Ointment special for filling of optical cables

A technology of ointment and optical cable, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of moisture and water penetration corrosion, poor aging resistance, poor fluidity, etc., to avoid oxidation failure, reduce viscosity, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

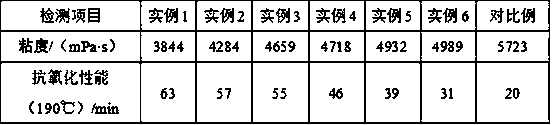

Examples

example 1

[0030]According to the mass ratio of 1:12, mix sepiolite and hydrochloric acid with a mass fraction of 20% and pour it into a beaker, and move the beaker into a digital speed measuring and constant temperature magnetic stirrer. Soak for 4 hours, then filter to obtain a filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain a dry filter cake. Then transfer the obtained dry filter cake to a tube furnace, and then heat-preserve and roast for 3 hours at a temperature of 240°C, then cool to room temperature with the furnace, and discharge the material to obtain modified sepiolite, which is the gelling agent; by weight Counting, take 15 parts of polyacrylamide, 5 parts of emulsifier, 6 parts of crosslinking agent, 50 parts of water in turn, first mix polyacrylamide and water into the reaction kettle, stir and mix at 600r / min for 45min, and then Add em...

example 2

[0032] According to the mass ratio of 1:12, mix sepiolite and hydrochloric acid with a mass fraction of 20% and pour it into a beaker, and move the beaker into a digital speed measuring and constant temperature magnetic stirrer. Soak for 4 hours, then filter to obtain a filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain a dry filter cake. Then the obtained dry filter cake is transferred to a tube furnace, and at a temperature of 240° C., after heat preservation and roasting for 3 hours, it is cooled to room temperature with the furnace, and discharged to obtain modified sepiolite, which is a gelling agent; -Amidino) lauryl acrylamide and polyethylene glycol phosphate are mixed in a mass ratio of 4:1 and poured into a three-necked flask, and 0.4 times the mass of polyethylene glycol phosphate is added to the three-necked flask in sequence. Be...

example 3

[0034] According to the mass ratio of 1:12, mix sepiolite and hydrochloric acid with a mass fraction of 20% and pour it into a beaker, and move the beaker into a digital speed measuring and constant temperature magnetic stirrer. Soak for 4 hours, then filter to obtain a filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain a dry filter cake. Then transfer the obtained dry filter cake to a tube furnace, and then heat-preserve and roast for 3 hours at a temperature of 240°C, then cool to room temperature with the furnace, and discharge the material to obtain modified sepiolite, which is the gelling agent; by weight Counting, take 15 parts of polyacrylamide, 5 parts of emulsifier, 6 parts of crosslinking agent, 50 parts of water in turn, first mix polyacrylamide and water into the reaction kettle, stir and mix at 600r / min for 45min, and then Add e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com