Inner Spraying Device and Technology of Large Volume Steel Seamless Gas Cylinder

A seamless gas cylinder and internal spraying technology, which is applied to the surface coating device, coating, pretreatment surface, etc., can solve the problems of cylinder failure, bulging, cracking, etc., to improve work efficiency and ensure spraying The effect of improving powder quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

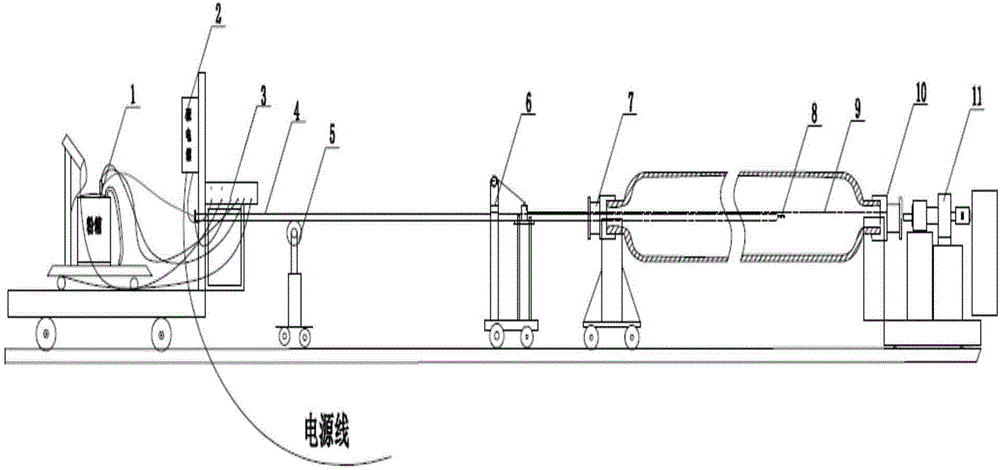

[0032] Such as figure 1 As shown, a large-volume steel seamless gas cylinder internal spraying device includes an operating workbench and a gas cylinder workbench, wherein:

[0033] The operation workbench includes a powder storage box 1, an electrostatic generator 2, a control cabinet 3, a conduit 4, a guiding device 5, a tensioning device 6 and a powder spray gun 8, and the powder storage box 1 and the electrostatic generator 2 are respectively connected with the control cabinet 3 electrical connection; the tip end of the powder spray gun 8 extends into the inner cavity of the gas cylinder, and the other end of the powder spray gun 8 is connected to the powder storage box 1 through the conduit 4; the conduit 4 is close to the control cabinet 3 ends A guiding device 5 is provided to control the smooth operation of the conduit, and a tensioning device 6 is provided near the gas cylinder end of the conduit 4 to prevent the powder spray gun from sagging;

[0034] The gas cylind...

Embodiment 2

[0046] The device of interior spraying is with embodiment 1, adopts the spraying process of this spraying device, comprises the following steps:

[0047] (1) Inner wall cleaning: Before the inner spraying treatment, the inner wall of the gas cylinder adopts low-pressure air (0.7) M for inner wall shot blasting equipment p a Drive the chrome-molybdenum steel shot to clean the inner wall for 30 minutes, then wash the inner wall with water for 3 times, degrease and dry with high-temperature steam;

[0048] (2) Inspection: Use standard test pieces to compare and check whether the inner wall reaches SA2.5, and then use ultraviolet light to check whether the inside of the steel cylinder meets the SA2.5 standard. After the inner wall inspection is qualified, send it to the inner spraying room to start inner spraying;

[0049] (3) Internal spraying: Fix the gas cylinder on the gas cylinder workbench through the front-end fixing device and the rear-end fixing device, turn on the electr...

Embodiment 3

[0053] The device of interior spraying is with embodiment 1, adopts the spraying process of this spraying device, comprises the following steps:

[0054] (1) Inner wall cleaning: Before the inner spraying treatment, the inner wall of the gas cylinder is cleaned with low-pressure air (0.7) Mpa to drive the chrome-molybdenum steel shots for 30 minutes, and then the inner wall is cleaned with water for 3 times, and then degreased and dried with high-temperature steam;

[0055] (2) Inspection: Use standard test pieces to compare and check whether the inner wall reaches SA2.5, and then use ultraviolet light to check whether the inside of the steel cylinder meets the SA2.5 standard. After the inner wall inspection is qualified, send it to the inner spraying room to start inner spraying;

[0056] (3) Internal spraying: Fix the gas cylinder on the gas cylinder workbench through the front-end fixing device and the rear-end fixing device, turn on the electrostatic generator, and set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com