Surface pattern spraying device for automobile door panel sealing strip

A technology for spraying devices and sealing strips, applied in spraying devices, cleaning methods using tools, spray booths, etc., can solve problems such as blurred patterns, affecting the aesthetics of patterns, and dust on the sealing strips, and achieve the effect of preventing misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

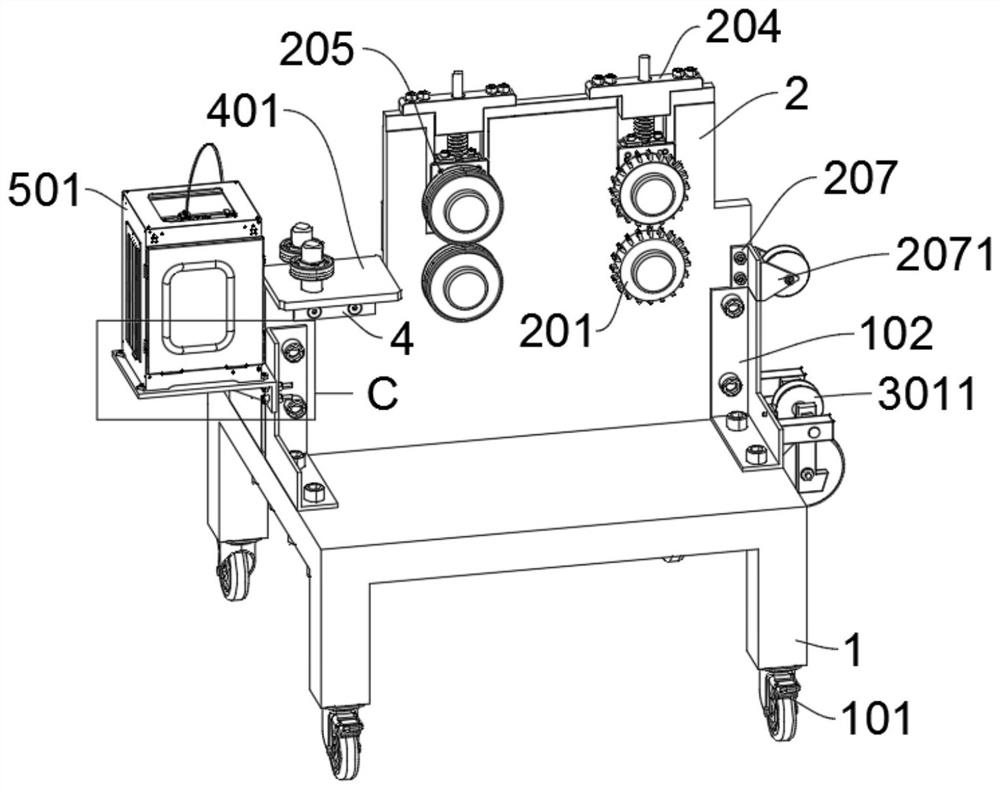

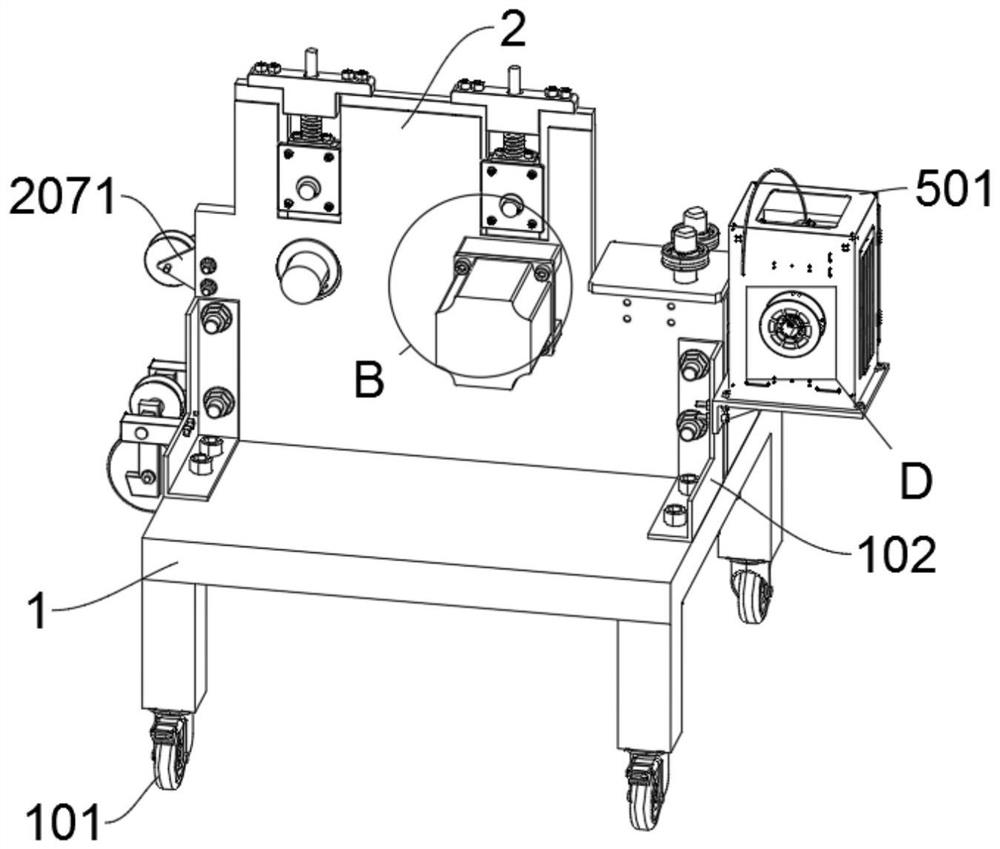

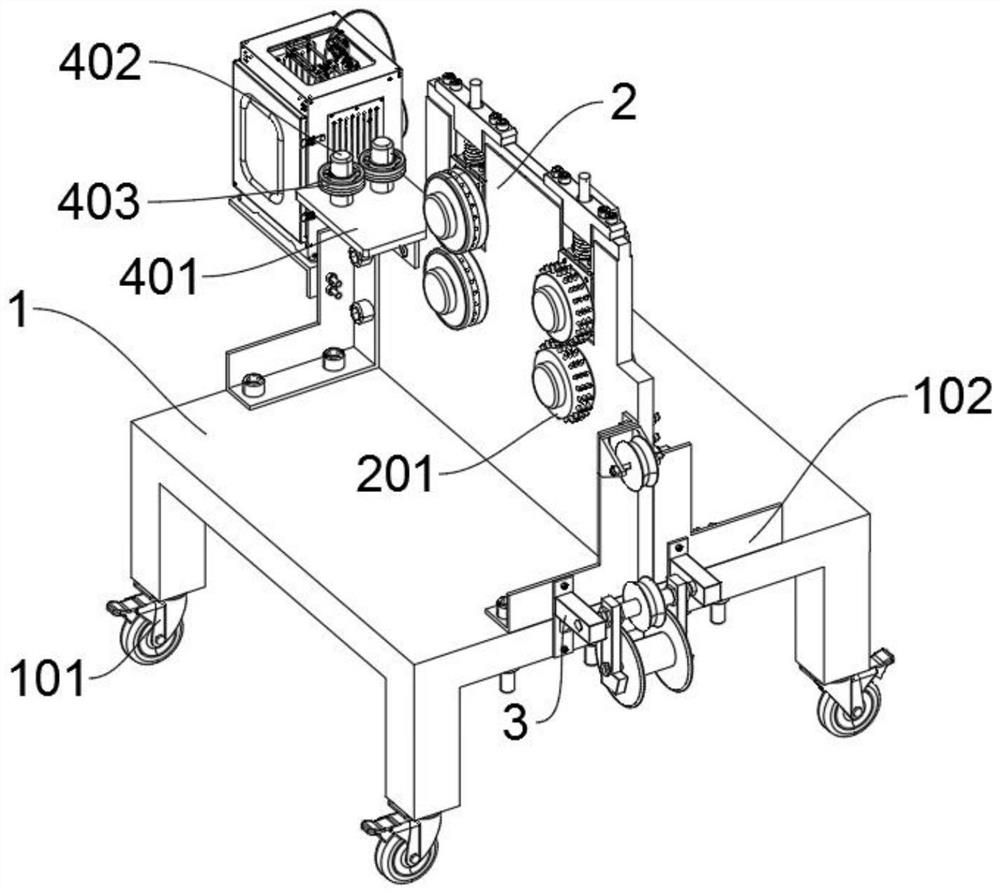

[0044] Example: please refer to Figure 1 to Figure 18 :

[0045] The present invention proposes a surface pattern spraying device for an automobile door panel sealing strip, comprising: a base 1, four groups of moving wheels 101 are installed on the lower end of the base 1, and a vertical plate 2 is installed on the upper end of the base 1, and bolts on the base 1 Four sets of right-angle plates 102 are installed, and the vertical plate 2 is bolted on the right-angle plate 102; the vertical plate 2 is axially connected with a brush roller 201, and the vertical plate 2 is provided with two through-slot structures. The slider 202, the upper end of the slider 202 is provided with a groove structure, a vertical rod 203 is installed in the groove structure, the lower end of the vertical rod 203 is provided with a clamping slot, a fixing plate 2031 is installed in the clamping slot, and the fixing plate 2031 is bolted. The upper end of the slider 202, and the vertical rod 203 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com