Crispy shredded cake making method

A production method and hand-grabbing cake technology are applied in the field of crispy hand-grasping cakes, which can solve the problems that the hand-grasping cakes are of average quality and cannot reach the golden brown and crispy outer layer, etc., so as to avoid excessively high oiling temperature and reduce the oil temperature difference , to ensure the effect of crispness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

[0027] A method for making crispy finger cakes, comprising the following steps:

[0028] S1 Kneading noodles: Pour 15kg of salt, 7kg of monosodium glutamate, and 27kg of sugar into 400kg of water to prepare a seasoning solution, pour 500kg of flour into the dough mixer, pour the prepared seasoning solution and 150kg of edible oil into the dough mixer, When stirring in the dough mixer, first adjust the stirring speed to 25r / min and the stirring time to 2min, then adjust the stirring speed to 55r / min and the stirring time to 6min.

[0029] S2 Proofing: After the dough is mixed, measure the temperature of the dough in the dough mixer. When the temperature of the dough is 30°C, take out the dough and put it in the proofing zone at 25°C for 12 minutes.

[0030] S3 chemical oil: 600kg of shortening is poured into the carburetor barrel and heated and stirred to melt. After melting to 70%, stop heating and continue to stir. The mixed oil is delivered to the replenishing tank for stan...

Embodiment A2

[0037]The difference from Example A1 is that in the dough kneading process of S1: pour 15kg of salt, 7kg of monosodium glutamate, and 27kg of sugar into 400kg of water to prepare a seasoning solution, pour 500kg of flour into the dough kneading machine, and successively mix the prepared seasoning Pour the solution and 70kg of edible oil into the dough mixer. When stirring the dough mixer, first adjust the stirring speed to 25r / min and the stirring time to 2min, and then adjust the stirring speed to 55r / min and the stirring time to 6min. Other steps are carried out in the same way Example A1.

Embodiment A3

[0039] The difference from Example A1 is that in the dough kneading process of S1: pour 15kg of salt, 7kg of monosodium glutamate, and 27kg of sugar into 400kg of water to prepare a seasoning solution, pour 500kg of flour into the dough kneading machine, and successively mix the prepared seasoning Solution and 250kg edible oil are poured into the dough mixer, first adjust the stirring speed 25r / min, and the stirring time is 2min, then adjust the stirring speed again to be 55r / min, and the stirring time is 6min, other steps are the same as embodiment A1.

[0040]

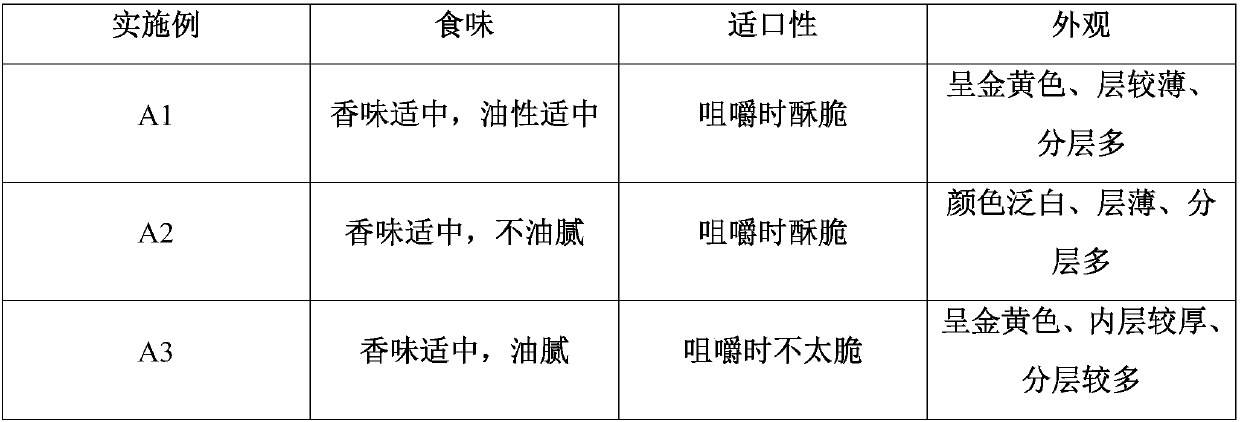

[0041] It can be seen from Examples A1, A2, and A3 that edible oil will affect the taste, crispness and number of layers of the hand-cooked cakes. If the content of edible oil is too high, it will not only affect the taste of the hand-picked cakes, but also affect its crispness .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com