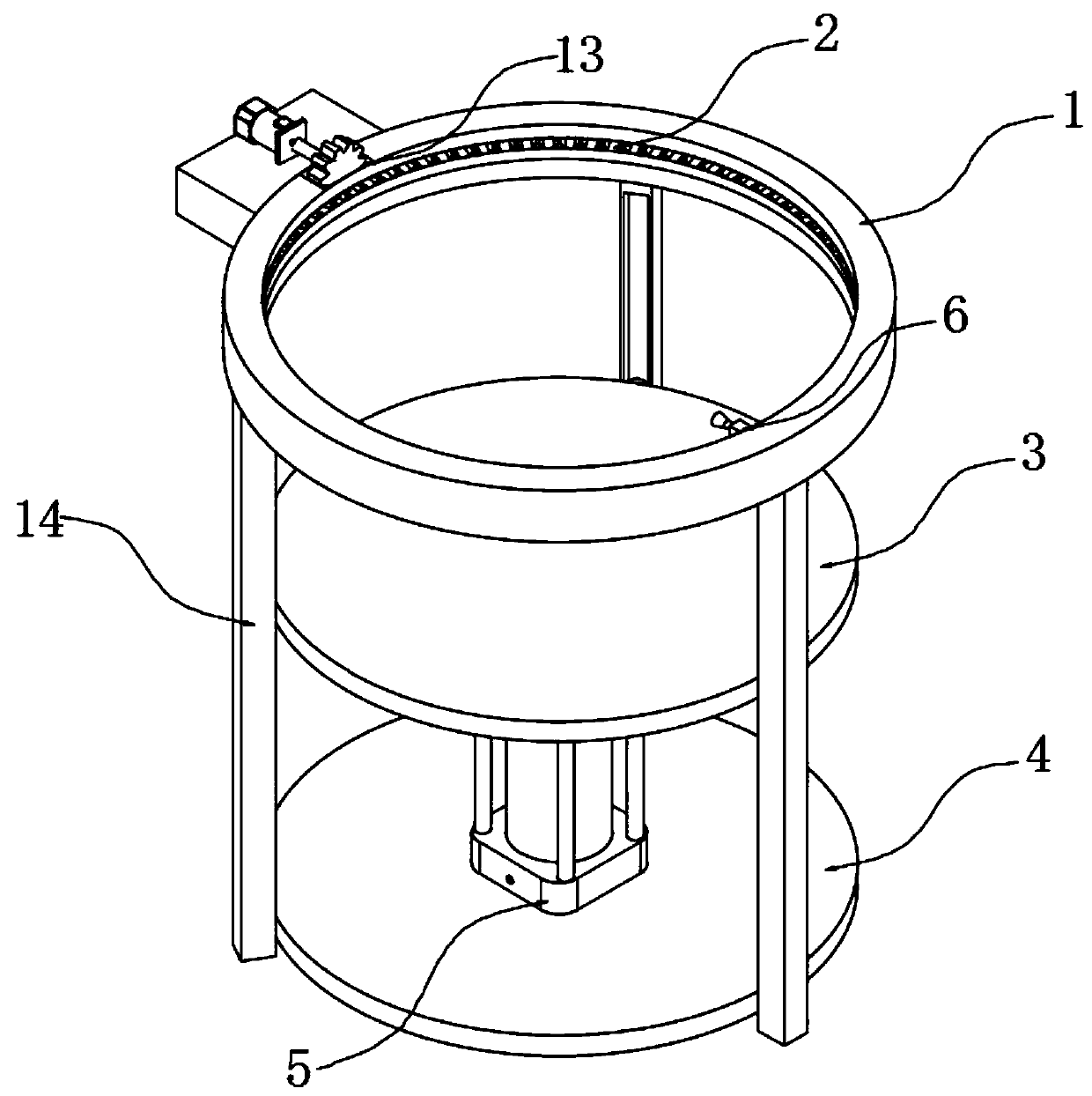

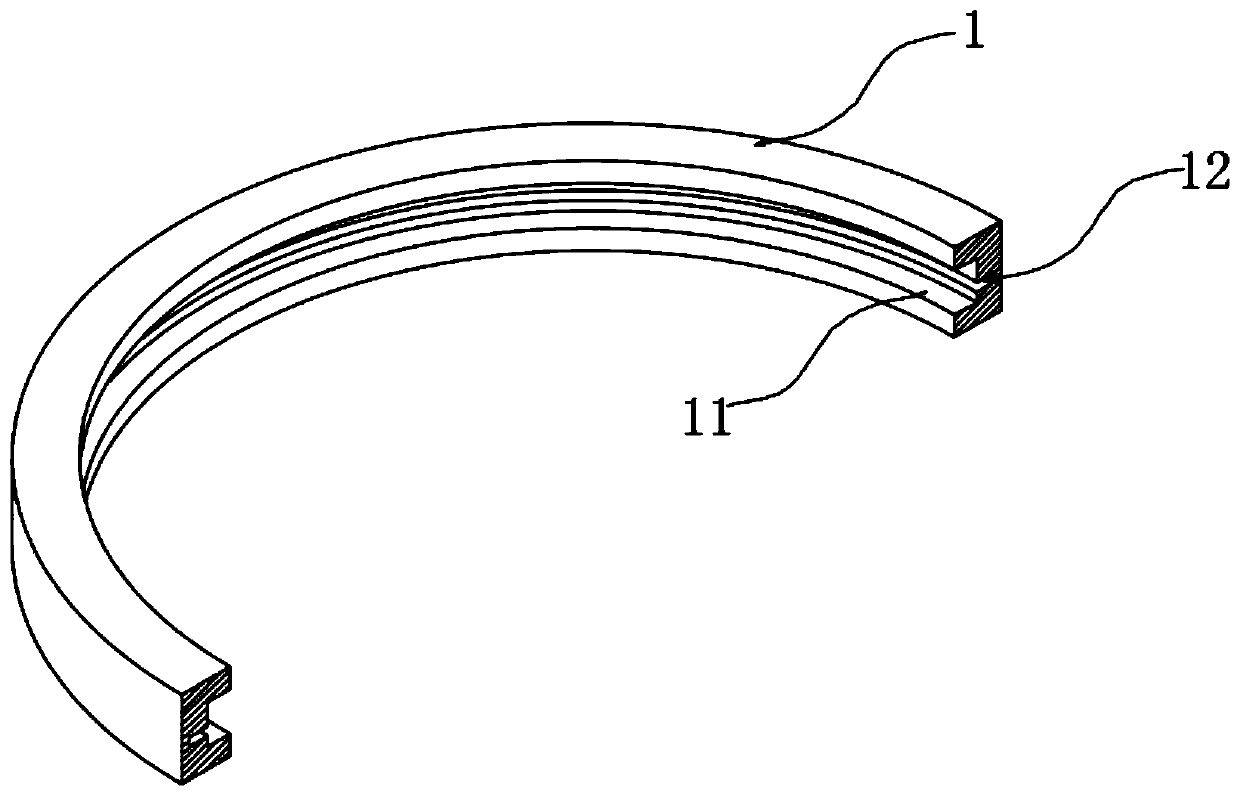

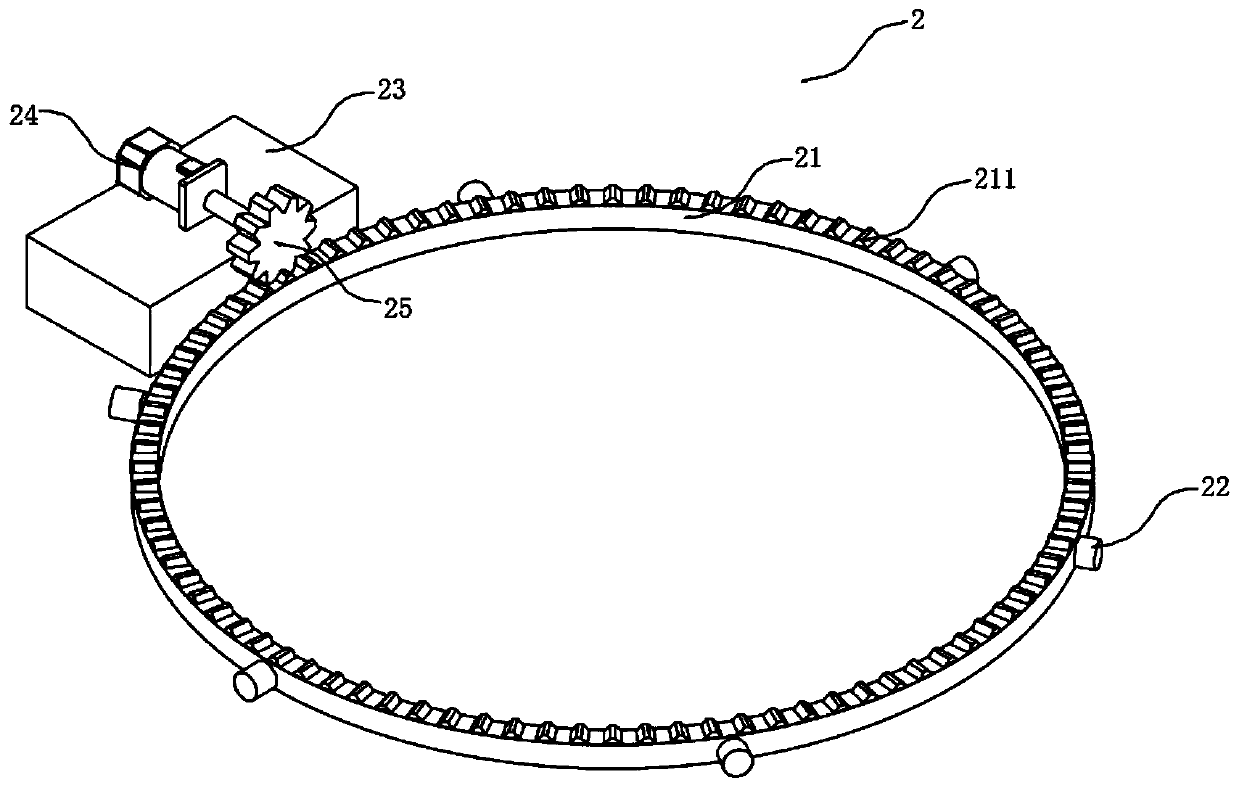

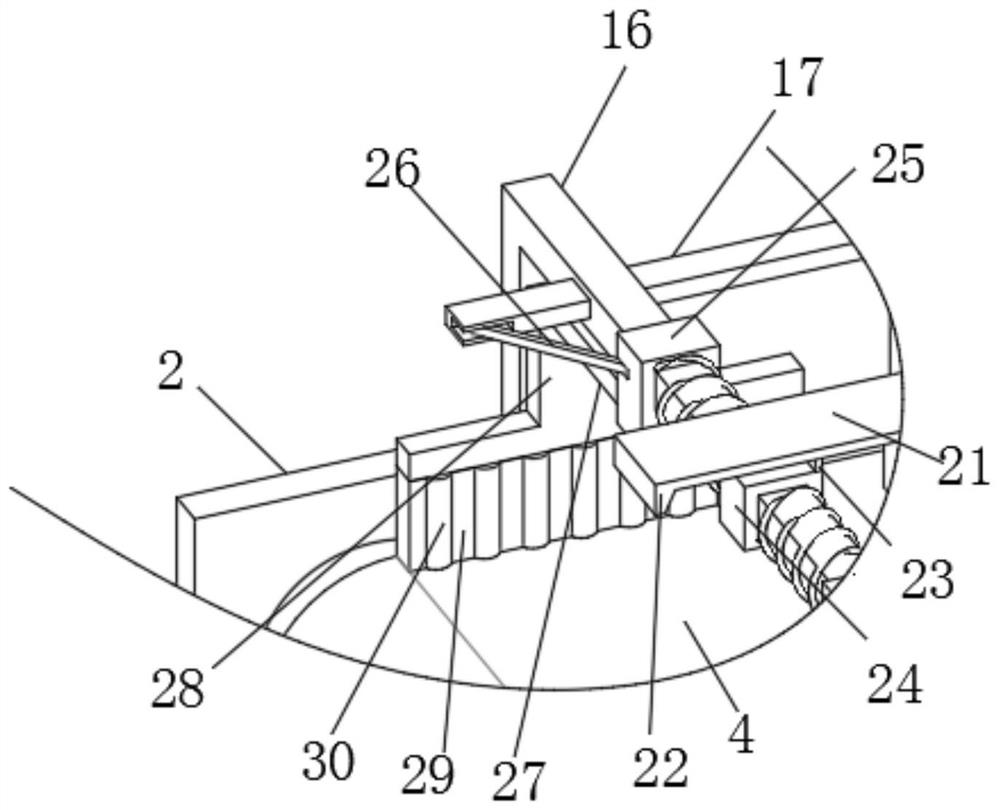

Surface powder spraying equipment for production of transformer

InactiveCN110773355ADust evenlyHandy dustSpraying apparatusInductances/transformers/magnets manufactureElectric machineTransformer

The invention relates to the technical field of powder spraying equipment for a transformer and particularly relates to surface powder spraying equipment for production of a transformer. The surface powder spraying equipment comprises a circular ring; the inner wall of the circumference of the circular ring is provided with a first annular groove; the inner wall of the circumference of the first annular groove is provided with a second annular groove; a rotating mechanism is arranged inside the first annular groove; the top surface of the circular ring is provided with a sunk groove; the bottom surface of the circular ring is provided with a plurality of supporting rods; and the sidewall of each supporting rod is provided with a sliding chute. According to the surface powder spraying equipment for the production of the transformer, a motor output shaft is arranged for driving the rotation of a gear so that a rotating ring can rotate; a sprayer can be driven to rotate by rotation of therotating ring so that powder can be uniformly sprayed to the four sides of the transformer; a cylinder is arranged for driving a lifting plate to move up and down so that the four sides of the transformer placed on the lifting plate are sprayed with powder; the powder spraying process is quite convenient; and thus the problem that the powder spraying equipment for the transformer is quite inconvenient is solved.

Owner:HUNAN CITY UNIV

Surface stain removal device used for electronic component pin lead production

InactiveCN111687141AEasy to moveDust evenlyCombination devicesDispersed particle filtrationElectric machineryElectronic component

The invention discloses a surface stain removal device used for electronic component pin lead production, and relates to the technical field of electronic element washing devices. One end of the surface of a base is fixedly connected with a support. The upper end of the support is fixedly connected with a suction fan. An air suction port of the suction fan is fixedly connected with an L-shaped pipe. The bottom and the inner portion of the position, close to the air suction port of the suction fan, of the L-shaped pipe are provided with a dust outlet and a filter screen correspondingly. A dustcollection box is arranged on the side, close to the suction fan, of the upper end of the base. Four telescopic rods are symmetrically arranged at the center position of the surface of the base. The upper end of each telescopic rod is fixedly connected with a frame. Bearings are fixedly and symmetrically arranged at the center positions of the two sides of the frame. One end of each rotating shaftis fixedly connected with the inner ring of the corresponding bearing. The rotating shafts are vertically arranged in a rotating plate at the center position in the frame in a penetrating and sleeving manner. According to the surface stain removal device, by arranging the suction fan, the rotating plate, a motor, a filter screen and the dust collection box, the problems that an existing pin leadcleaning manner is tedious, the cleaning efficiency is low and no related dust collection devices exist are solved.

Owner:马鞍山秉信光电科技有限公司

Glass powder spraying device for automobile laminated glass production

The invention discloses a glass powder spraying device for automobile laminated glass production, and relates to the technical field of glass processing.The glass powder spraying device comprises a base, four mounting plates are mounted at the top of the base, a conveying mechanism is mounted on the four mounting plates, a U-shaped plate is mounted at the top of the base, and a powder storage tank is mounted on the U-shaped plate; sliding holes are formed in the inner walls of the two sides of the U-shaped plate correspondingly, rectangular sliding columns are slidably installed in the two sliding holes correspondingly, and powder pipes are installed on the sides, close to each other, of the two rectangular sliding columns. According to the glass powder spraying device, glass can be transmitted through the conveying mechanism, the conveying mechanism drives the connecting mechanism to move in the conveying process, so that the multiple evenly-arranged spray heads move back and forth, powder spraying is uniform, meanwhile, the glass can be blocked through the blocking mechanism, and meanwhile the aligning mechanism is driven to align the glass; and then the glass is released through the releasing mechanism to ensure that the glass is in the optimal position during powder spraying every time, so that powder spraying is uniform.

Owner:TAIWAN GLASS YUEDA AUTO GLASS CO LTD

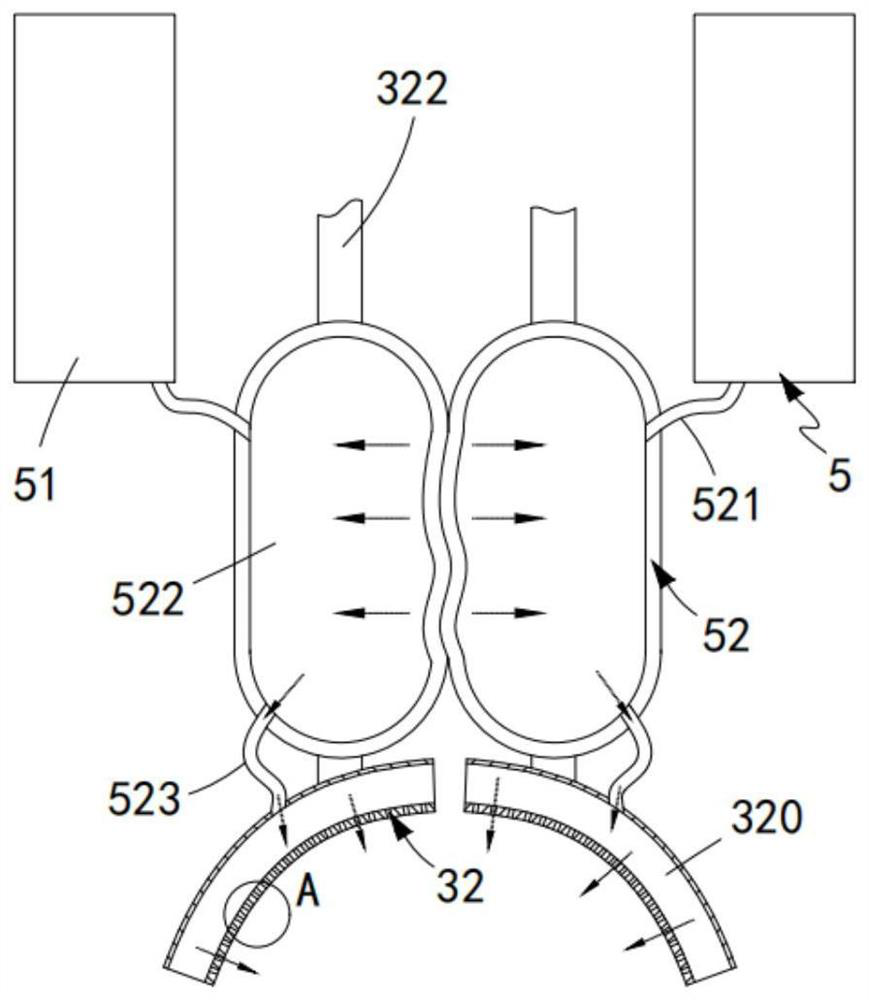

Production equipment and processing technology of a fully water-repellent polyester fusible interlining

ActiveCN111940232BSave spacePrecise ratioBiochemical fibre treatmentPretreated surfacesPolyesterPolymer science

The invention relates to a production equipment for fully water-repellent polyester adhesive interlining, which includes powdering equipment, and the powdering equipment includes: a driving mechanism, which includes a driving component and a transmission component; a glue output mechanism, which includes a pulp feeding component, a glue dispensing assembly and guide assembly; forming mechanism, which includes a support assembly and a tear-off assembly; a transmission mechanism; and a powder spraying mechanism; the present invention also relates to a sweat-absorbing and antibacterial fusible interlining processing technology, step 1, semi-finished composite interlining transmission; step 2 , pulp switching; Step 3, quantitative pulping; Step 4, automatic glue dispensing; Step 5, slurry molding; Step 6, spraying bamboo charcoal powder; Step 7, drying; When the glue is connected to the first cotton layer, the glue and the powder need to be evenly bonded together. When the powder is sprayed, there will be technical problems such as uneven size of glue and uneven distribution of glue.

Owner:浙江长兴维美丝特衬布有限公司

Coarse food grain tea bubble preparing equipment based on heat conduction

The invention provides coarse food grain tea bubble preparing equipment based on heat conduction. The coarse food grain tea bubble preparing equipment comprises supporting legs, coarse food grain teabubbles and a plurality of powder rolling trays, wherein a powder rolling tank is fixedly connected to the surfaces of supporting legs; supporting hollow steel pipes are fixedly connected to the innerwall of the powder rolling tank; a plurality of disk rolling balls are fixedly connected to the surfaces of the supporting hollow steel pipes; penetrating holes are formed in the surface of each powder rolling tray; a plurality of disk rolling balls are embedded in the inner wall of each penetrating hole. The invention relates to the field of coarse food grain tea bubbles. According to the coarsefood grain tea bubble preparing equipment based on heat conduction disclosed by the invention, through circular wind sucking and wind blowing of a sucking and blowing fan, the recycling of tea powderis convenient; gravity is utilized to enable the whole rolling device to be in continuous circulating operation, so that energy is saved, and the working efficiency is improved; the working temperature in the powder rolling tank is in thermostatic control through heat condition, so that the problems that when powder rolling is performed by conventional coarse food grain tea bubble preparing equipment, the situation that the powder rolling is not uniform is easy to generate, the working efficiency is low, and during continuous working, the energy consumption of the equipment is high are effectively solved.

Owner:广东玺瑞健康产业科技有限公司

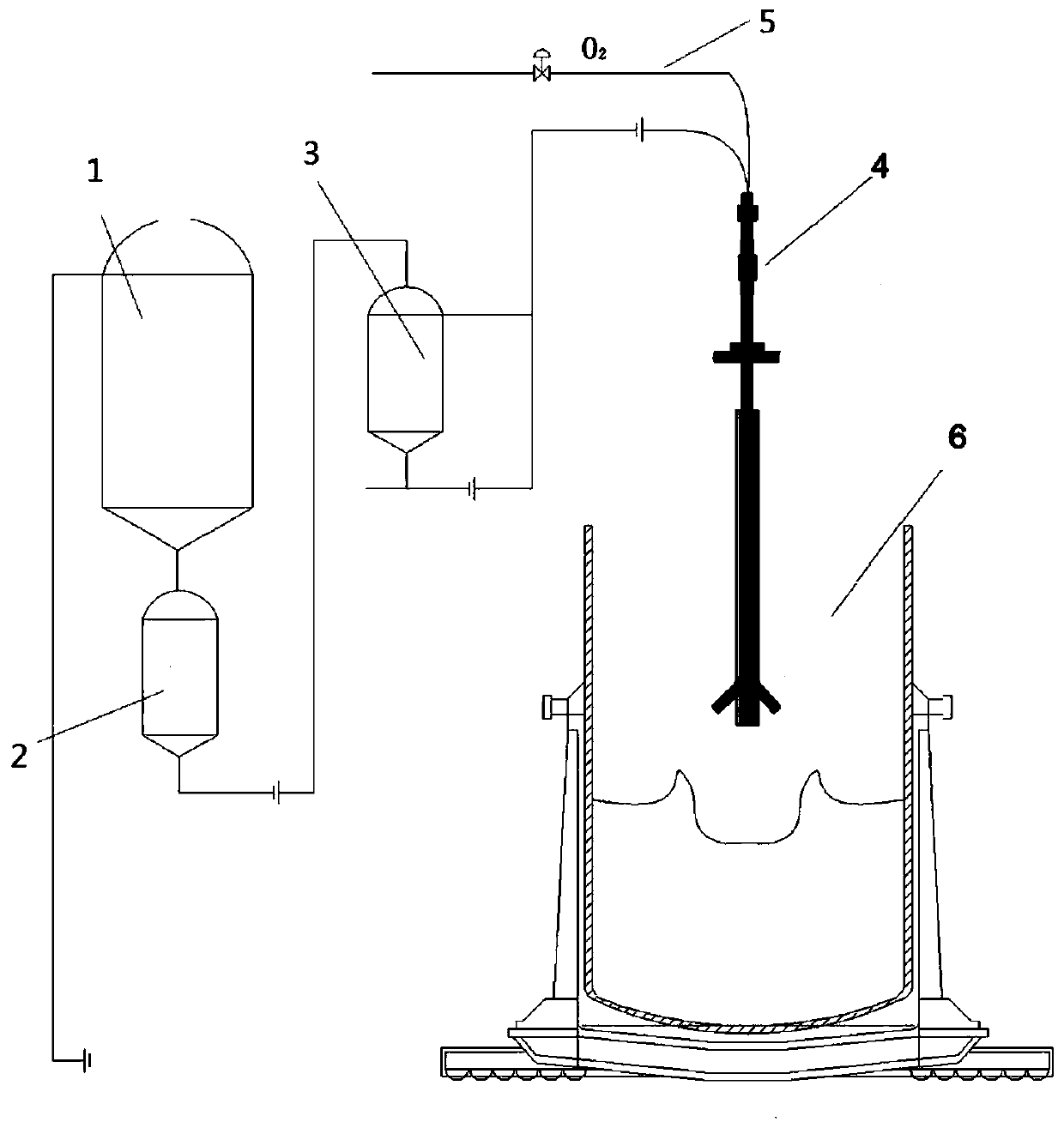

Molten iron dephosphorization device and dephosphorization method for smelting stainless steel

The invention relates to a molten iron dephosphorization device and dephosphorization method for smelting stainless steel, belongs to the technical field of ferrous metallurgy, and solves the problemsthat an existing dephosphorization device is large in occupied space, large in powder loss and low in smelting efficiency. The molten iron dephosphorization device comprises a storage tank, a conveying tank, a blowing tank, a spray gun, a ventilation pipe and a steel ladle, wherein the storage tank is connected with the blowing tank through the conveying tank, and the blowing tank and the ventilation pipe are connected with the spray gun; the spray gun comprises a first pipe and a second pipe, the first pipe is provided with a supporting bearing or the first pipe consists of flexible connecting pipes, and the first pipe is telescopically arranged in the second pipe; and the second pipe is provided with N spray gun outlets. The dephosphorization method comprises the following steps that desiliconization treatment is carried out on molten iron, desiliconized slag is removed, the molten iron is sprayed with oxygen and slagging materials, and molten slag is formed on the surface of the molten iron; and the steel ladle is sprayed with oxygen and slagging materials for dephosphorization treatment, wherein the oxygen spraying flow is 0.9 Nm<3> / t.min-1.2 Nm<3> / t.min, and the oxygen supply pressure is not less than 0.6 Mpa, so that the self-rotation of the spray gun is guaranteed. The device and the method can be used for molten iron dephosphorization for smelting the stainless steel.

Owner:CENT IRON & STEEL RES INST

Powder spraying equipment for pressure type nonpolar lamp

InactiveCN101567289AAvoid hand dustingSpeed up the spraying speedLuminescent coatings applicationSlurryHand shaking

The invention provides powder spraying equipment for a pressure type nonpolar lamp, which comprises a powder spraying chamber, a power spraying tube, a sealing plate, a recoverer and a recovering tube; an upper mouth of the powder spraying chamber is provided with the sealing plate; the cahmber wall of the powder spraying chamber is provided with an air inlet; the bottom of the recoverer is arranged on the sealing plate; an upper mouth of the recoverer is open; the sealing plate is provided with a powder spraying port and a recovering port; the powder spraying tube runs through the powder spraying port; the lower end of the powder spraying tube extends to the inside of the powder spraying chamber; the upper end of the power spraying tube extends to the inside of a nonpolar bulb body on the upper part of the recoverer; the recovering tube runs through the recovering port; the upper end of the recovering pipe is leveled with the upper surface of the sealing plate; and the lower end of the recovering tube extends the inside of the powder spraying chamber. The power spraying equipment can avoid the hand-shaking type power spraying, accelerates the power spraying speed of a product and has even powder spraying; and sprayed powdery slurry can be recovered to a powdery slurry tank for secondary spraying.

Owner:江苏世杰光电有限公司

Mechanical grate type garbage gasifying and incinerating system and combustion chamber with inverted-cone-shaped cavity

ActiveCN106224970AAccelerated settlementLow suctionBlast-producing apparatusIncinerator apparatusCombustion chamberSlag

The invention discloses a mechanical grate type garbage gasifying and incinerating system and a combustion chamber with an inverted-cone-shaped cavity. The cavity of the combustion chamber with the inverted-cone-shaped cavity comprises a combustion channel, a conical channel, a fly ash settling chamber, a conical slag outlet, an annular smoke channel and an annular draught flue, wherein the combustion channel, the conical channel, the fly ash settling chamber and the conical slag outlet are successively arranged from top to bottom; the annular smoke channel and the annular draught flue surround the conical channel; the top of the conical channel is small while the bottom of the conical channel is large; the diameter of the fly ash settling chamber is greater than that of the lower end of the conical channel; the annular smoke channel is conical; the top of the annular smoke channel is small while the bottom of the annular smoke channel is large; the lower end of the annular smoke channel communicates with the fly ash settling chamber; the lower end of the annular draught flue communicates with the upper end of the annular smoke channel; and the top of the conical slag outlet is large while the bottom of the conical slag outlet is small. The combustion chamber with the inverted-cone-shaped cavity has relatively high dust removal efficiency and combustion efficiency and relatively high heat recycling efficiency; controlled combustion and controlled collection can be realized; heat loss is reduced; and emission of pollutants can be reduced effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

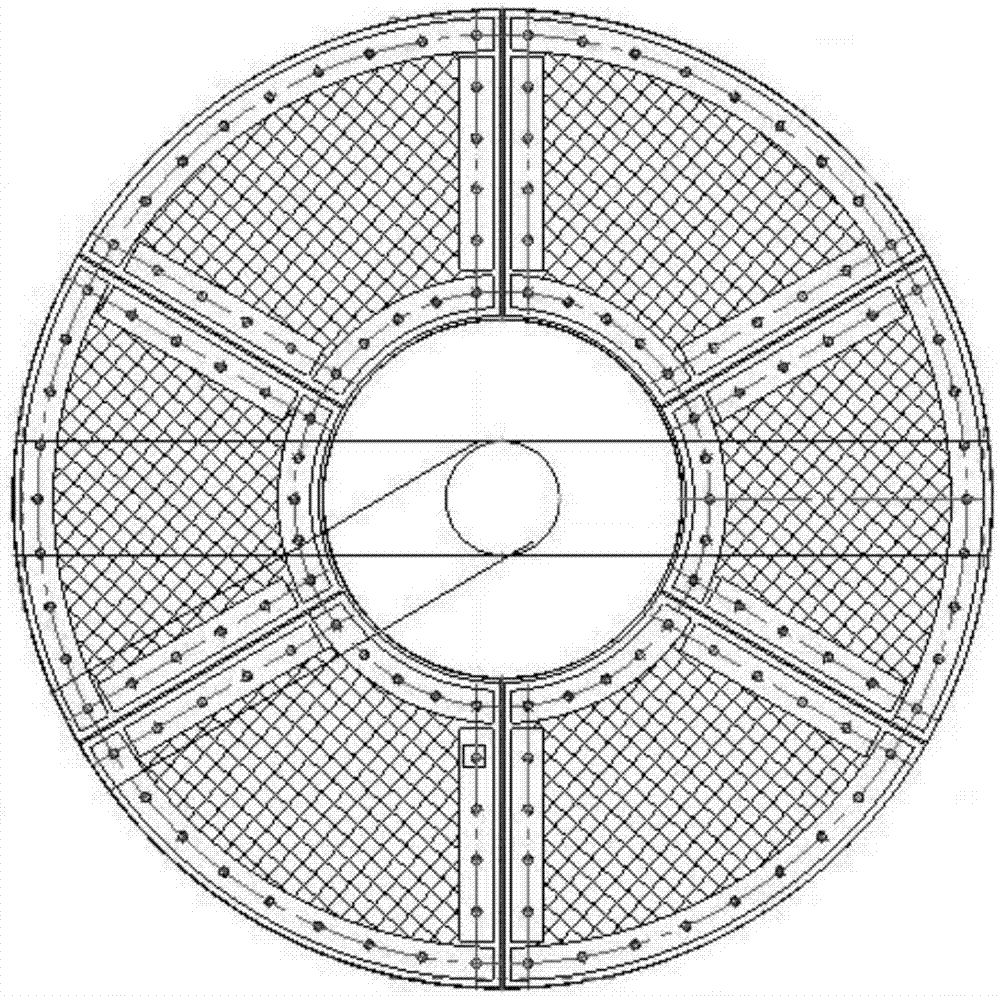

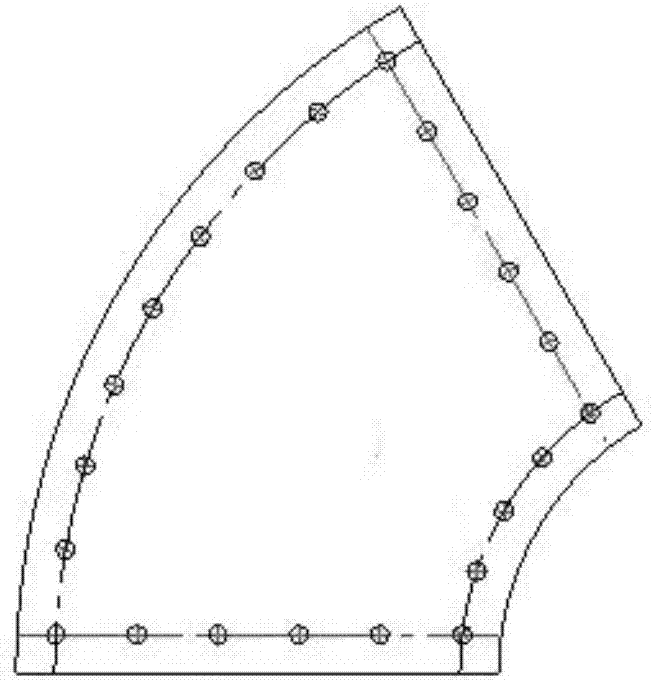

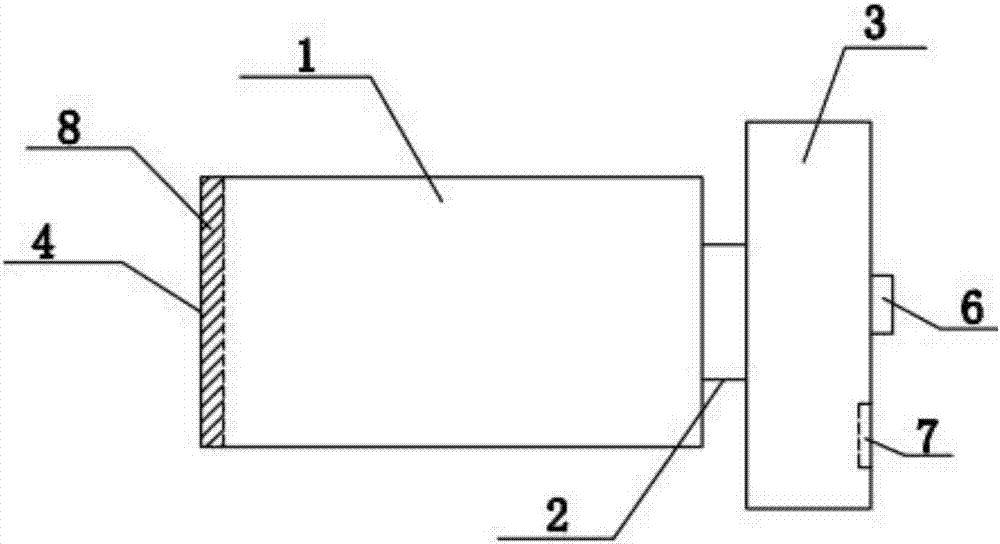

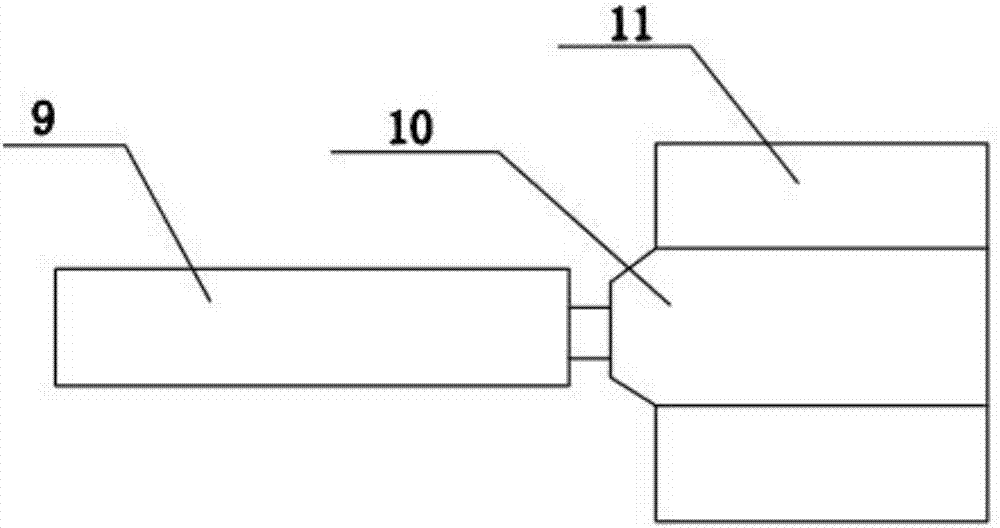

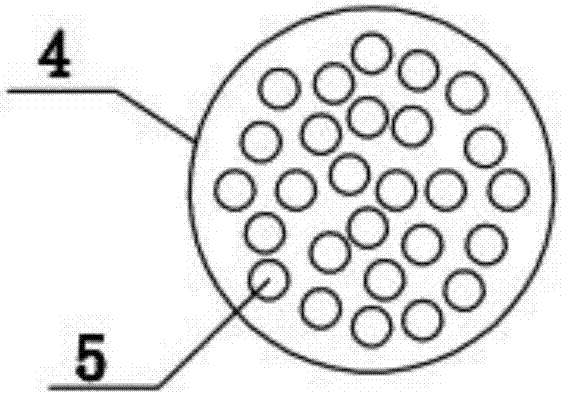

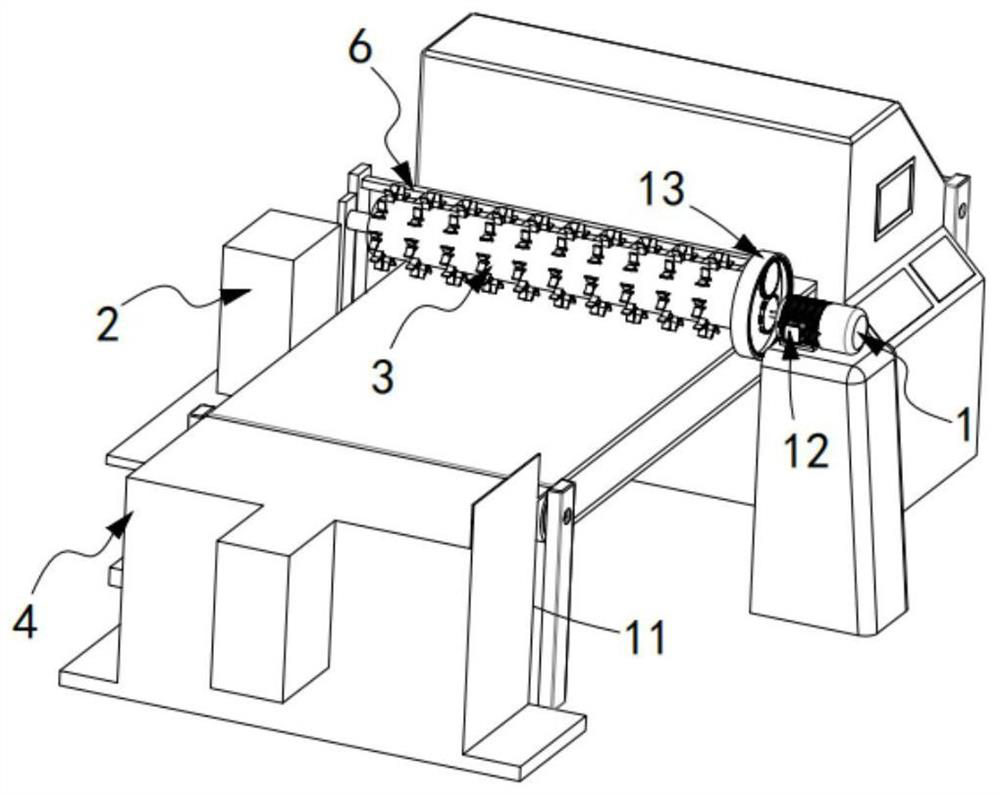

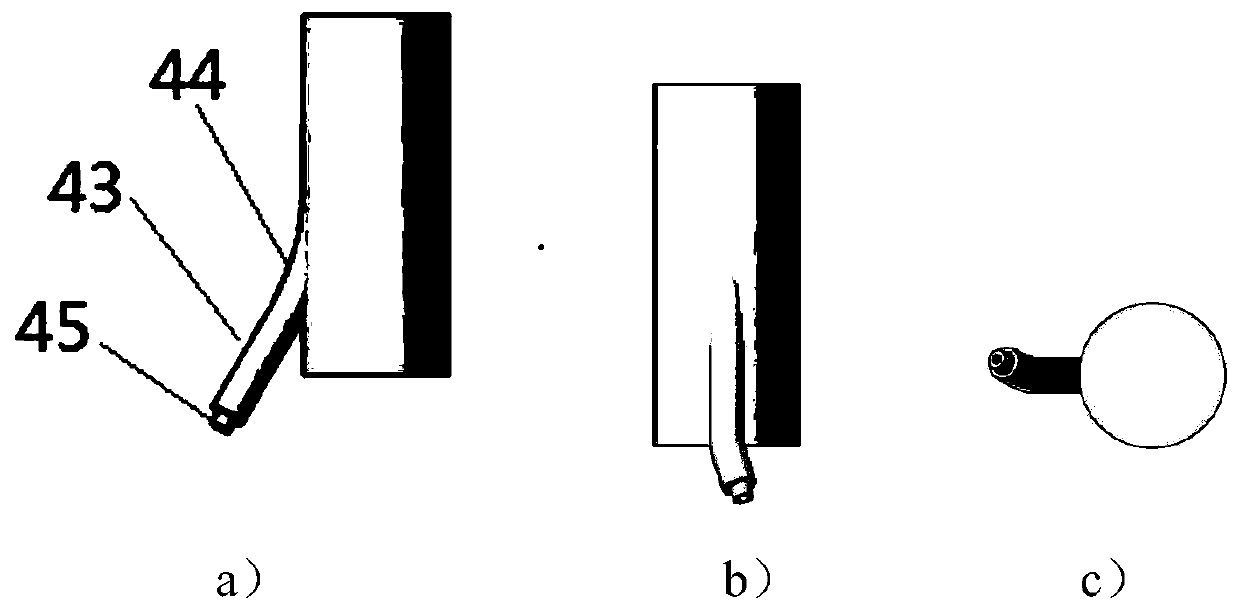

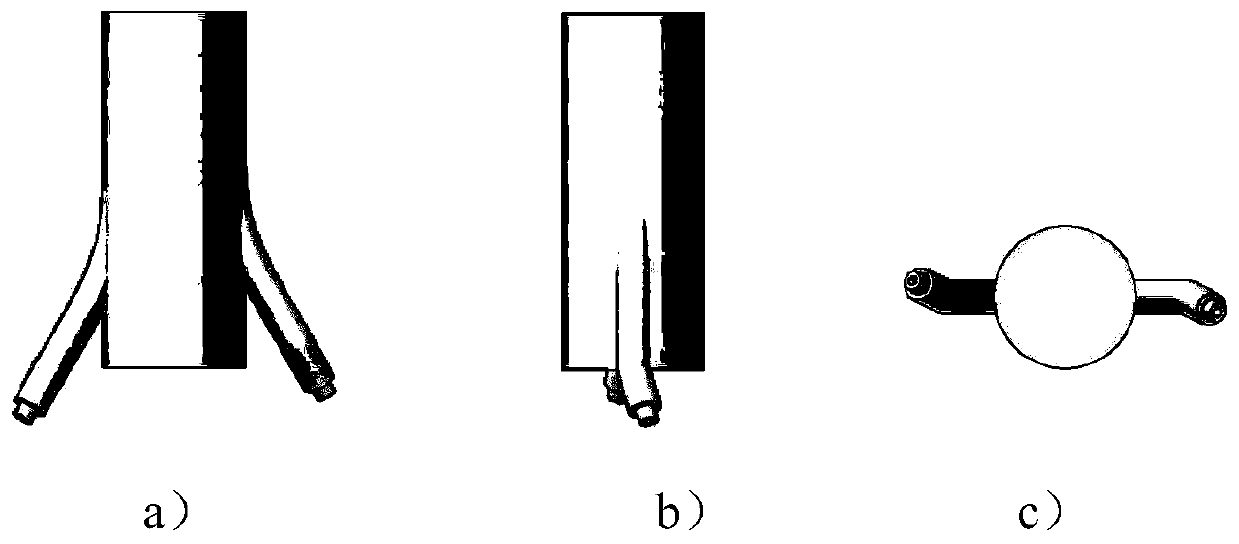

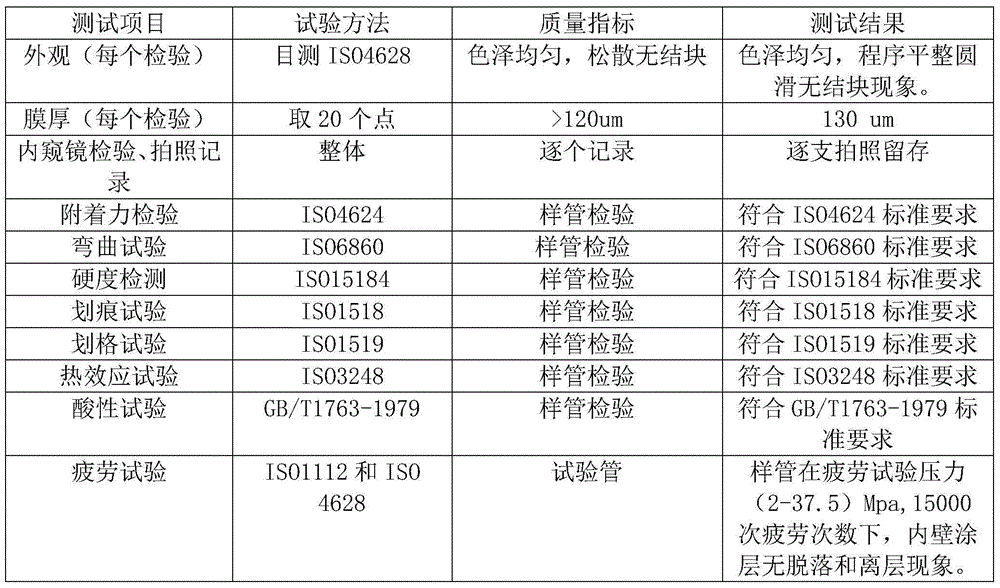

Inner Spraying Device and Technology of Large Volume Steel Seamless Gas Cylinder

ActiveCN104128294BGuaranteed distanceGuarantee the quality of powder sprayingPretreated surfacesCoatingsFurnace temperatureGas cylinder

Owner:ZHONGYOU GENERAL LUXI NATURAL GAS EQUIP

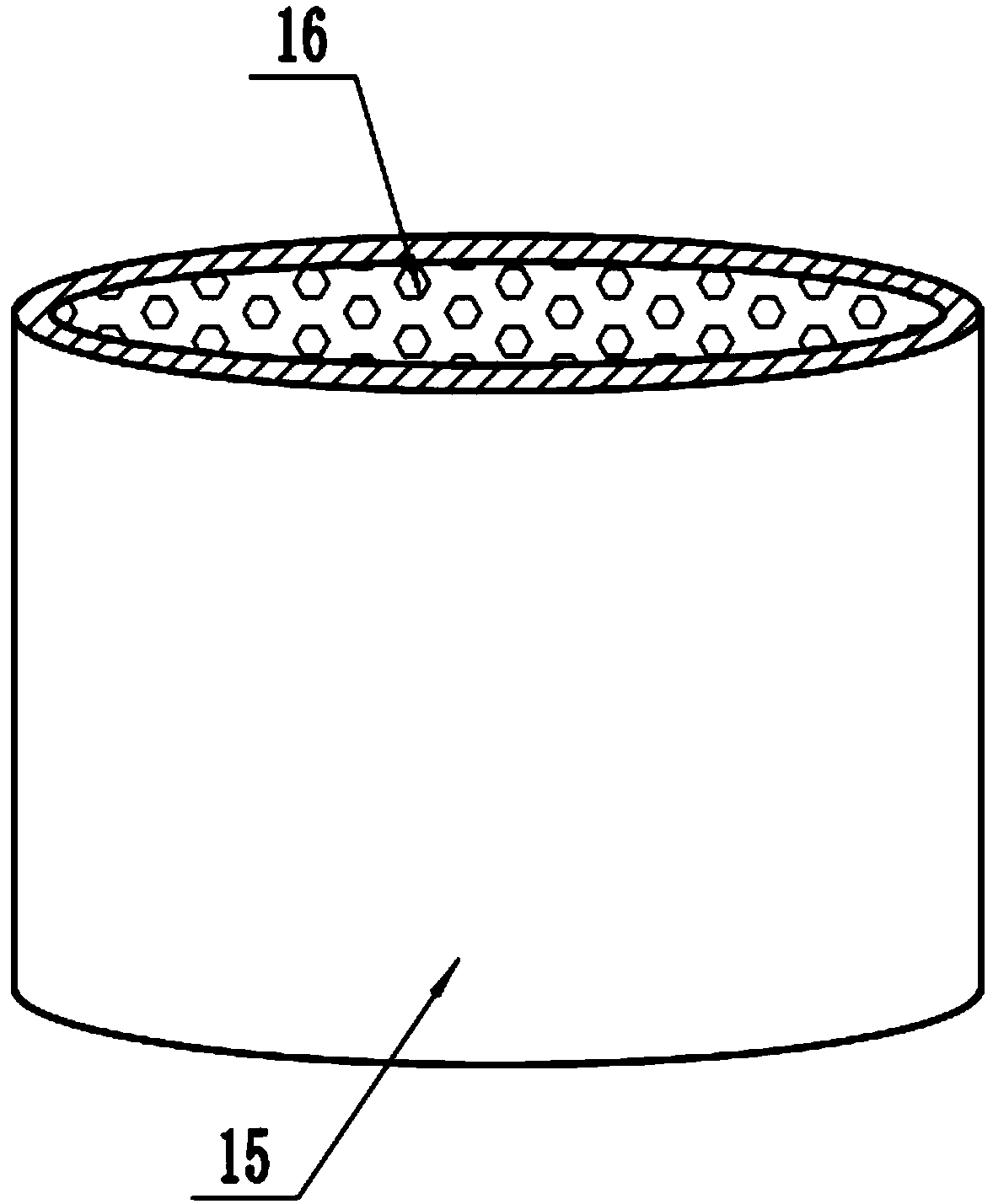

Kettle bell casting environmental protection dust-cleaning device

The invention discloses a kettle bell casting environmental protection dust-cleaning device and belongs to the technical field of the dumbbell casting dust-cleaning. The kettle bell casting environmental protection dust-cleaning device comprises a dust-cleaning box. The middle part of the upper end of the dust-cleaning box is provided with a driving box. The diving box is internally provided witha driving shaft. Driving blades are evenly installed on the outer side of the driving shaft. A plurality of gas ejector pipes are installed on the horizontal position of the driving box and the blades. The left end of the gas ejector pipe is connected with an air intake pipe. The middle of the air intake pipe is provided with a booster pump. The lower end of the driving shaft is connected with a rotary shaft. The rotary shaft is a hollow structure. The lower end of the rotary shaft is connected to the lower end of the dust-cleaning box through a sealing block. The middle of the driving shaft is evenly provided with fixing rods. The linage rods are arranged on the lower ends of the fixing rods evenly. The lower ends of the leakage rods are connected with hooks. The inner side of the dust-cleaning box is evenly provided with gas erection rings. The gas erection rings are connected with diffluent cavities through gas erection pipes. According to the kettle bell casting environmental protection dust-cleaning device, the rotation of the dumbbell casting below the hooks is guaranteed and even dust-cleaning of the dumbbell casting is ensured, meanwhile, dry dust-cleaning of the dumbbell casting is achieved and flushing to clean dust by water is avoided.

Owner:如东天力健身器材有限公司

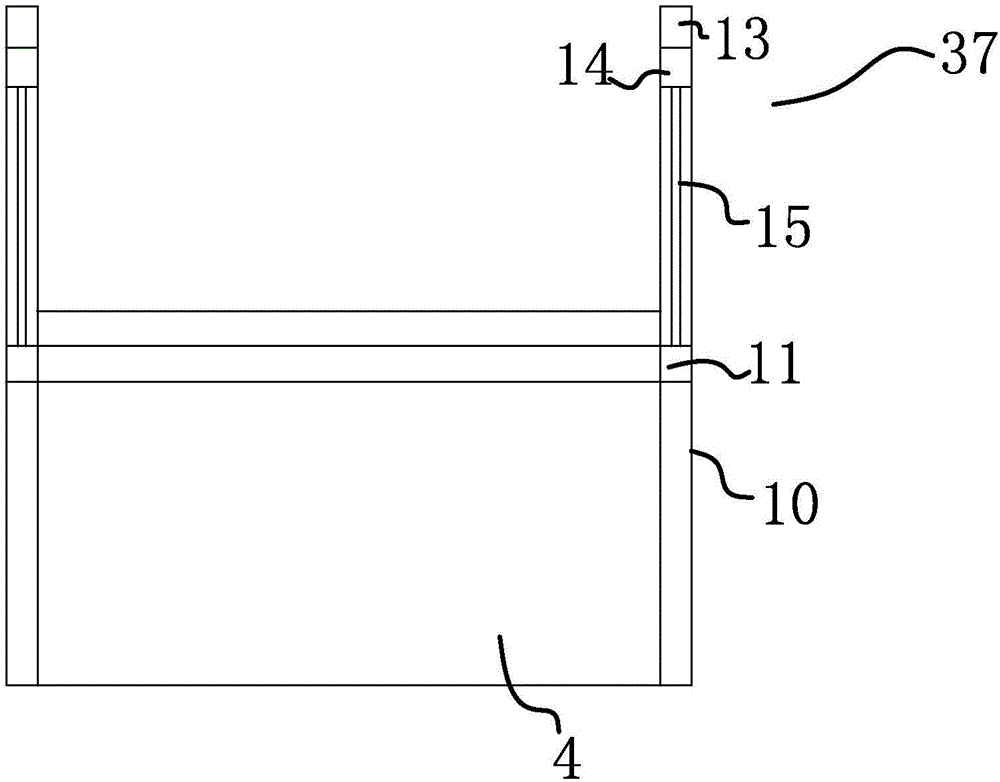

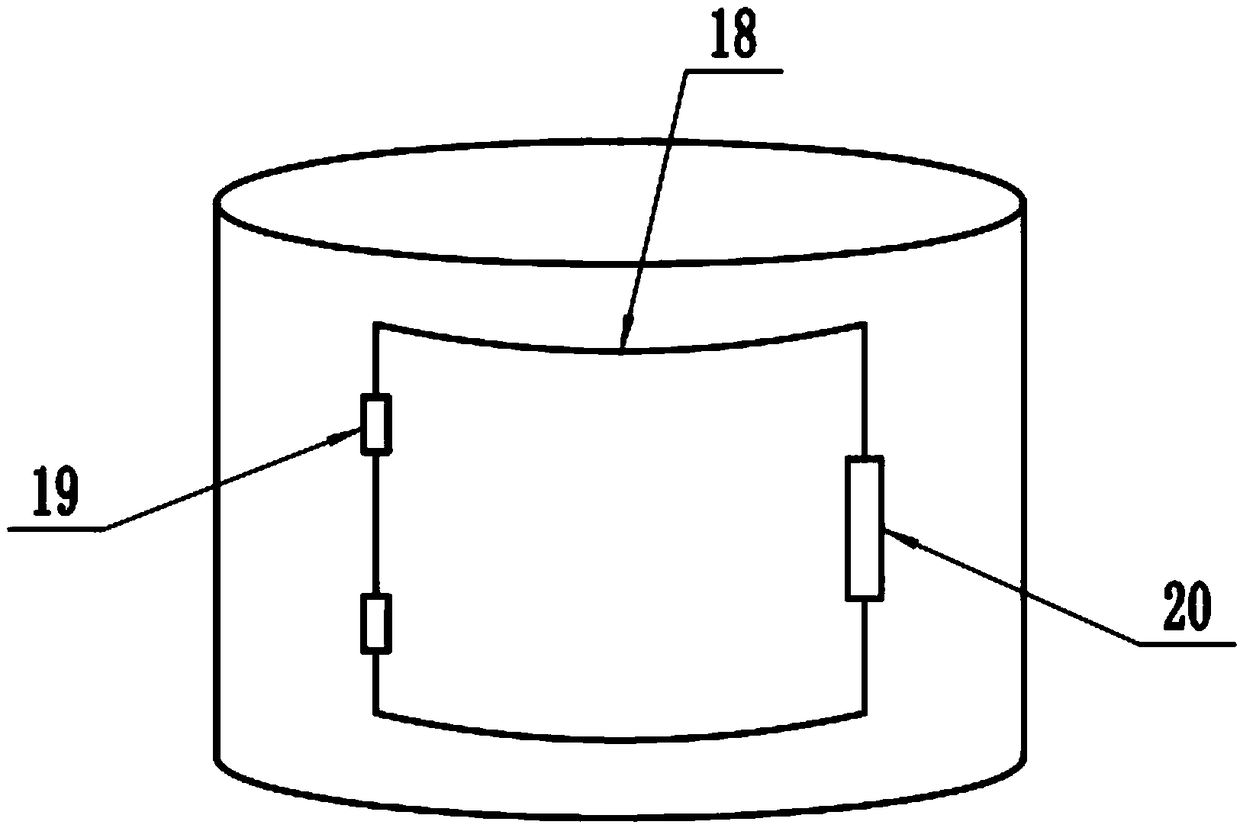

Sling for hanging middle beam of refrigerator

ActiveCN107902530ADust evenlyAvoid deformationLoad-engaging elementsArchitectural engineeringRefrigerated temperature

The invention discloses a sling for hanging a middle beam of a refrigerator. The sling comprises a hanging rod and a U-shaped rod, wherein the U-shaped rod is connected to the upper end of the hangingrod; hanging plates are vertically connected to the two ends of the U-shaped rod; a plurality of hooks in the same number are arranged on the two hanging plates; the bottom end of the hanging rod isfixedly connected with a bottom plate; the hanging rod is vertically fixed to the center of the bottom plate; inverted hooks with springs are arranged on the two sides of the bottom plate; the numbersof the inverted hooks and the hooks are the same; and the inverted hooks and the hooks are arranged on the same vertical line in one-to-one correspondence. When the middle beam of the refrigerator ishung by the sling to be subjected to powder spaying, the hung middle beam of the refrigerator does not shake, and the rework situation is avoided.

Owner:ANHUI JIULI MACHINERY EQUIP

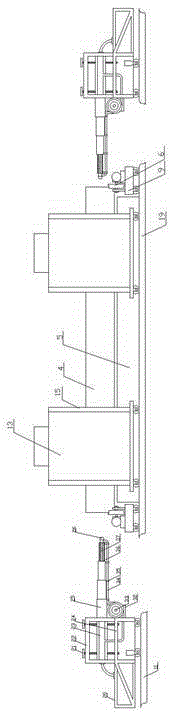

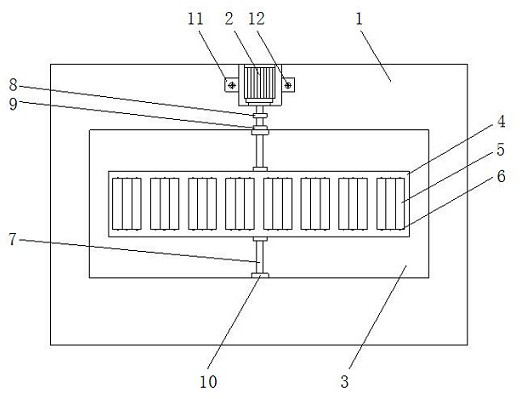

Assembly line for spraying powder to filter and drying filter

ActiveCN110813617AImprove scrubbing efficiencyGuaranteed resetCleaning using toolsCleaning using gasesSpray nozzleAssembly line

The invention discloses an assembly line for spraying powder to a filter and drying the filter. The assembly line for spraying the powder to the filter and drying the filter comprises a rack, a conveying mechanism, the filter, a filter drive mechanism, a spray nozzle, a scrubbing mechanism, a drying mechanism, a powder spraying and drying mechanism and a control unit. The conveying mechanism drives the filter to move, the filter drive mechanism drives the filter to rotate, the spray nozzle sprays a cleaning solution to the surface of the filter, the scrubbing mechanism scrubs the surface of the filter, the scrubbed filter is dried through the drying mechanism so as to be cleaned, and the cleaned filter enters the powder spraying and drying mechanism so as to be sprayed with powder and dried, so that a film is formed on the surface of the filter. The assembly line for spraying the powder to the filter and drying the filter provided by the invention has the advantages that the filter canbe thoroughly cleaned, water is effectively prevented from entering the filter, meanwhile, cleaning, powder spraying and film forming of the filter are ingeniously integrated, powder spraying and film forming are carried out while cleaning, the production efficiency is greatly improved, the powder is sprayed uniformly, and the later-period film forming quality is better.

Owner:SIXIAN TENGMA AUTO PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com