Patents

Literature

47results about How to "Impact molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural biological matrix filter rod particles and preparation method and application thereof

ActiveCN110810918AImprove adsorption capacityGood removal effectTobacco smoke filtersGranulation by liquid drop formationBiotechnologyCellulose

The invention provides natural biological matrix filter rod particles and a preparation method and application thereof, and belongs to the technical field of tobacco processing. The natural biologicalmatrix filter rod particles comprise the following components in parts by mass: main components including 5-15 parts of a smoke sweetener, 4-10 parts of a smoke moistening agent, 2-5 parts of an antioxidant bacteriostatic agent, 0-3 parts of a particle film-forming agent, 1-3 parts of a smoke adsorbent and 0-3 parts of a particle structure enhancer, and auxiliary components including 0.005-0.01 parts of stevioside, 0.02-0.05 parts of sodium carboxymethyl cellulose, 0.005-0.02 parts of ethyl cellulose, 0-0.005 parts of polyethylene glycol and 0.005 parts of a combined food grade pigment. A particle formula is subjected to performance coordination and comprehensive optimization, and factors such as smoke release, adsorption and aroma enhancement release are considered, so that on the premise of ensuring the sufficient adsorption performance of the particles and reducing generation of harmful substances, the filter rod particles which have the proper mouth feel, smoke humidity, smoke temperature and aroma and facilitate production and processing are provided.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

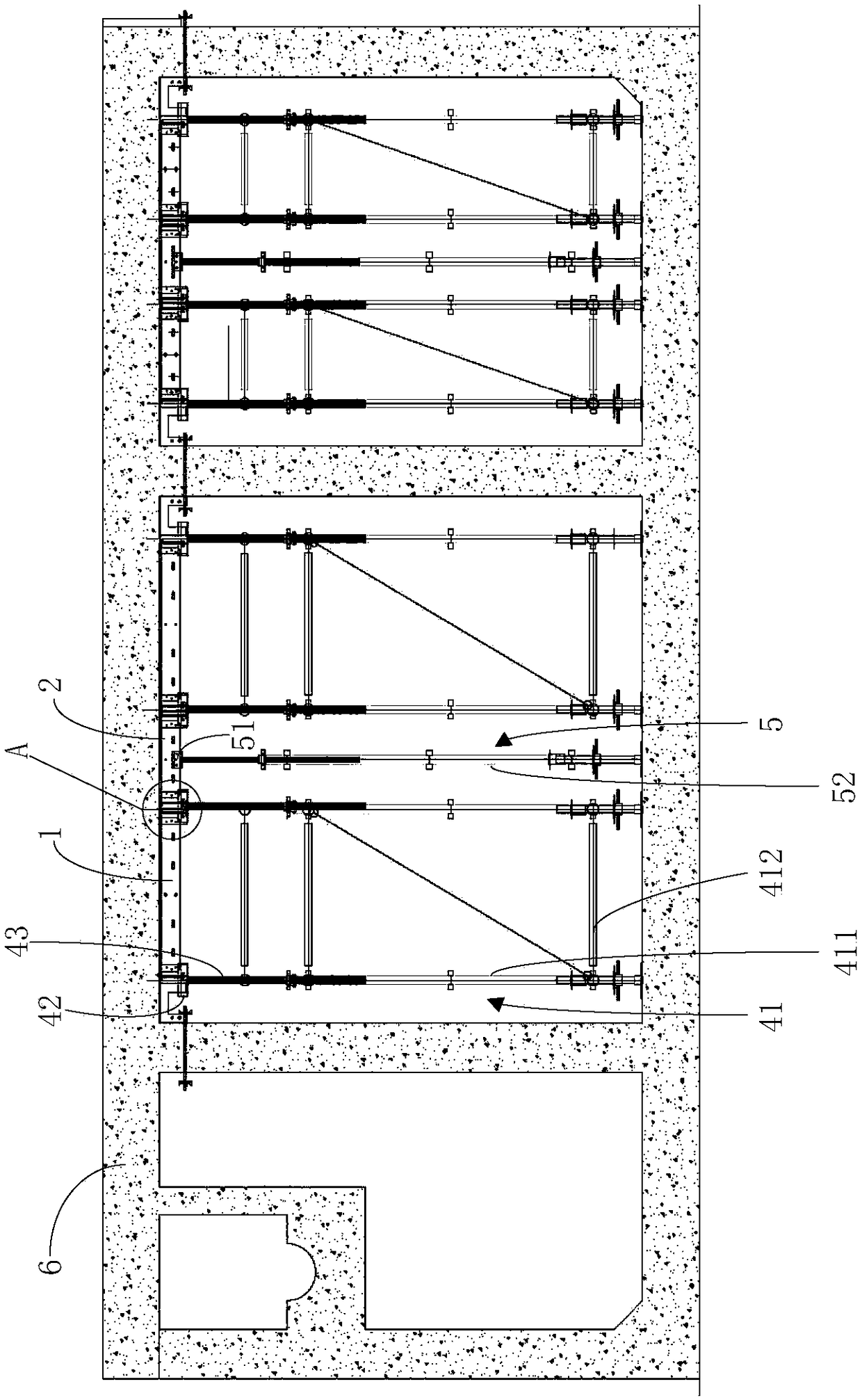

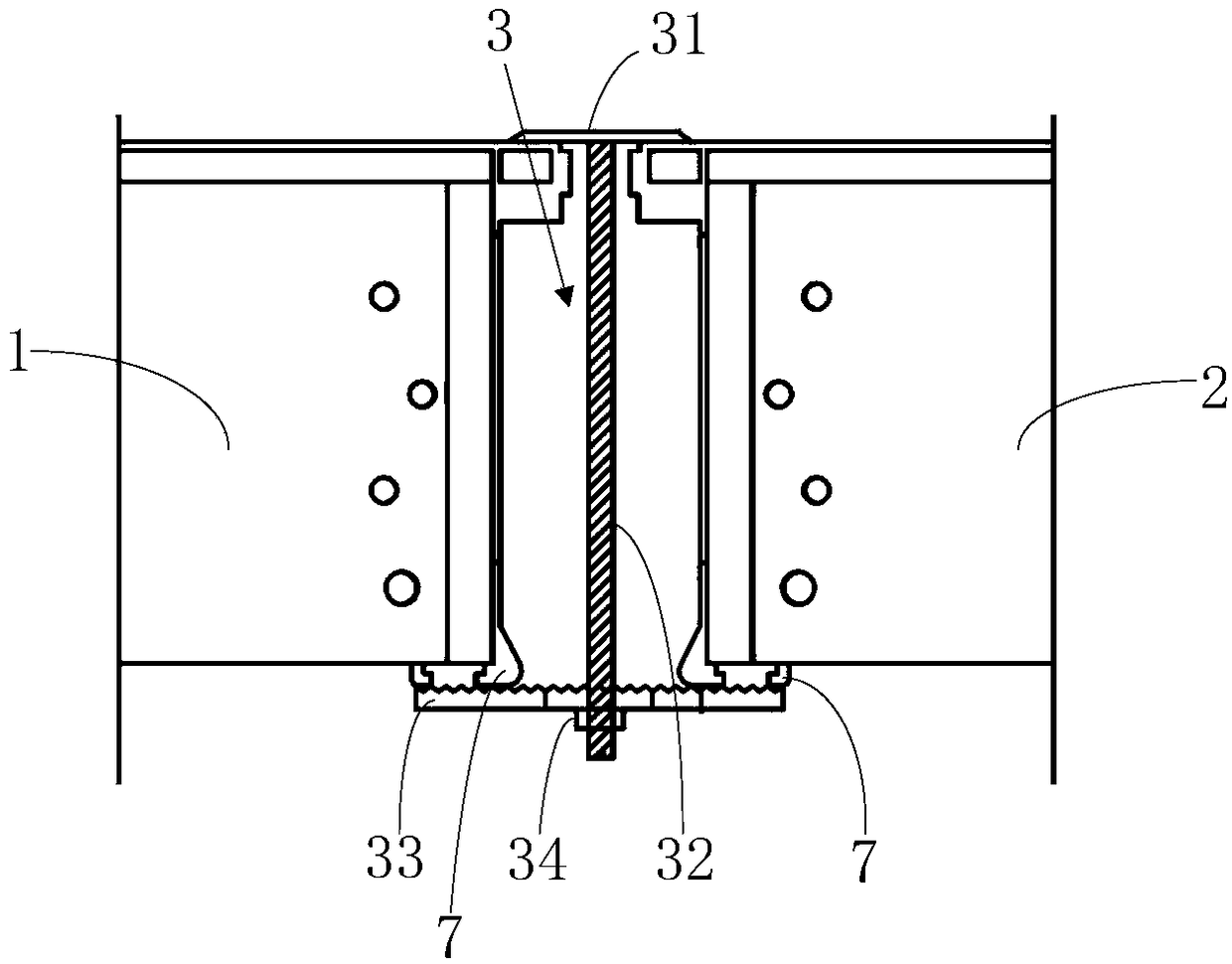

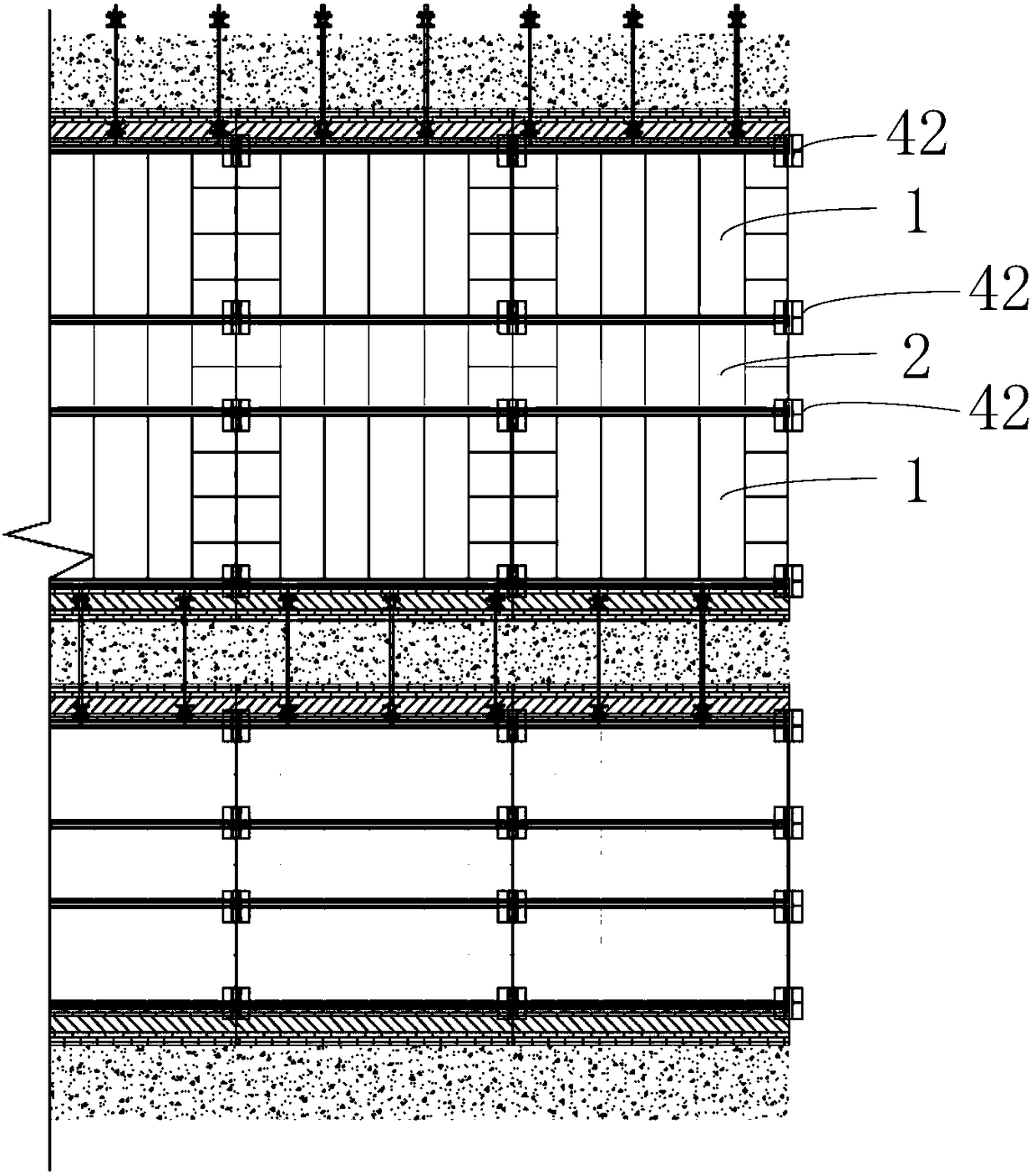

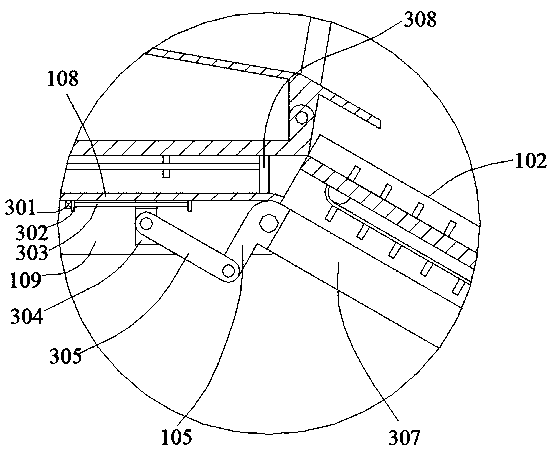

Bench formwork system used for pipe gallery roof and early dismounting method of early-dismounting formwork

PendingCN108589772AEnsure integrityGuaranteed aestheticsArtificial islandsUnderwater structuresButt jointLap joint

The invention provides a bench formwork system used for a pipe gallery roof and an early dismounting method of an early-dismounting formwork. The system comprises the early-dismounting formwork and alater-dismounting formwork which are in butt joint through a seam splicing device; a butt joint space is formed between the butt joint positions of the early-dismounting formwork and the later-dismounting formwork; reinforcement strips are formed at the lower portions of the butt joint positions of the early-dismounting formwork and the later-dismounting formwork; the seam splicing device comprises a seam splicing connection board arranged in the length direction of the butt joint space, at least one suspender arranged in the butt joint space in a penetrating mode, and limiting parts detachably installed at the bottom ends of the suspenders and abutting against the reinforcement strips; the two sides of the seam splicing connection board are in lap joint with the upper surfaces of the early-dismounting formwork and the later-dismounting formwork; the top ends of the suspenders are connected to the seam splicing connection board; first lines are formed on one side of each limiting partand arranged in the length direction of the butt joint space; and second lines matched with the first lines are formed on one side of each reinforcement strip. The bench formwork system used for the pipe gallery roof and the early dismounting method of the early-dismounting formwork solve the problems that formworks are difficult to dismount and roofs are prone to being damaged when the formworksare dismounted by a traditional formwork early dismounting process.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

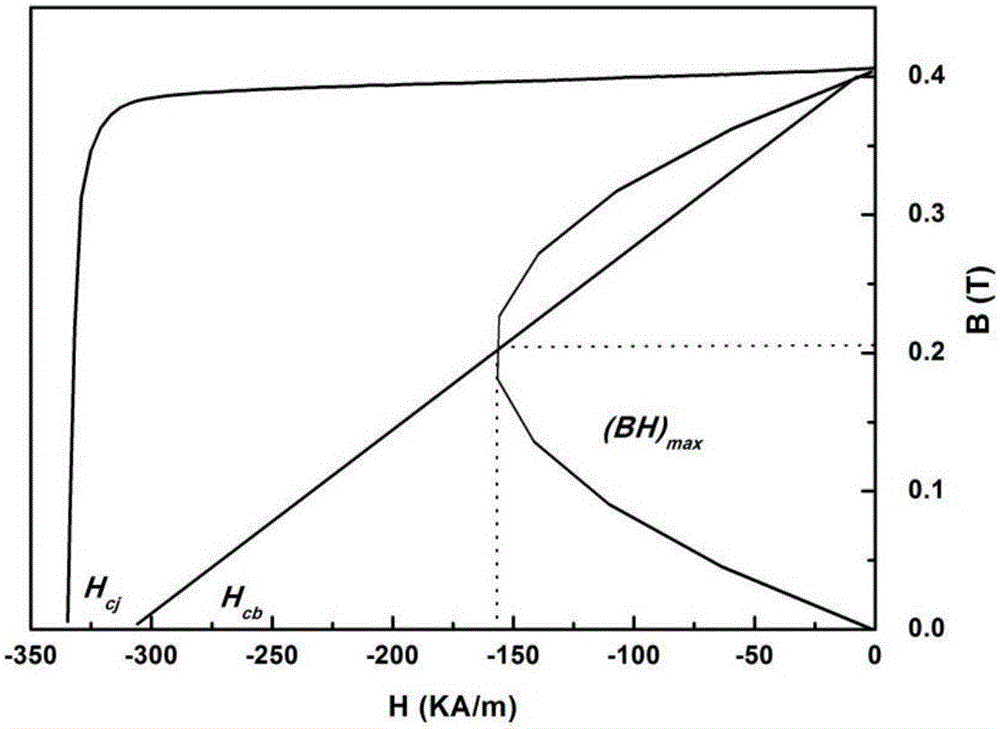

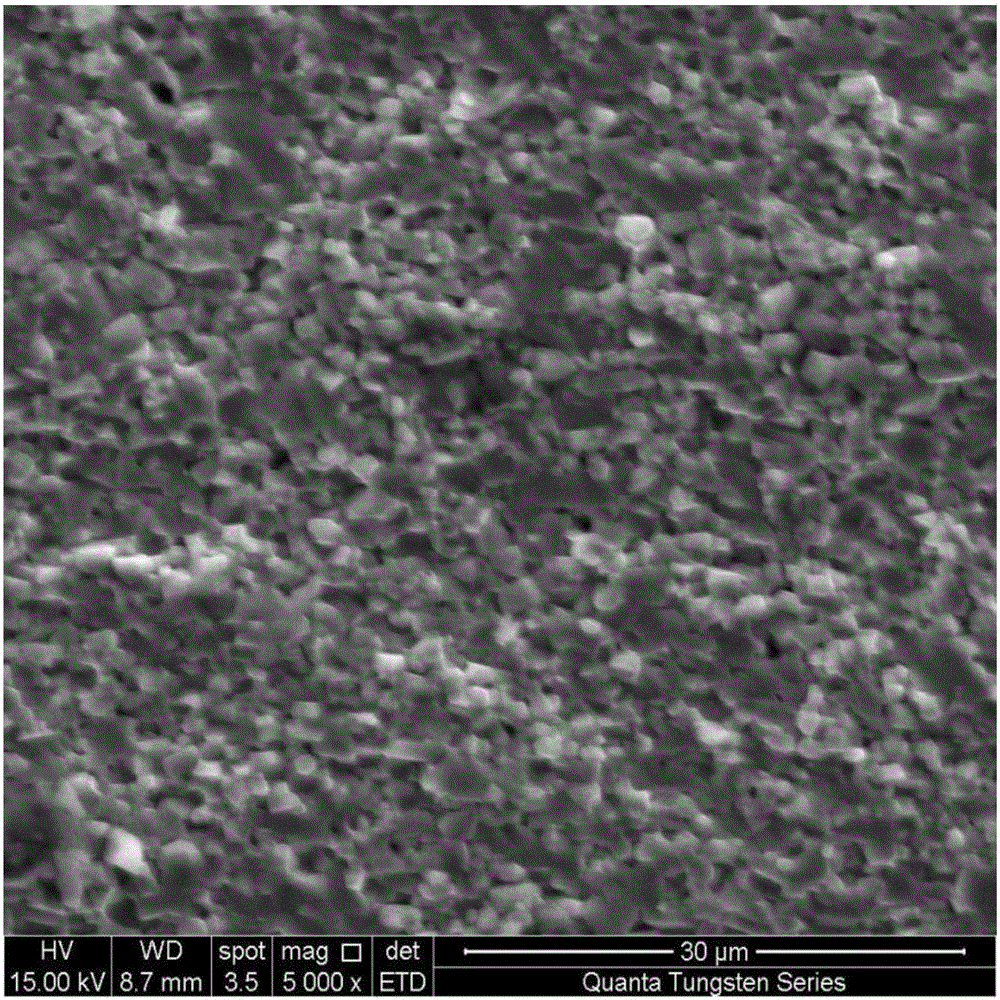

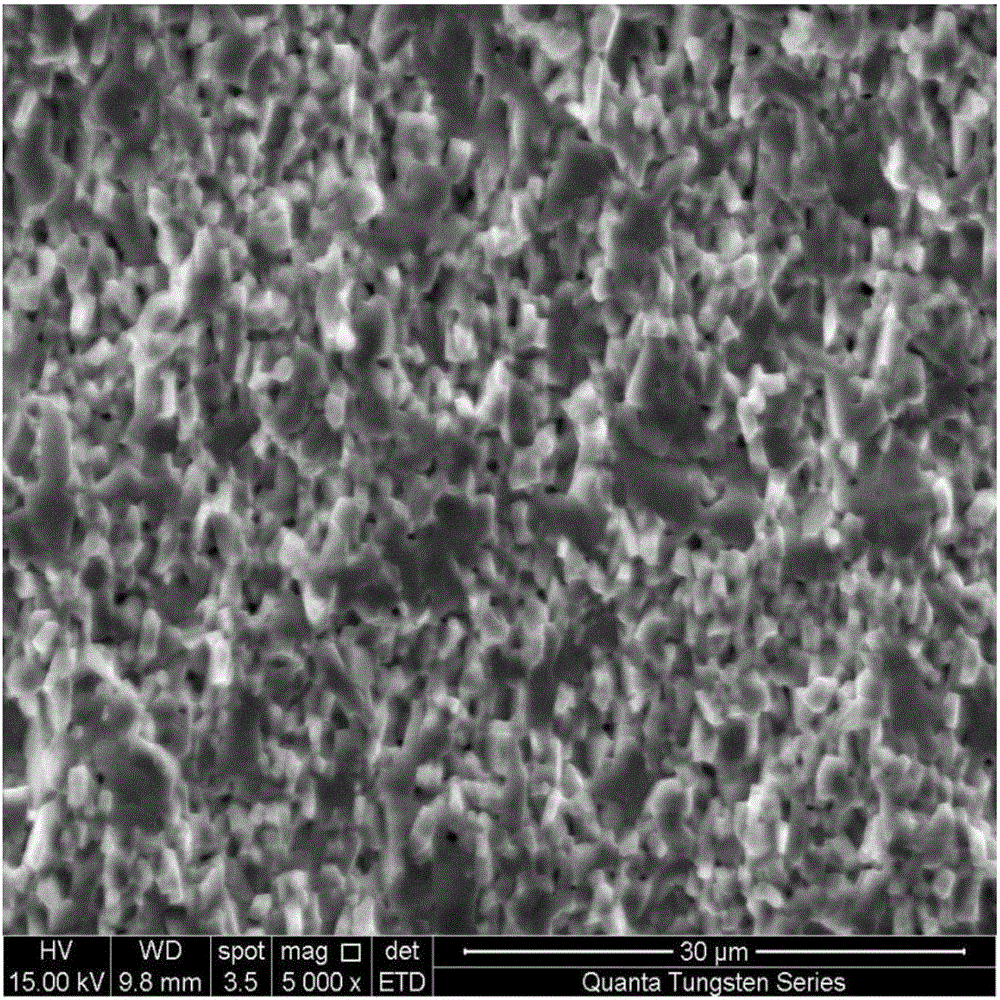

Two-time compounding addition method for improving coercivity of permanent magnetic strontium ferrite

InactiveCN106145917AKeep remanenceImprove performanceInorganic material magnetismRemanenceRare earth

The invention discloses a two-time compounding addition method low in price. The intrinsic coercivity of a material can be improved on the premise of not reducing residual magnetism. The method specifically includes the steps of firstly, preparing materials, wherein on the basis of a strontium ferrite pre-sintering material, two-time compounding addition is conducted; secondly, conducting ball-milling, wherein a dispersing agent is added during ball-milling, and the dispersing agent includes one or more of C6H14O6, HCOOH, Ca(C6H11O7)2 and C6H7NaO6; thirdly, conducting dehydrating; fourthly, conducting forming; fifthly, conducting sintering; sixthly, conducting grinding and performance testing. The additives related in two-time compounding addition are low in price, rare earth or noble metallic oxide high in price is not added, and on the premise of ensuring that the residual magnetism of the material is not changed, the intrinsic coercivity can be improved by about 136-144 kA / m and reaches 336-344 kA / m.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

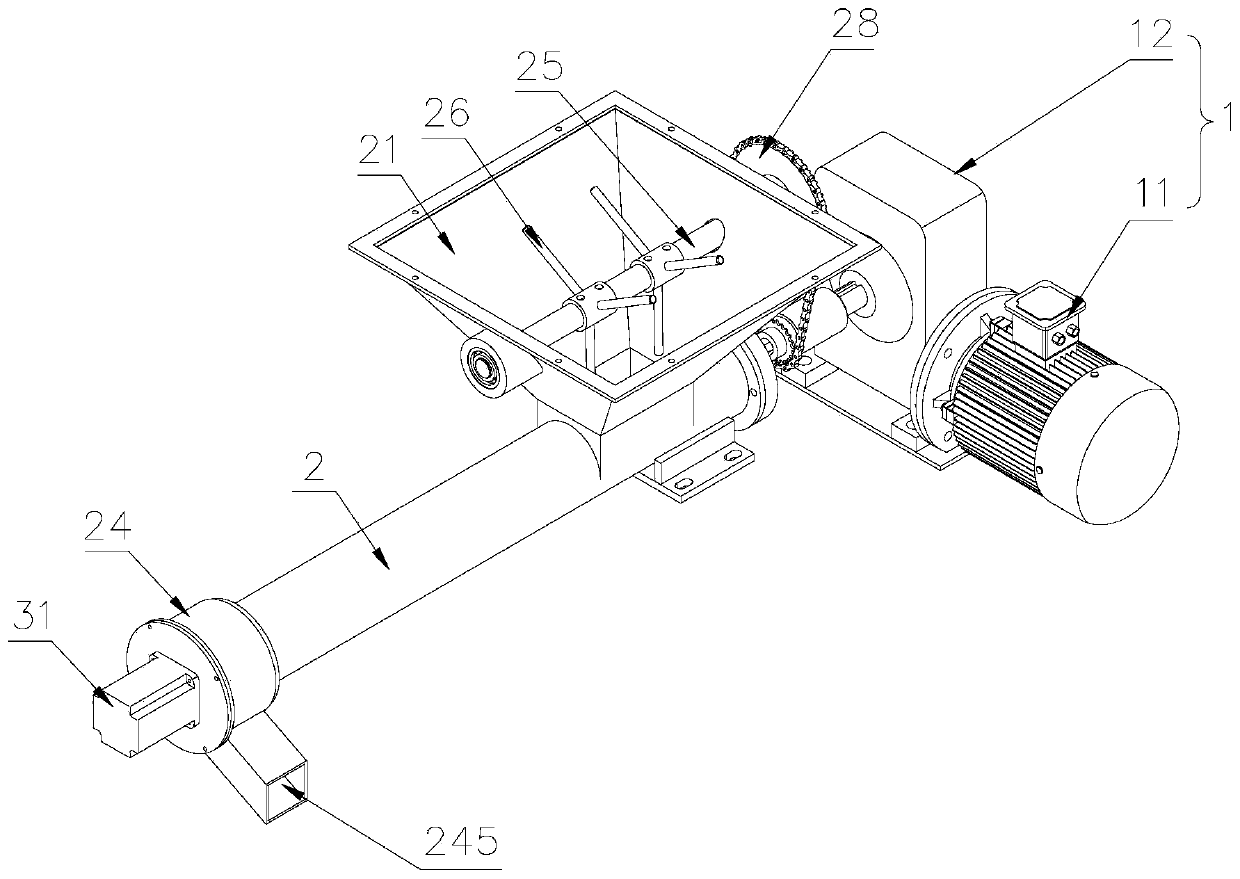

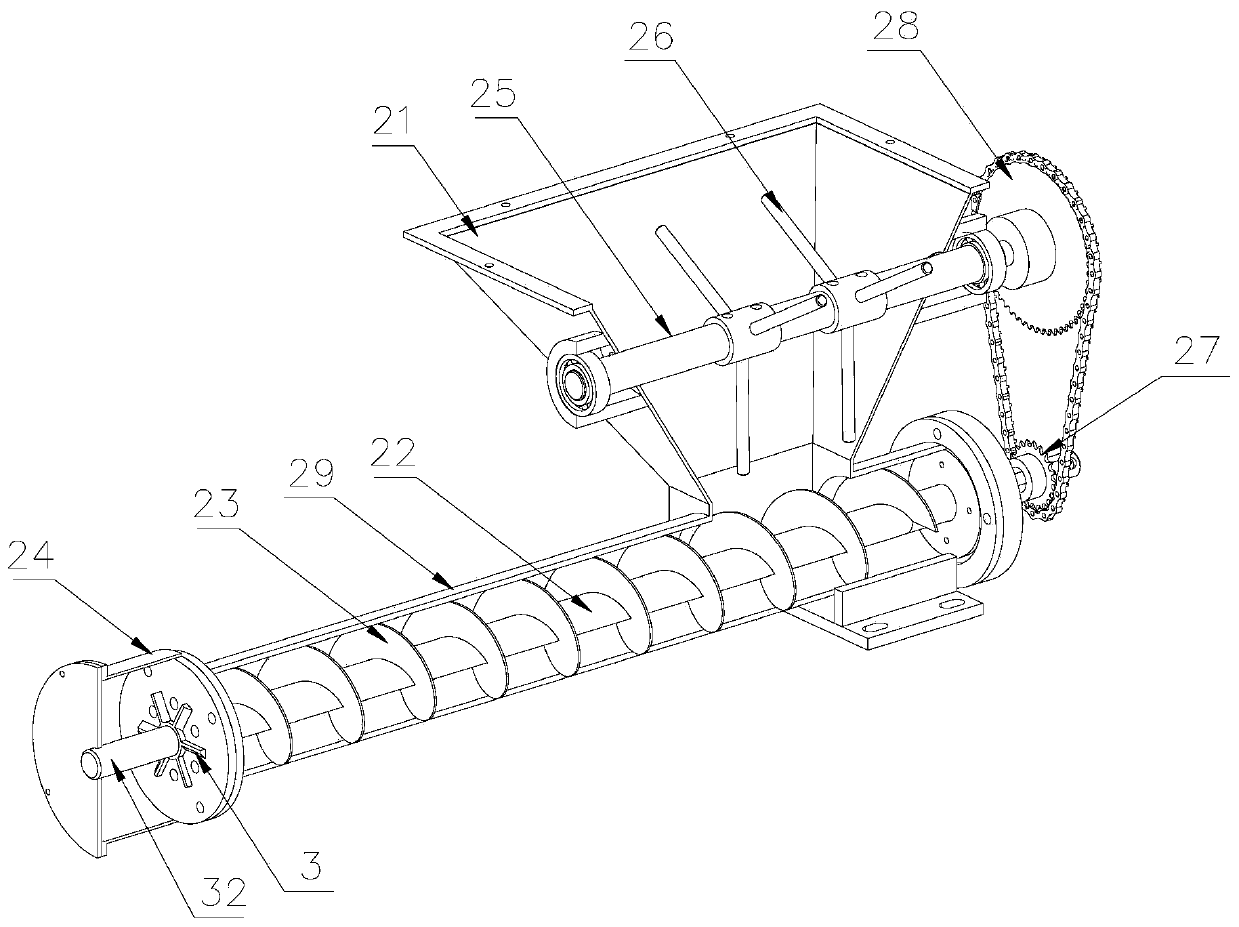

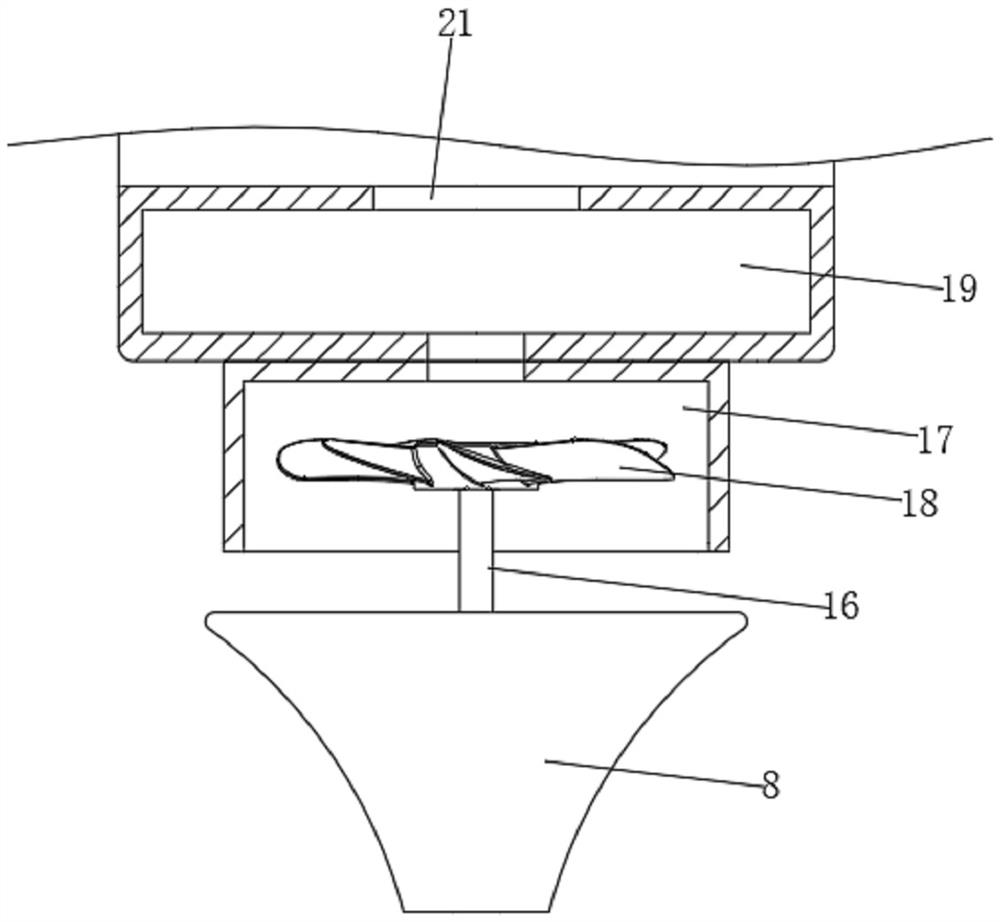

Oval ceramic particle granulator and preparation method

InactiveCN111482129AImpact resistantImprove impact resistanceGranulation by material expressionSpiral bladeElectric machinery

The invention discloses an oval ceramic particle granulator and a preparation method. A driving mechanism comprises a driving motor and a speed reducer connected to one side of the driving motor, andan extrusion mechanism comprises a conveying cylinder, a feeding hopper arranged on the upper portion of the conveying cylinder, a first rotating shaft arranged in the conveying cylinder and a spiralblade arranged outside the first rotating shaft. One end of the conveying cylinder is connected with an extrusion head, an extrusion plate is arranged in the extrusion head and provided with a plurality of extrusion holes, and a cutting mechanism is arranged at one end of the conveying cylinder. The preparation method of the oval ceramic particles comprises the following steps: 1) burdening, 2) wet ball milling, 3) mud filtering, 4) aging, 5) granulation, 6) sintering, 7) cooling, and 8) grading and grading. The oval ceramic particles prepared by the method have smooth surfaces of molten ceramic particles and also have the characteristics of pressure resistance, impact resistance and long service life of sintered ceramic particles, and the process applicability of the ceramic particles under different working conditions is obviously improved.

Owner:赵华星

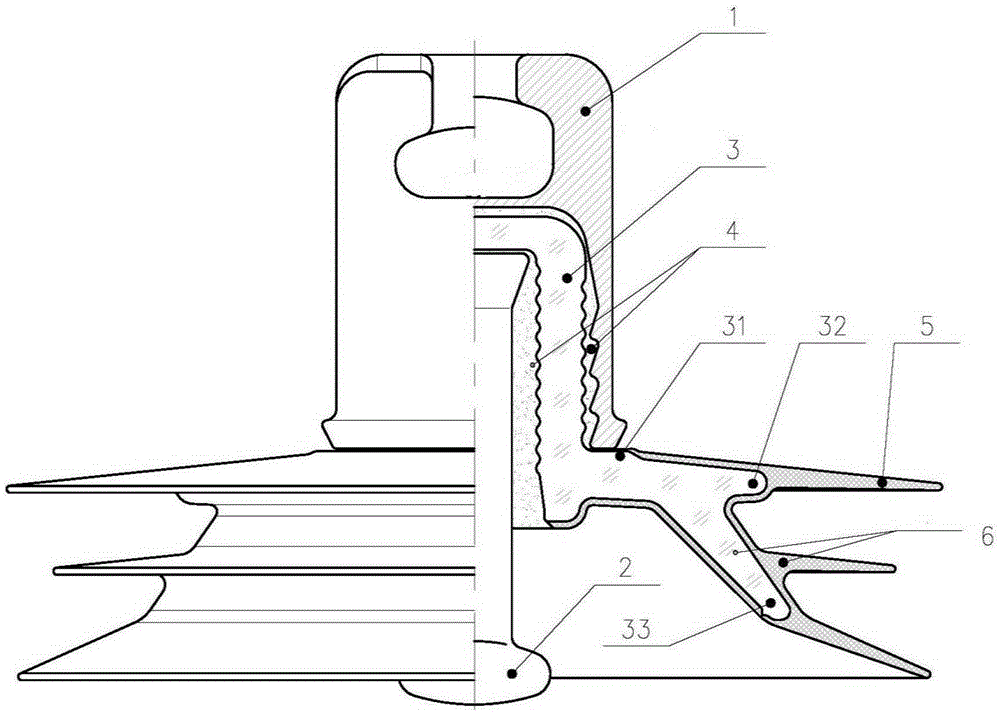

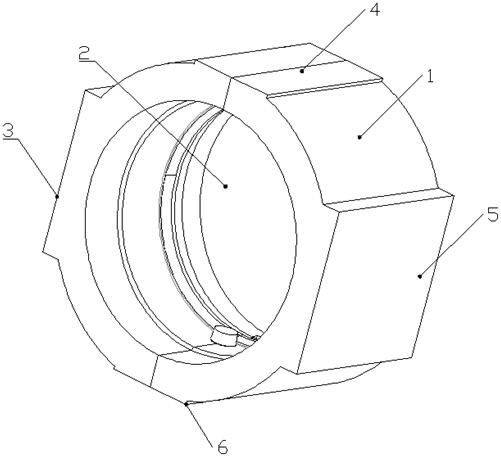

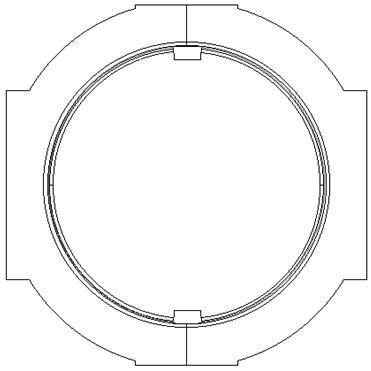

Glass composite insulator and manufacturing method therefor

ActiveCN105355340AStrong antifoulingBalance stressSuspension/strain insulatorsSupporting insulatorsRubber materialGlass composites

A manufacturing method for a glass composite insulator is disclosed. The manufacturing method comprises the following steps: a skeleton umbrella edge structured glass part is moulded; a silicone rubber umbrella cover is covered and wrapped with the glass part; an assembling mold integral injection mode is adopted; due to the use of the assembling mold, the silicone rubber umbrella cover (with multiple umbrella skirts) is integrally molded, so that the molded silicone rubber umbrella cover is attractive in appearance, high in efficiency, and less in interfaces, the electrical performance of the product is improved; a multi-point symmetrical type adjustable glue injection technology is adopted to be matched with a mold cavity pressure control scheme in the molding process in order to balance the stress conditions of each point on the glass part to prevent the glass part from being crushed; the mold cavity is integrally subjected to vacuumizing processing to reduce the generation of rubber material bubbles; iron caps and steel caps are cemented with insulating parts through cement adhesive, so that the influence on the cement adhesive performance caused by the high temperature of the molds is avoided, and the mechanical property dispersion of the product is greatly reduced; the cement adhesive is not covered with the silicone rubber, so that the product completely follows the zero self-destruction characteristic of the glass insulator; and the influence on the umbrella cover molding caused by the central straightness of caps generated by cement adhesive fittings is avoided.

Owner:南京电气绝缘子有限公司

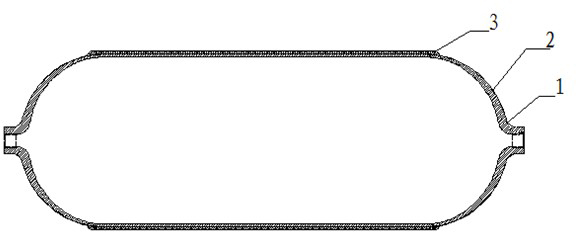

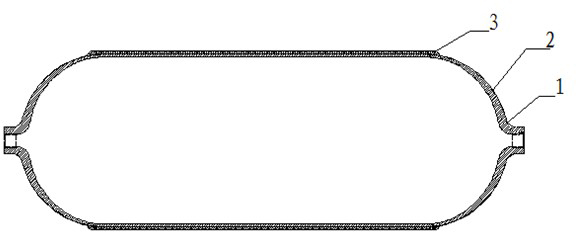

High-pressure gas cylinder for gas transportation vehicle

InactiveCN102434776AImprove fatigue performanceImprove impact resistancePressure vesselsEpoxyGlass fiber

The invention provides a high-pressure gas cylinder for a gas transportation vehicle. The high-pressure gas cylinder comprises a barrel body section which is positioned in the middle, two cylinder openings which are positioned at two ends respectively, and end sockets which are connected with the barrel body section and the cylinder openings, wherein the wall of the high-pressure gas cylinder sequentially comprises an inner container which is made of steel, a combined coating layer which is made of a polyurethane material, a composite material layer which is made of a glass fiber-epoxy composite material, and an outer protection film from inside to outside. The high-pressure gas cylinder has the advantages that: by adopting the steel inner container and the composite material layer with a glass fiber-epoxy system, the fatigue property and the impact resistance are high, and a special requirement of the high-pressure gas cylinder for the gas transportation vehicle can be met; and the outer protection film is wrapped outside the composite material layer, so that a phenomenon that the wet air in the air and corrosive substances corrode the outer surface of the compound material layer, and thus the property of the gas cylinder is influenced can be avoided.

Owner:SINOMA SCI & TECHSUZHOU

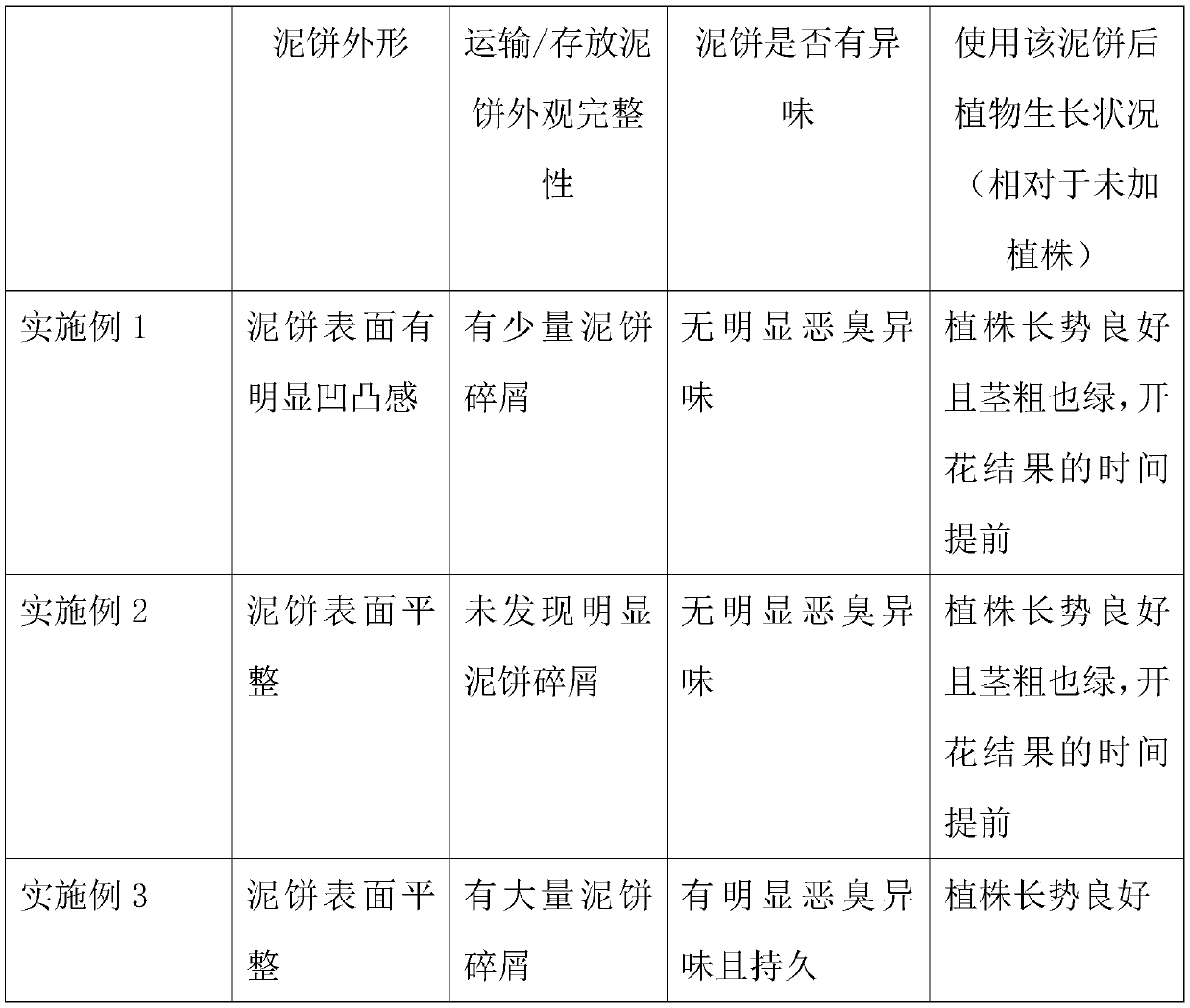

Sludge treatment method for biological treatment of wastewater

InactiveCN110698011AComplete appearanceImpact moldingClimate change adaptationSewage/sludge fertilisersSludgeWastewater

The invention discloses a sludge treatment method for the biological treatment of wastewater and in particular relates to the field of sludge treatment. The sludge treatment method specifically comprises the following steps: I, sludge-water separation; II, sand separation; III, fermentation; IV, performing mixing; V, dehydration and compacting; VI, drying and hardening; and VII, crushing and use.Through the step of stone separation, influence of sundries or rubbles in sludge upon the appearance of mud cakes prepared later can be ensured, the completeness of the appearance of molded mud cakescan be ensured, and deficiency of compactness of the mud cakes, which is caused by mixing of hard impurities and can affect molding or transportation of the mud cakes later, can be avoided; and through the step of mixing, quick lime can be reacted with water reaction and can be also reacted with a hydrogen sulfide gas, fetid odor in the sludge can be removed, the mud cakes mixed with the quick lime are good in overall performance after being hardened, chippings are not easily generated, and convenience can be brought to storage and transportation.

Owner:QILU UNIV OF TECH

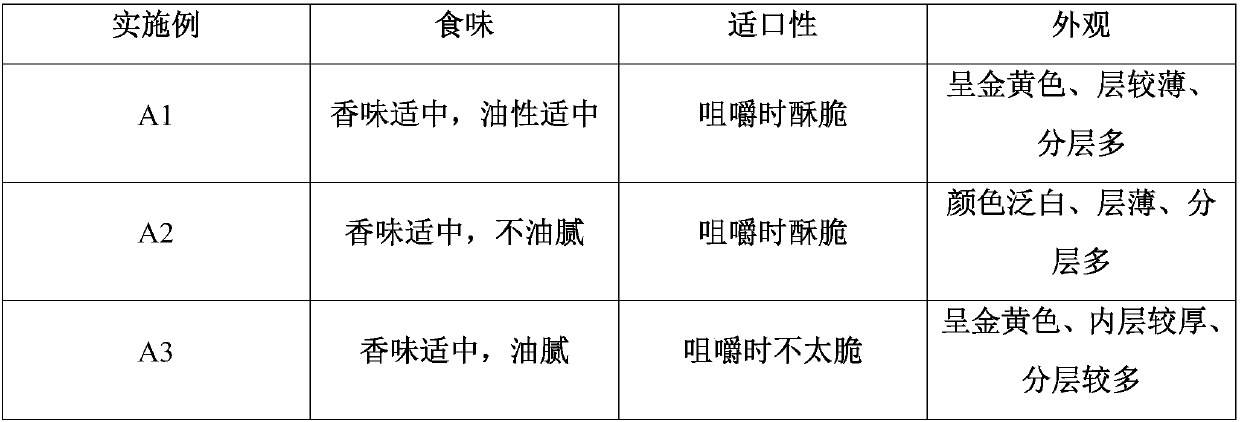

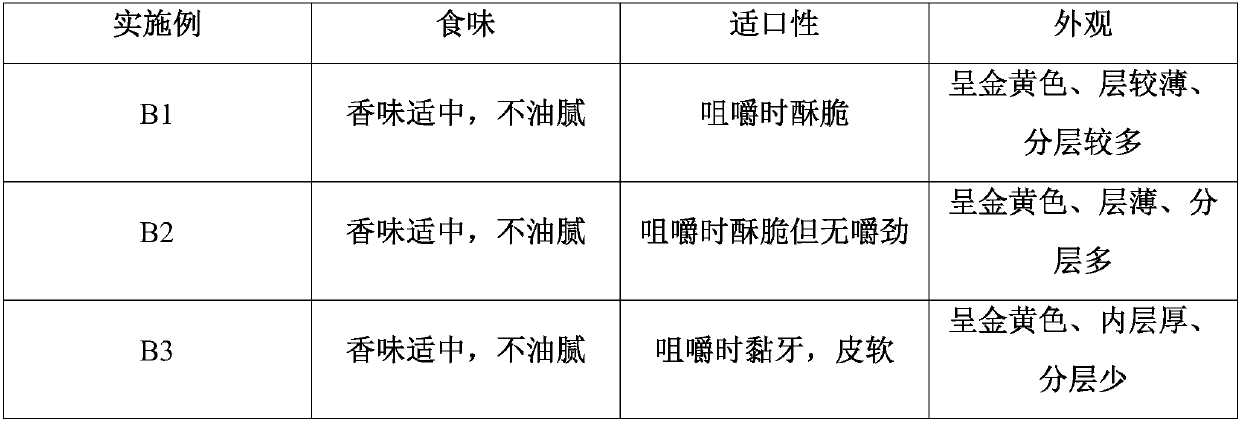

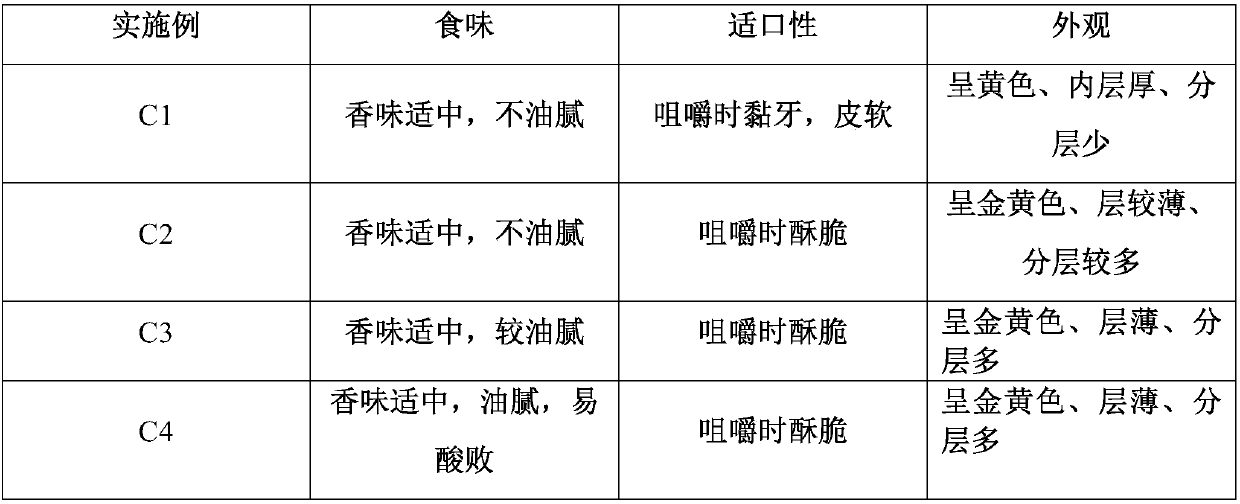

Crispy shredded cake making method

ActiveCN107549264AImprove crispnessGuaranteed non-greasyDough treatmentPre-baking dough treatmentProcess conditionsOrganic chemistry

The invention discloses a crispy shredded cake making method which includes the operation steps: dough kneading; dough leavening; carburetion; cake making; oil coating; baking; cake pressing; quick-freezing to obtain a quick-frozen crispy shredded cake. By controlling shredded cake synthesis process conditions, crispness of the shredded cake is remarkably improved, and the shredded cake is not oily and good in taste.

Owner:上海粮全其美食品技术有限公司 +1

Numerical-control forming mold

InactiveCN109676030AImpact moldingHigh quality and precisionShaping toolsMetal-working feeding devicesNumerical controlEngineering

Owner:PHNIX GUANGZHOU ELECTRICAL

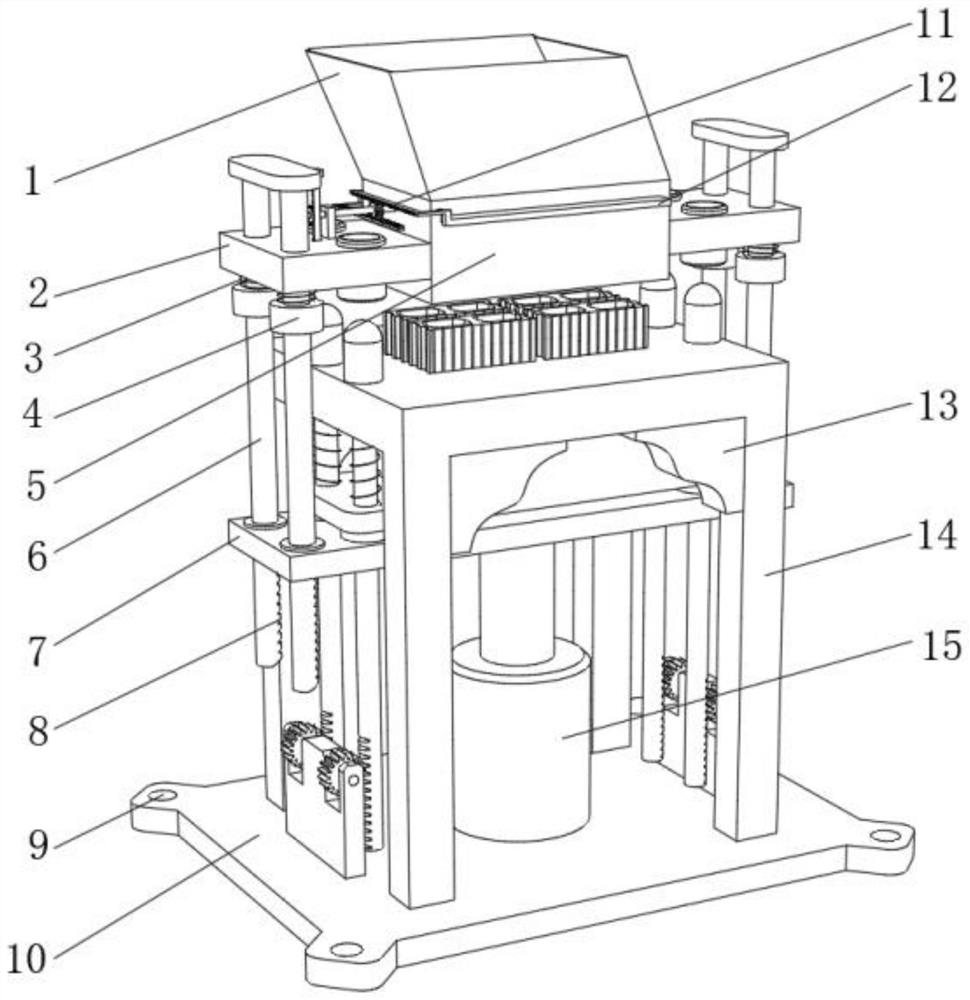

Novel lithium battery cover plate forming die

PendingCN114013083AEasy to take outEasy to operateCell lids/coversCleaning using toolsEngineeringStructural engineering

The invention discloses a novel lithium battery cover plate forming die which comprises a base, four supporting rods are symmetrically and fixedly connected to the upper end of the base, a lower die is fixedly connected to the upper ends of the four supporting rods jointly, a U-shaped frame is fixedly connected to the upper end of the base, and a hydraulic oil cylinder is fixedly connected to the upper end of the U-shaped frame. The movable end of the hydraulic oil cylinder penetrates through the upper end of the U-shaped frame and is fixedly connected with an upper die, an ejection mechanism is installed on the base and comprises a driving box fixedly connected to the upper end of the base, a sliding plug is slidably connected to the inner wall of the driving box in a sealed mode, an ejection rod is fixedly connected to the upper end of the sliding plug, and a groove is formed in the bottom in the lower die. Compressed gas is injected into a high-pressure gas inlet pipe and converted through a vortex tube to generate hot gas, the hot gas enters the driving box to enable the sliding plug to move upwards, then a top plate is driven to move upwards, the formed lithium battery cover plate is ejected out of the lower die, the formed lithium battery cover plate is conveniently taken out, operation is easy and convenient, and practicability is high.

Owner:XUZHOU UNIV OF TECH

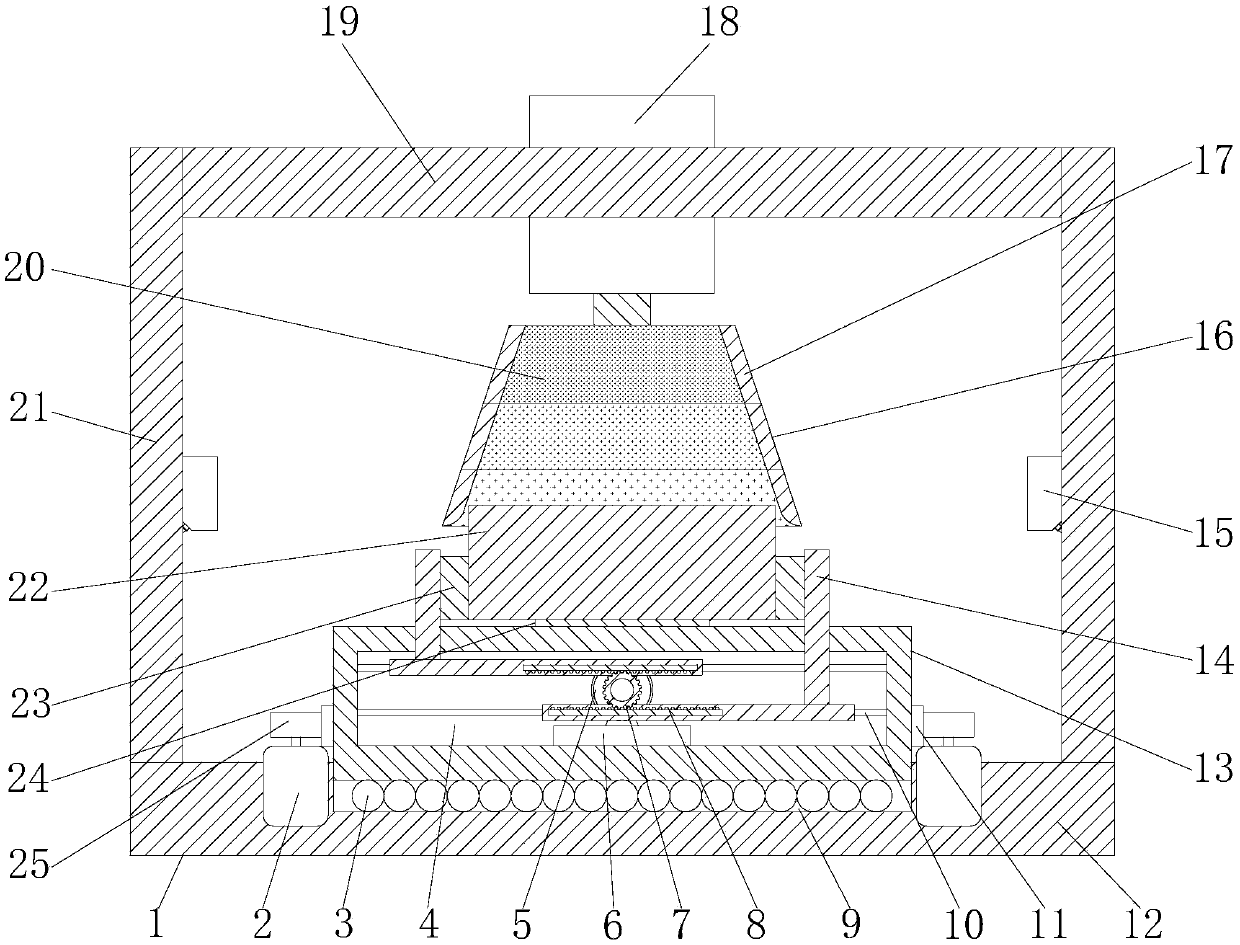

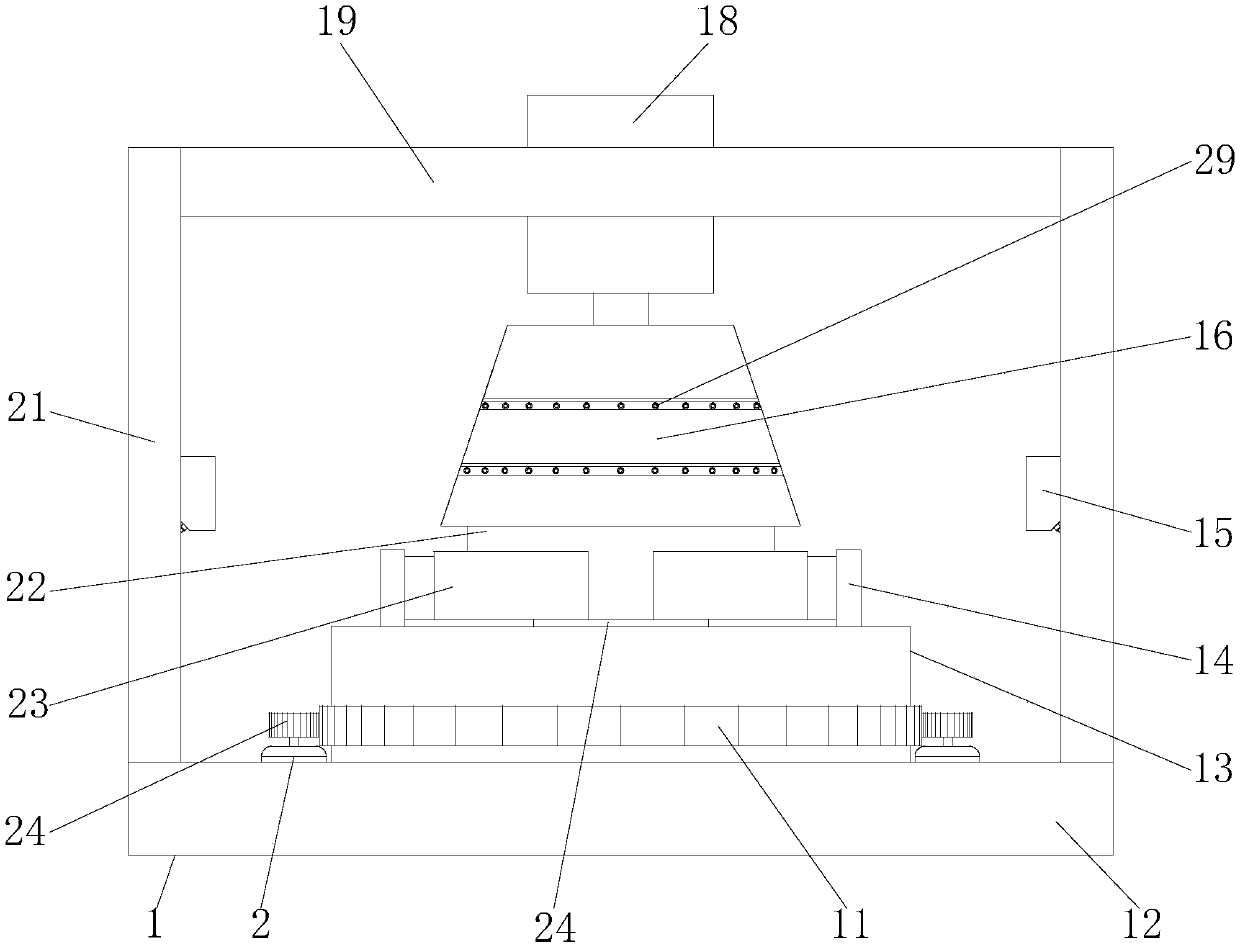

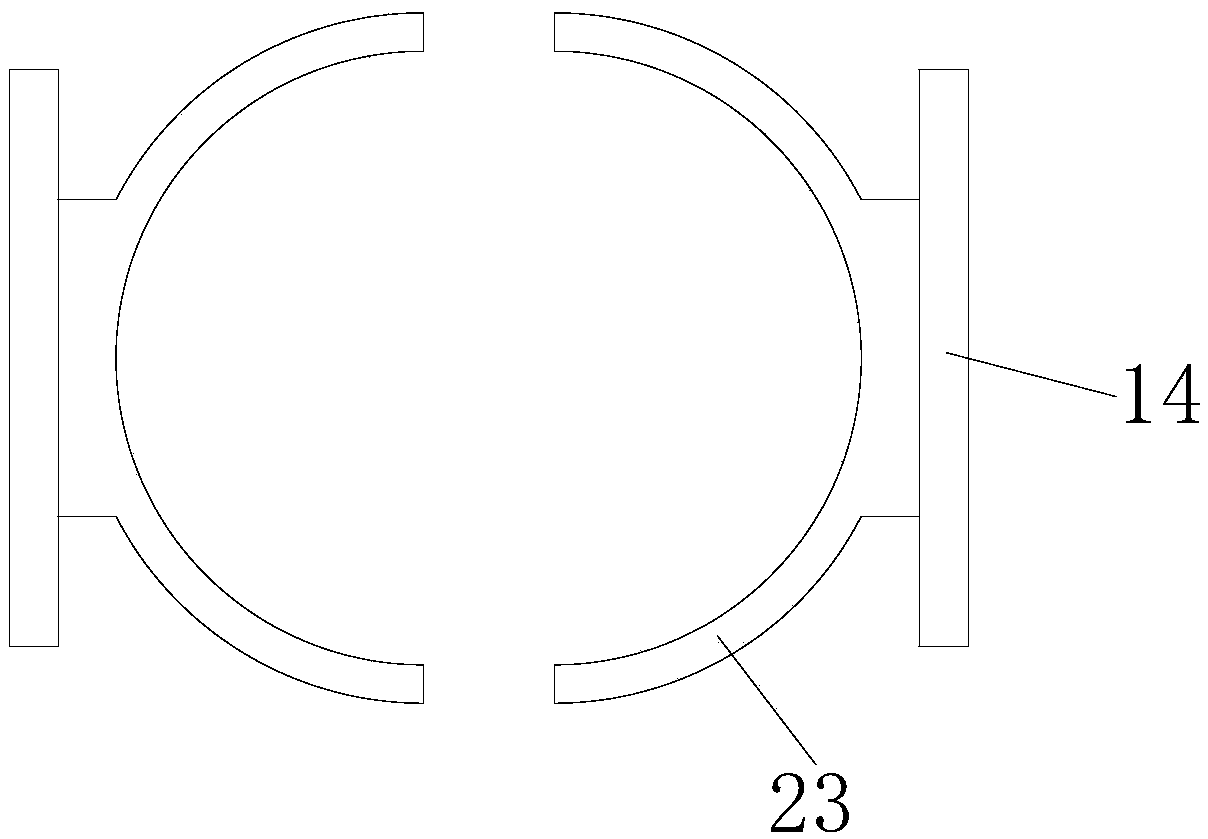

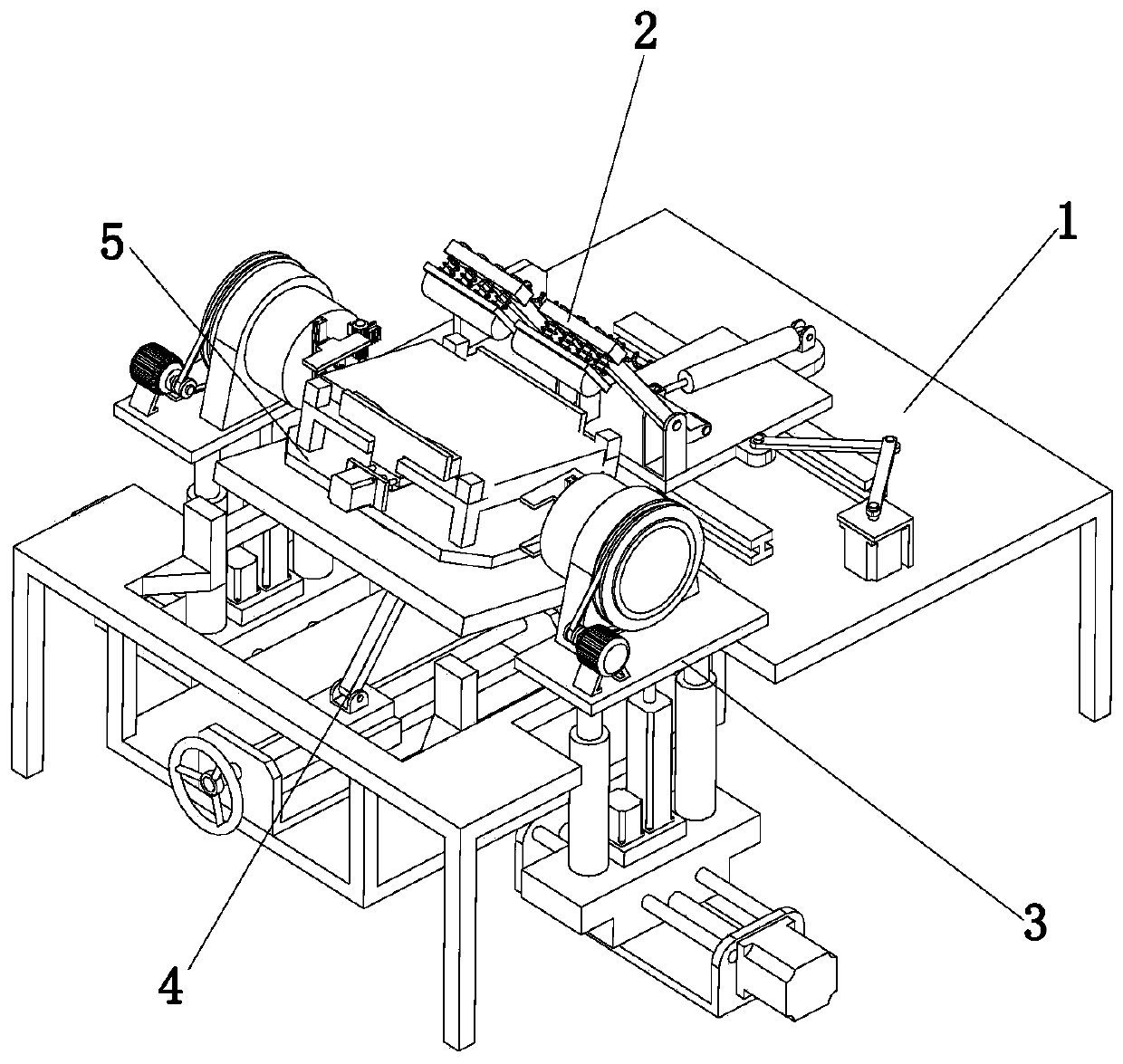

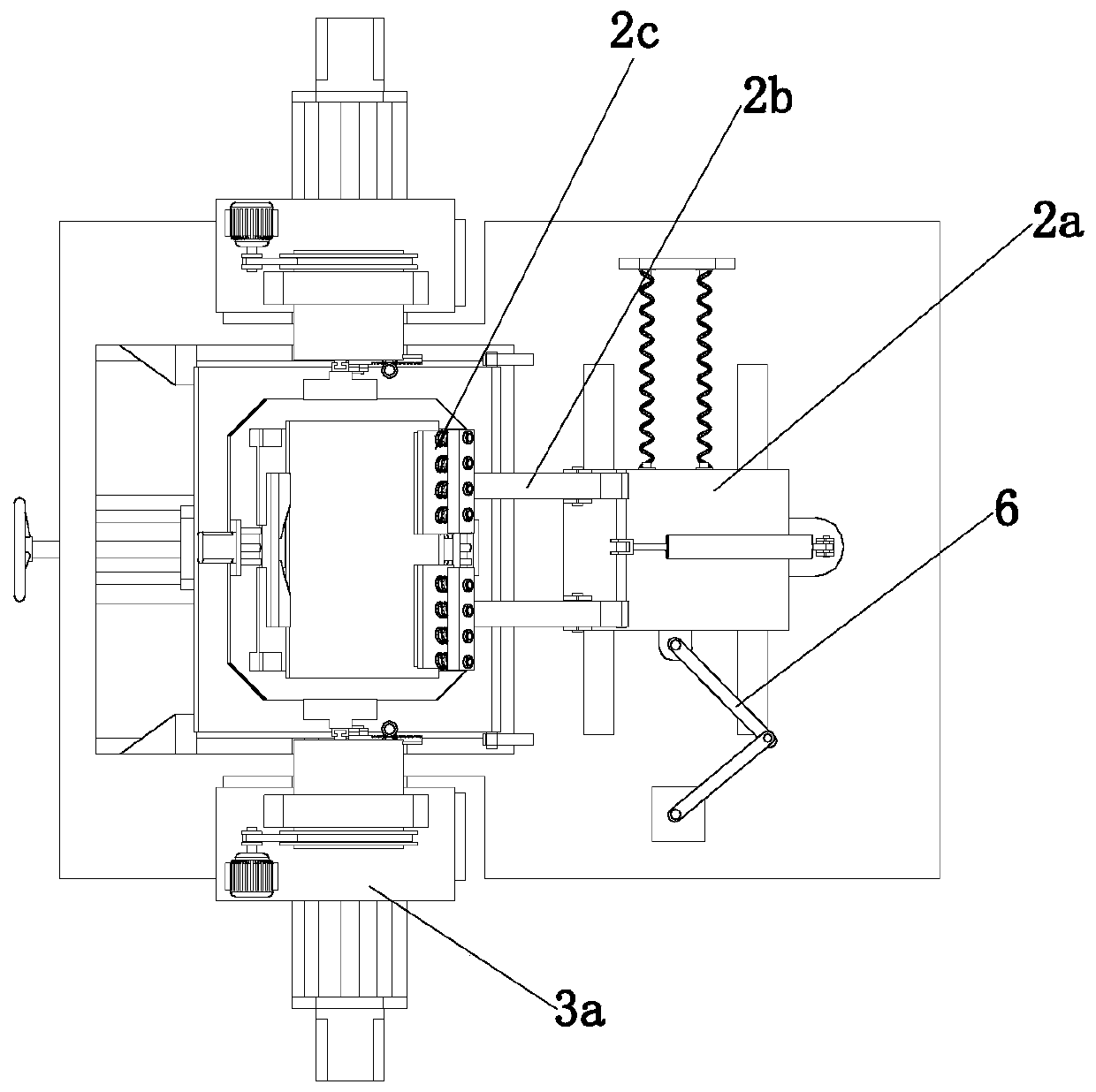

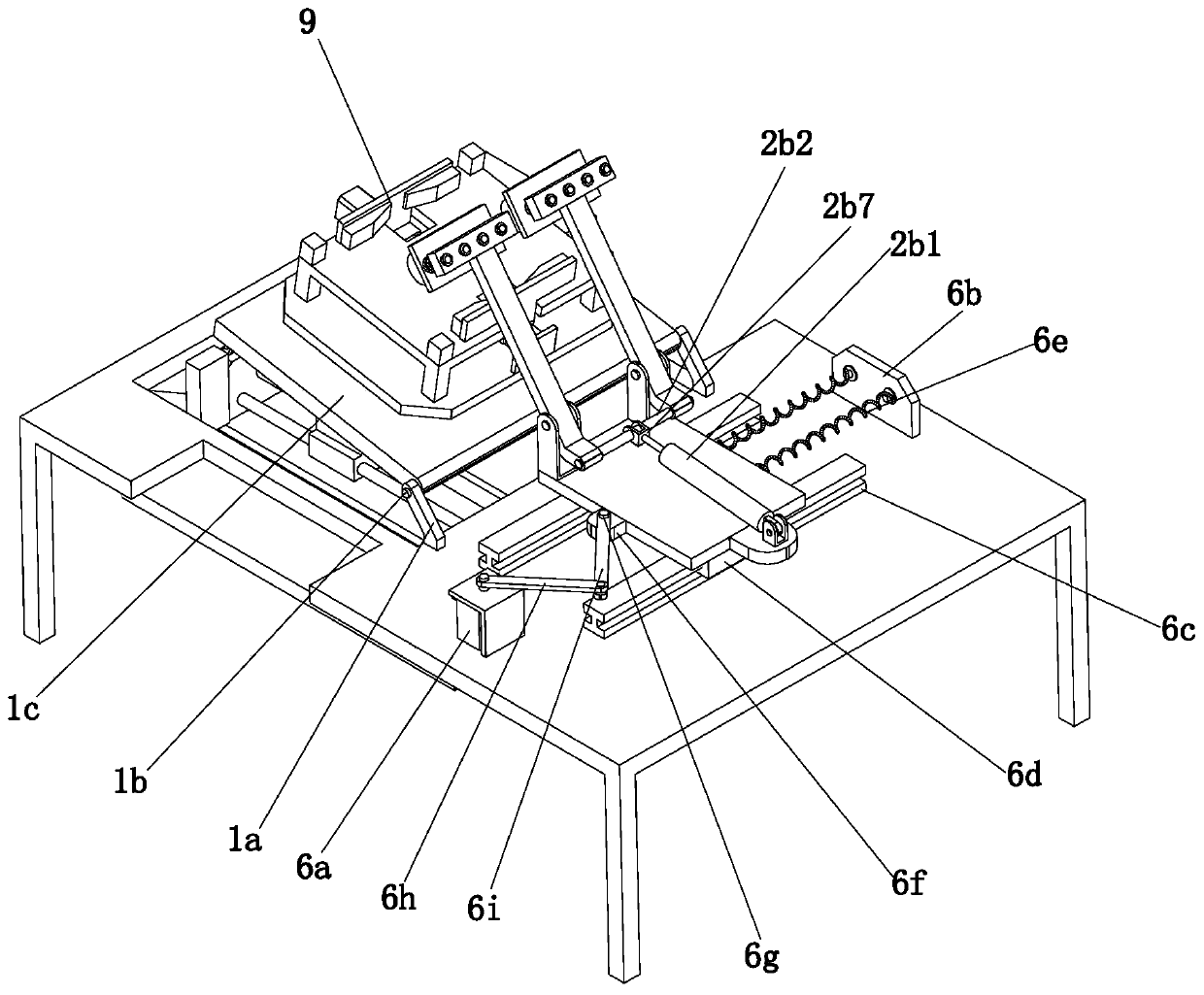

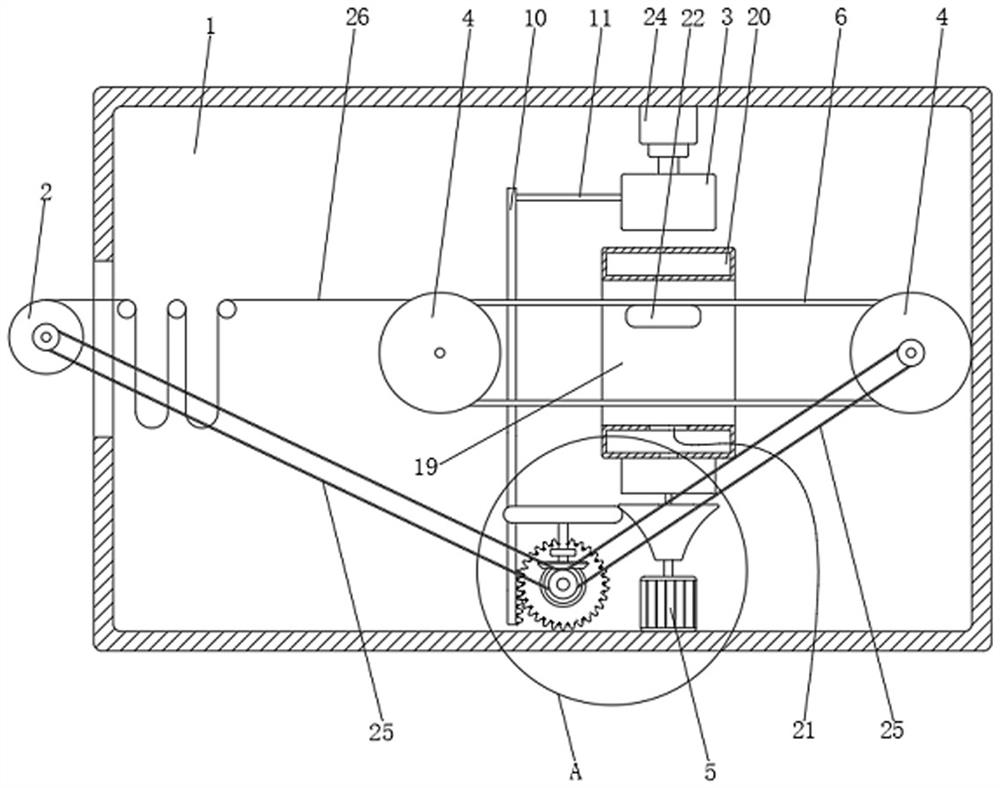

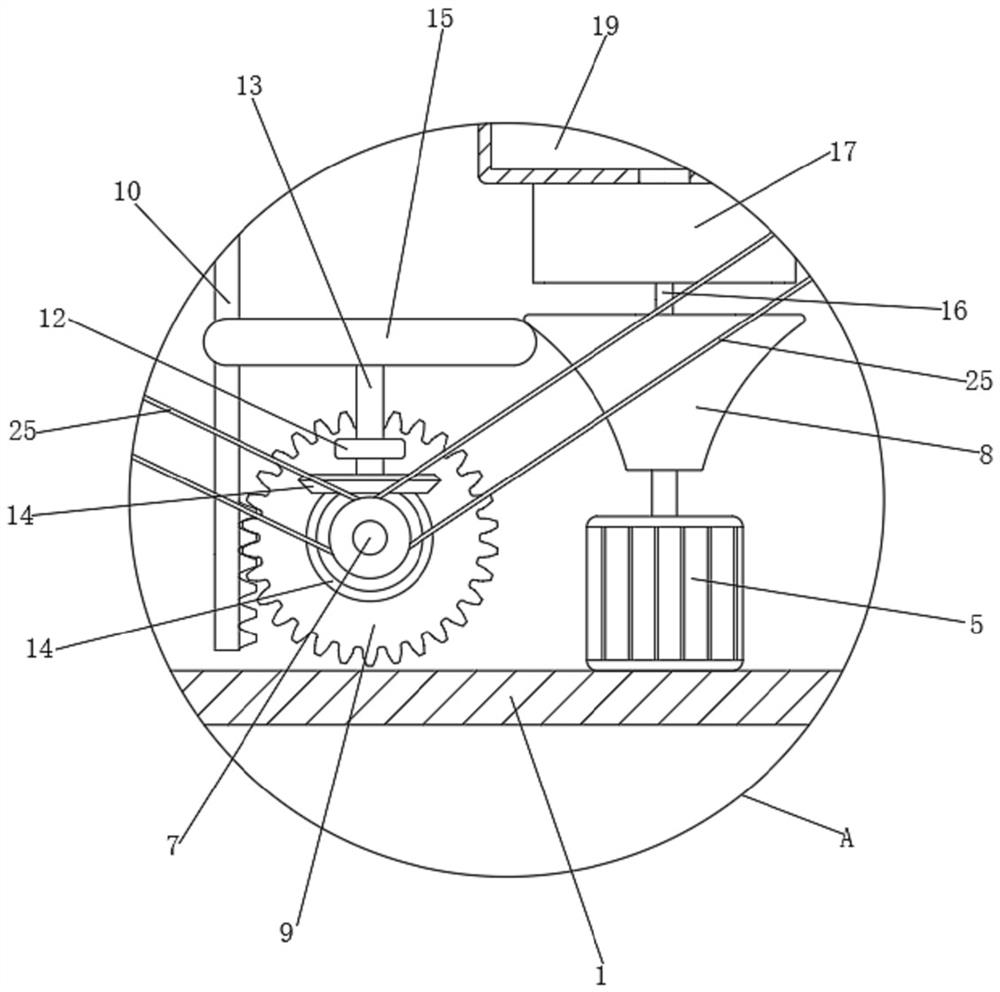

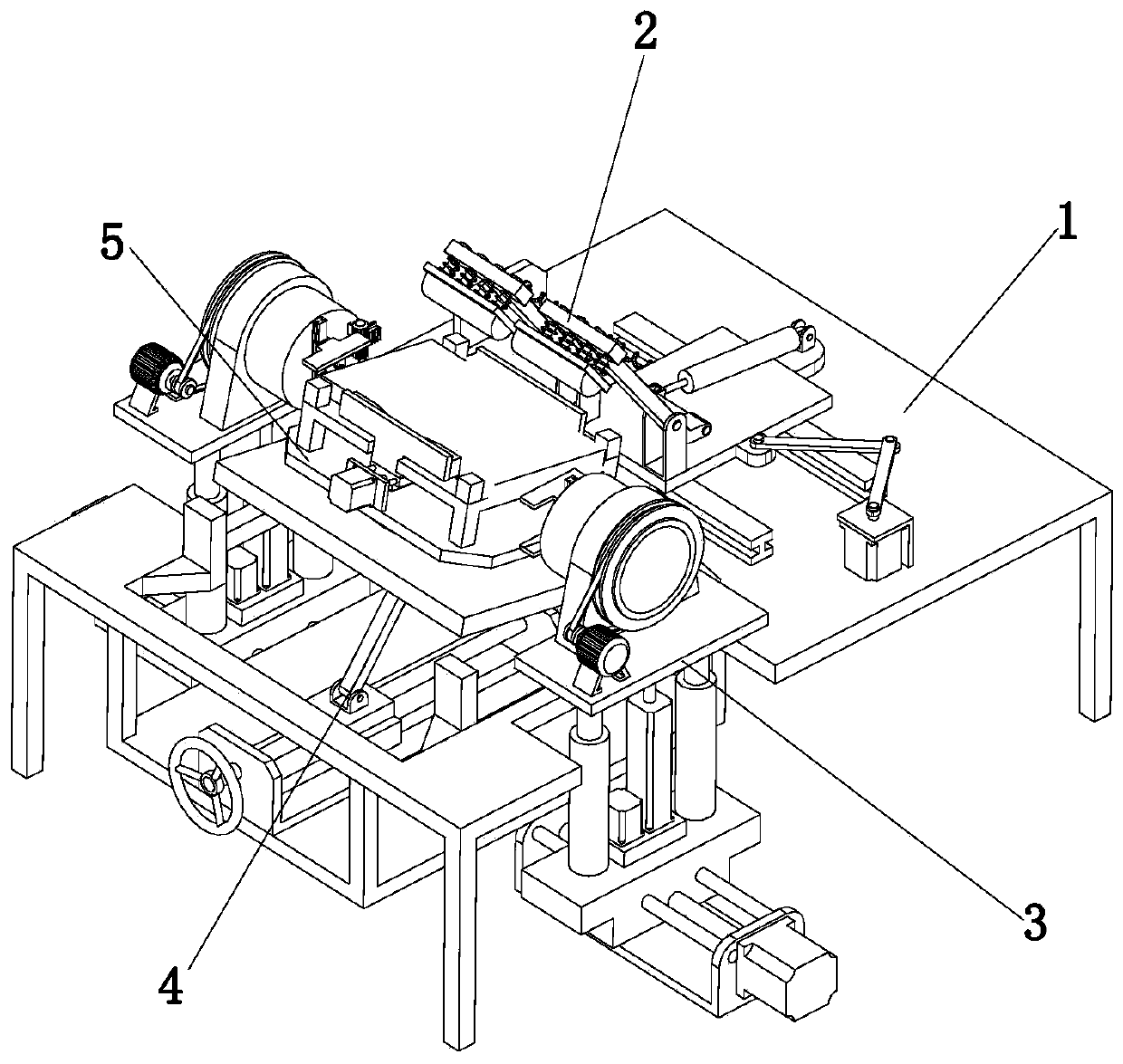

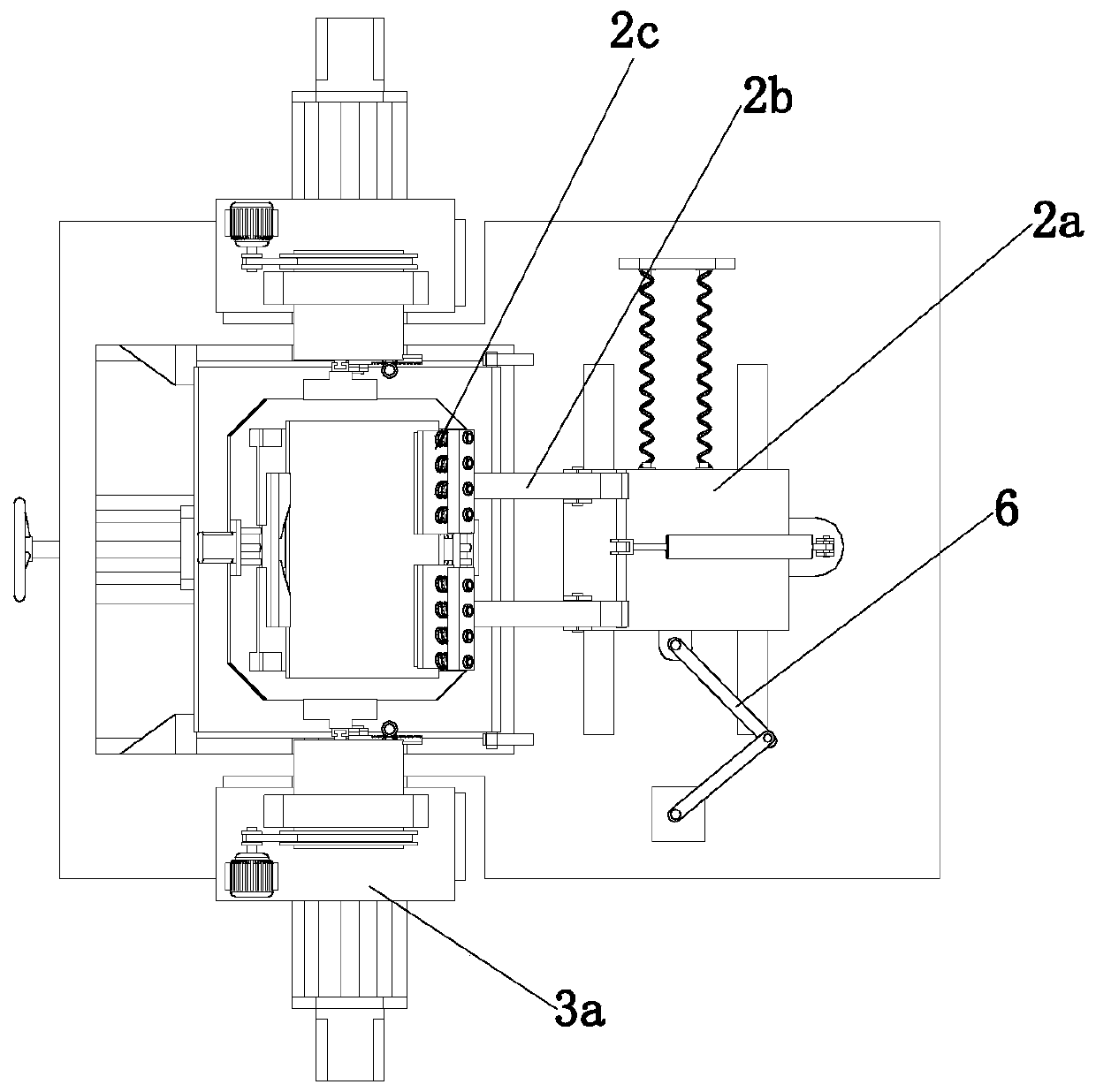

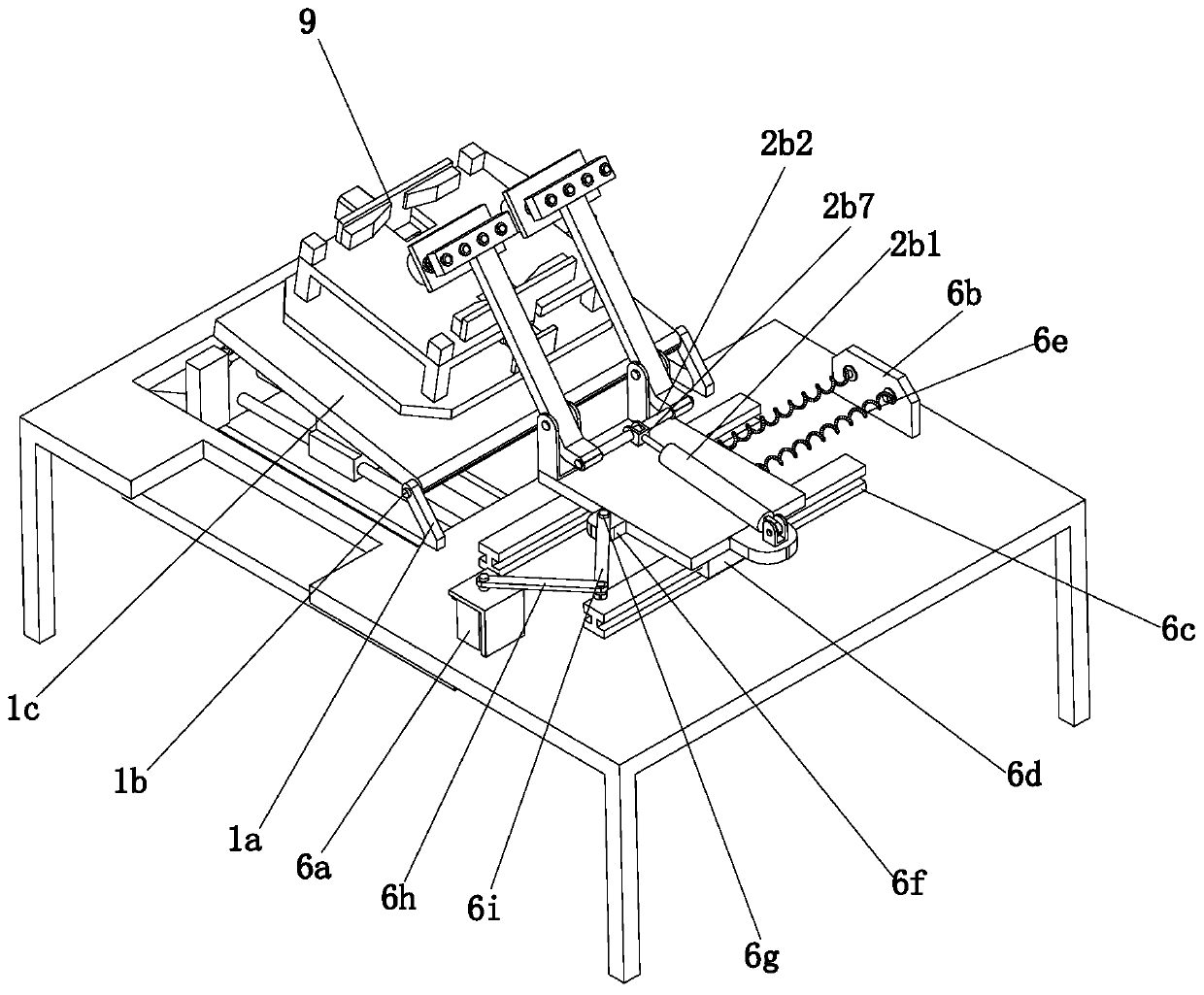

Working method of a steel hammer forming device for iron and steel production

ActiveCN109396313BReduce labor intensityAvoid the Unhammered SituationForging hammersForging/hammering/pressing machinesTemperingEngineering

The invention discloses a steel hammering forming device for iron and steel production, and belongs to the field of iron and steel equipment. The steel hammering forming device for iron and steel production comprises a workbench, a hammering mechanism, a turnover mechanism and an angle adjusting mechanism. Two installation plates which are separated are arranged on the top of the workbench, and arotating shaft which is connected with the two installation plates in a rotating mode is arranged between the two installation plates. A supporting plate sleeves the rotating shaft, and a rotating assembly is arranged on the top of the supporting plate. The hammering mechanism comprises a material moving plate, a hammering assembly and a material conveying assembly. The material conveying assemblyis used for driving the material moving plate to move in the horizontal direction, and the hammering assembly is arranged on the top of the material moving plate. By the adoption of the steel hammering forming device for iron and steel production, the steel can be automatically overturned through the turnover mechanism, the operation that workers conduct the turnover work manually is not required, and the labor intensity of the workers is reduced; and the position of the hammering assembly can be adjusted by the material conveying assembly and the angle adjusting mechanism, and therefore thehammering assembly can conduct hammering operation on each corner of the steel.

Owner:上海尧哲工程技术有限公司

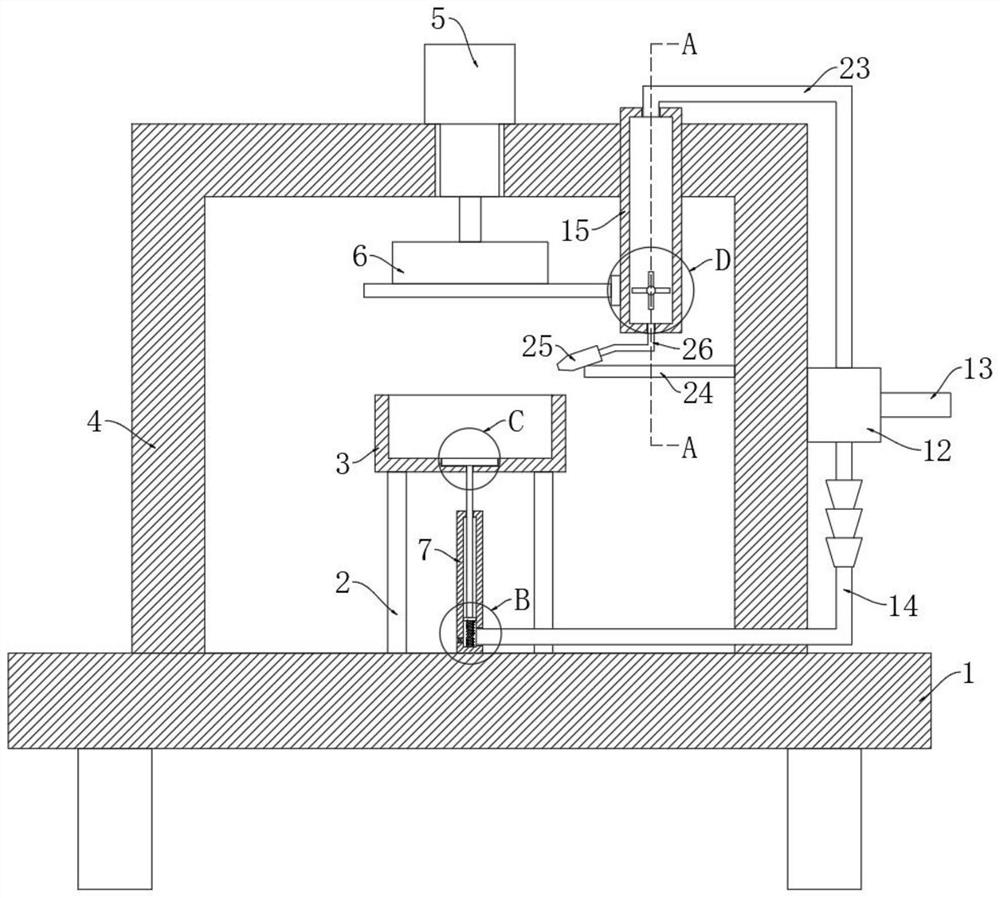

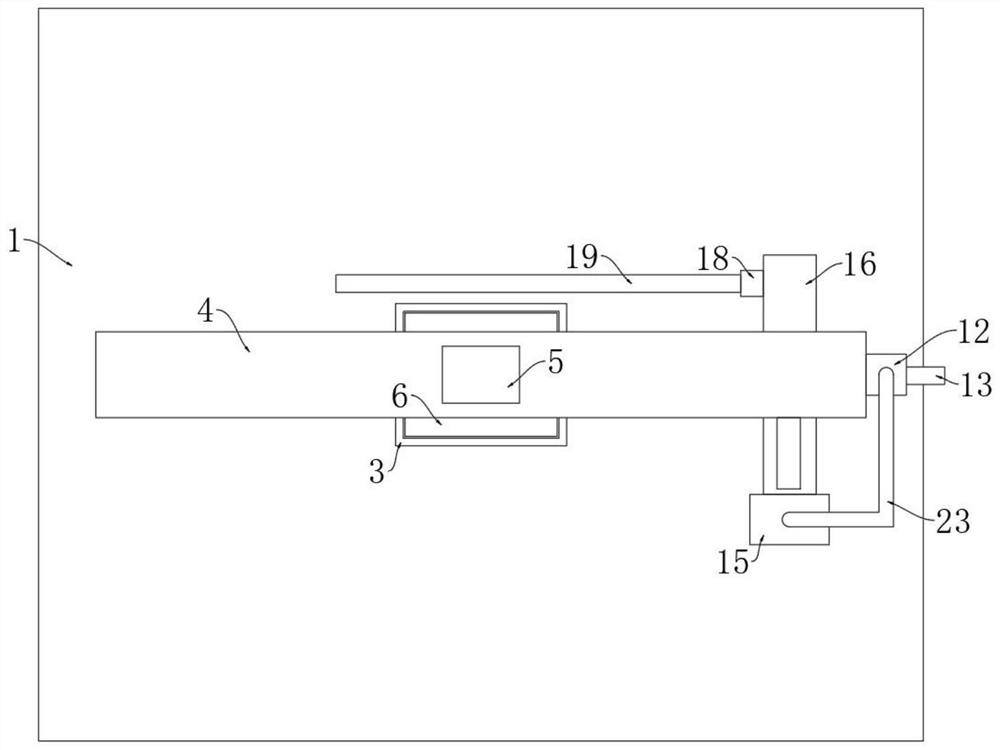

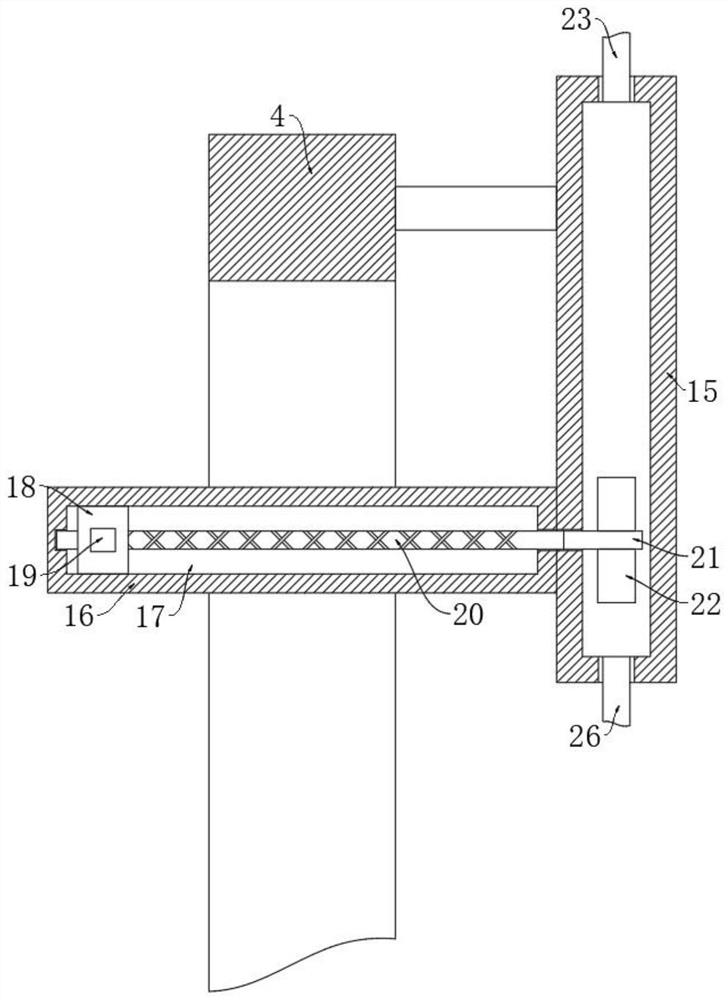

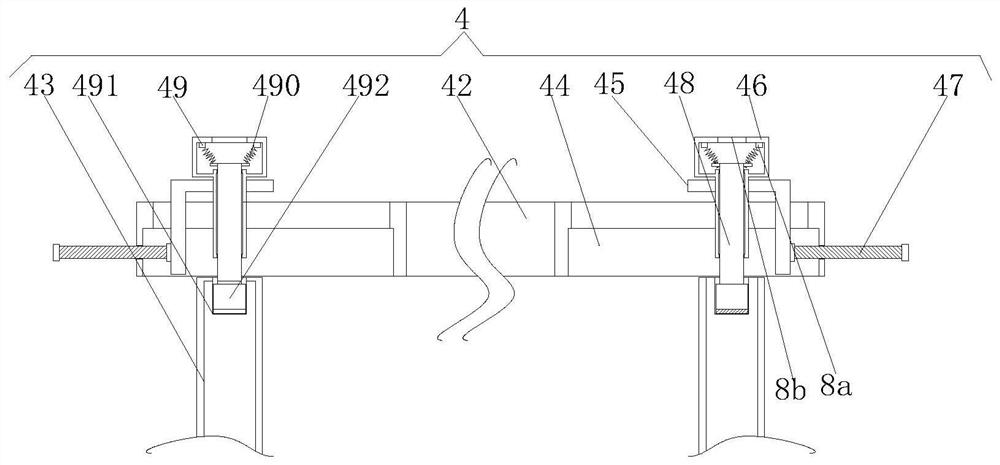

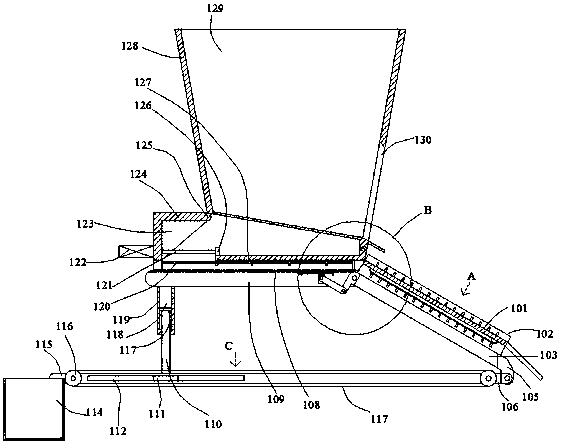

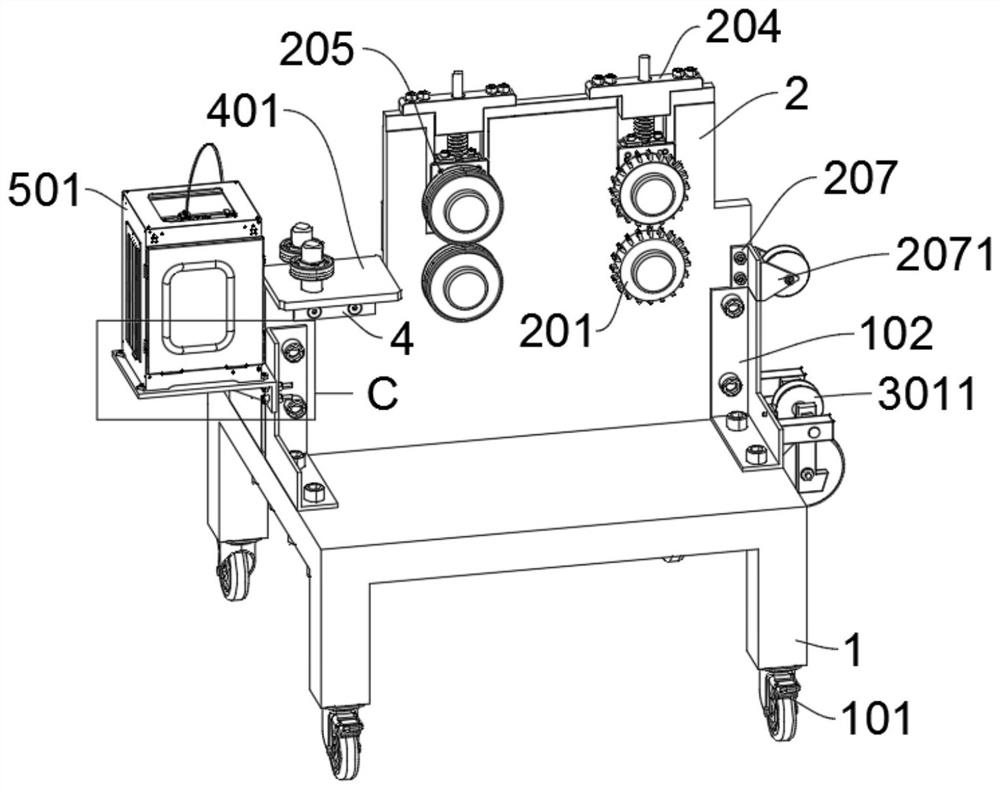

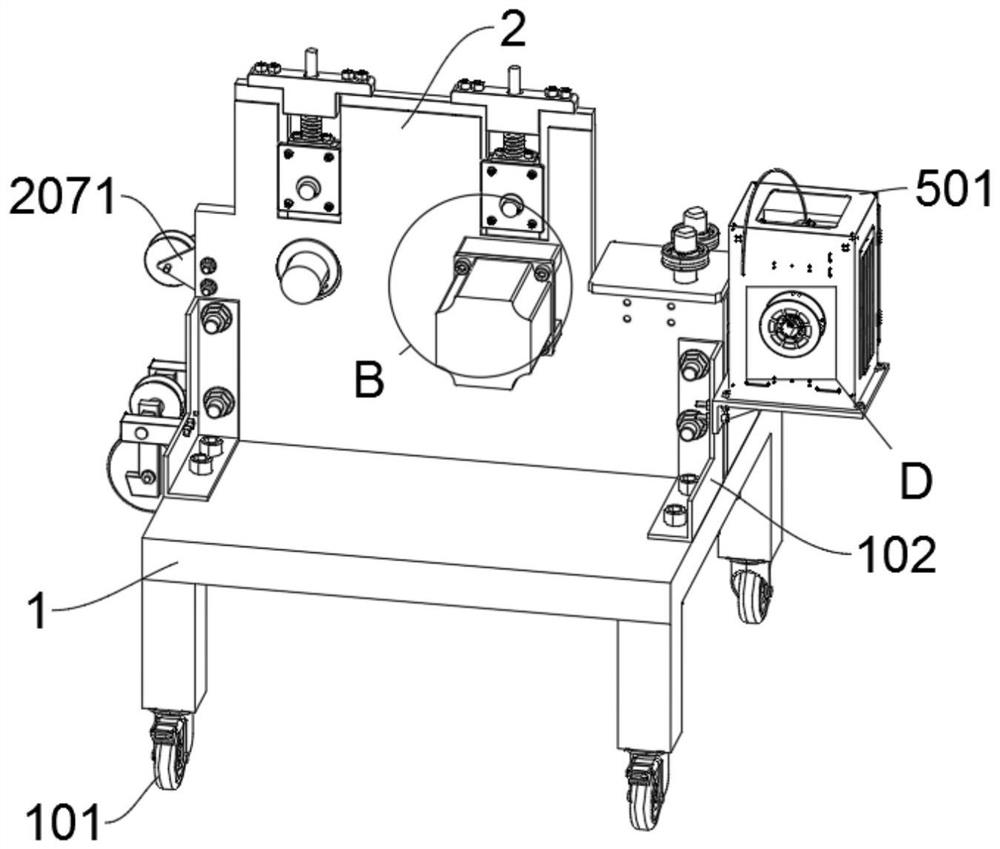

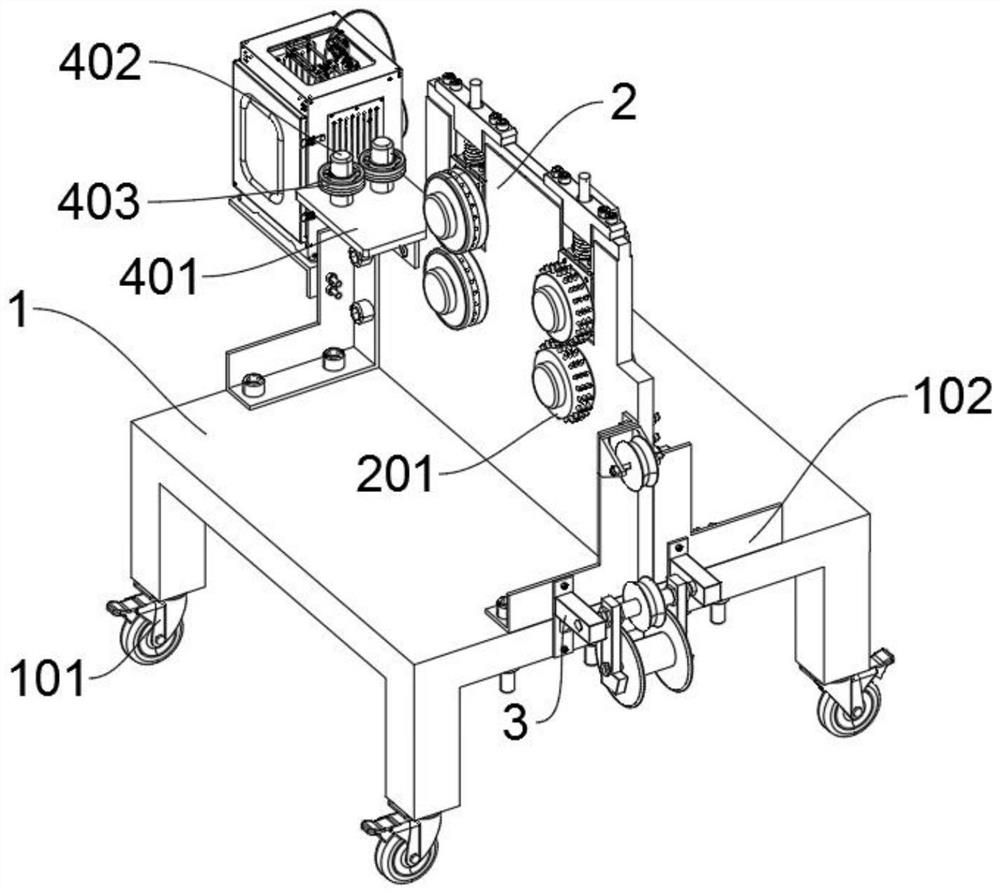

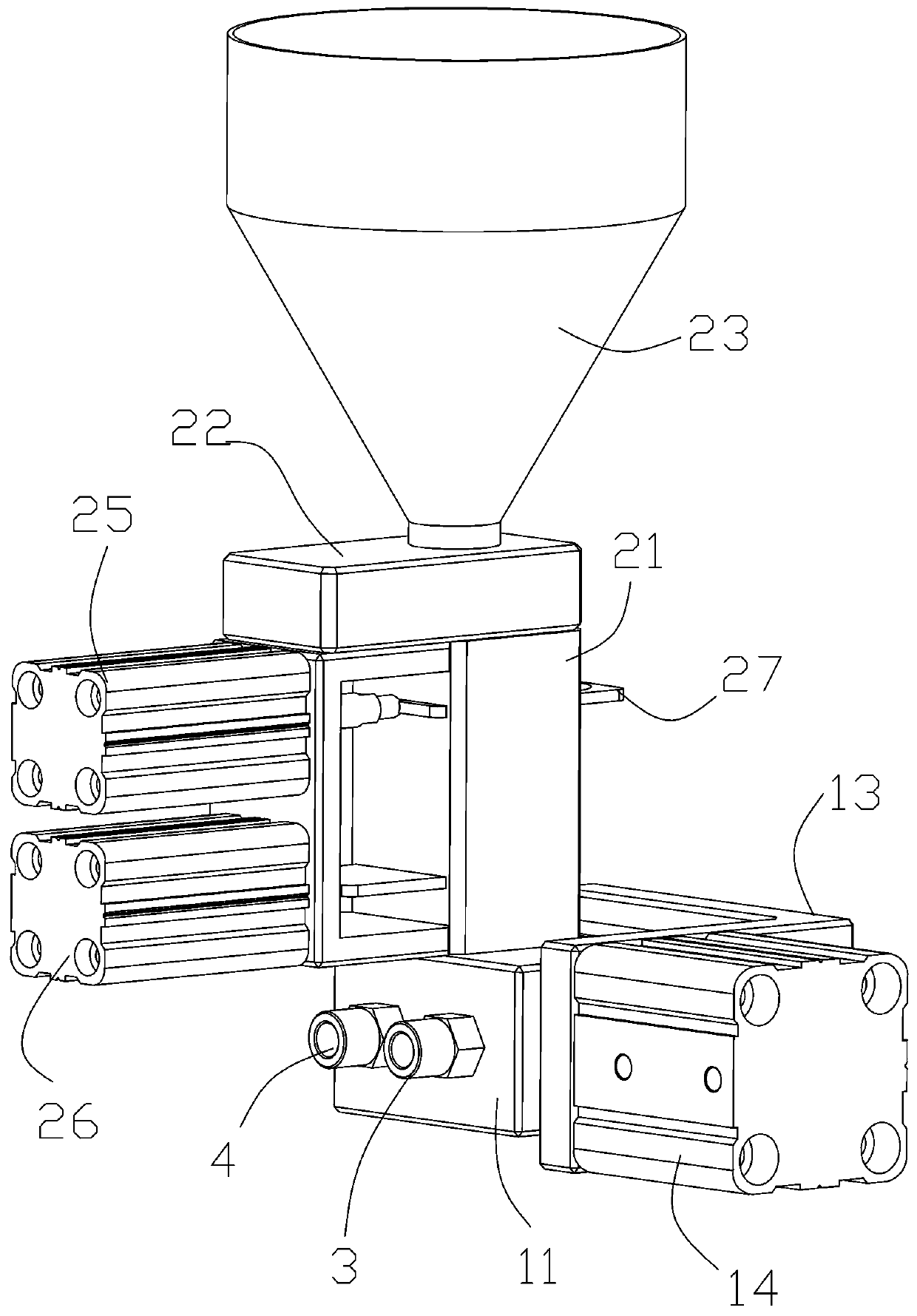

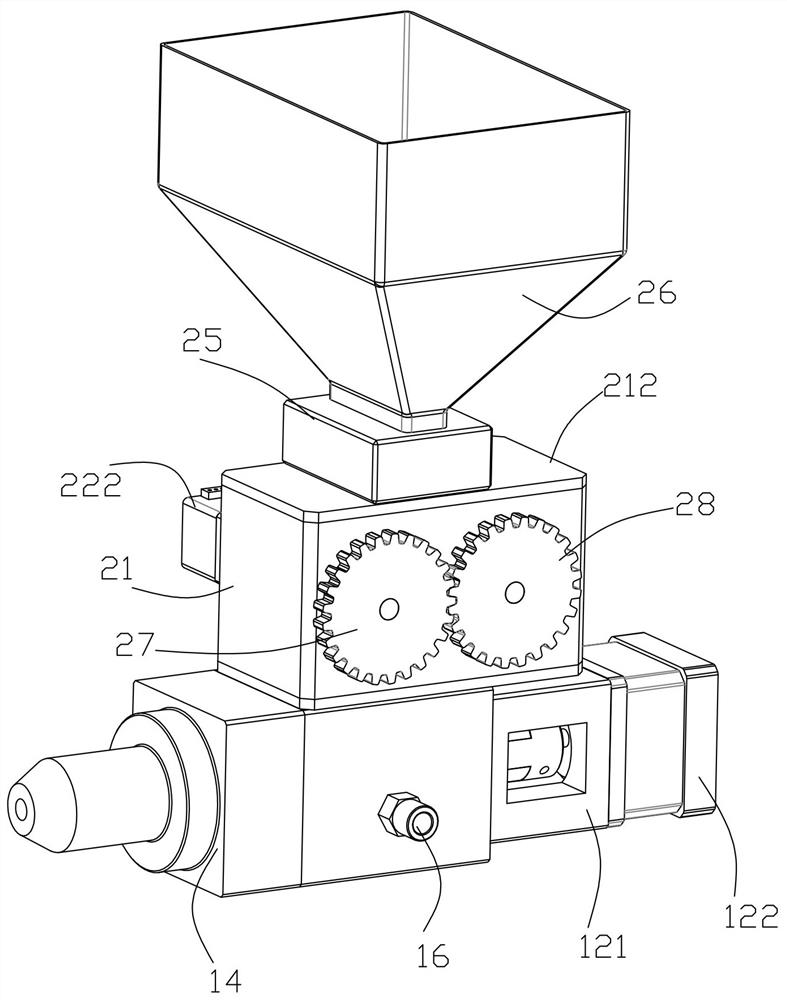

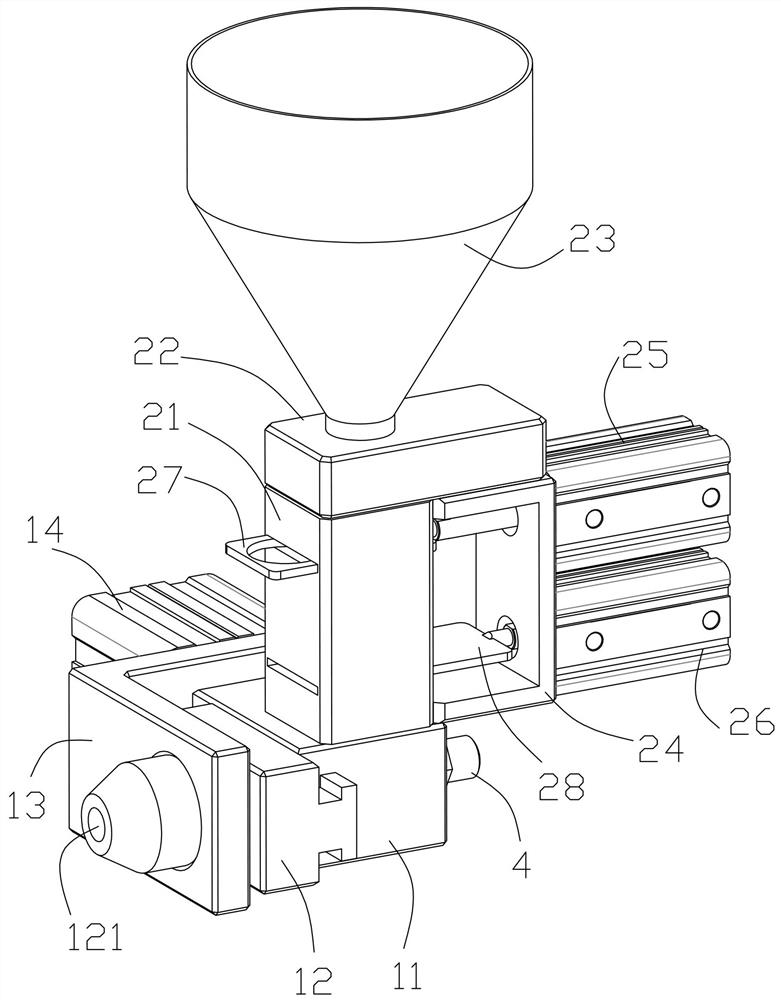

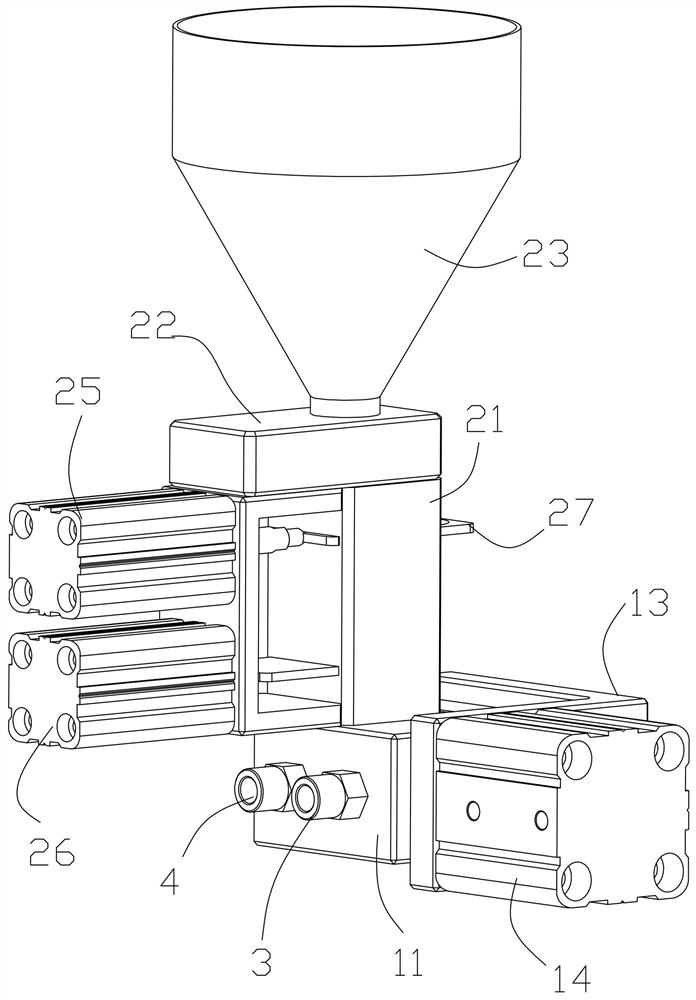

Material hanging type automatic wax injecting and quantitative powder spraying mechanism

The invention discloses a material hanging type automatic wax injecting and quantitative powder spraying mechanism. The material hanging type automatic wax injecting and quantitative powder spraying mechanism comprises a feeding device, a quantitative powder feeding device and a wax injecting and powder spraying nozzle; the wax injecting and powder spraying nozzle is used for spraying powder and injecting wax liquid into a mold; powder materials enter the quantitative feeding device through the feeding device; the quantitative feeding device communicates with the wax injecting and powder spraying nozzle; the quantitative powder feeding device comprises a belt wheel support, a driving motor, a driving belt heel, a driven belt wheel, a transmission belt and a material scraping part; the driving belt wheel and the driven belt wheel are both connected to the belt wheel support in a shaft connection manner; the driving motor is connected with the driving belt wheel; and the transmission belt is provided with powder feeding grooves at intervals, and the material scraping part is arranged on the belt wheel support. According to the material hanging type automatic wax injecting and quantitative powder spraying mechanism, due to cooperation of the feeding device and the quantitative powder feeding device, it is achieved that powder is quantitatively fed to the wax injecting and powder spraying nozzle, and therefore a quantitative powder spraying procedure is completed, manual operation is not needed, the work efficiency is greatly improved, powder spraying in the mold is uniform, itis avoided that due to the fact that manual powder spraying is not uniform, forming of a wax mold is affected, and the qualification rate of wax mold forming is increased.

Owner:昕致潮贸易(深圳)有限公司

Processing method of chinquapin seed and green tea bean curd

The invention relates to the field of food processing, and particularly discloses a processing method of chinquapin seed and green tea bean curd. The processing method comprises the following steps: (a) weighing chinquapin seed powder and green tea powder at the mass ratio of 3 to (0.5-1.5), mixing and adding water with the weight being 8-12 time of that of the mixture to the mixture for modulating into paste; and (b) suffocating the paste in high-pressure steam for 3-5 minutes, taking out and cooling to obtain the chinquapin seed and green tea bean curd. A certain amount of green tea powder is added to the chinquapin seed powder to be used as the raw material for processing and preparing the chinquapin seed and green tea bean curd, so that the prepared chinquapin seed and green tea bean curd has a slight tea aroma; and meanwhile, the chinquapin seed powder is subjected to deacidification, astringency removal and decolorizing treatment, so that a prepared dish is relatively cool and tasty to eat, has the light green color and luster, and is nutrient and healthy. Therefore, the chinquapin seed and green tea bean curd is popular among people.

Owner:黄山紫霞茶业有限公司

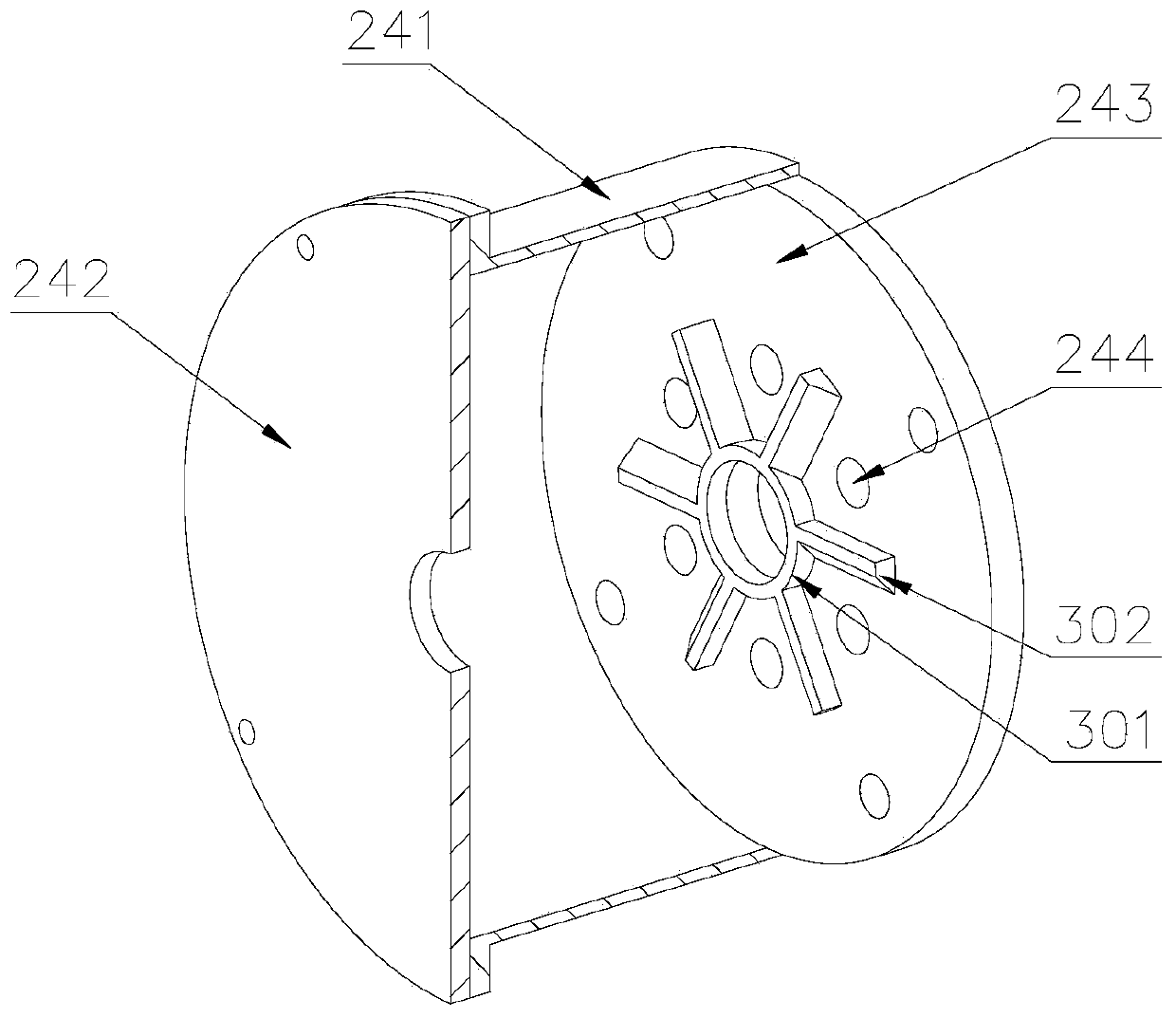

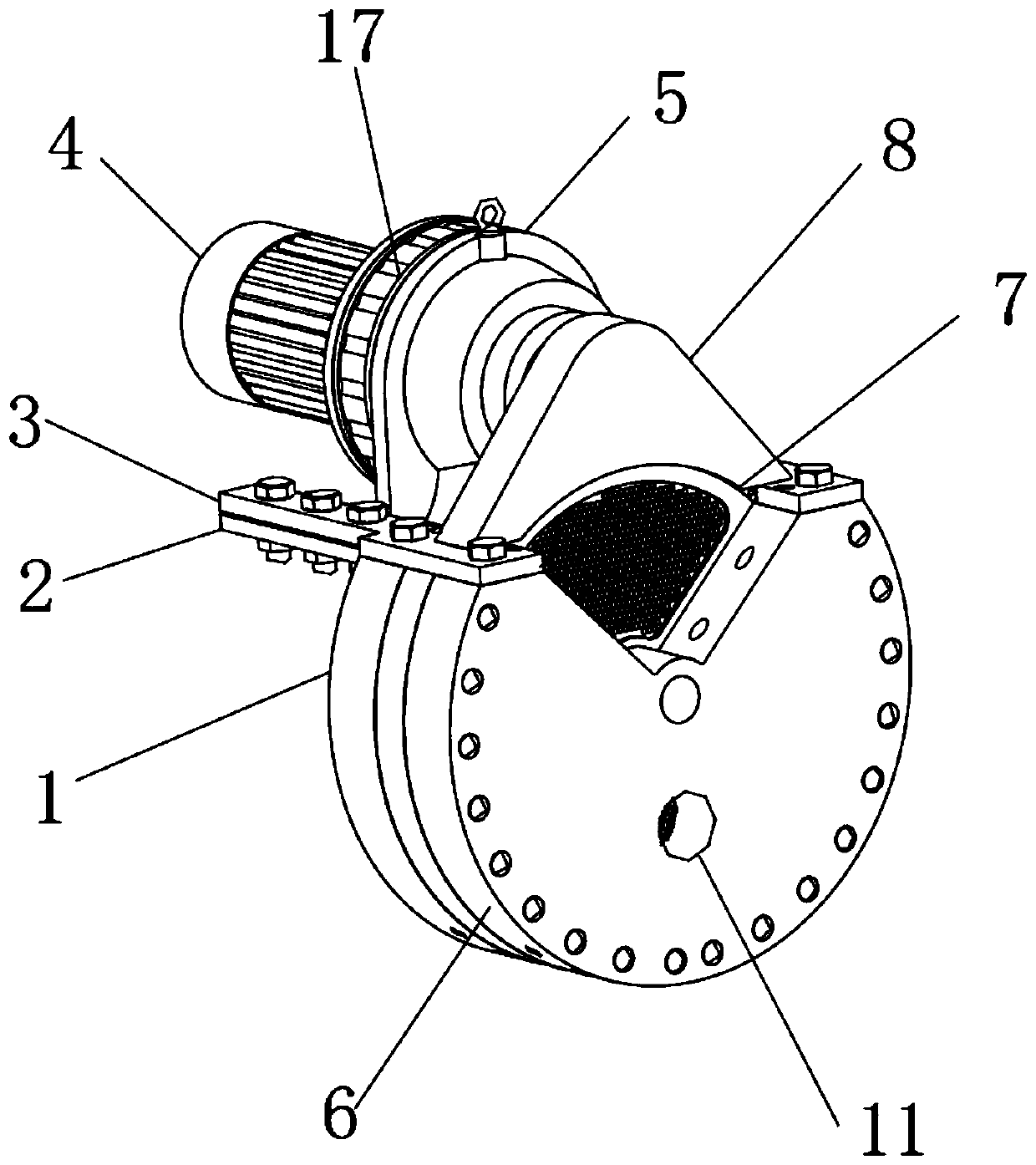

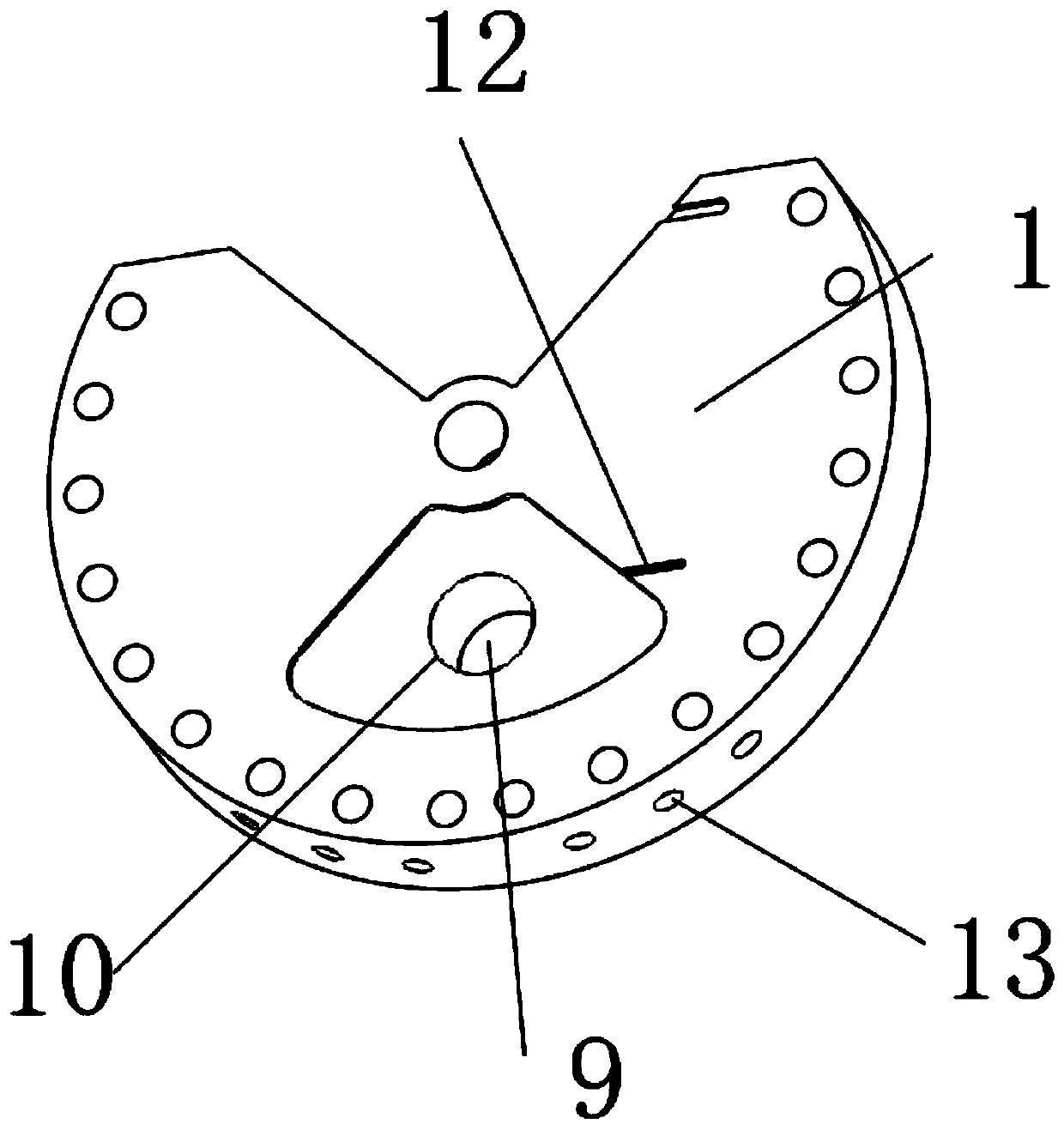

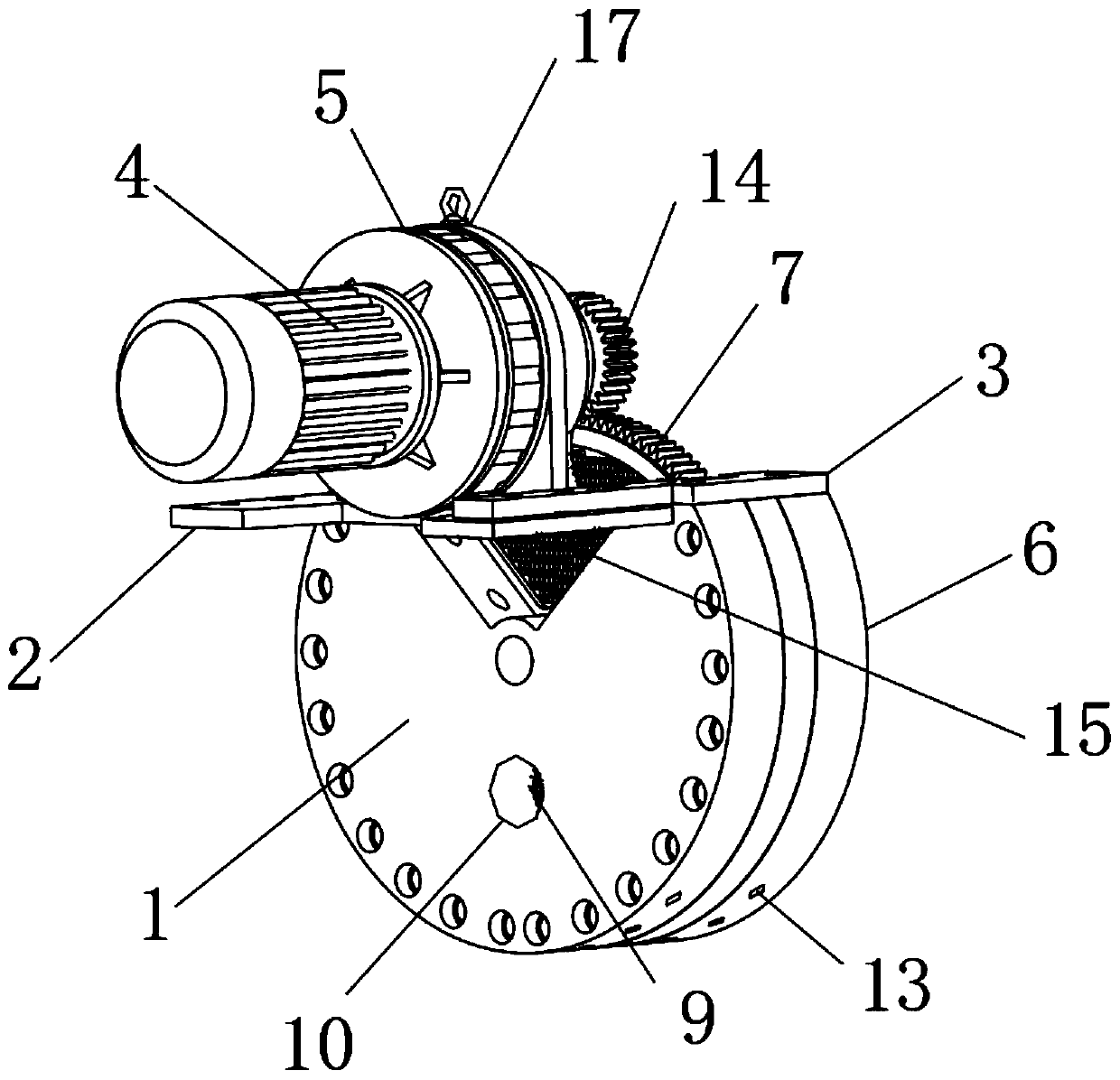

Non-stop automatic screen changer

The invention discloses a non-stop automatic screen changer comprising a front shell, a support plate, a motor bracket, a rotating motor, a speed reducer, a rear shell, a gear disk, a gear housing, adriving gear, a filter plate and filter screen clamping slots. Fixing plates are fixedly welded on the top of one side of the front shell symmetrically, and the top of each fixing plate is fixedly connected with the motor bracket by bolts; one side of the motor bracket is fixedly provided with the rotating motor, and an output shaft of the rotating motor is fixedly provided with the speed reducer;an output shaft of the speed reducer is fixedly provided with the driving gear, and the side, far away from the fixing plates, of the front shell is provided with the rear shell; and the top end of the rear shell is fixedly connected with the motor bracket by bolts, and the gear disk is arranged between the front shell and the rear shell. According to the non-stop automatic screen changer, filterscreens can be replaced under the non-stop condition of a plastic extruding machine, not only is the machining speed of the plastic extruding machine increased, but also the efficiency of the plasticextruding machine is improved.

Owner:李增现 +1

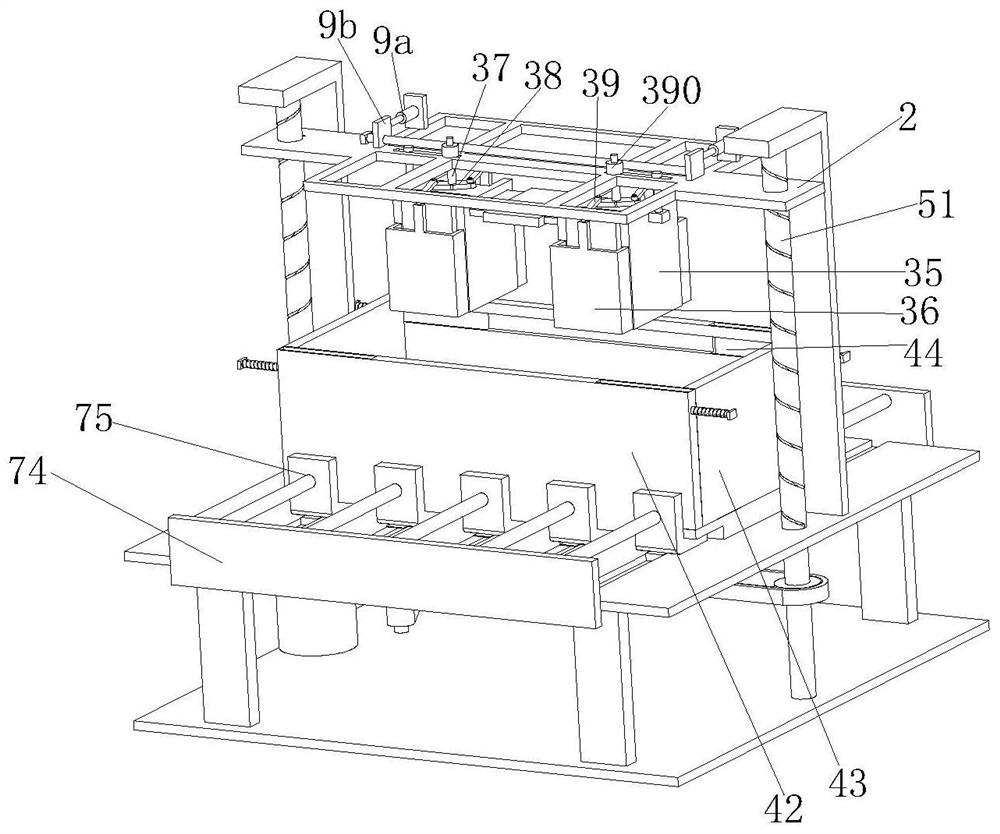

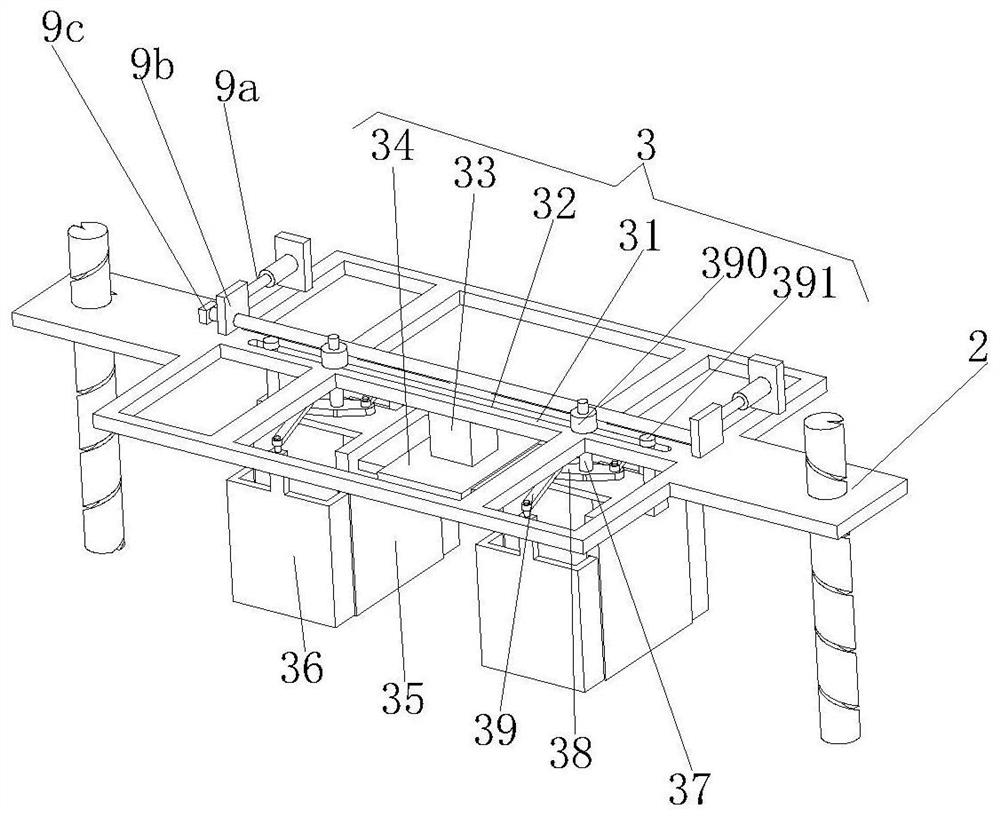

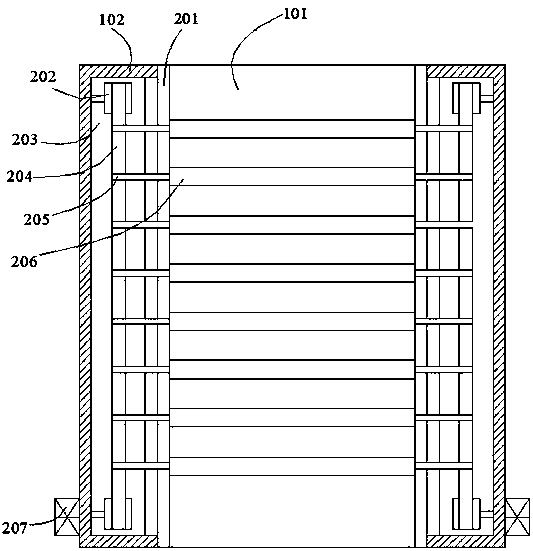

Autoclaved lightweight aerated concrete product manufacturing and processing system

PendingCN113183287AAdjustable lengthAchieve fixationMouldsFeeding arrangmentsStructural engineeringMechanical engineering

The invention relates to an autoclaved lightweight aerated concrete product manufacturing and processing system. The autoclaved lightweight aerated concrete product manufacturing and processing system comprises a base, a supporting frame, an adjusting device, a moving device and a lifting device. According to the autoclaved lightweight aerated concrete product manufacturing and processing system, the adjusting device is arranged, by driving adjusting rotating shafts to rotate, the adjusting rotating shafts rotate forwards to drive adjusting wheels to rotate, through relative movement of inner core adjusting frames at two sides, the length of an inner core hole is adjusted when building blocks are formed through pouring, the moving device is arranged, the lengths of the building blocks are adjusted and controlled by moving moving plates at two sides when the building blocks are formed through pouring, thus the building blocks with different lengths can be conveniently formed through pouring, T-shaped rods in inner cavities of T-shaped frames are pushed inwards until cross-shaped clamping blocks on the T-shaped rods are located in fixing grooves, thus the moving plates are fixed after being moved, and by fixing the moving plates, the situation that after the moving plates and overturning plates are combined into an outer mold, the moving plates are loosened due to the gravity of concrete, and then forming of the building blocks is affected is avoided.

Owner:肖尧

Melt-blown fiber production mechanism

ActiveCN113403701AHigh degree of automationAutomatic adjustment of blanking distanceMelt spinning methodsNon-woven fabricsFiberSpinning

The invention discloses a melt-blown fiber production mechanism, and relates to the technical field of melt-blown cloth fiber production equipment. The melt-blown fiber production mechanism comprises a shell, a wind-up roller and a melt-blown machine body, wherein the inner wall of the shell is further rotationally connected with a transmission shaft through a fixed shaft; and the surface of the transmission shaft is in transmission connection with the wind-up roller and any one belt pulley I through a transmission part and synchronously rotates with the wind-up roller and any one belt pulley I. The melt-blown fiber production mechanism further comprises a monitoring component for detecting the spinning speed of the melt-blowing machine body, and an auxiliary component I for automatically reducing the rotating speed of the transmission shaft along with increase of the spinning speed of the melt-blowing machine body, wherein the monitoring component is in signal connection with a telescopic driving component; and the auxiliary component I is in transmission connection with a motor. The melt-blown fiber production mechanism provided by the invention has the advantages that once the spinning speed of a discharge hole in the melt-blowing machine body is increased, the spinning blanking distance can be automatically adjusted, the final blanking speed is changed, meanwhile, the winding storage speed of the wind-up roller on the melt-blowing cloth is reduced, the contact time of the melt-blowing cloth and air can be prolonged, and heat carried by the melt-blowing cloth is transferred into the air.

Owner:江苏柏琳家用纺织品有限公司

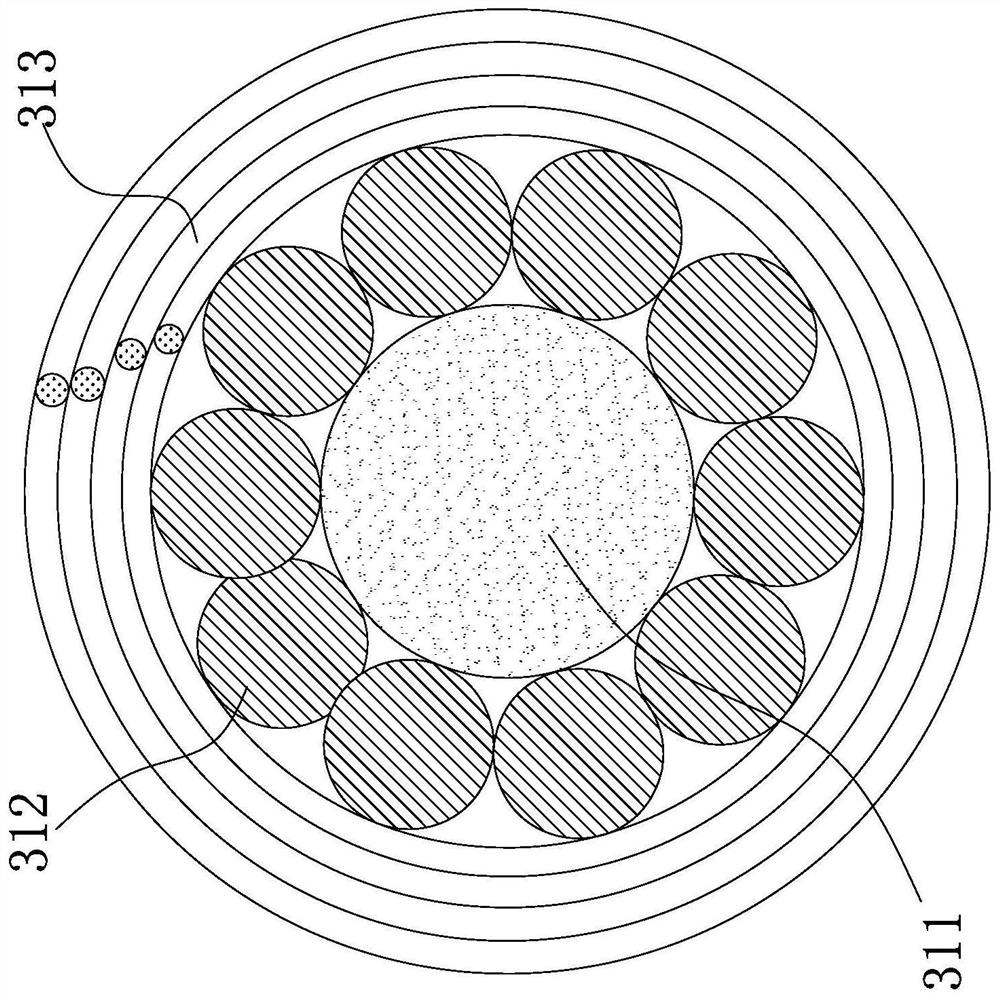

Ointment special for filling of optical cables

InactiveCN108219745APrevent oxidation failureLow viscosityOther chemical processesBuilding insulationsTarPolyacrylamide

The invention discloses an ointment special for filling of optical cables and belongs to the technical field of electronic information materials. The ointment special for filling of optical cables, developed by the invention, is prepared from base oil, a gelling agent, an antioxidant, isocyanate, a No.1 additive and a No.2 additive, wherein the No.1 additive is obtained by firstly stirring and mixing polyacrylamide and water, then sequentially adding an emulsifying agent and a cross-linking agent, performing stirring dispersion, performing thermal insulation standing and then performing high-speed stirring and mixing; the No.2 additive is obtained by mixing (N-guanyl) dodecyl acrylamide and polyethylene glycol phosphate, adding p-dichlorobenzene and ferrocene and performing constant-temperature stirring reaction; the base oil is prepared from dimethyl silicone oil, white oil and coalite tar; and the gelling agent is modified sepiolite. The prepared ointment special for filling of optical cables has excellent bubble stability, can effectively reduce the viscosity of a system, increases the air resistance of the inside of the system, and avoids external humidity and moisture from permeating into the optical cables so as to obviously enhance the oxidation resistance of the optical cables.

Owner:雷笑天

Asphalt laying device

InactiveCN110804926AEasy dischargeAvoid strandedRoads maintainenceStructural engineeringMechanical engineering

The invention discloses an asphalt laying device. The asphalt laying device comprises a top box body, wherein an open accommodating cavity is formed in the top box body; a top supporting block is fixedly arranged on the upper end surface of the top box body; an open accommodating cavity is formed in the top supporting block; an opposite side seat body fixed to the top box body is arranged on the right side of the top supporting block; an extension rod is fixedly arranged between the opposite side seat body and the end wall of the accommodating cavity; a dome is fixedly arranged on the right end surface of the top supporting block; and a shaking device used for loading asphalt and shaking out the asphalt is arranged on the upper sides of the top supporting block and the top box body. The asphalt laying device is simple in structure, adopts the design of various devices, realizes rapid discharge of the asphalt, avoids retention of the asphalt, enables the asphalt to be poured more efficiently, and can collect redundant falling asphalt to achieve the purpose of energy conservation.

Owner:齐嘉蕾

Butterfly valve body casting process

PendingCN112387938APrevent shrinkageFirmly connectedFoundry mouldsFoundry coresManufacturing engineeringMetallurgy

The invention relates to a butterfly valve body casting process which comprises the following steps that firstly, a mold drawing is designed according to a product drawing, a special mold is manufactured according to the mold drawing, and whether the mold is qualified or not is checked; magnetic bars are embedded into magnetic bar mounting grooves of core box split bodies, a circle of chilling blocks are installed in a core box main body, and sand is charged into the core box provided with the chilling blocks to form a sand core; the prepared sand core is matched with a template; molten iron melting and pouring are conducted; shakeout treatment is carried out; and inspecting and storing are performed, and casting of a butterfly valve body is completed. The casting process provided by the invention has the advantages that the chilling blocks can be conveniently fixed to the sand core through cooperation of the special mold, so that the chilling purpose can be conveniently achieved in the subsequent pouring molten iron cooling process, and the shrinkage phenomenon is effectively prevented.

Owner:NANTONG GUANFENG CASTING

Surface pattern spraying device for automobile door panel sealing strip

ActiveCN114700211AAvoid misalignmentAvoid distortionCleaning using toolsSpray boothsSurface patternEngineering

The invention provides a surface pattern spraying device for an automobile door panel sealing strip, and relates to the technical field of automobile sealing strip machining, the surface pattern spraying device comprises a base, four groups of right-angle plates are mounted on the base through bolts, and vertical plate bolts are mounted on the right-angle plates; the vertical plate is coupled with a brush roller; the support and the support bolt are mounted on a right-angle plate at the right end of the base; the fixing piece is installed at the left end of the vertical plate, and a partition plate is installed at the upper end of the fixing piece through a bolt; a supporting plate is installed on a right-angle plate at the left end of the base through bolts, and a shell is installed on the supporting plate through bolts. In the conveying process of the sealing strips, the first positioning wheel and the second positioning wheel can position the sealing strips, the sealing strips are prevented from being staggered, the positions of the sealing strips can be corrected through the two sets of positioning bearings, and the sealing strips are prevented from being twisted when being conveyed towards the interior of the shell. And the sealing strips can drive the brush rollers to rotate while being conveyed, so that dust on the sealing strips can be cleaned, and the situation that the sealing strips are stained with the dust to affect pattern forming is avoided.

Owner:佛山市顺德区杰润五金塑料有限公司

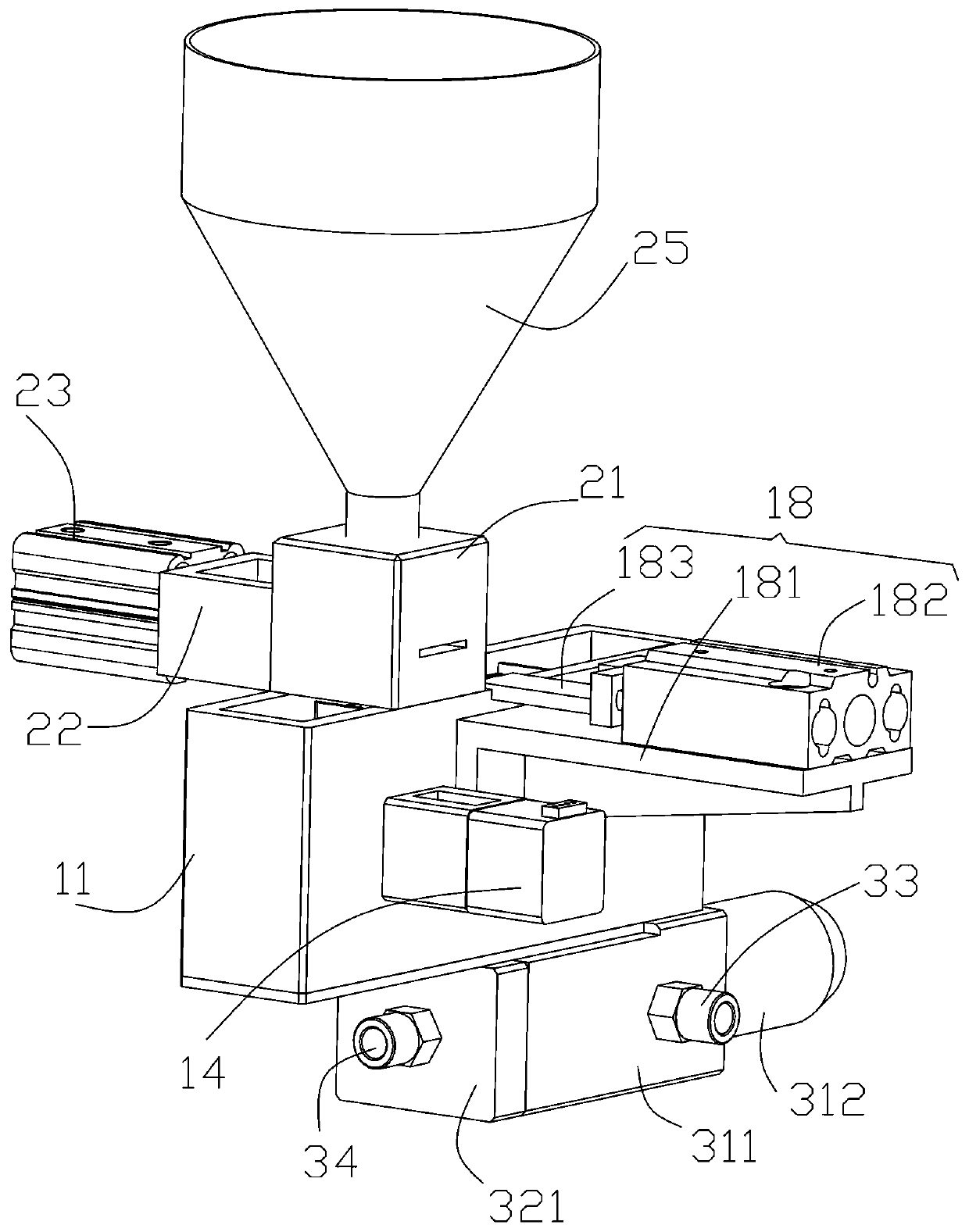

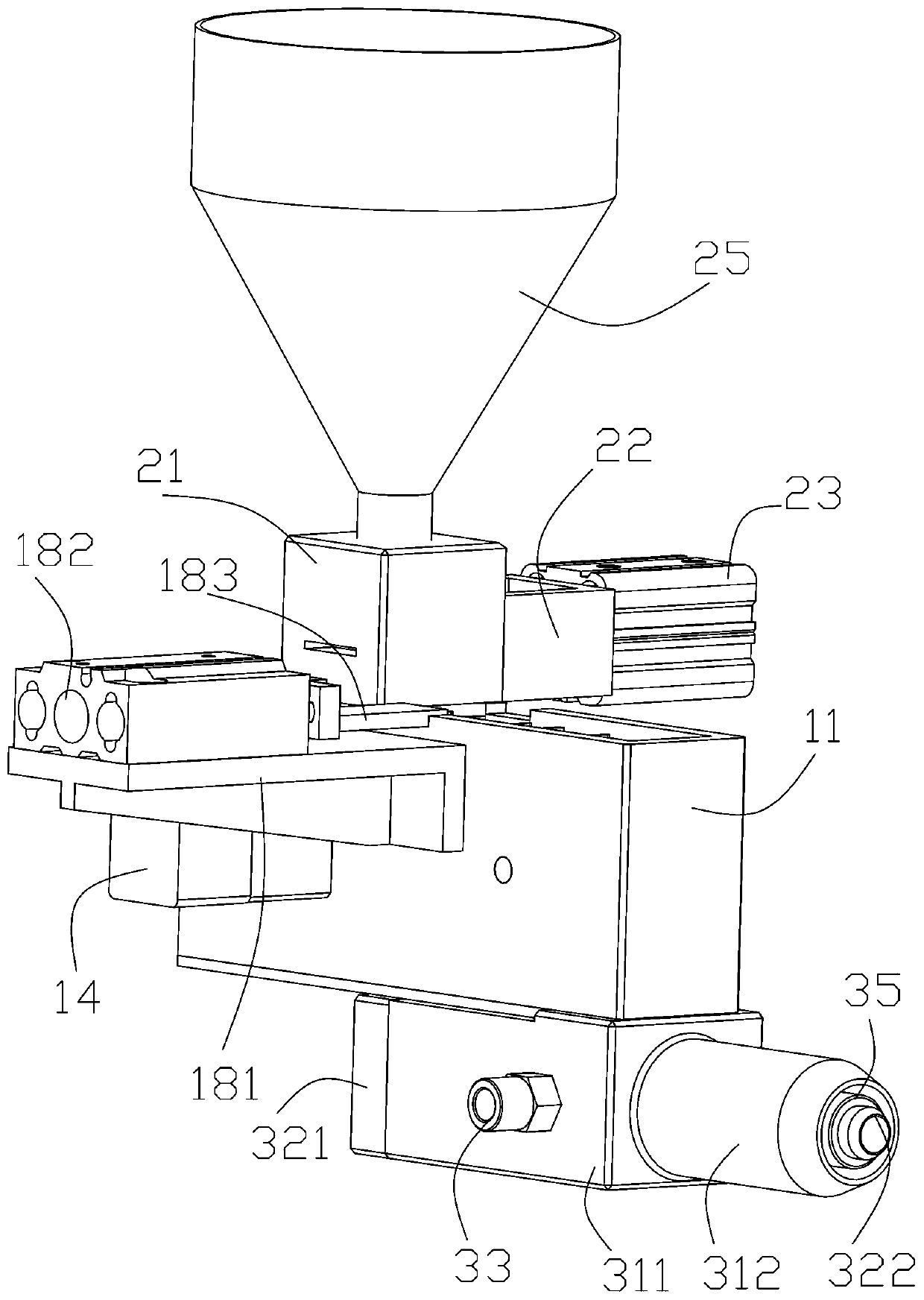

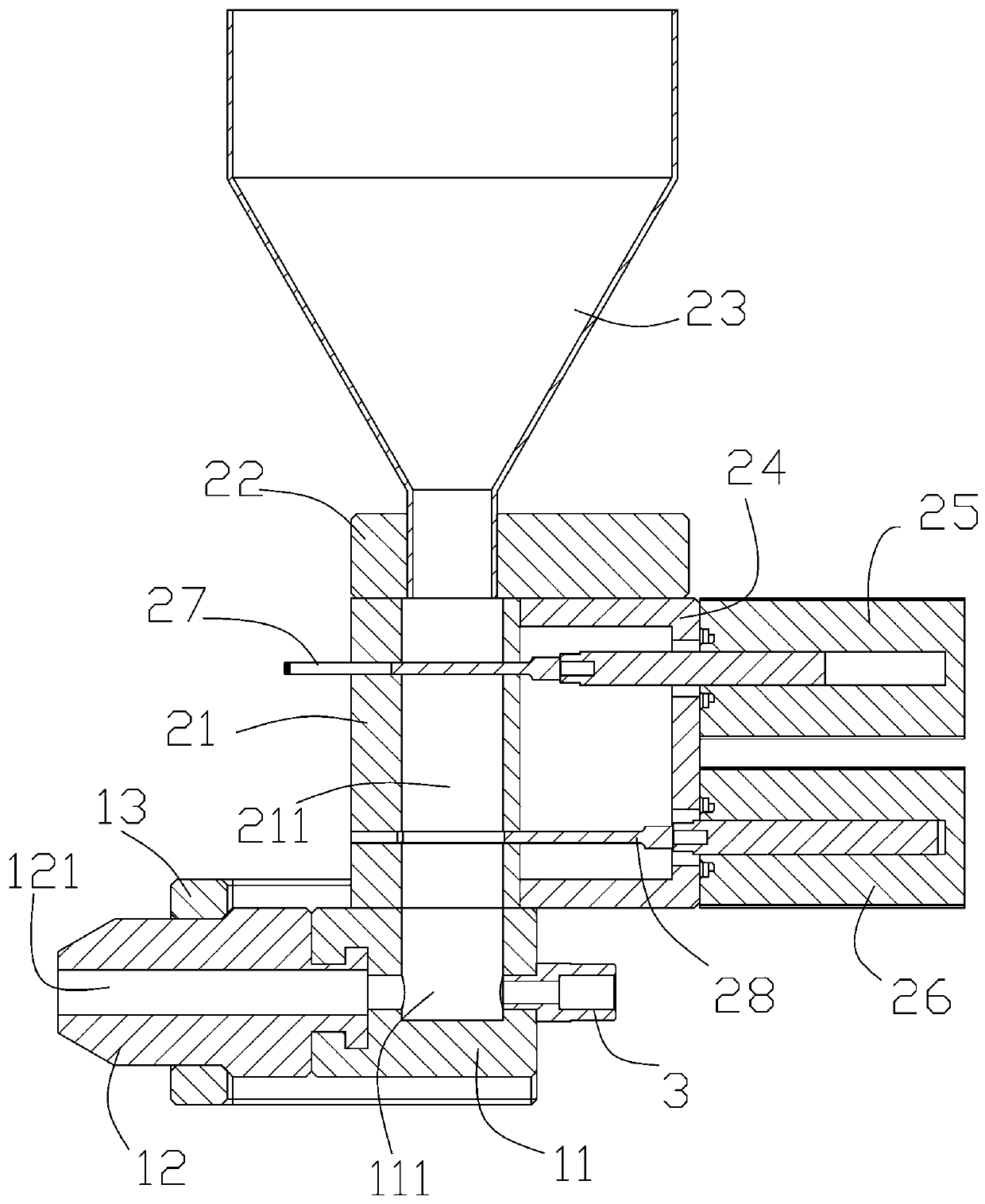

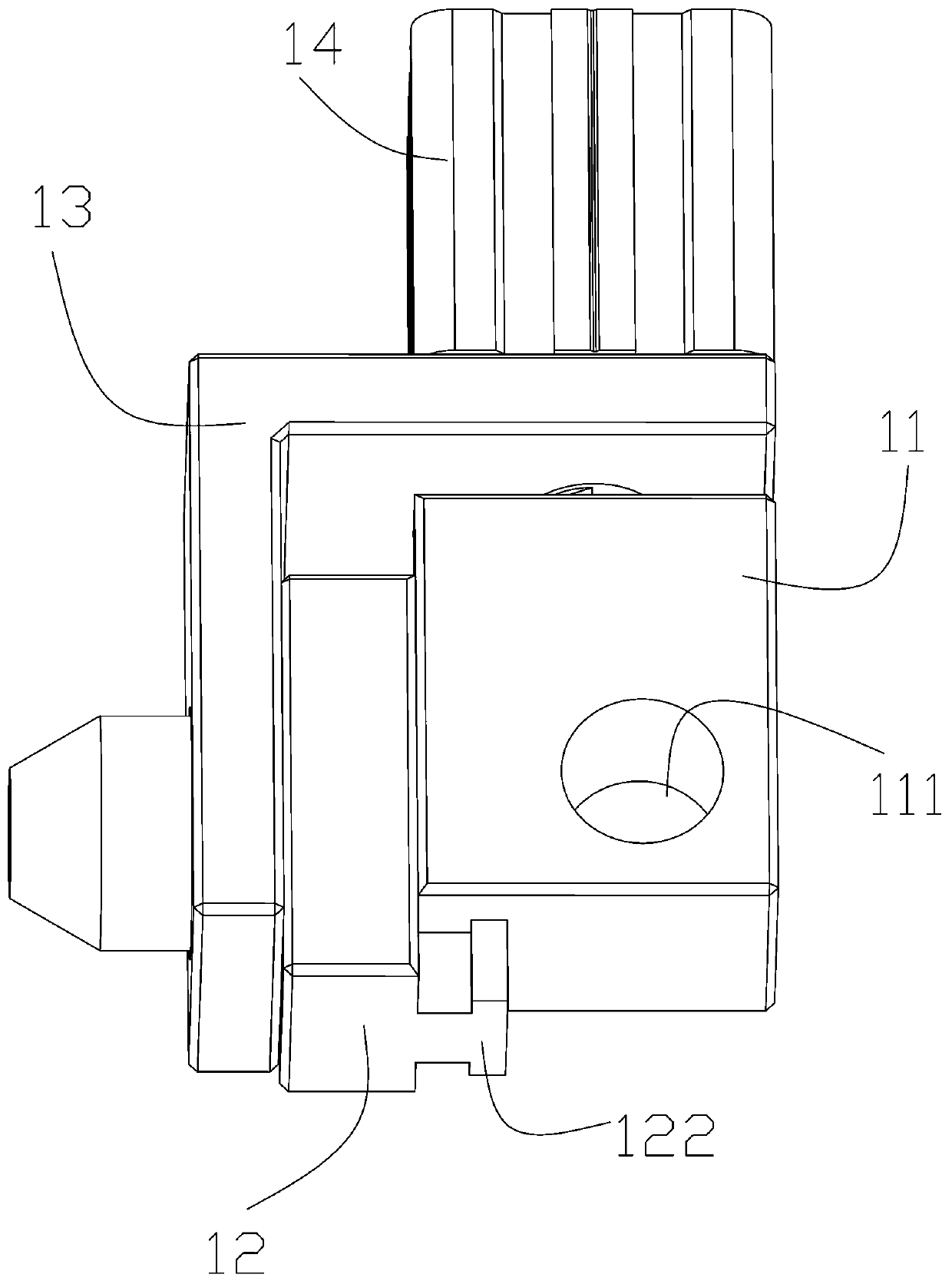

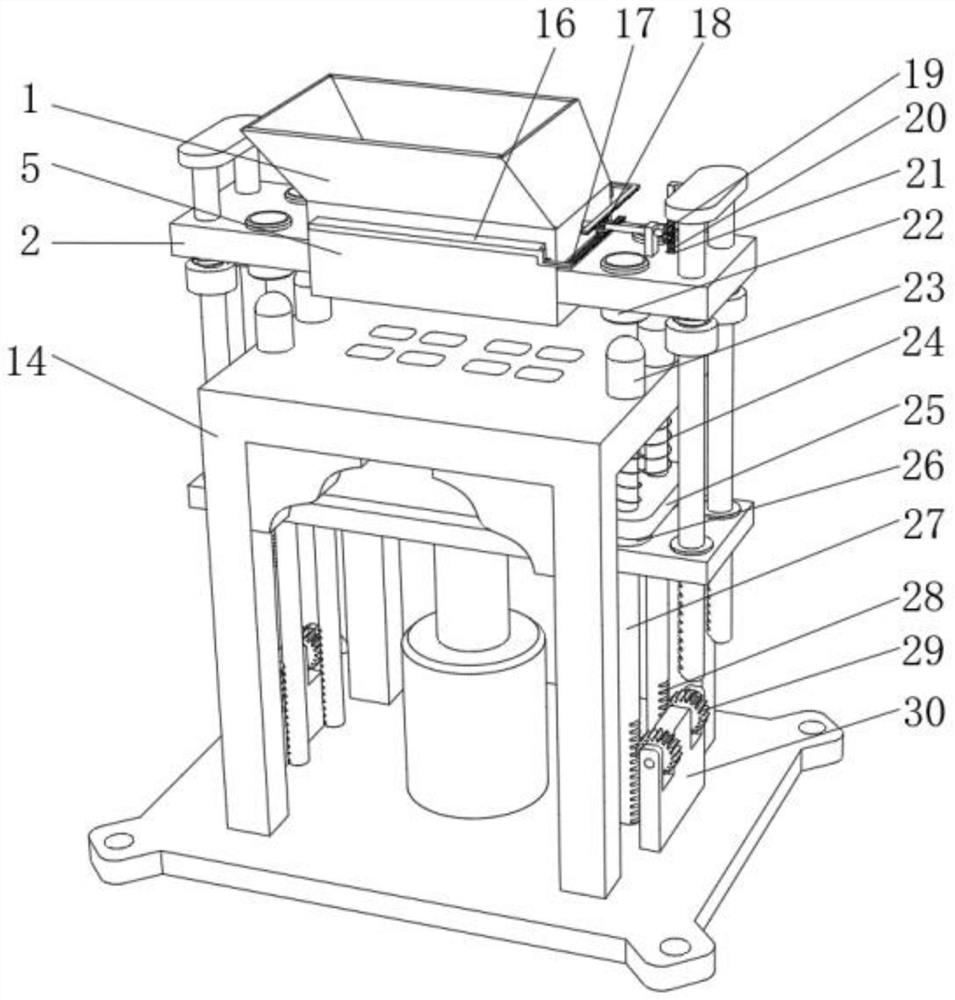

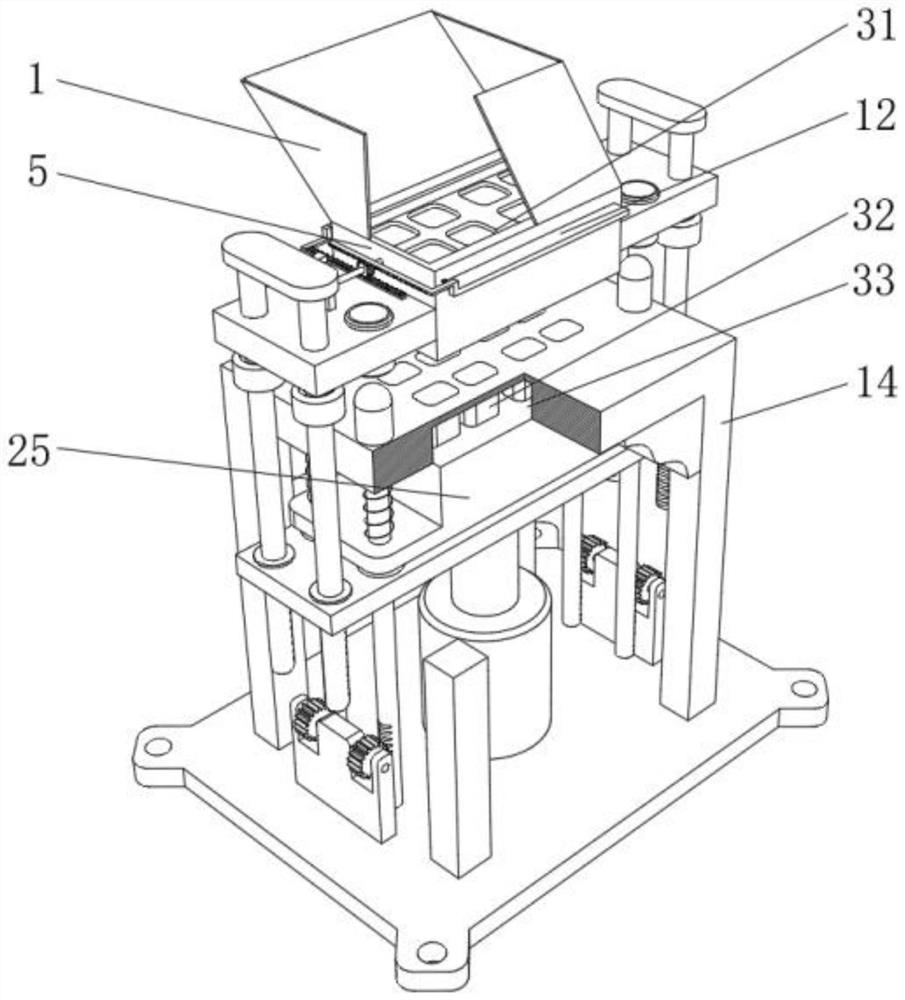

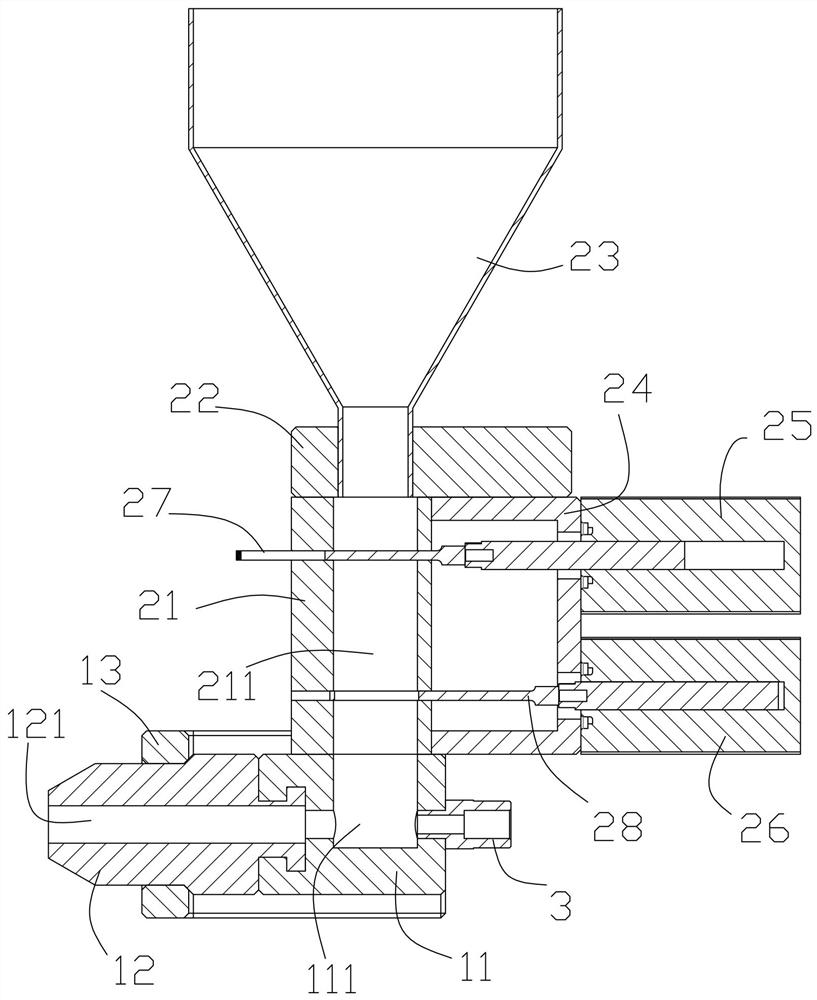

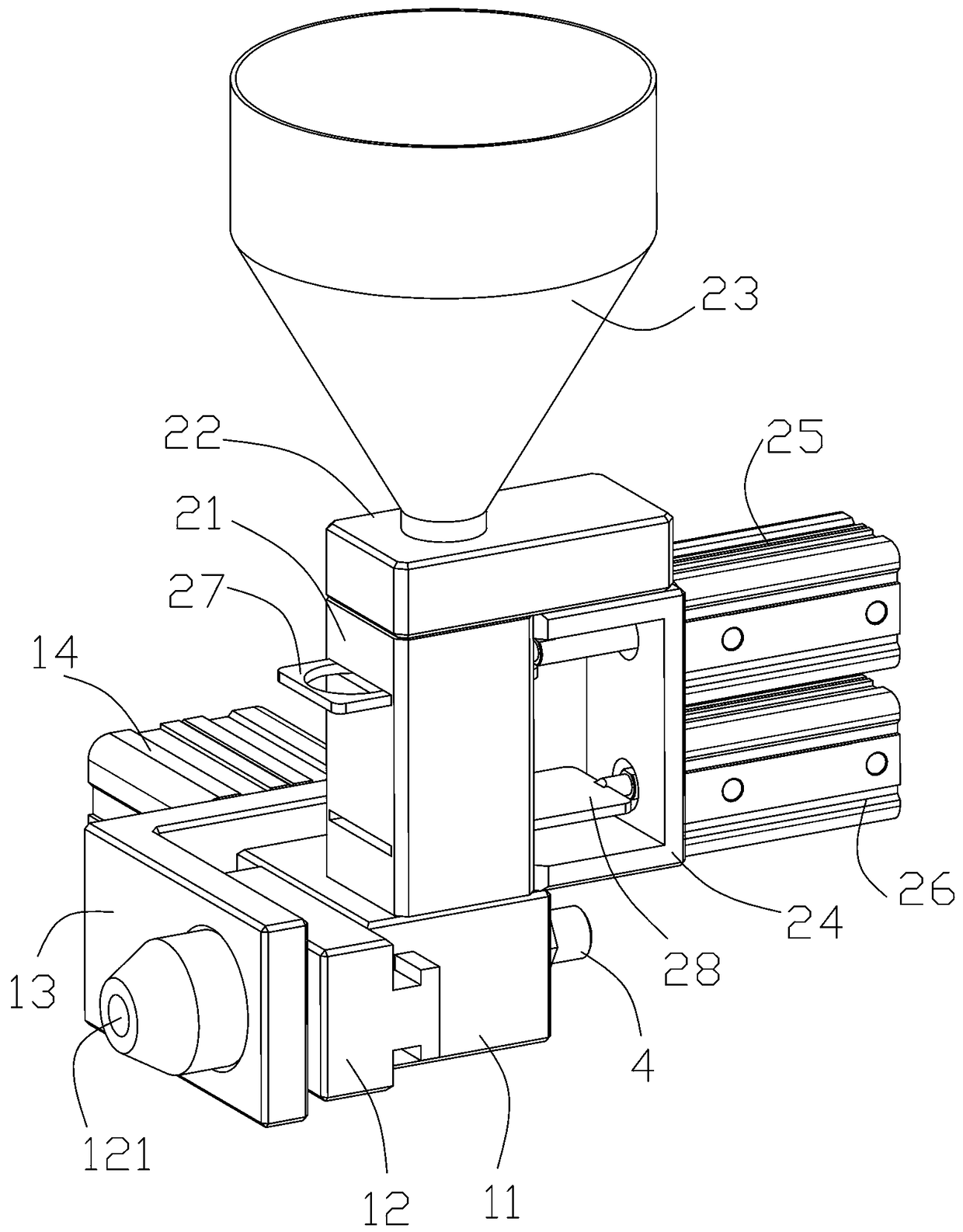

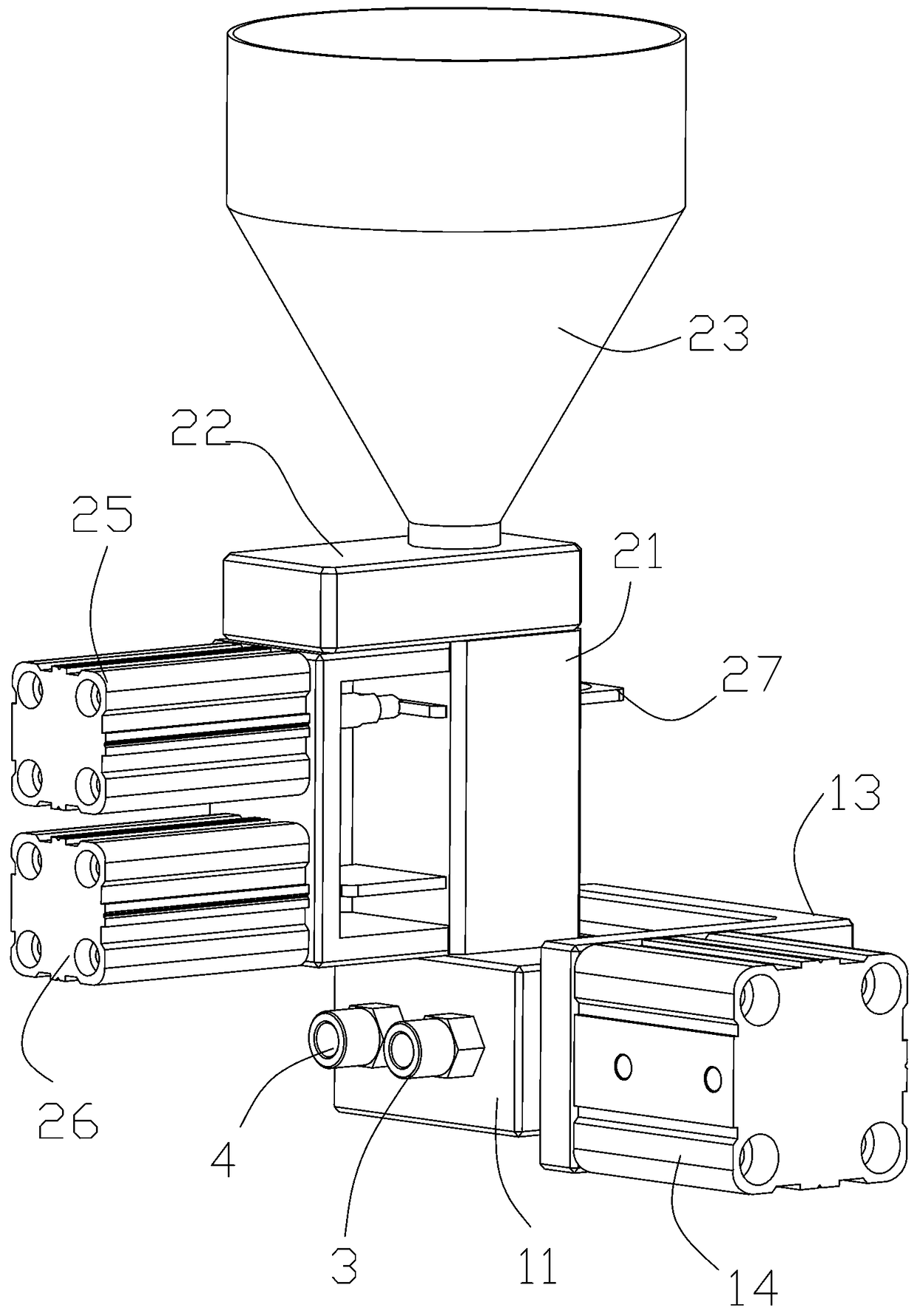

Slide block type device for powder spraying and wax injection

ActiveCN109693328ARealize quantitative deliveryImprove pass rateFoundry moulding apparatusWaxBlock type

The invention discloses a slide block type device for powder spraying and wax injection. The slide block type device for powder spraying and wax injection comprises a quantitative powder feeding part,a material injection part, a wax liquid injection nozzle and a vacuum interface, wherein the quantitative powder feeding part is used for quantitatively conveying powder for the material injection part, the material injection part comprises a feeding nozzle, a first air cylinder and a feeding sliding block, and the feeding nozzle is in sliding connection with the feeding sliding block; the wax liquid injection nozzle and the vacuum interface are connected with the feed sliding block; a first through hole and a second through hole are formed in the feeding sliding block; a material injection through hole is formed in the feeding nozzle; and under the drive of the first air cylinder, the first through hole communicates with the material injection through hole or the second through hole communicates with the material injection through hole. According to the slide block type device for powder spraying and wax injection, the first air cylinder drives the feeding sliding block to move to switch powder spraying and wax injection, so that the powder spraying and wax injection are integrally completed, and the working efficiency is greatly improved; and meanwhile, two baffle plates are arranged to realize quantitative conveying of powder under the drive of the air cylinders, so that powder spraying in a mould is uniform every time, the uneven manual powder spraying is prevented from influencing the forming of a wax mould, and the qualified rate of the wax mould forming is improved.

Owner:盐城恒远投资发展有限公司

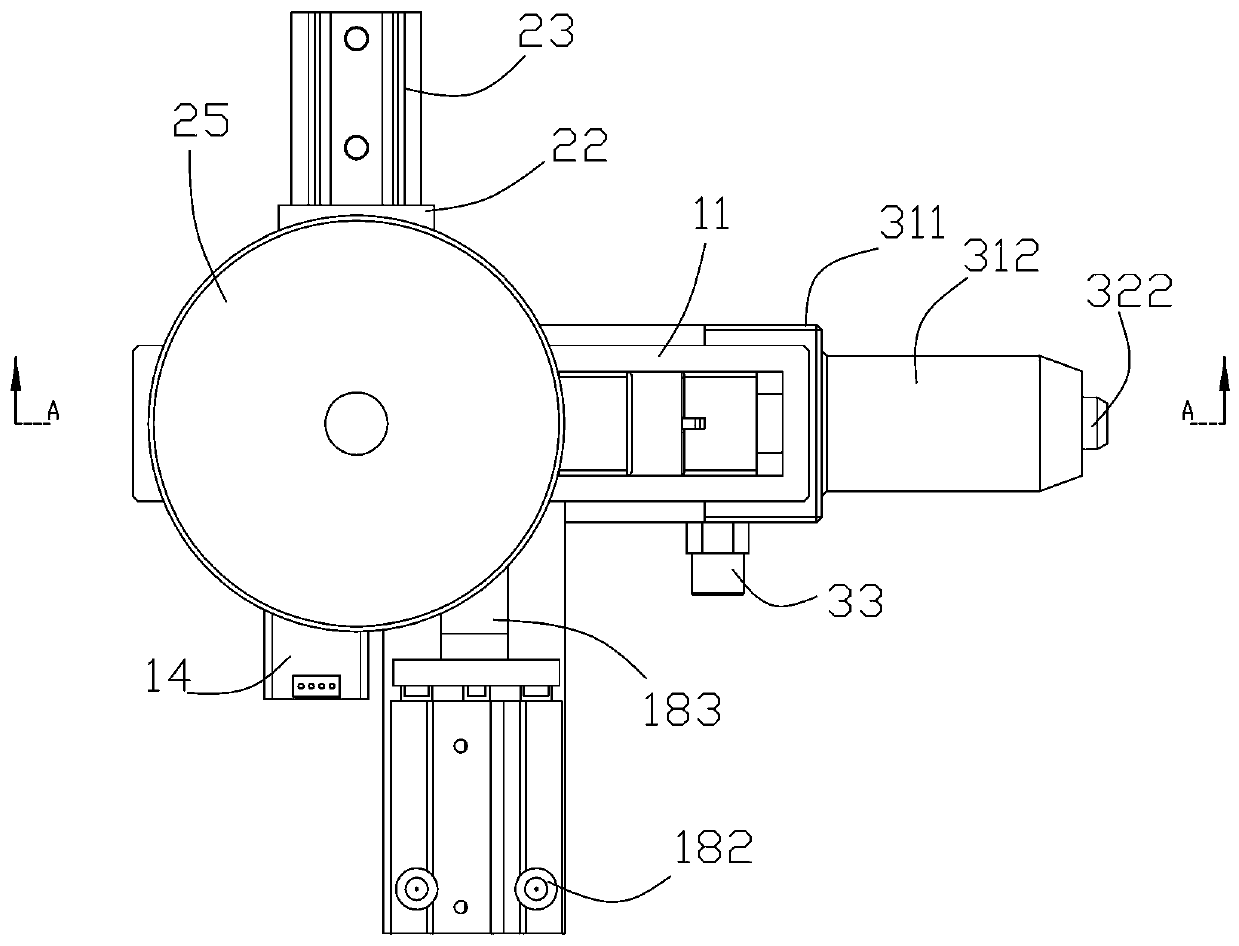

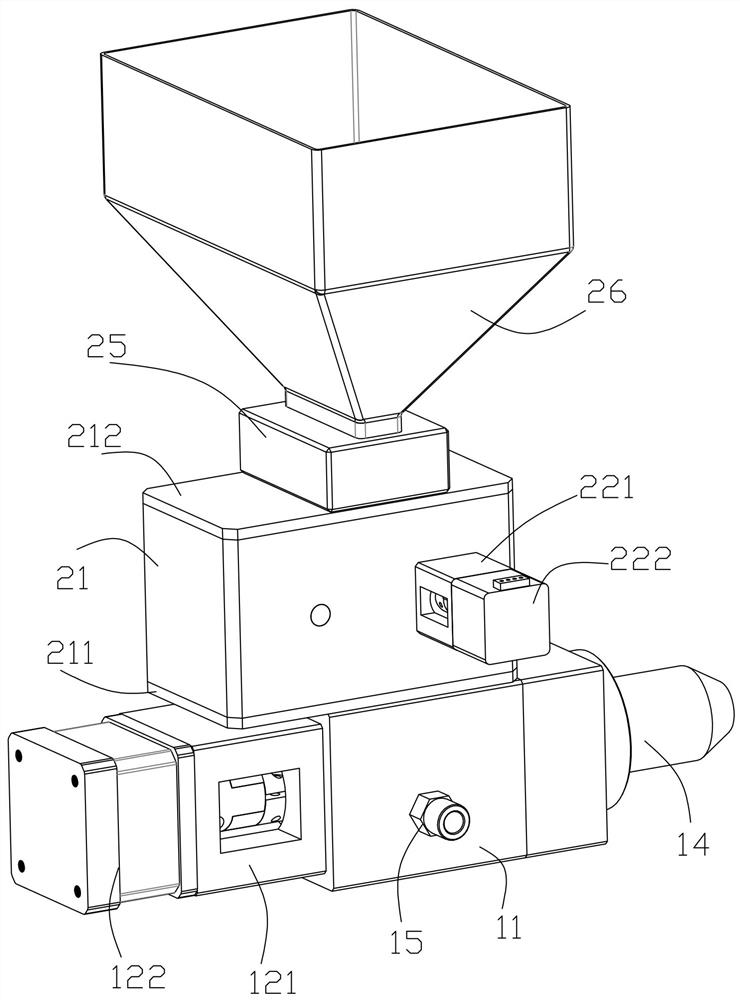

Rotary powder spraying and wax injection machine

The invention discloses a rotary powder spraying and wax injection complete machine, a rotary powder spray and wax injection complete machine, comprising a double-station workbench, on which two symmetrically arranged spray sprayers are arranged. Powder injection wax integrated structure; one end of the rotating feeding shaft is embedded in the feeding nozzle, the other end of the rotating feeding shaft is connected to the first driving device, and the rotating feeding shaft is provided with feeding holes at intervals, and the feeding hole and the feeding nozzle Connected, the feeding seat is equipped with a powder hole, wax hole and vacuum hole, the feeding seat is equipped with a wax liquid nozzle and a vacuum nozzle, the wax liquid nozzle is connected to the wax liquid hole, and the vacuum nozzle is connected to the vacuum hole. A driving device is used to drive the rotating feed shaft to rotate; the present invention realizes the vacuuming in the mould, the powder spraying process and the wax liquid injection process by driving the rotary feed shaft to rotate, and completes the production of the wax mold, thereby eliminating the need for manual powder spraying operations , greatly improving work efficiency.

Owner:磐安县阳安科技有限公司

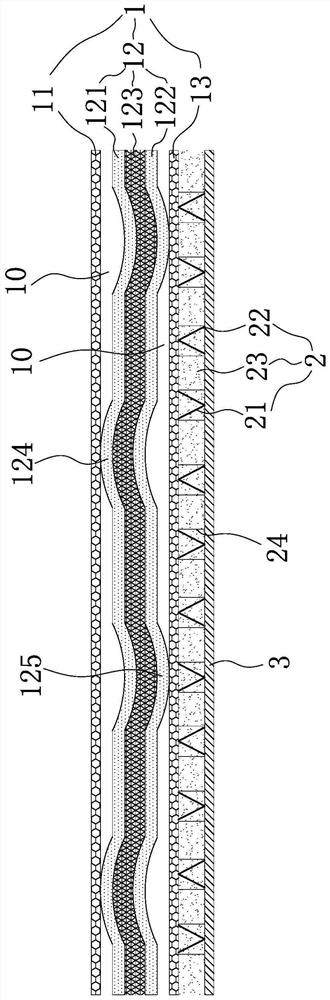

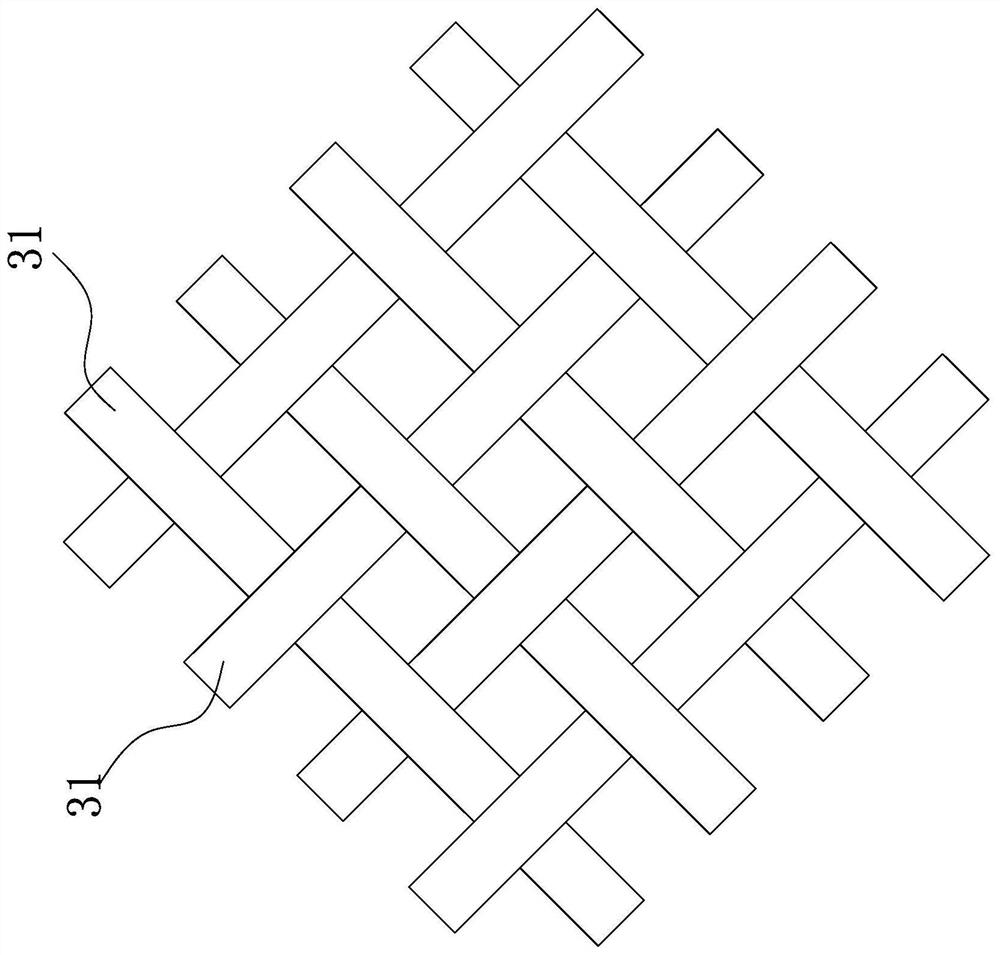

Antibacterial and anti-wrinkle knitted fabric

The invention relates to an antibacterial and anti-wrinkle knitted fabric. The fabric comprises an antibacterial layer, a connecting layer and an anti-wrinkle layer which are arranged in an up-down stacked mode. The antibacterial layer comprises an upper bacterium filtering layer, a middle bacterium filtering layer and a lower bacterium filtering layer. The middle bacterium filtering layer comprises an upper non-woven fabric layer, a lower non-woven fabric layer and a plurality of monofilaments arranged in a crossed mode. The top of the middle bacterium filtering layer protrudes upwards to form a plurality of cambered surface convex parts, and the bottom of the middle bacterium filtering layer sinks downwards to form a plurality of cambered surface concave parts. The connecting layer comprises a plurality of first connecting parts, a plurality of second connecting parts and a cotton layer arranged between the antibacterial layer and the anti-wrinkle layer. The anti-wrinkle layer is formed by interweaving a plurality of anti-wrinkle yarns. The invention relates to the field of fabrics. The antibacterial layer is of a three-layer antibacterial structure, the antibacterial effect is good, the comfortable sensation is high, a good anti-wrinkle effect is achieved, and the technical problem that an antibacterial knitted fabric is poor in antibacterial effect, poor in comfortable sensation and poor in anti-wrinkle effect is solved.

Owner:厦门鸿绮实业有限公司

A kind of natural biological matrix filter stick particle and its preparation method and application

ActiveCN110810918BImprove adsorption capacityGood removal effectTobacco smoke filtersGranulation by liquid drop formationBiotechnologyCellulose

The invention provides a natural biological matrix filter rod particle and its preparation method and application, which belong to the technical field of tobacco processing, and include the following components in parts by mass: the main ingredients include: 5-15 parts of smoke sweetener, tobacco 4-10 parts of air moisturizer, 2-5 parts of anti-oxidation and antibacterial agent, 0-3 parts of particle film-forming agent, 1-3 parts of smoke adsorbent, 0-3 parts of particle structure enhancer; auxiliary materials include: Stevia 0.005-0.01 part of glycoside, 0.02-0.05 part of sodium carboxymethylcellulose, 0.005-0.02 part of ethyl cellulose, 0-0.005 part of polyethylene glycol, 0.005 part of combined food-grade pigment; Coordination and comprehensive optimization, considering factors such as smoke release, adsorption, and flavor release, to provide suitable taste, smoke humidity, smoke temperature and aroma under the premise of ensuring that the particles have sufficient adsorption performance and reduce the generation of harmful substances. At the same time, it is convenient to produce filter rod particles which are convenient for processing.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

A steel tempering and forming device for iron and steel production

ActiveCN109396312BReduce labor intensityAvoid the Unhammered SituationForging hammersForging/hammering/pressing machinesUltimate tensile strengthMechanical engineering

The invention discloses a steel hammering forming device for steel production and belongs to the field of steel equipment. The steel hammering forming device comprises a workbench, a hammering mechanism, an overturning mechanism and an angle adjusting mechanism. The top of the workbench is provided with two mounting plates at intervals. A rotating shaft rotatably connected with the two mounting plates is arranged between the two mounting plates. A supporting plate sleeves the rotating shaft. A rotating assembly is arranged on the top of the supporting plate. The hammering mechanism comprises amaterial moving plate, a hammering assembly and a feeding assembly, wherein the feeding assembly is used for driving the material moving plate to move in the horizontal direction, and the hammering assembly is arranged on the top of the material moving plate. According to the steel hammering forming device, steel can be automatically overturned through the overturning mechanism, and manual overturning operation is not required, so that the labor intensity of workers is reduced; and the position of the hammering assembly can be adjusted through the feeding assembly and the angle adjusting mechanism, so that the hammering assembly can be used for hammering each corner of the steel.

Owner:广东立纬新材料科技有限公司

Coal gangue building block mold for road construction

PendingCN113650134AQuality variesImprove quality performanceMould auxillary partsFeeding arrangmentsHydraulic cylinderArchitectural engineering

The invention relates to the technical field of building block molds, and discloses a coal gangue building block mold for road construction. The mold comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with a mounting frame, the upper surface of the bottom plate is fixedly connected with a hydraulic cylinder, and one end of a hydraulic rod of the hydraulic cylinder is fixedly connected with a connecting plate; and the upper surface of the connecting plate is fixedly connected with two sliding frames, a fixing plate is movably connected between the two sliding frames, one side of the fixing plate is fixedly connected with an upper mold plate, and a first sliding groove and a second sliding groove are formed in the upper mold plate. According to the mold, through cooperative use of a cavity and a material leakage hole, the mold can automatically and uniformly feed materials, the quality effect of coal gangue building blocks is improved, meanwhile, redundant raw materials in the cavity can be ejected out through the material leakage hole by an ejection block through an ejection mechanism, the forming effect of the mold is improved, the moving position of the fixing plate can be limited through a first fixing ring, and the limiting effect of the mold is improved.

Owner:徐淑华

Making method of delicacies rice noodles

The invention provides a making method of delicacies rice noodles. The method comprises the following steps: soaking rice for 8-12h, fishing out the rice, placing the rice in a water filtration container at the bottom for airing until water does not drop, smashing the rice, adding the rice into wild mushroom powder, uniformly stirring the mixture and feeding the mixture into a rice noodles machine for making the delicacies rice noodles, wherein the ratio of the rice and the wild mushroom powder is that 0.15-0.25kg of wild mushroom powder is added into every 25kg rice before soaking; the wild mushroom powder is obtained by smashing dried wild mushrooms into powder. The delicacies rice noodles provided by the invention are abundant in nutrition, contain nutrition of various peculiar wild mushrooms in Yunnan and have rich mushroom fragrance. Through adding different wild mushroom powder into the rice noodles, the rice noodles have different tastes and fragrances; the rice noodles maintain the elastic, soft and smooth tastes of the traditional rice noodles and have unique fragrances of various wild mushrooms.

Owner:云南普莉姐农特产品有限公司

A slider type device for powder spraying and wax injection

Owner:盐城恒远投资发展有限公司

Slide block type integrated machine used for powder spraying and wax injecting

The invention discloses a slide block type integrated machine used for powder spraying and wax injecting. The slide block type integrated machine comprises an integrated machine rack, wherein a wax mould storage drawer is arranged on the integrated machine rack; a wax injecting and powder injecting integrated structure is mounted on the top of the integrated machine rack; a first through hole anda second through hole are formed in a feeding slide block; a feeding nozzle is equipped with an injecting through hole; and under driving of a first gas cylinder, the first through hole communicates with the injecting through hole or the second through hole communicates with the injecting through hole. According to the slide block type integrated machine disclosed by the invention, the first gas cylinder drives the feeding slide block to move to switch powder spraying and wax injecting, so that powder spraying and wax injecting are accomplished in an integrated mode, and therefore, working efficiency is greatly improved; and meanwhile, two material blocking plates are arranged for realizing quantitative conveying of powder under driving of the gas cylinder, and powder is sprayed uniformlyin a mould every time, so that moulding of a wax mould is prevented from being affected by uneven manual powder spraying, and a qualification rate of wax mould moulding is increased.

Owner:泗县智来机械科技有限公司

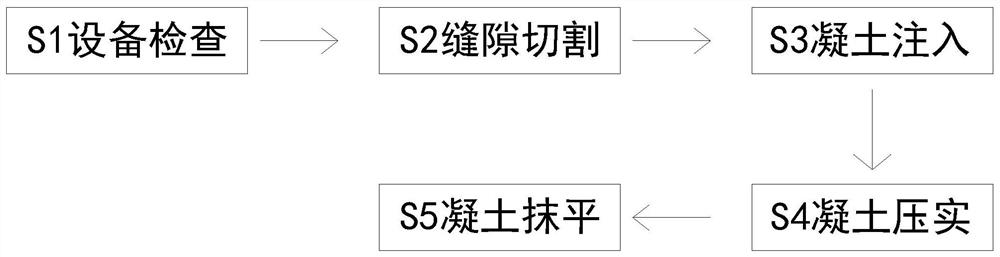

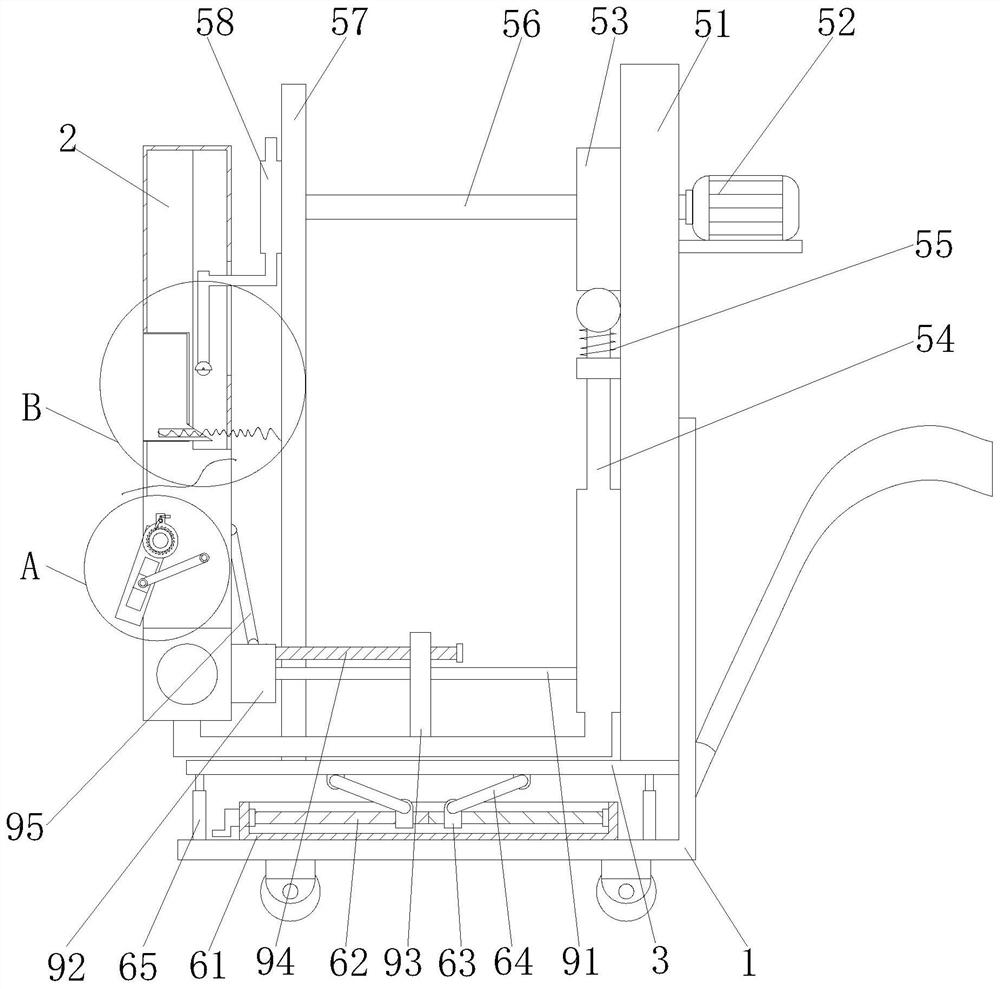

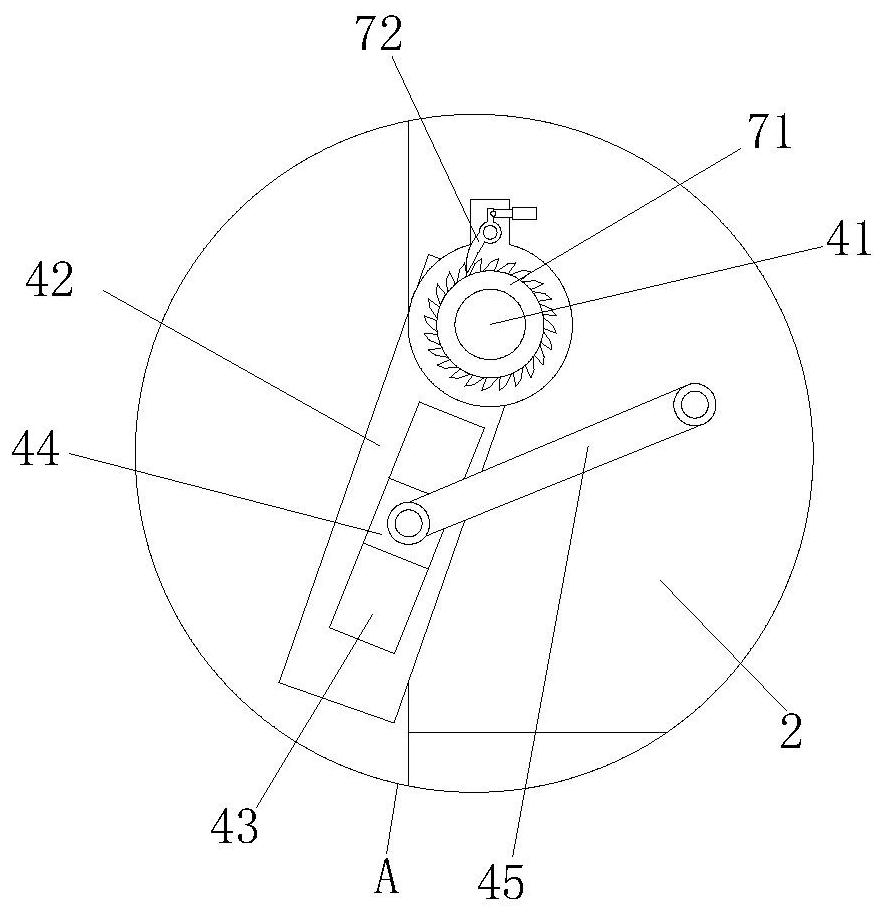

Concrete pier repairing construction method

InactiveCN112502054AImplement bufferingImpact moldingBridge structural detailsBridge erection/assemblyArchitectural engineeringElectric machinery

The invention relates to a concrete pier repair construction method which uses compaction trowelling equipment. The compaction trowelling equipment comprises a base, a trowelling plate, a lifting plate, a leading-in device, a compaction device and a lifting device. A direction adjusting rotating rod is rotated to drive a guide plate to rotate outwards so that the guide plate inclines to the bottomend of a notch, concrete is conveniently injected along the guide plate, meanwhile, the situation that the concrete flows out after being injected into the notch is avoided, a connecting shaft of a driving motor rotates, then a cam rotates to drive a sliding frame to slide up and down, and therefore the trowelling plate moves up and down to carry out trowelling on the concrete, and meanwhile, anextrusion rod ascends and descends to drive a compaction plate to contract to achieve trowelling on the concrete with the trowelling plate; and the compaction plate is matched with the trowelling plate to compact the concrete, meanwhile, a first elastic plate buffers the concrete through the spring in a buffer block, compaction buffering of the concrete is achieved, and the situation that formingof the concrete is affected due to an excessive stress is avoided.

Owner:南京珊秀科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com