Two-time compounding addition method for improving coercivity of permanent magnetic strontium ferrite

A technology of composite addition and strontium ferrite, applied in the direction of inorganic material magnetism, can solve the problems of cost increase, complicated preparation process, time-consuming and laborious, etc., and achieve the effect of low price and improved intrinsic coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A secondary composite addition method for improving the coercive force of permanent magnet strontium ferrite, the specific steps are as follows: on the basis of the primary calcined material of strontium ferrite, perform secondary composite addition, and the secondary composite additive is first pretreated , the mass percentage of the total weight is 1%, and the pretreated secondary compound additive includes 0.2% CaCO 3 , 0.15% Al 2 o 3 , 0.5%Cr 2 o 3 , 0.1%H 3 BO 3 , 0.05% SiO 2 ·nH 2 O. Add dispersant C 6 h 14 o 6 , HCOOH and Ca(C 6 h 11 o 7 )2 The weight percent of the mixture is 7%. Secondary ball milling is carried out in the ball mill, the steel balls used are bearing steel balls with a diameter of 5.50-7.50mm, and the ball milling time is ≥18h; the mass percentage of material, ball and water is 1:(13-16):(1.6-1.9 ), the slurry particle size after secondary ball milling is ≤0.9μm. Transfer the slurry from the second ball mill to a dehydrator for d...

Embodiment 2

[0033] Compared with Example 1, the weight percent of the secondary composite additive is 3%, and includes 1.0% CaCO in the secondary composite additive after pretreatment 3 , 0.15% Al 2 o 3 , 0.6%Cr 2 o 3 , 0.25%H 3 BO 3 ,, 0.2% SiO 2 ·nH 2 O, 0.3% MgO, 0.2% Mn 2 o 3 , 0.3% NaCl.

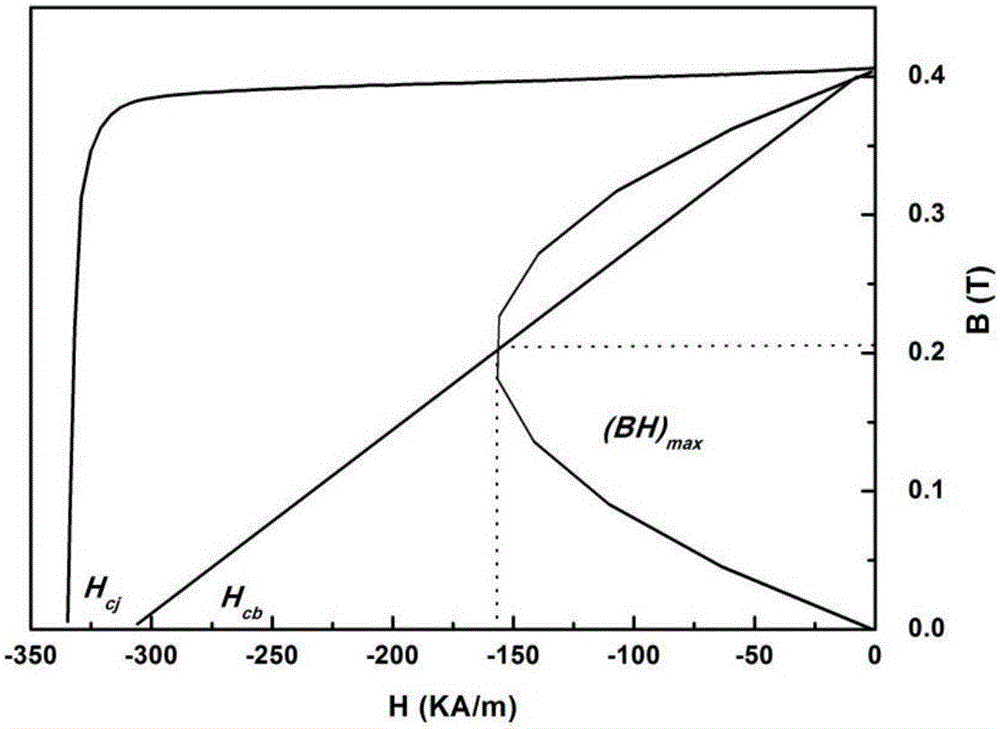

[0034] figure 1 It is the demagnetization curve figure of the present embodiment, as can be seen from this figure, the magnetic performance of embodiment 2 is: B r =412.7mT,H cb =310.6kA / m, H cj =338.6kA / m, (BH) max =33.9kJ / m 3 .

Embodiment 3

[0036] Compared with Example 1, the percentage of the secondary composite additive is 5%, including 1.0% CaCO in the secondary composite additive after pretreatment 3 , 0.4% Al 2 o 3 , 1.0%Cr 2 o 3 , 0.6%H 3 BO 3 ,, 0.6% SiO 2 ·nH 2 O, 0.4% MgO, 0.5% Mn 2 o 3 , 0.5% KCl. The magnetic property of embodiment 3 is: B r =390.8mT,H cb =300.3kA / m, H cj =319.2kA / m, (BH) max =30.4kJ / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com