Glass powder spraying device for automobile laminated glass production

A technology of laminated glass and glass, applied in the direction of the spraying device, etc., can solve the problems of uneven powder spraying, difficulty in matching the nozzle position, affecting uniform powder spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

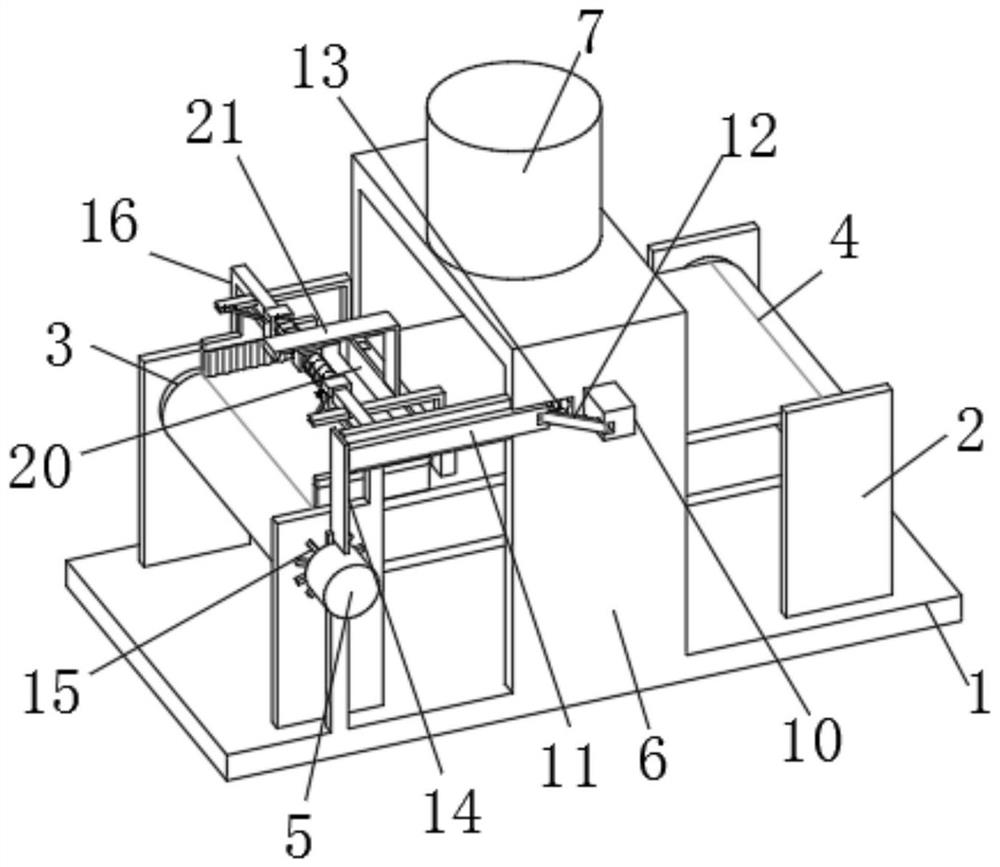

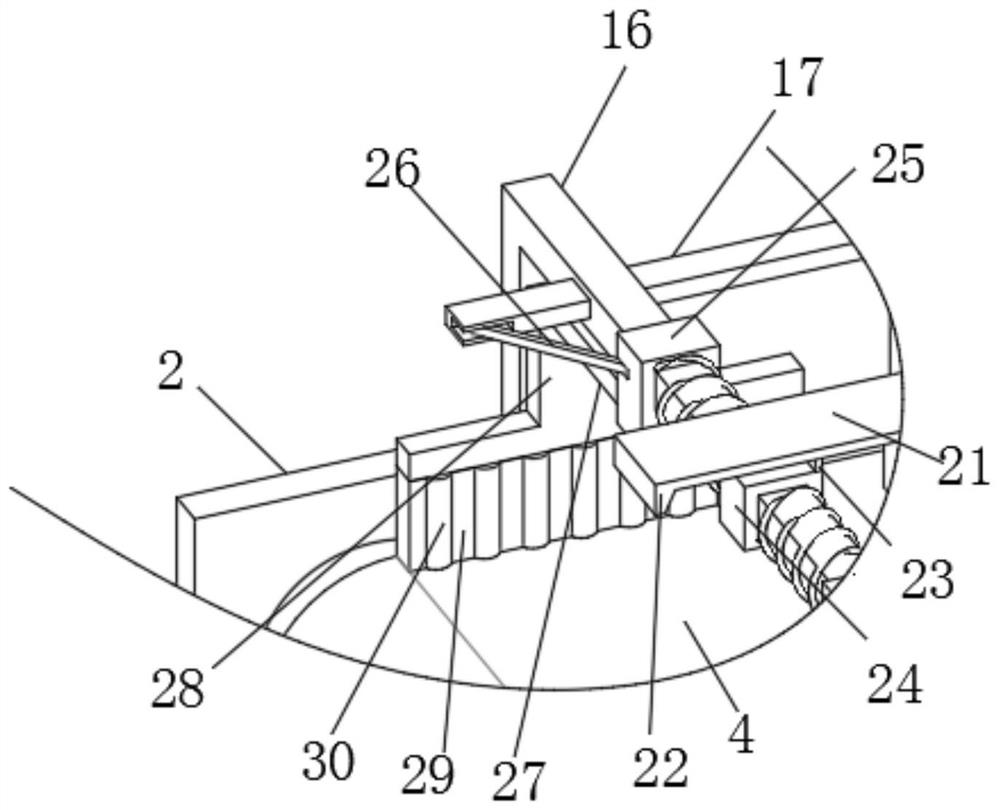

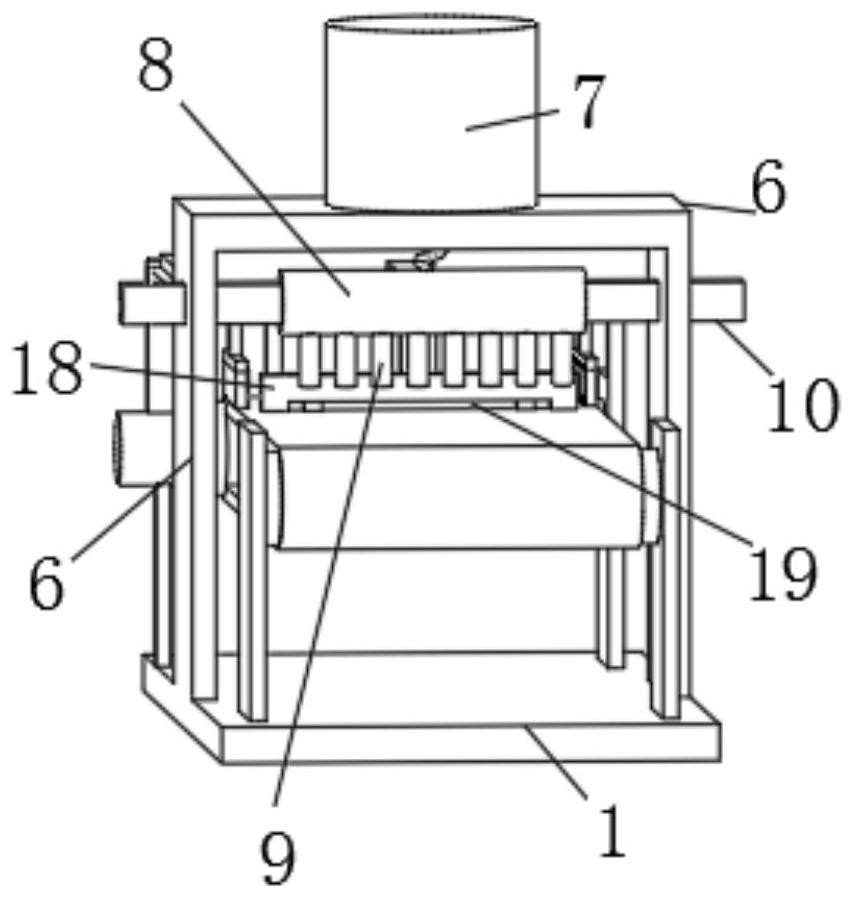

[0028] refer to Figure 1-6 The shown glass powder spraying device for the production of laminated glass for automobiles includes a base 1, four mounting plates 2 are installed on the top of the base 1, and transmission mechanisms are installed on the four mounting plates 2, and the top of the base 1 is installed There is a U-shaped plate 6, and a powder storage tank 7 is installed on the U-shaped plate 6. There are sliding holes on the inner walls of both sides of the U-shaped plate 6, and rectangular sliding columns 10 are slidably installed in the two sliding holes. There are powder pipes 8 installed on the sides of the spools 10 that are close to each other. The powder pipes 8 communicate with the powder storage tank 7 through connecting pipes. The bottom of the powder pipes 8 is equipped with a plurality of uniformly arranged nozzles 9, and one of the rectangular spools 10 passes through The connecting mechanism is connected with the transmission mechanism, wherein U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com