Patents

Literature

83results about How to "Affect integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

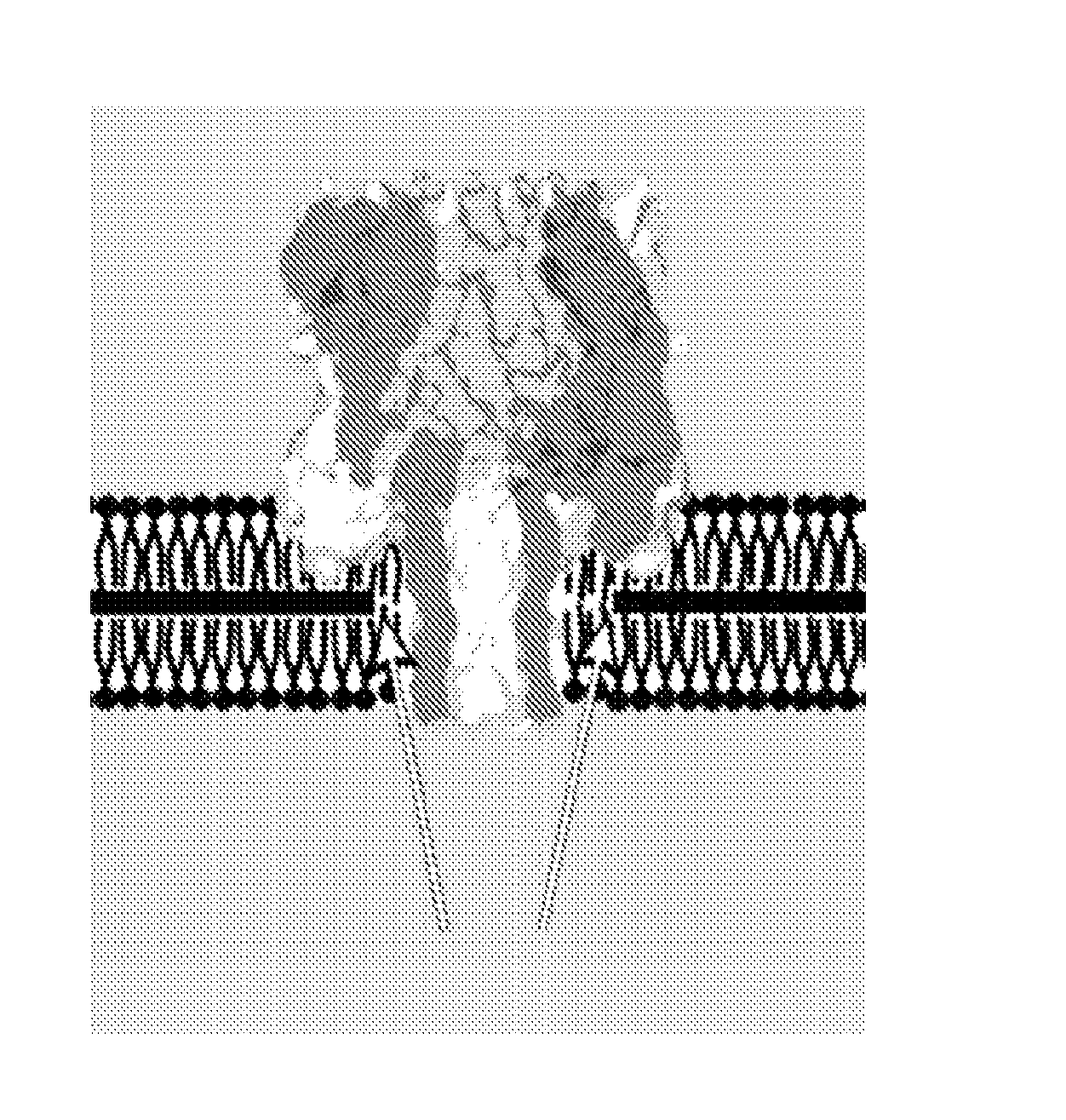

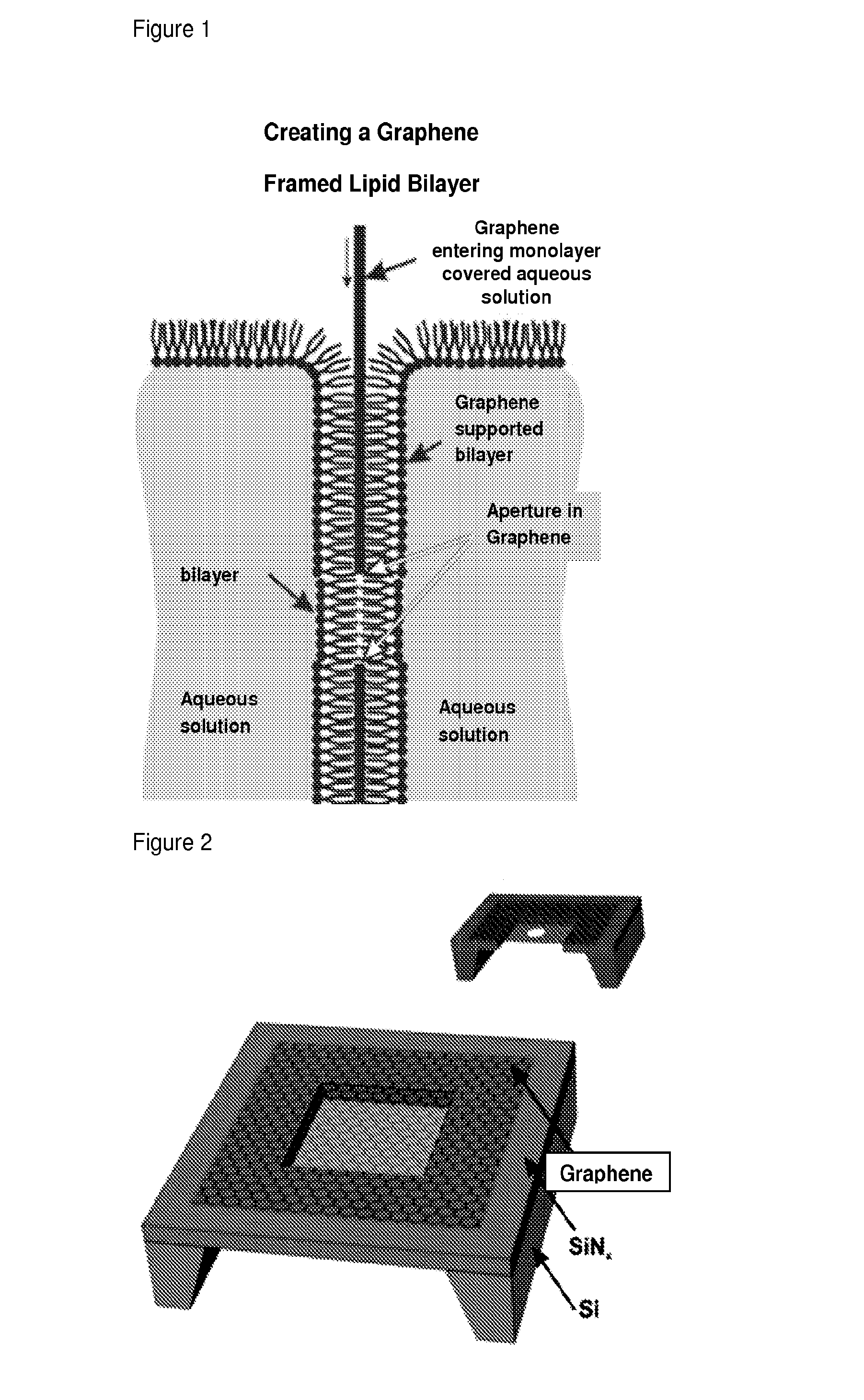

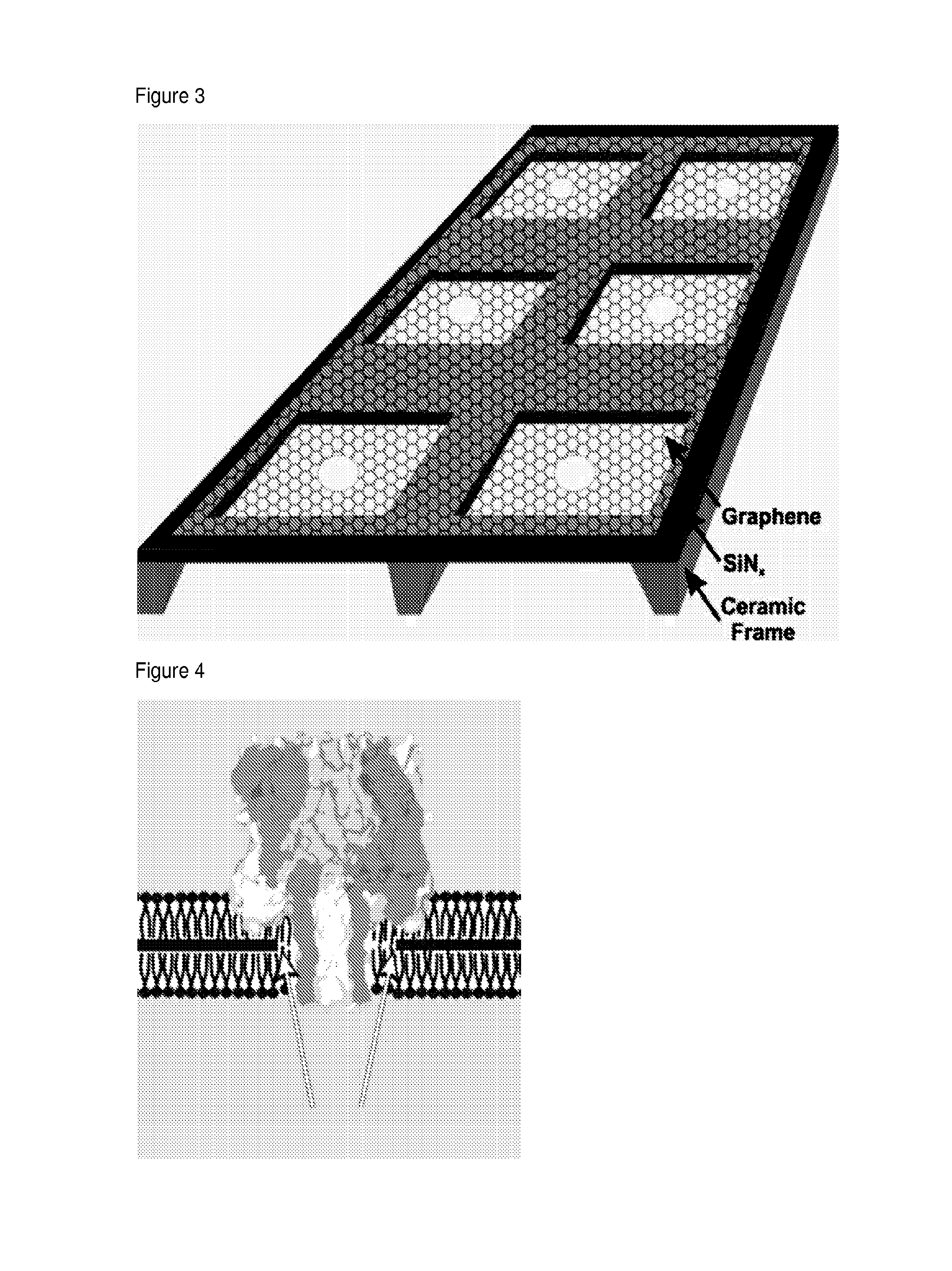

Nanopore device with graphene supported artificial lipid membrane

ActiveUS20130146480A1Rate of movement can be alteredAffect integrityImmobilised enzymesSludge treatmentMembrane protein interactionsCvd graphene

The invention features the use of graphene, a one atom thick planar sheet of bonded carbon atoms, in the formation of artificial lipid membranes. The invention also features the use of these membranes to detect the properties of polymers (e.g., the sequence of a nucleic acid) and identify transmembrane protein-interacting compounds.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

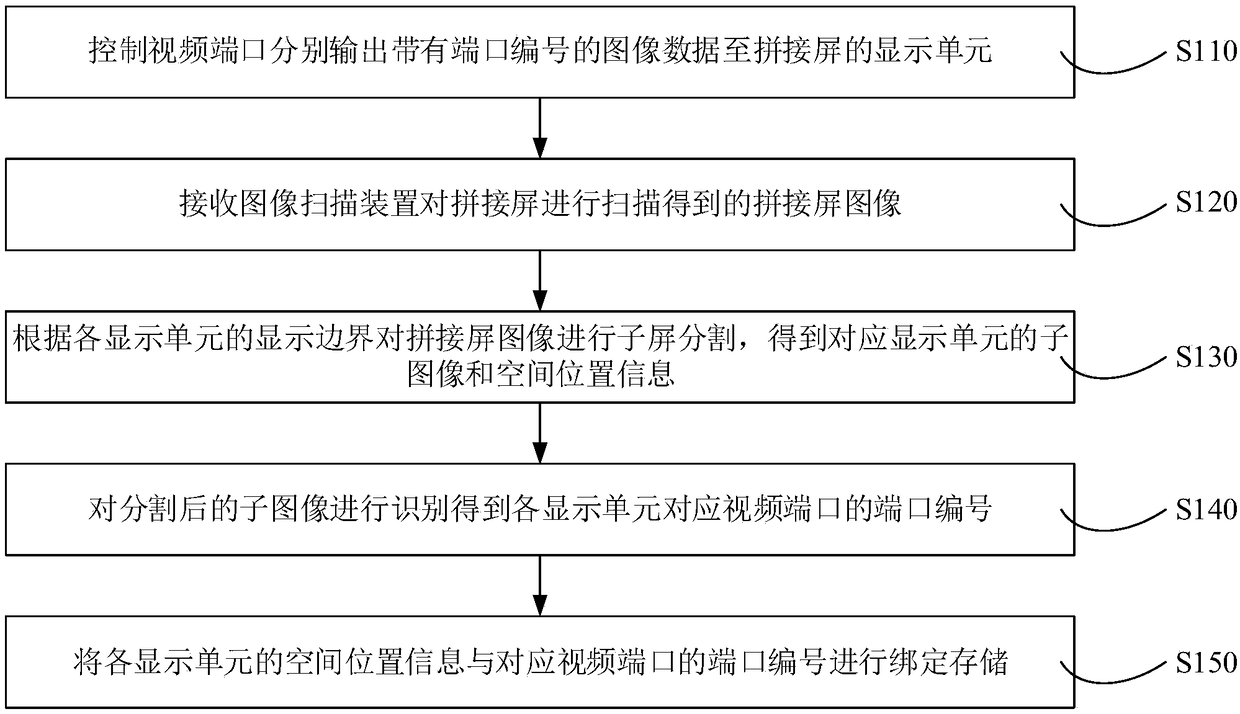

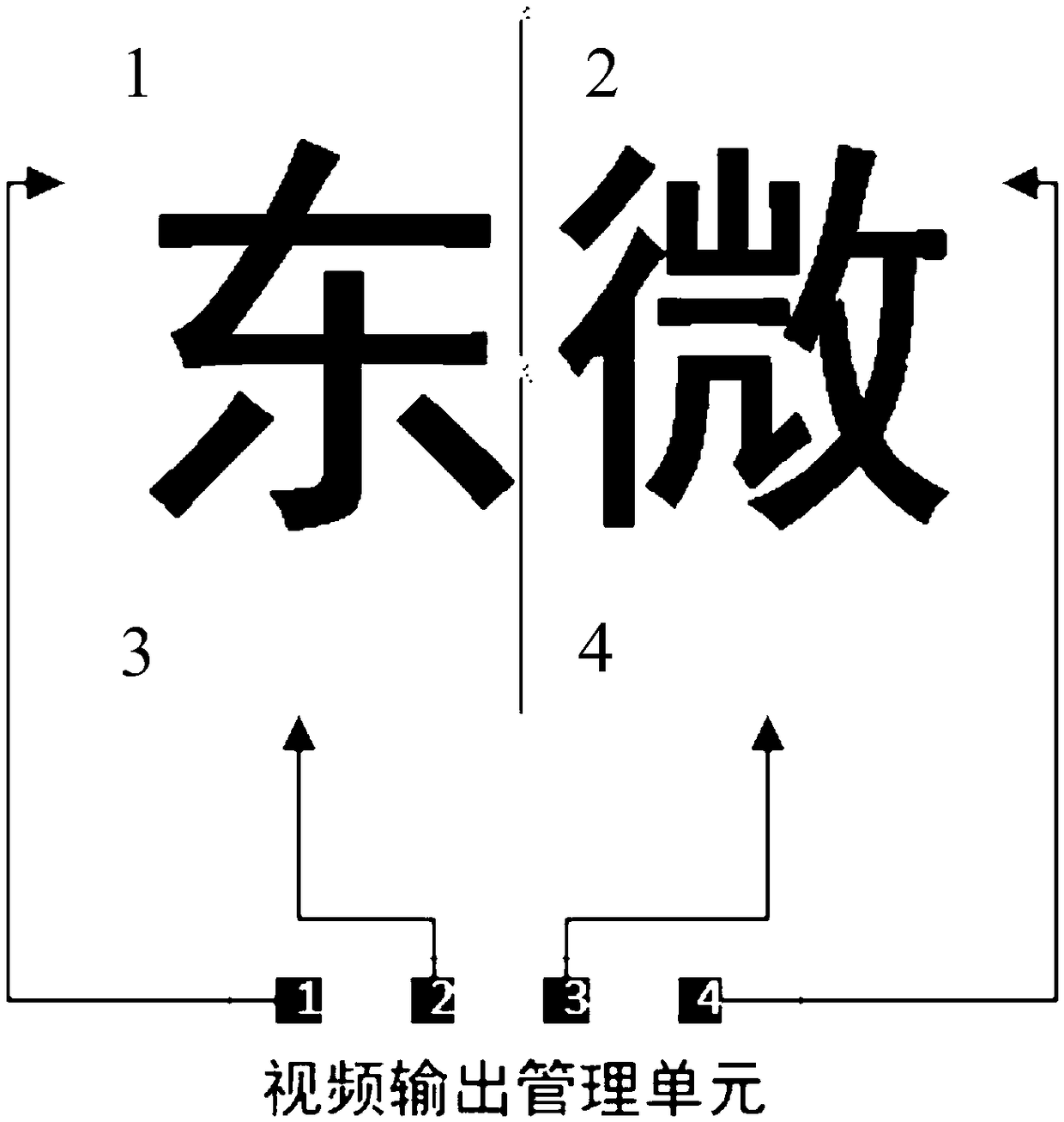

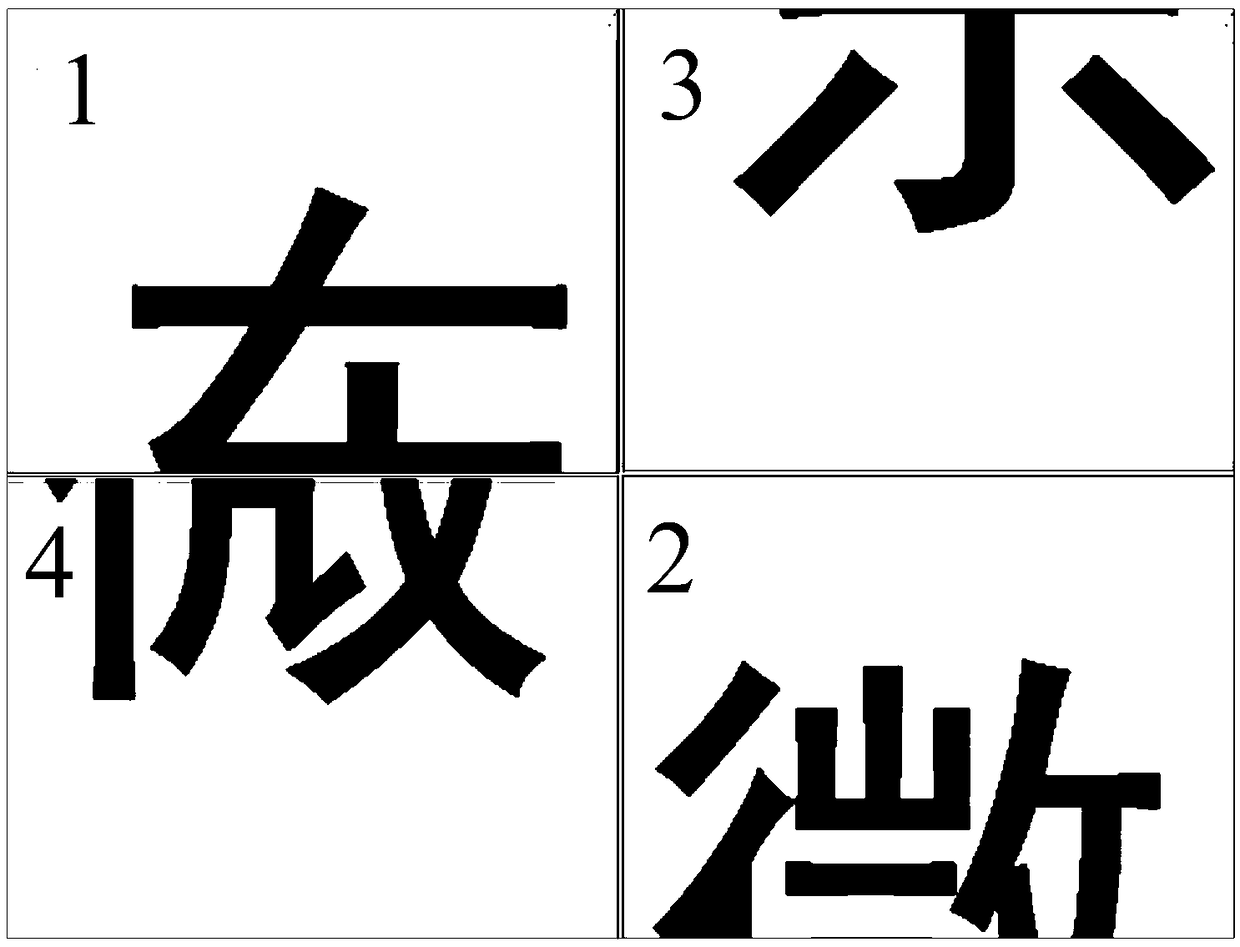

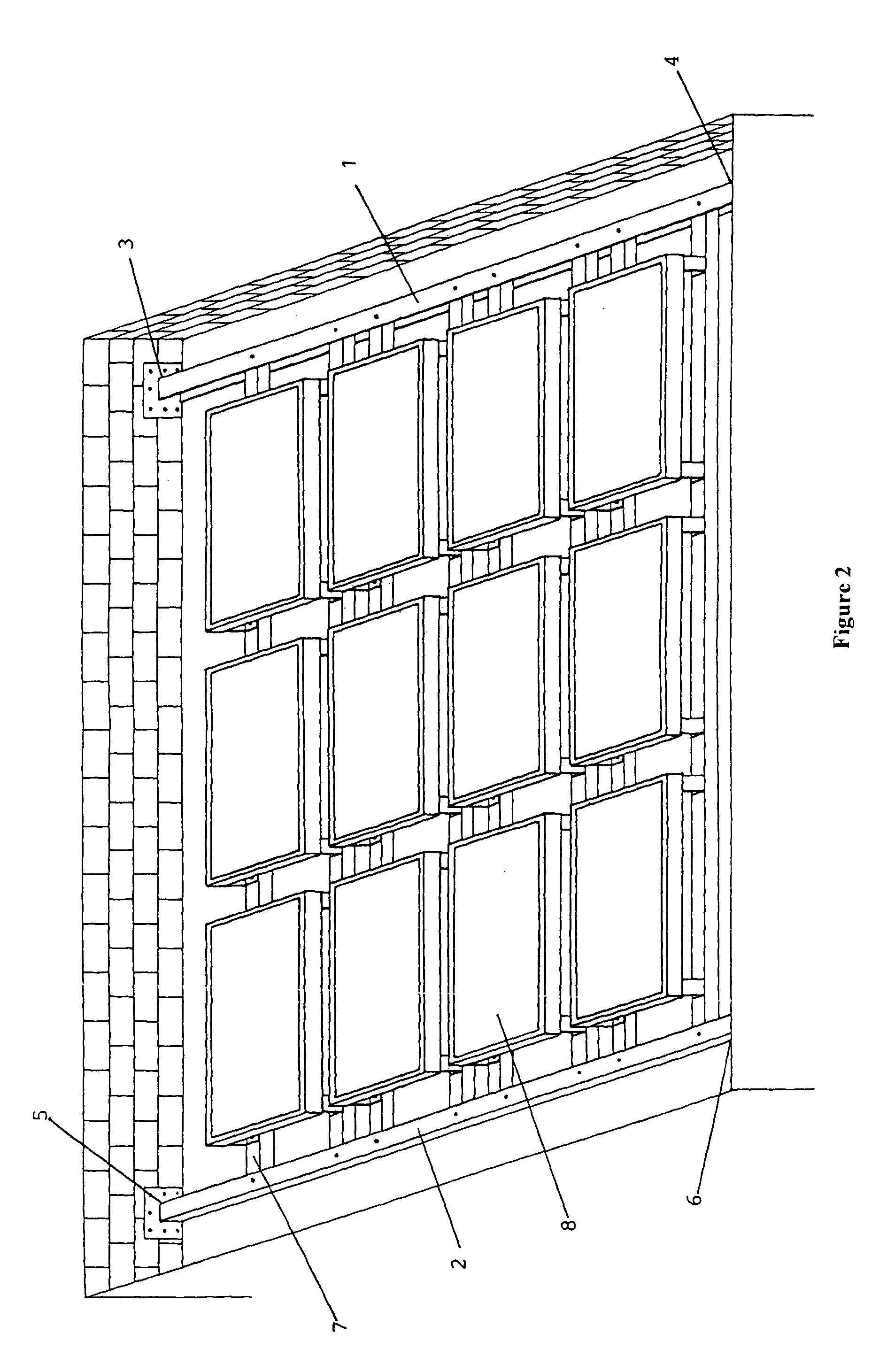

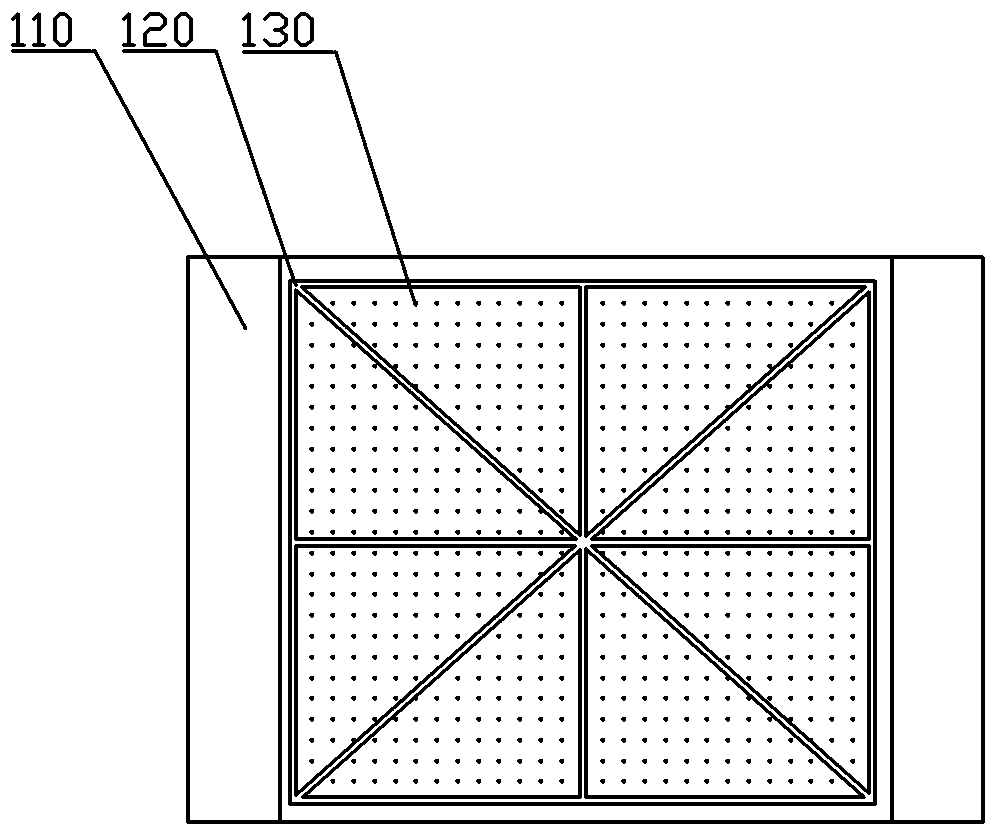

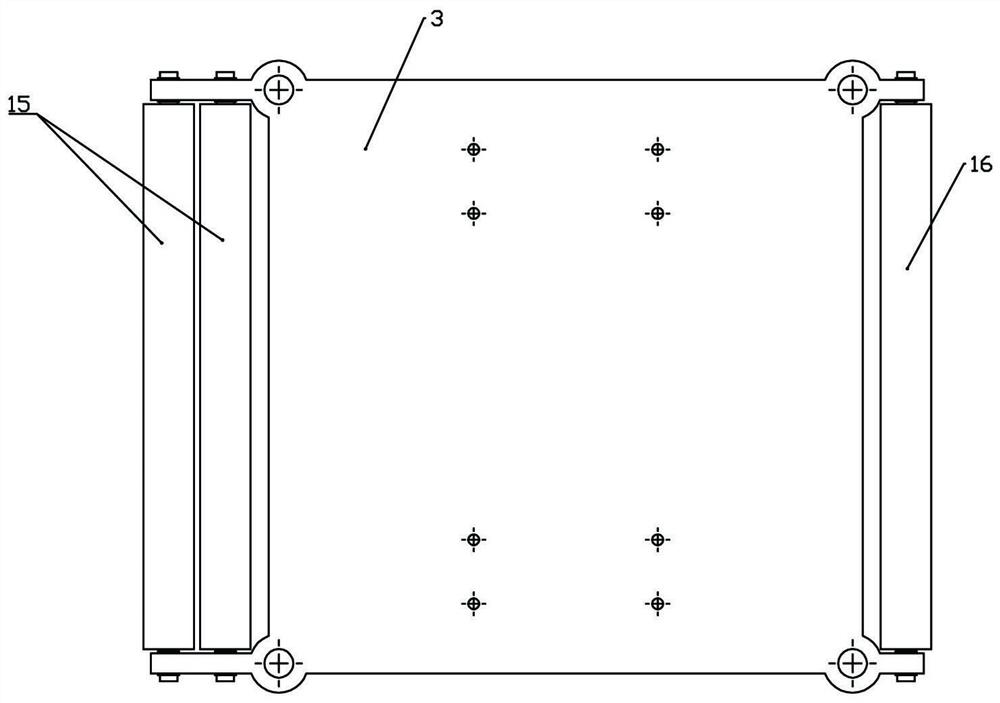

Method and apparatus for binding splicing screen with video port, and splicing screen display system

InactiveCN108848324AImprove the convenience of binding operationAffect integrityTelevision system detailsColor television detailsVideo imageOn-screen display

The invention relates to a method and apparatus for binding a splicing screen with a video port, a computer device, a storage medium, and a splicing screen display system. The method comprises the following steps: controlling the video port to respectively output image data with port serial numbers to display units of the splicing screen; receiving a splicing screen image obtained by an image scanning device by scanning the splicing screen, and performing sub-screen division on the splicing screen image according to display boundaries of the display units to obtain sub-images and spatial position information of the corresponding display units; identifying the divided sub-images to obtain the port serial numbers of the video ports corresponding to the display units, and binding the spatialposition information of the display units with the port serial numbers of the corresponding video ports for storage. The image data with the port serial numbers are output to the display units, and the spatial position information of the display units is bound with the corresponding video ports to serve as the reference for outputting video images to the video ports, so that the binding operationconvenience of the splicing screen and the video port is improved.

Owner:SHENZHEN TENDZONE INTELLIGENT TECH

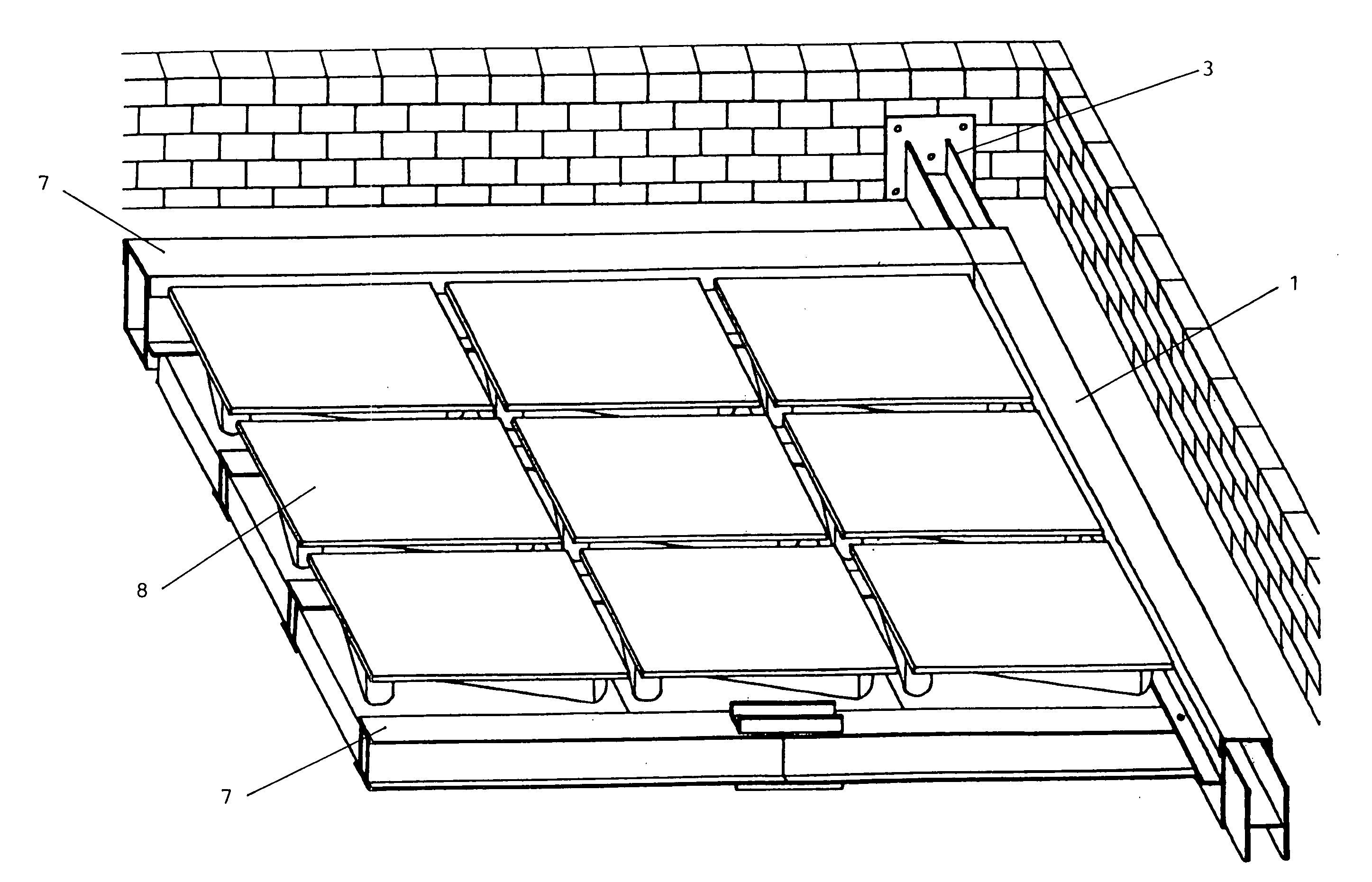

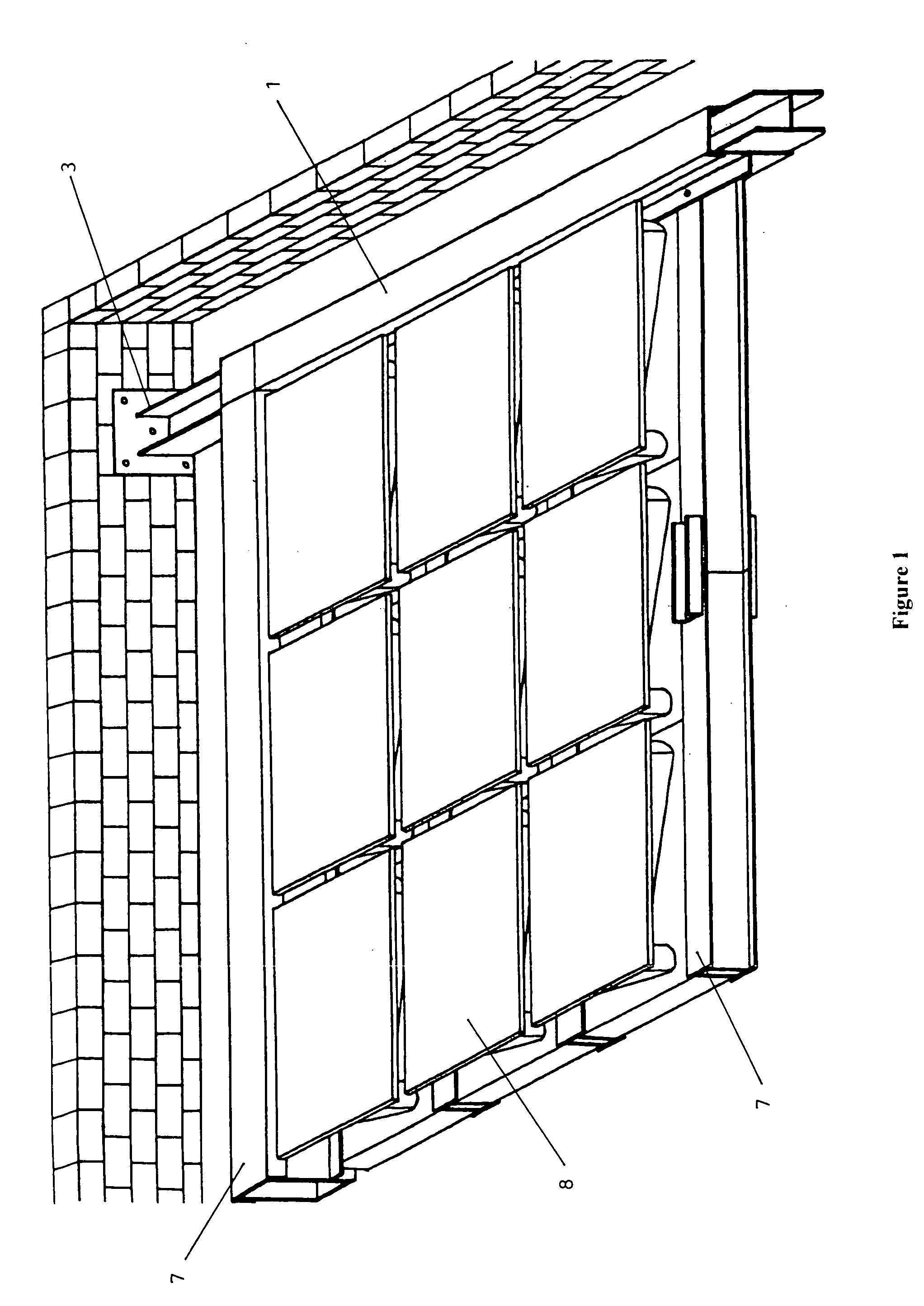

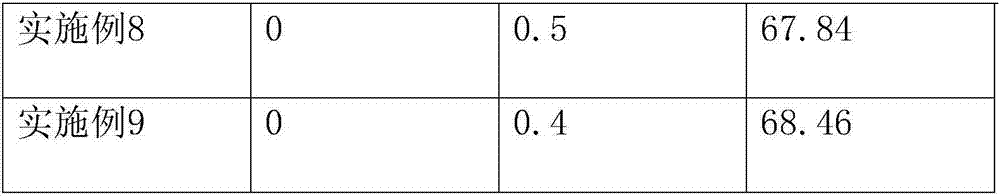

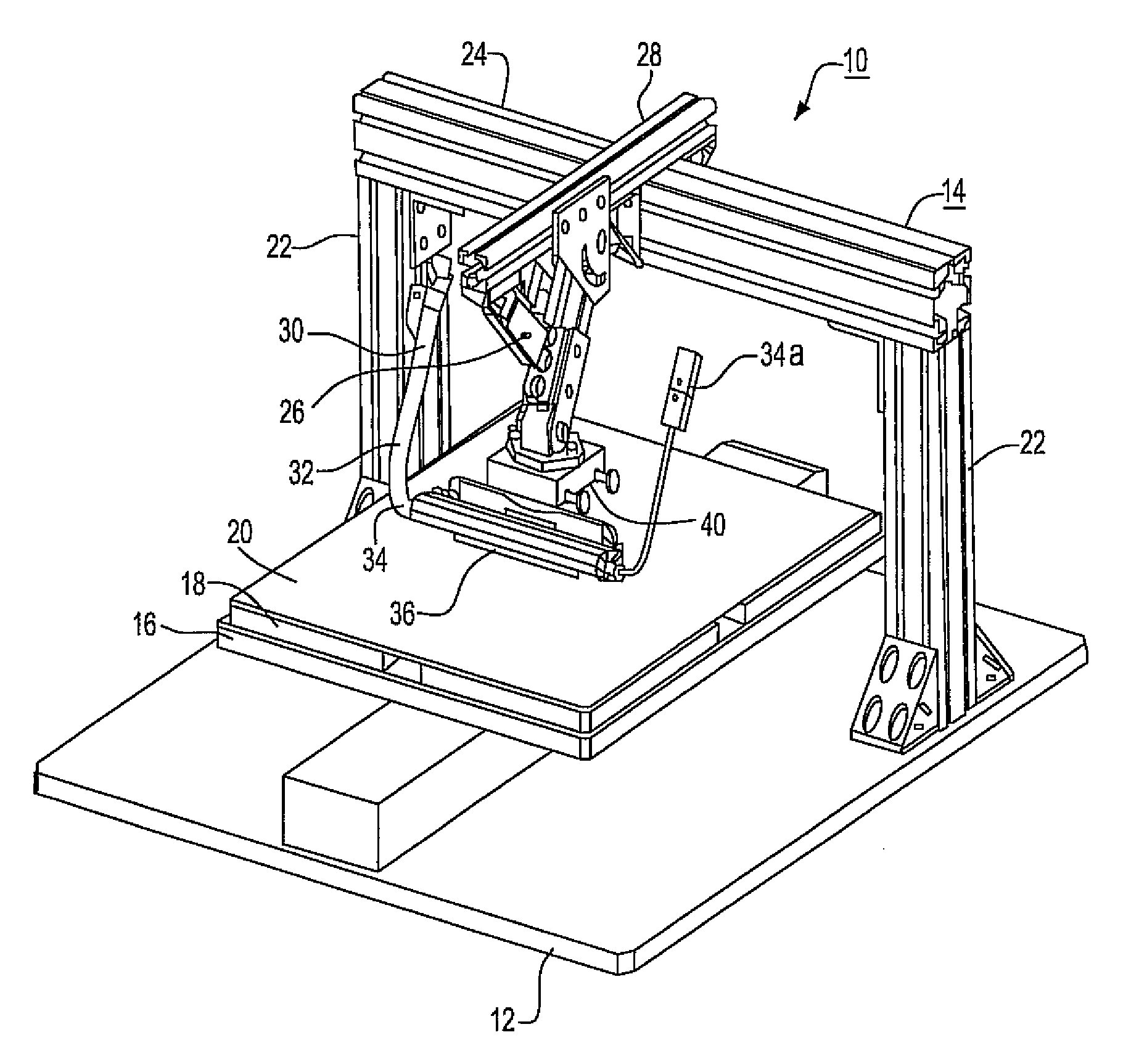

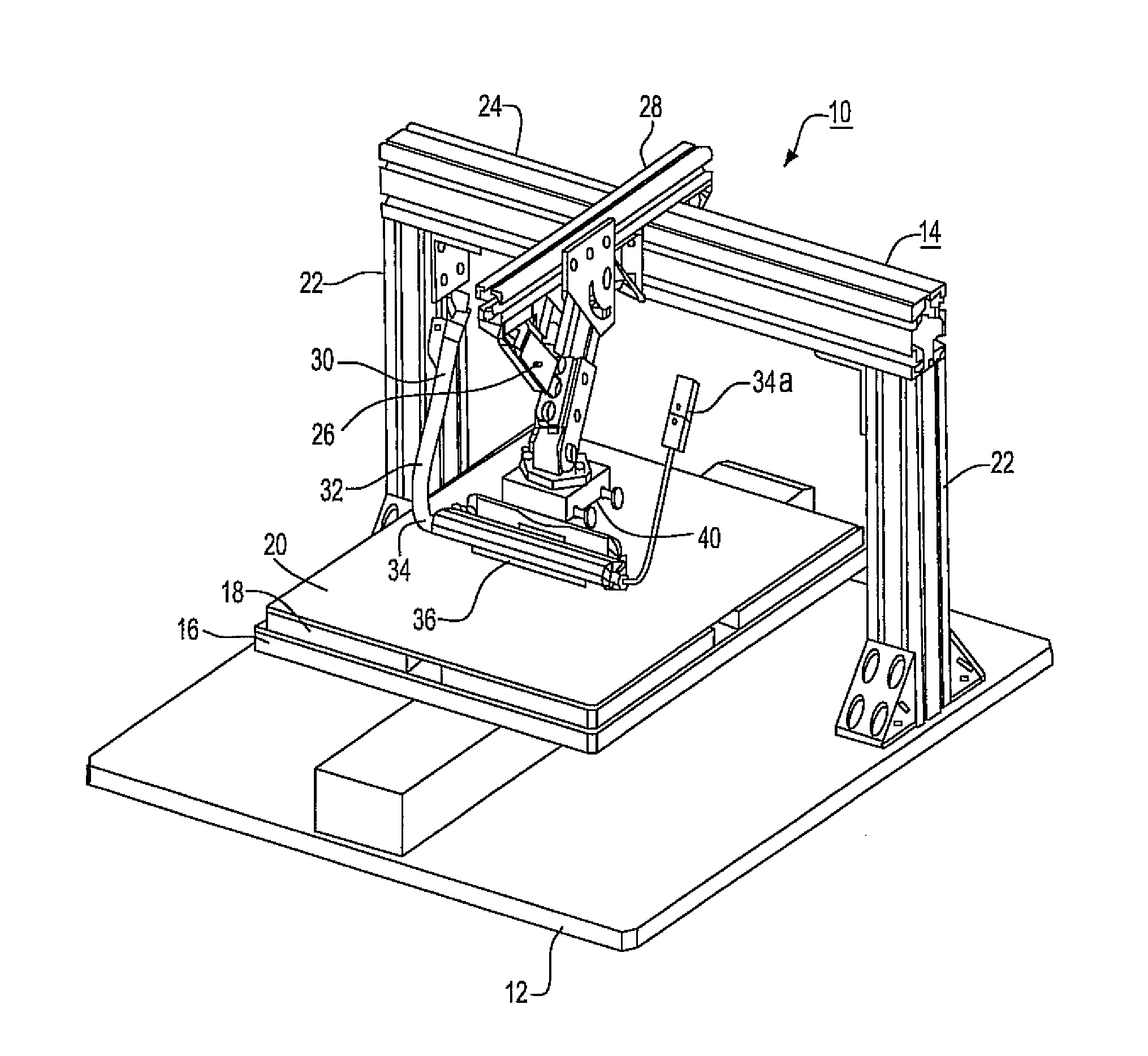

Photovoltaic attachment system

InactiveUS20050050811A1Affect integrityPhotovoltaic supportsSolar heating energyEngineeringElectrical and Electronics engineering

A photovoltaic attachment system for mounting photovoltaic panels on top of a building's roof is disclosed. The attachment system does not require drilling of holes into the roof and does not affect the integrity of the roof. The photovoltaic attachment system comprises of a grid of photovoltaic panels mounted on top of beams that are attached to the walls around the roof. The roof structure is not affected. No holes are drilled into or through the roof and no leakage of water through the roof will result from the mounting of the photovoltaic panels.

Owner:HSIAO CHUNG HOU TONY

Natural biological matrix filter rod particles and preparation method and application thereof

ActiveCN110810918AImprove adsorption capacityGood removal effectTobacco smoke filtersGranulation by liquid drop formationBiotechnologyCellulose

The invention provides natural biological matrix filter rod particles and a preparation method and application thereof, and belongs to the technical field of tobacco processing. The natural biologicalmatrix filter rod particles comprise the following components in parts by mass: main components including 5-15 parts of a smoke sweetener, 4-10 parts of a smoke moistening agent, 2-5 parts of an antioxidant bacteriostatic agent, 0-3 parts of a particle film-forming agent, 1-3 parts of a smoke adsorbent and 0-3 parts of a particle structure enhancer, and auxiliary components including 0.005-0.01 parts of stevioside, 0.02-0.05 parts of sodium carboxymethyl cellulose, 0.005-0.02 parts of ethyl cellulose, 0-0.005 parts of polyethylene glycol and 0.005 parts of a combined food grade pigment. A particle formula is subjected to performance coordination and comprehensive optimization, and factors such as smoke release, adsorption and aroma enhancement release are considered, so that on the premise of ensuring the sufficient adsorption performance of the particles and reducing generation of harmful substances, the filter rod particles which have the proper mouth feel, smoke humidity, smoke temperature and aroma and facilitate production and processing are provided.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

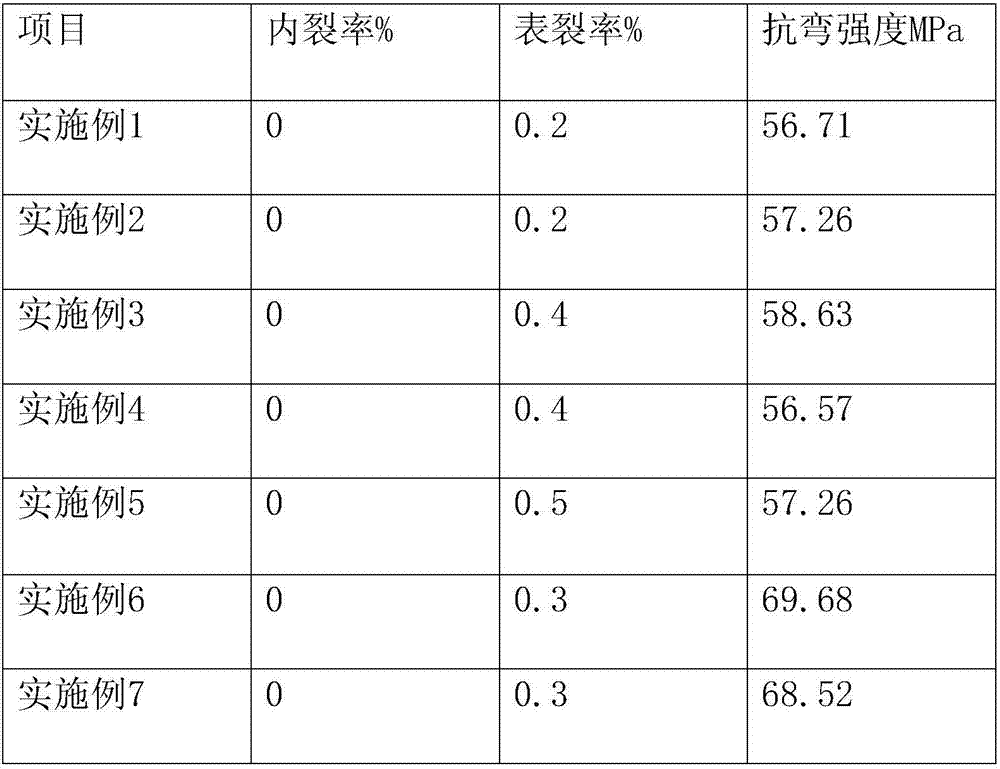

Wood conditioning method

ActiveCN107116643AIdeal elastic strengthIdeal compressive strengthImpregnation spraying apparatusWood treatment detailsCell wallHigh-temperature corrosion

The invention discloses a wood conditioning method. The method comprises following steps of immersion treatment, primary heating and humidifying treatment, primary drying, primary cooling, secondary heating and humidifying treatment, secondary drying, secondary cooling and ventilation drying. According to the wood conditioning method, the high-temperature and low-temperature alternative drying manner is adopted to reduce the wood water containing rate, through immersion treatment, ammonium bicarbonate is guided into the wood, due to alkalescence of an ammonium bicarbonate solution, cellulose on the wood cell wall can be swelled up, introduction of subsequent heat and water flowing can be facilitated, according to high-temperature and high-humidity treatment, overheat water steam is used for forming partial pressure so as to move water out of the wood, through cooling, temperature gradient is used for diffusing water to the outer portion, the high temperature drying and the low temperature drying are alternatively carried out, the water containing rate of the wood is reduced to the proper range, the anti-mildew anti-corrosion property of the wood can be increased, consumed time is short, and energy consumption is small.

Owner:浙江润格木业科技有限公司

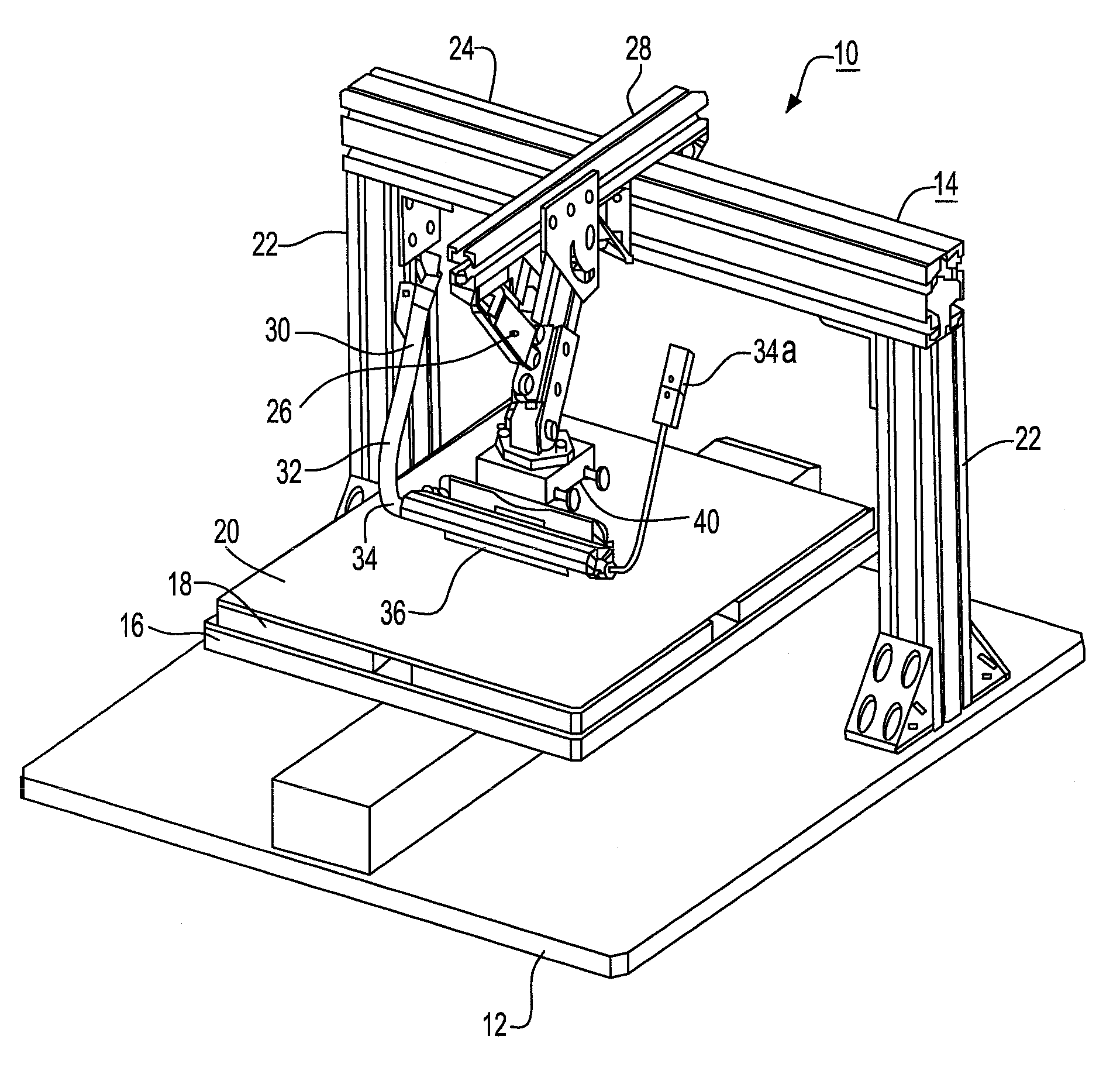

Mold shave apparatus and injection molded soldering process

InactiveUS20080156849A1Easy to shaveAdversely affectingPrinted circuitsMetal working apparatusSiliconSoldering process

An apparatus and a method for the removal of excess solder or contaminant, which are encountered on the surfaces of injection mold prior to the transfer of a solder on a silicon wafer. More particularly, there is provided for the removal of excess solder, which may be present on a mold surface, without removing any solder, which is located in cavities formed in the mold, and wherein the solder is applied through an injection molded soldering process.

Owner:IBM CORP

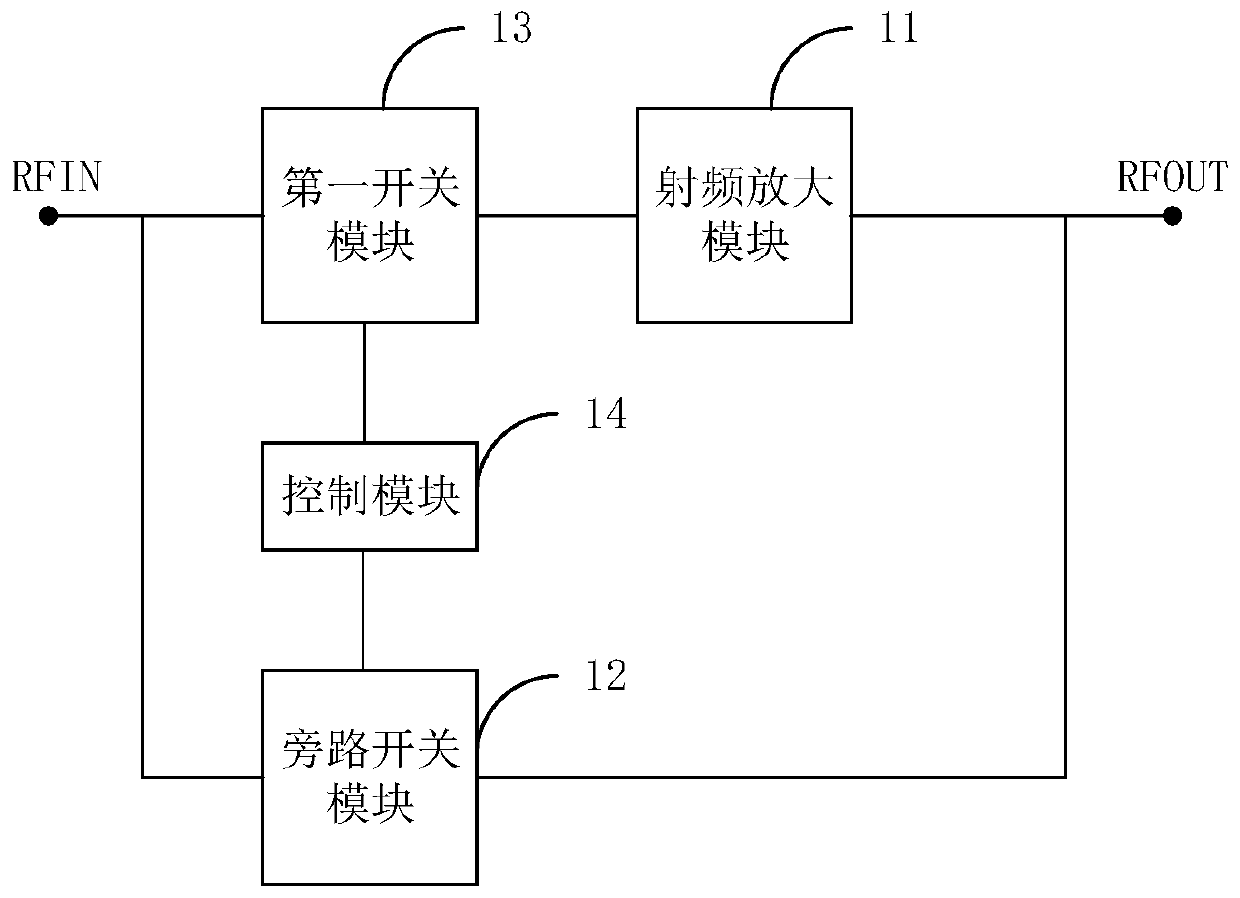

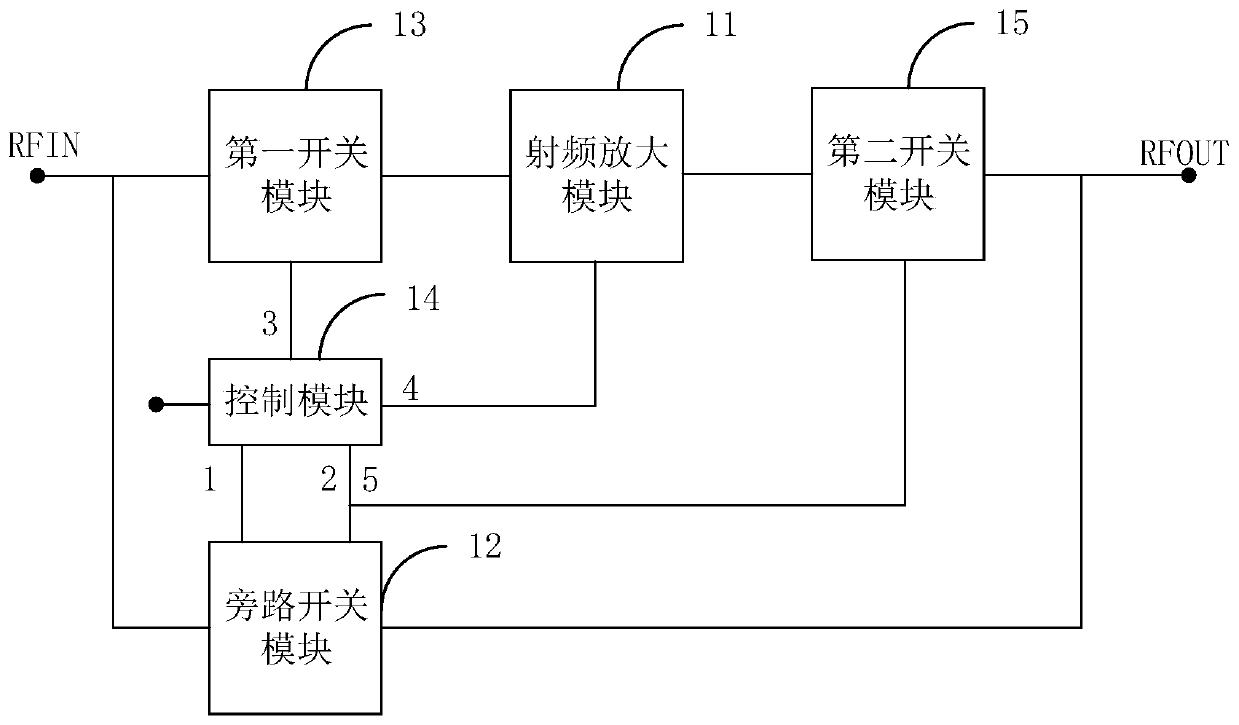

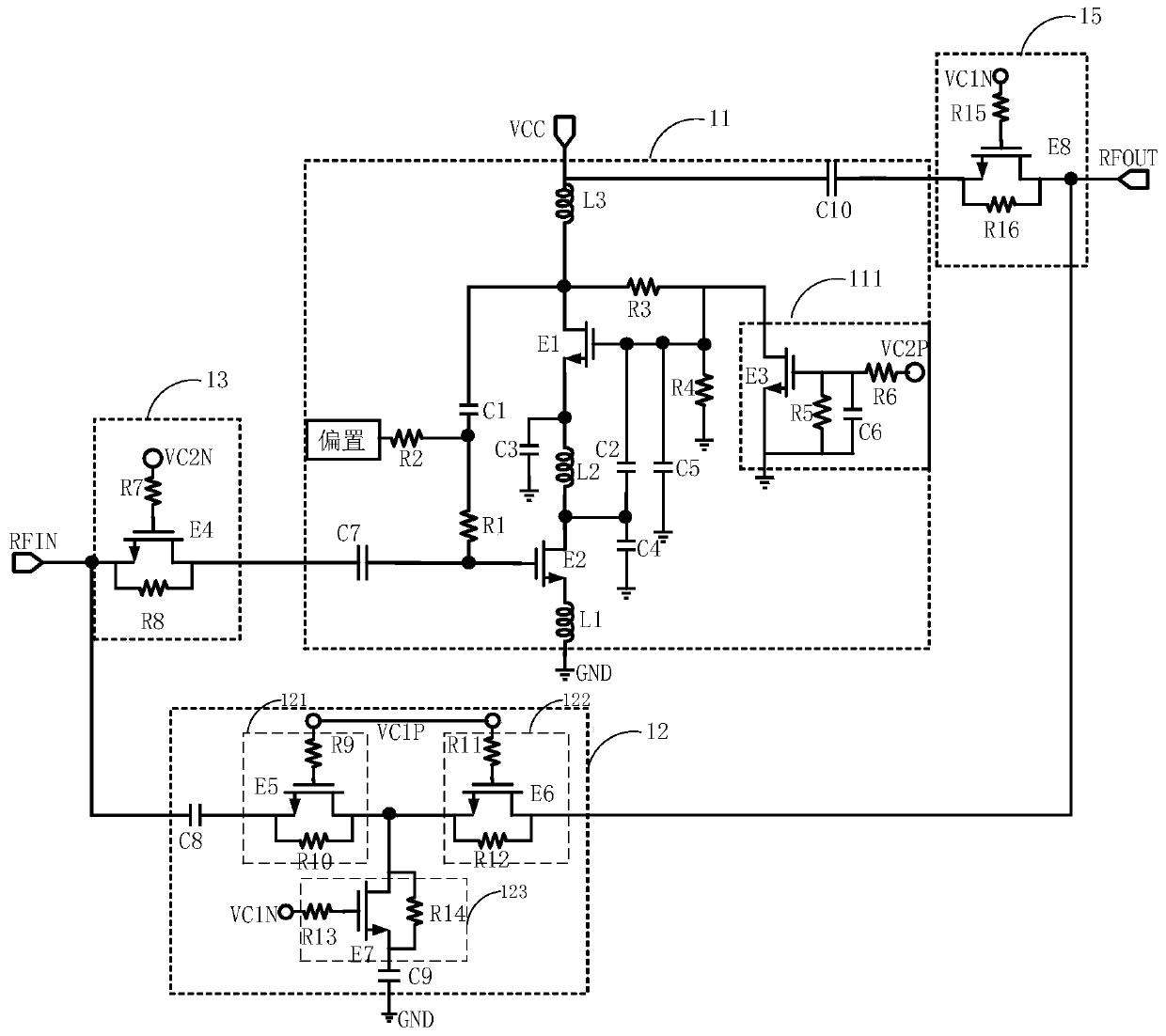

Low noise amplifier and radio frequency receiver

PendingCN111600556AAffect integrityGuaranteed reliabilityAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceLow noiseNoise (radio)

The invention is applicable to the technical field of wireless communication, and provides a low-noise amplifier and a radio frequency receiver, the amplifier comprises a radio frequency amplificationmodule, a bypass switch module, a first switch module and a control module; a first end of the first switch module is connected with an input terminal of the low-noise amplifier, a second end is connected with an input end of the radio frequency amplification module, and a control end is connected with the control module; the output end of the radio frequency amplification module is connected with the output terminal of the low-noise amplifier; the first end of the bypass switch module is connected with the input terminal, the second end is connected with the output terminal, and the controlend is connected with the control module; the control module is used for receiving an external control signal and controlling on-off of the first switch module and the bypass switch module according to the external control signal. By controlling the conduction of the access where the radio frequency amplification module is located or the access where the bypass switch module is located, differentaccesses are selected according to different signal intensities, so that the gain of the low-noise amplifier is adjustable, and the reliability of radio frequency signals is ensured.

Owner:NORTH-CHINA INTEGRATED CIRCUIT CO LTD

Mold shave apparatus and injection molded soldering process

InactiveUS20090294090A1Easy to disassembleWeak degree of adherenceLiquid surface applicatorsInking apparatusSiliconSoldering process

An apparatus for the removal of excess solder or contaminant, which are encountered on the surfaces of injection mold prior to the transfer of a solder on a silicon wafer. More particularly, there is provided an apparatus for the removal of excess solder, which may be present on a mold surface, without removing any solder, which is located in cavities formed in the mold, and wherein the solder is applied through an injection molded soldering process.

Owner:IBM CORP

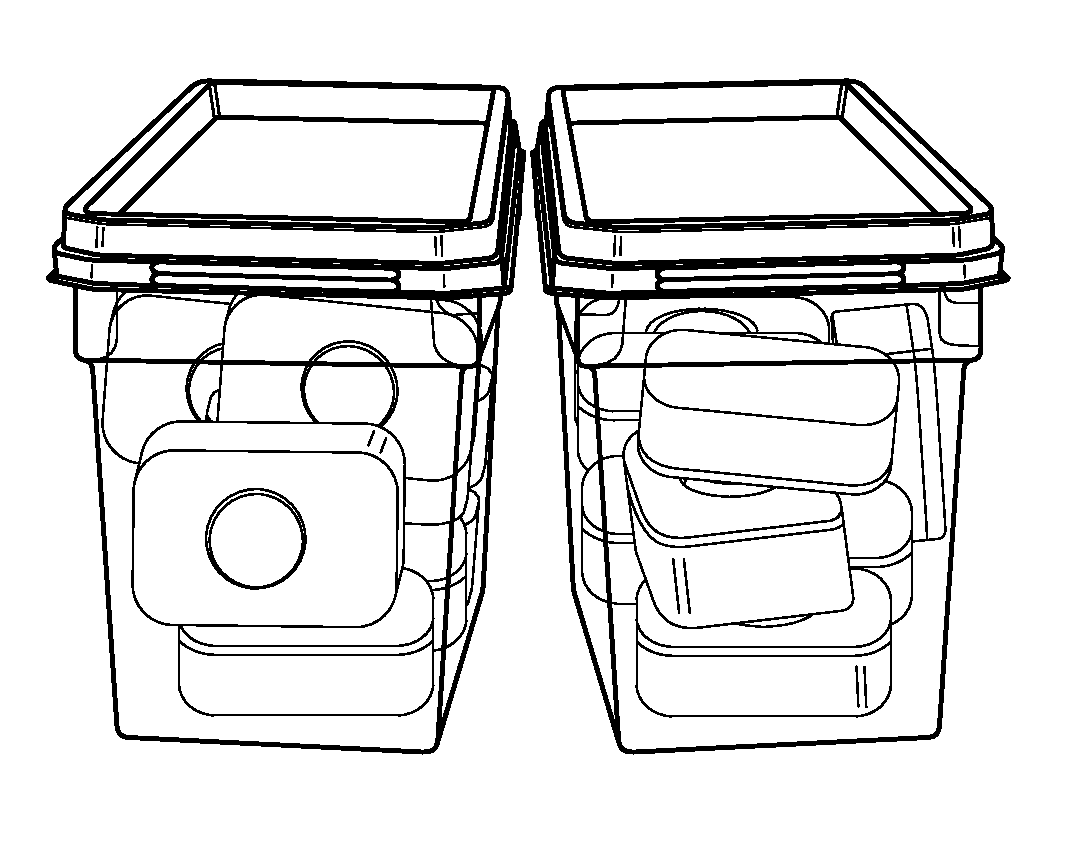

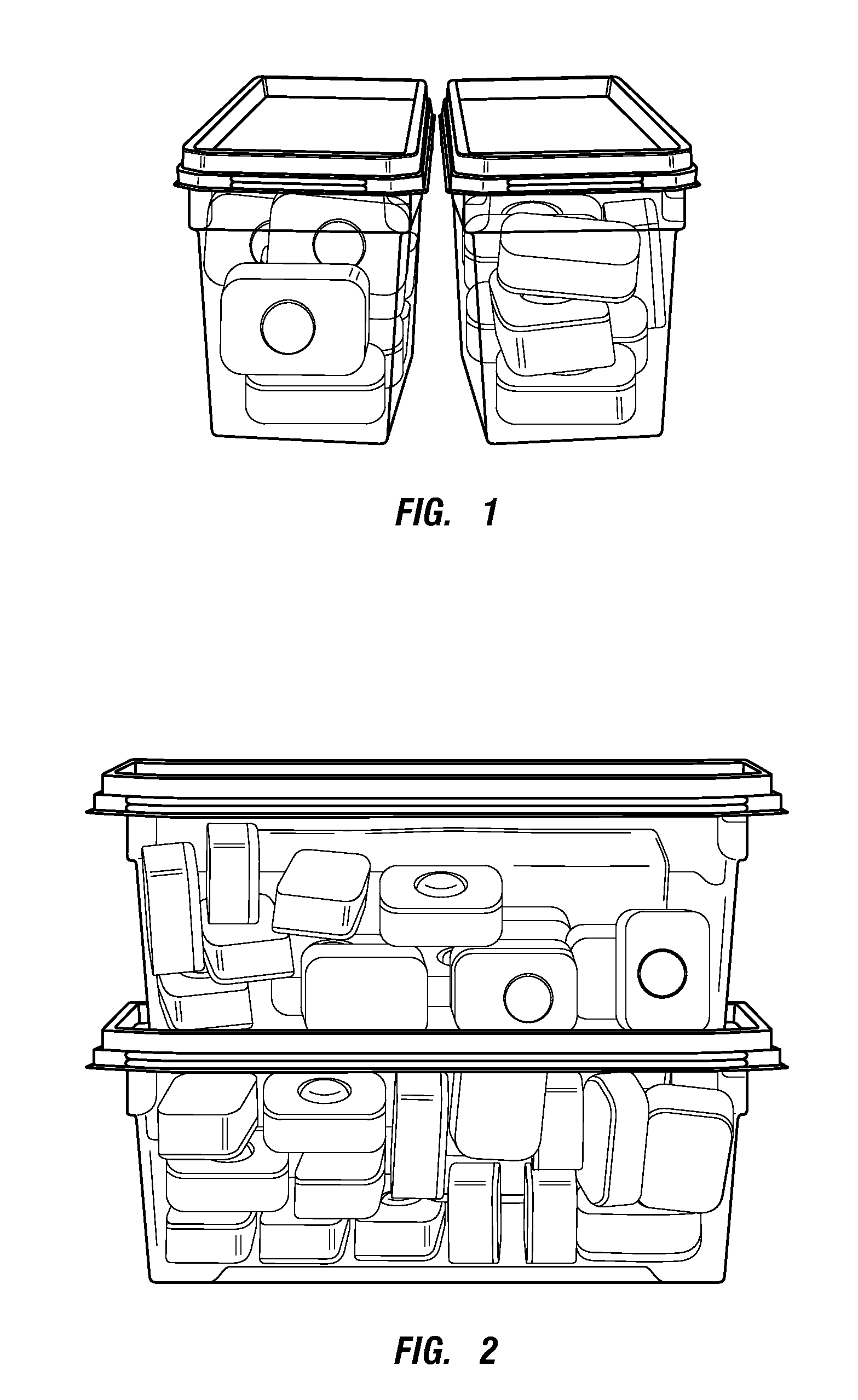

Packaging

InactiveUS20110127271A1Affect integrityExposure was also limitedInternal framesDetergent materialsEngineeringBiomedical engineering

A primary package comprising two or more compartments which can be opened individually, each compartment comprising a plurality of unit dose detergent portions and wherein at least one compartment is substantially air-tight before it is opened for the first time. The package provides for good stability of the detergent portions.

Owner:RECKITT BENCKISER NV

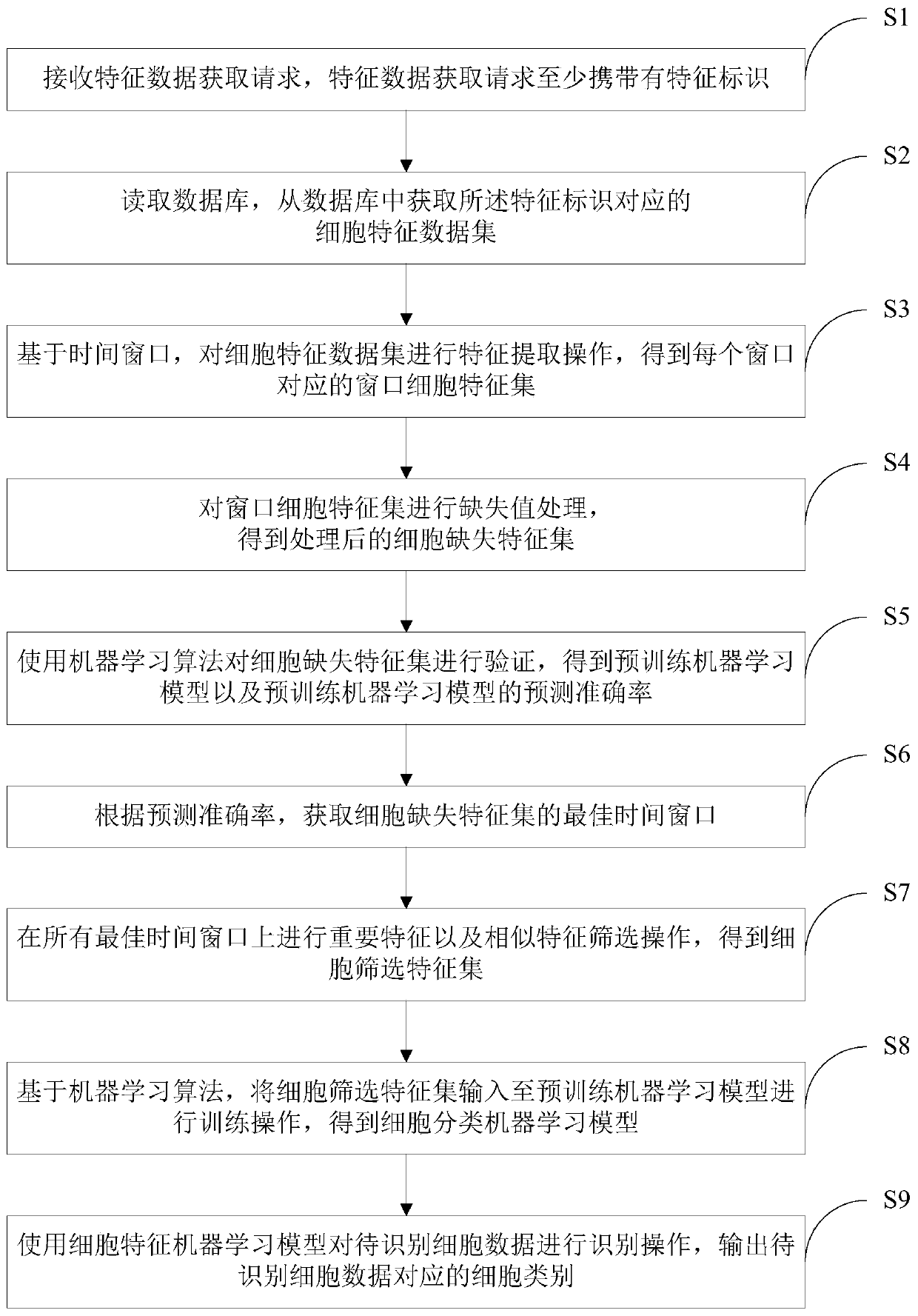

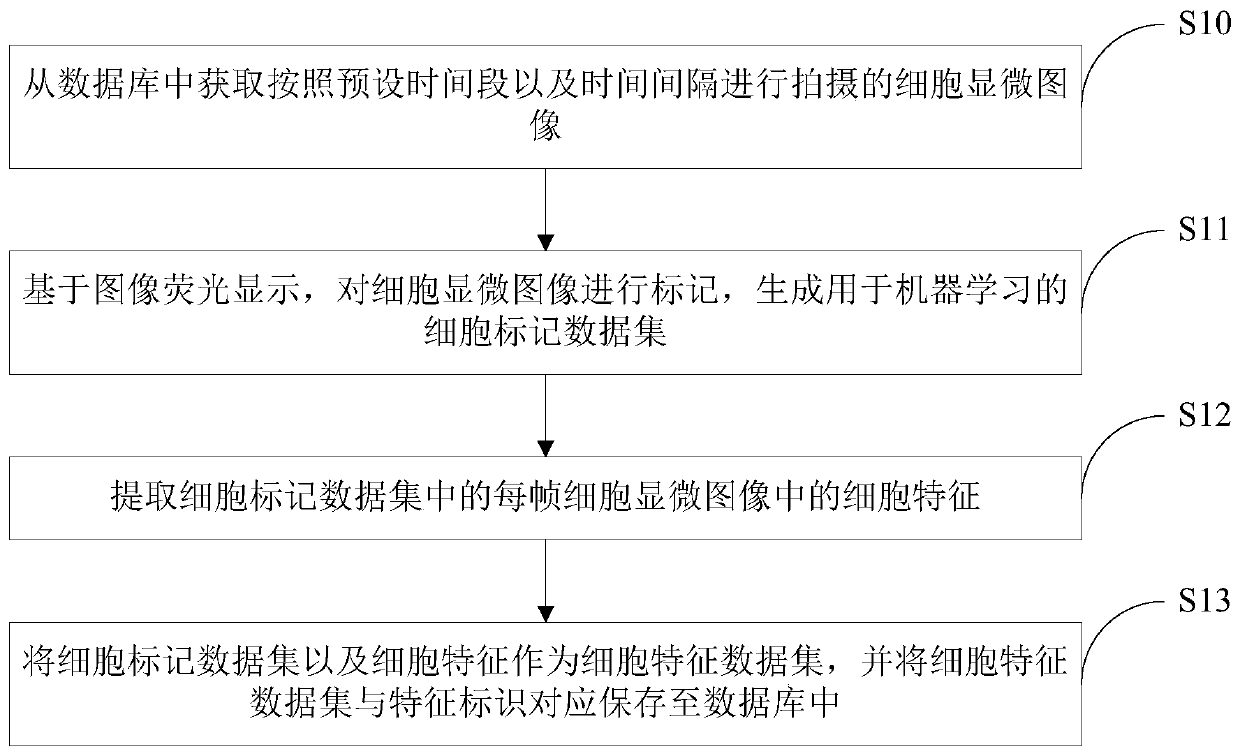

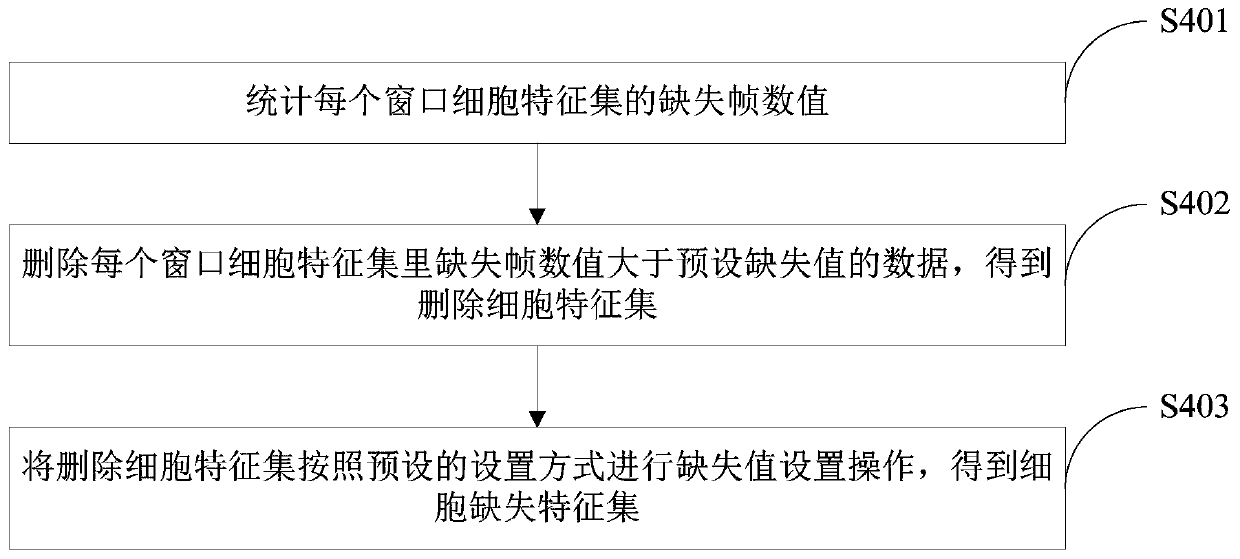

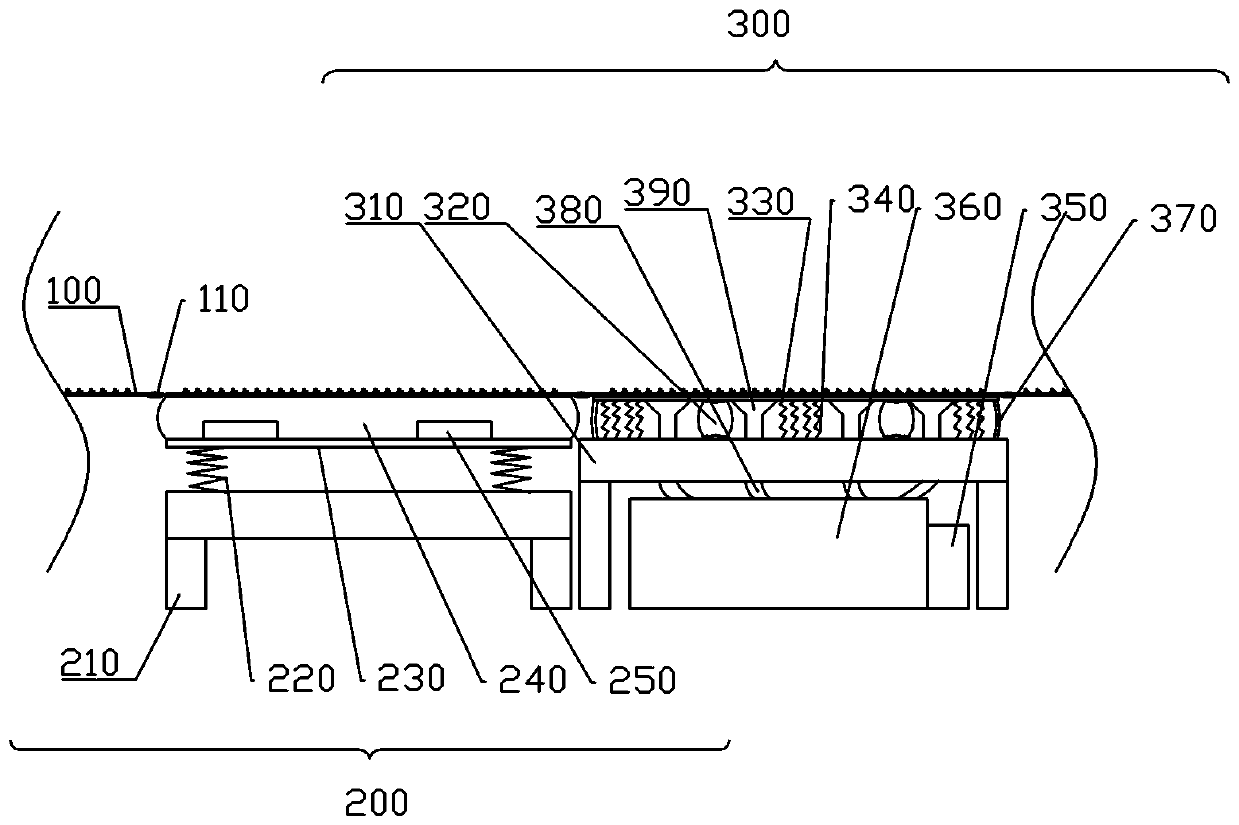

Cell identification method and device based on machine learning

ActiveCN111553206AGuaranteed accuracyIntegrity guaranteedCharacter and pattern recognitionMachine learningData setFeature set

The invention relates to the technical field of machine learning, in particular to a cell identification method and device based on machine learning. The cell identification method comprises the following steps: acquiring a cell characteristic data set corresponding to a characteristic identifier from a database; performing feature extraction on the cell feature data set to obtain a window cell feature set; performing missing value processing on the window cell feature set to obtain a cell missing feature set; verifying the cell deletion feature set to obtain a pre-trained machine learning model and prediction accuracy; obtaining an optimal time window of the cell deletion feature set according to the prediction accuracy; performing screening operation on all the optimal time windows to obtain a cell screening feature set; and based on a machine learning algorithm, inputting the cell screening feature set into a pre-trained machine learning model for training to obtain a cell classification machine learning model. According to the cell identification device and method, the technical problem that an existing cell identification device based on machine learning is low in identification precision is solved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

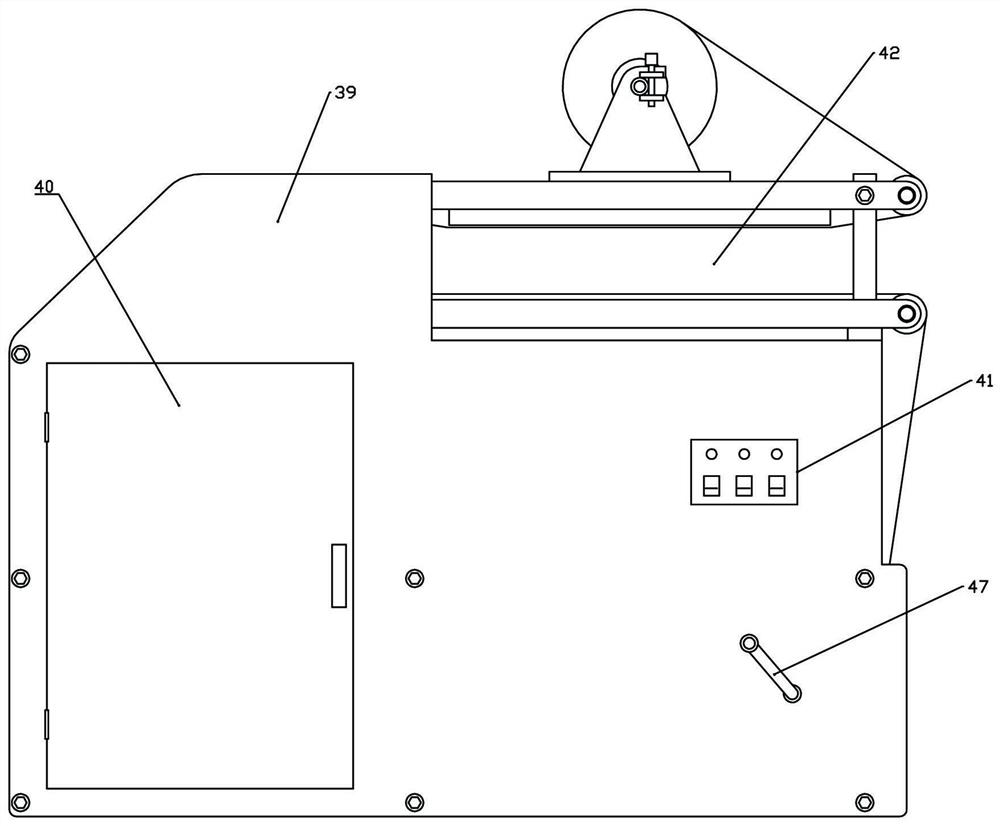

Anti-sticking conveying method for quick-frozen food

The invention relates to a material moving device related to a conveyor, in particular to an anti-sticking conveying device for quick-frozen dumplings. The anti-sticking conveying device comprises a conveying belt, a preliminary crushing mechanism and a separating mechanism, wherein the separating mechanism comprises a separating frame, cams mounted above the separating frame, a tension spring with the lower end connected to the upper end surface of the separating frame, a support plate located above the cams and connected to the upper end of the tension spring, a high-pressure pump fixed to the separating frame and a high-pressure tank communicated with the high-pressure pump, wherein the conveying belt is attached to the upper end of the support plate, a magnetic plate is embedded in thesupport plate, air holes are formed in the support plate, an air outlet is formed in the high-pressure tank, a closing valve is arranged at the air outlet, and the air outlet leads to the lower end surface of the support plate; an iron core is embedded in the conveying belt, air vents with pore diameter matched with that of the air holes are formed in the conveying belt, and elastic connecting bands are uniformly distributed on the conveying belt. In order to solve the problem that the dumplings stick to the surface of the conveying belt and are not easy to fall off in the conveying process,the conveying device for separating the frozen dumplings from the conveying belt without damage is provided.

Owner:CHONGQING QIGE FOOD CO LTD

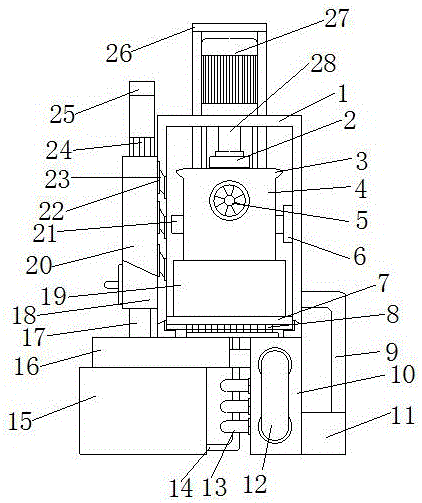

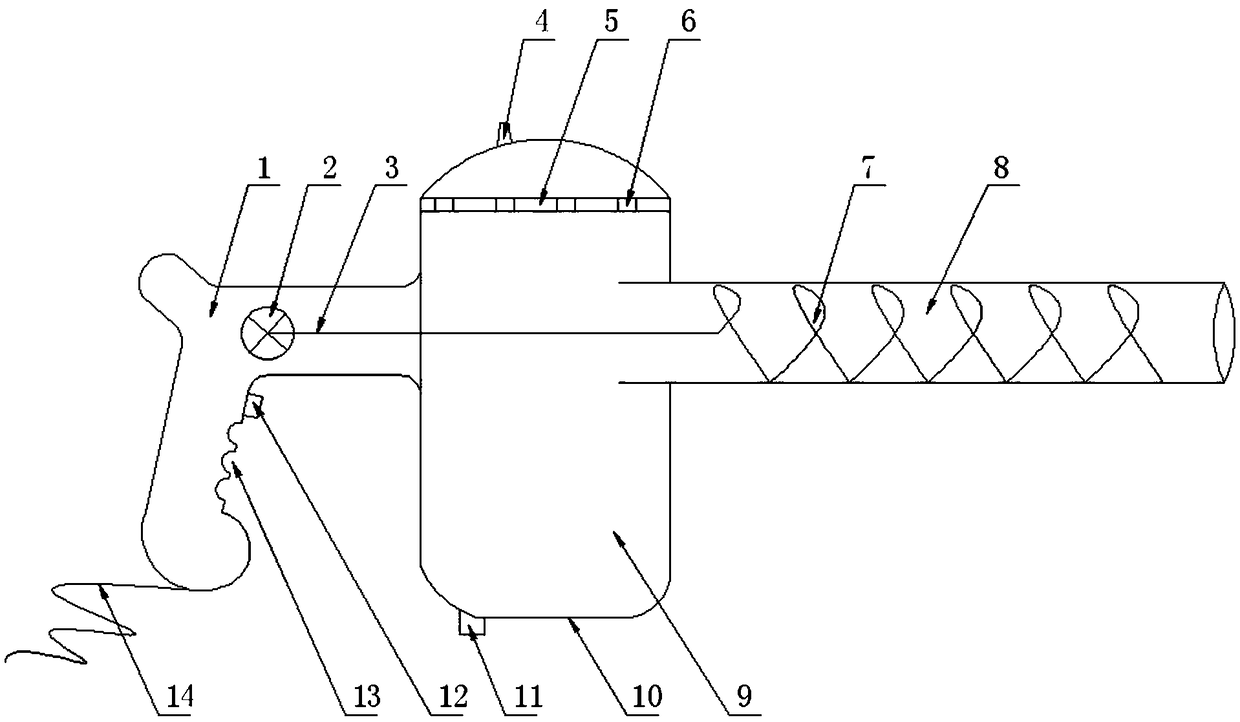

Smelting metal furnace convenient to cool and clean

ActiveCN106839767ASimple structureEasy to useCrucible furnacesFurnace coolingWater storage tankHot melt

The invention discloses a smelting metal furnace convenient to cool and clean. The smelting metal furnace comprises a furnace body, one side of the furnace body is connected with a first water pump through a water outlet pipe, a water outlet on one side of the first water pump is connected with a water storage tank, the upper end of one side of the water storage tank is connected with an intermediate conversion water tank through a water pipe, the top of the intermediate conversion water tank is connected with a filter tank through a filter pipe, a water conveying tank is installed at the top of the filter tank, a water inlet at the top of the water conveying tank is connected with a second water pump, one side of the water conveying tank is connected with an inner cavity of the furnace body through a water conveying pipe, a heating plate is installed at the bottom of the inner cavity of the furnace body, a hot melting cylinder is installed at the top of the heating plate, and a ladle is installed at the top of the hot melting cylinder. According to the smelting metal furnace convenient to cool and clean, on the whole through the ladle arranged in the furnace body and the hot melting cylinder adaptive with the ladle, frequency movement of molten metal and filling of the molten metal are avoided, the smelting metal furnace is a circulation type washing water cooling device, and dirt and waste metal in the metal furnace can be cleaned.

Owner:广西埃索凯循环科技有限公司

Bill classification packaging machine for financial management

InactiveCN113022962AWon't leaveConvenient packaging requirementsWrapping material feeding apparatusWrapper twisting/gatheringStart buttonPackaging machine

The invention discloses a bill classification packaging machine for financial management. The bill classification packaging machine comprises a support, an upright post, a fixed disk, a movable disk and a vertical driving mechanism, wherein a heat sealing device and a shearing device are arranged between the fixed disk and the movable disk; new film output rollers and waste film storage rollers are installed at two sides of the fixed disk and two sides of the movable disk separately; and adhesive film layers located between each pair of new film output roller and waste film storage roller pass through and are restrained on the disk surface of the fixed disk and the disk surface of the movable disk separately. According to the bill classification packaging machine for financial management, the convenient packaging requirement for financial bills and other files can be met; and in the storing and packaging process, due to the fact that the upper and lower adhesive film layers are located at the upper position and the lower position of an operation area, corresponding files only need to be placed in the operation area and a start button is pressed down. Therefore, the operation is easy and convenient.

Owner:JIANGXI NORMAL UNIV

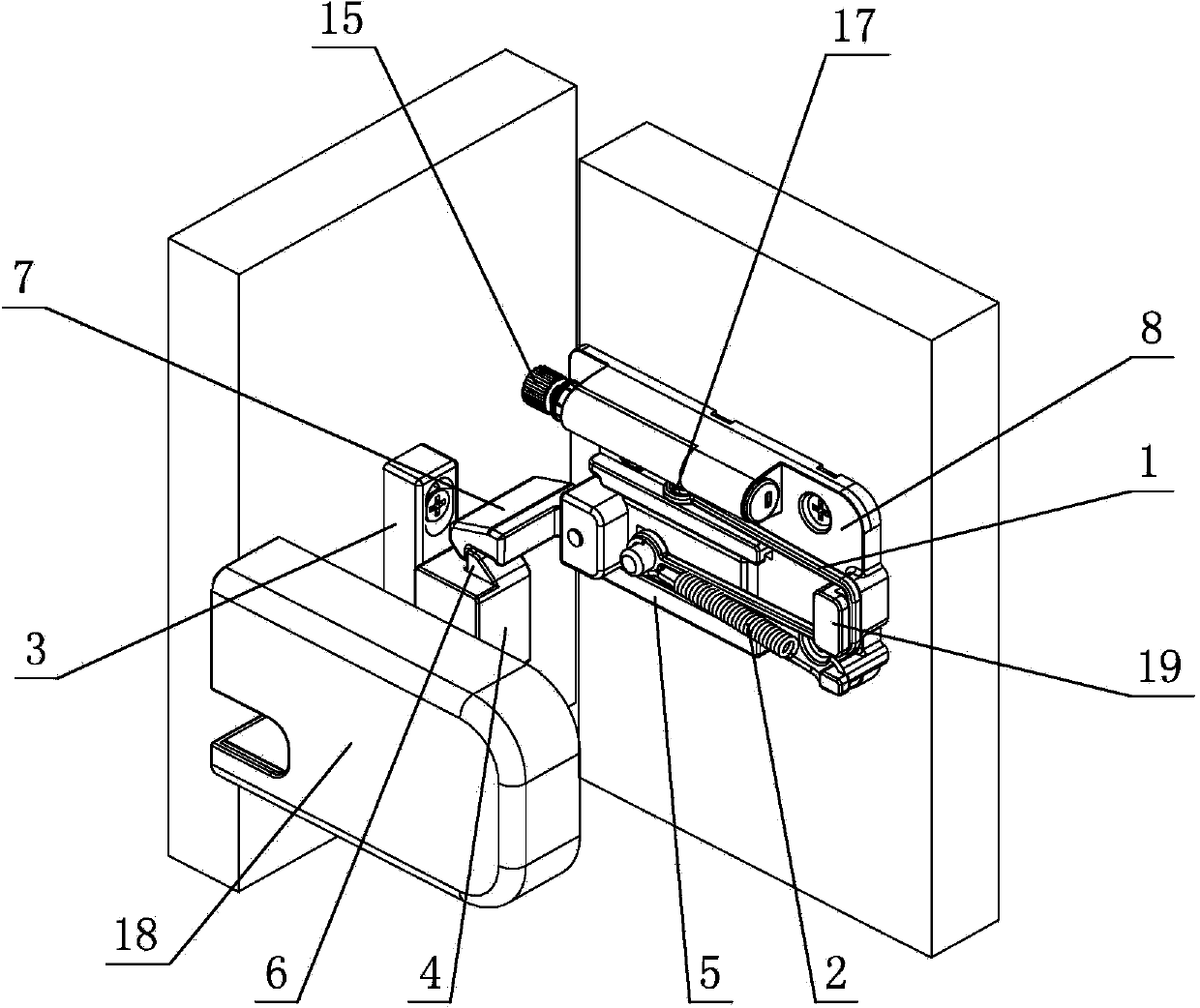

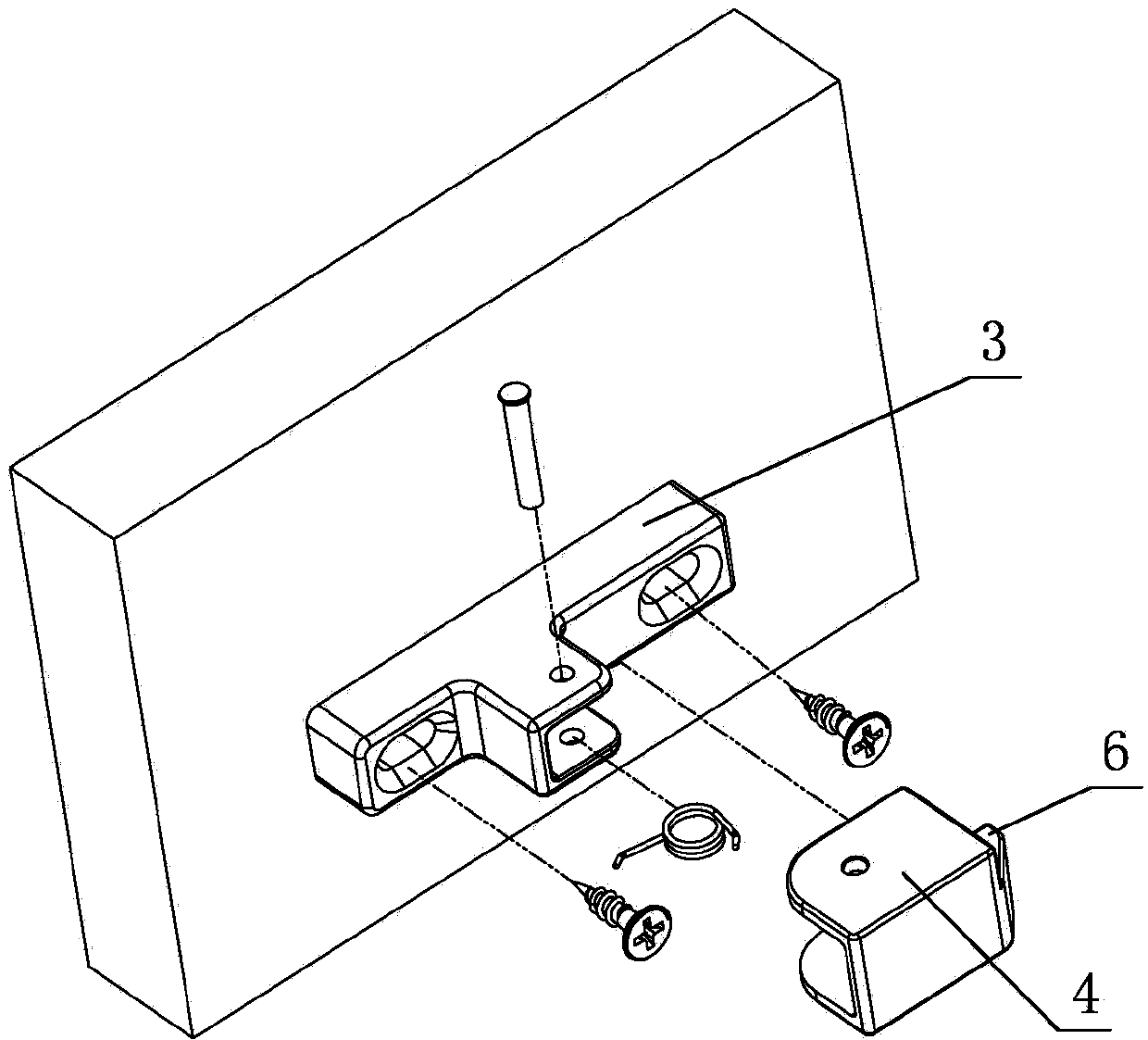

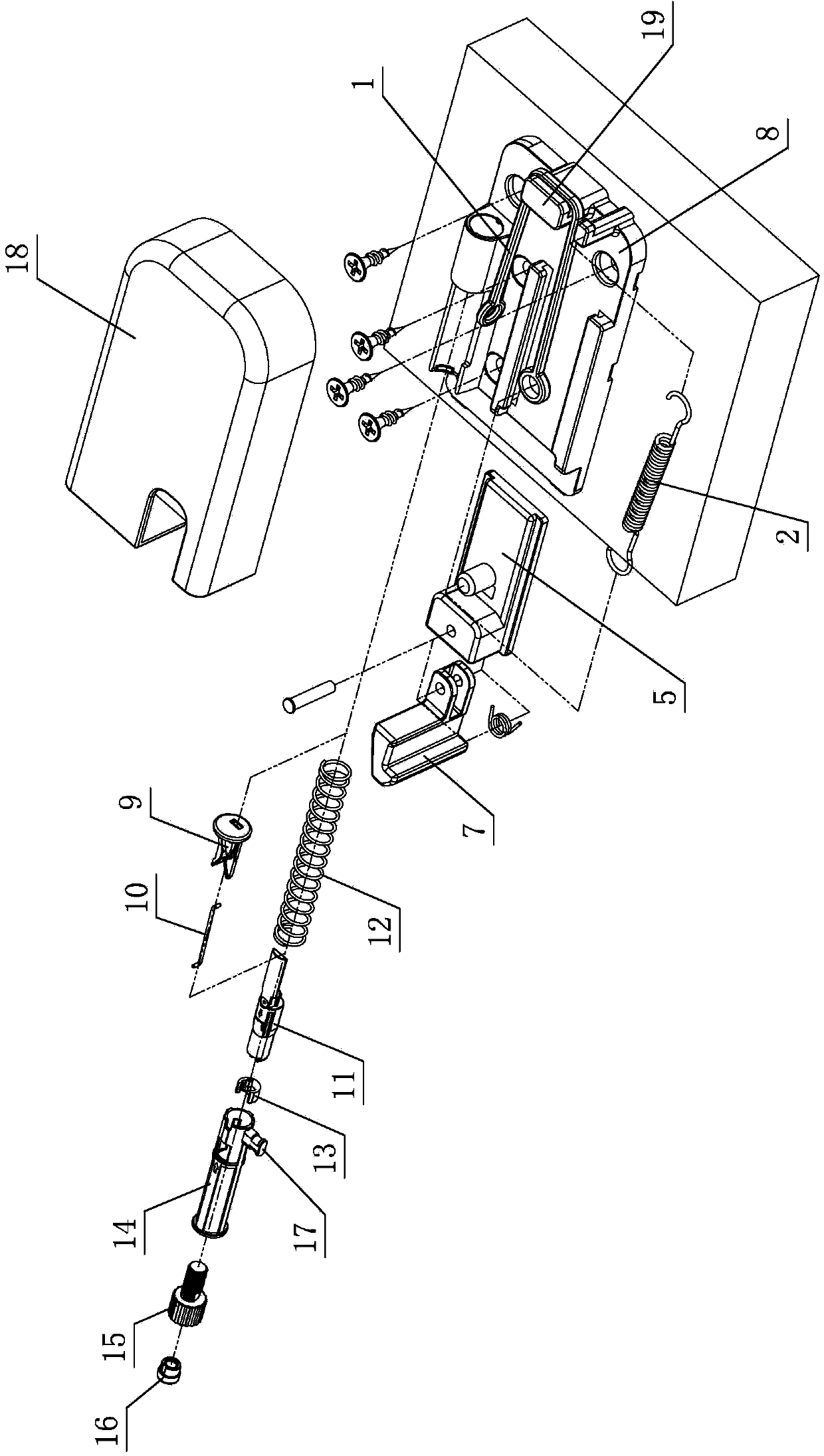

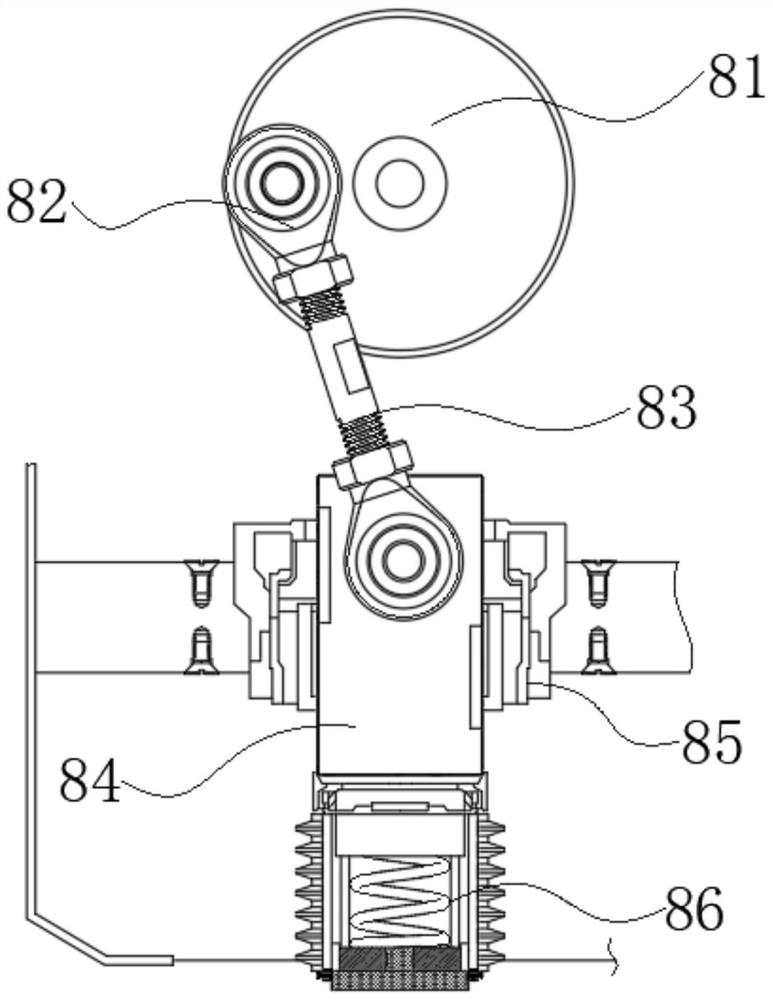

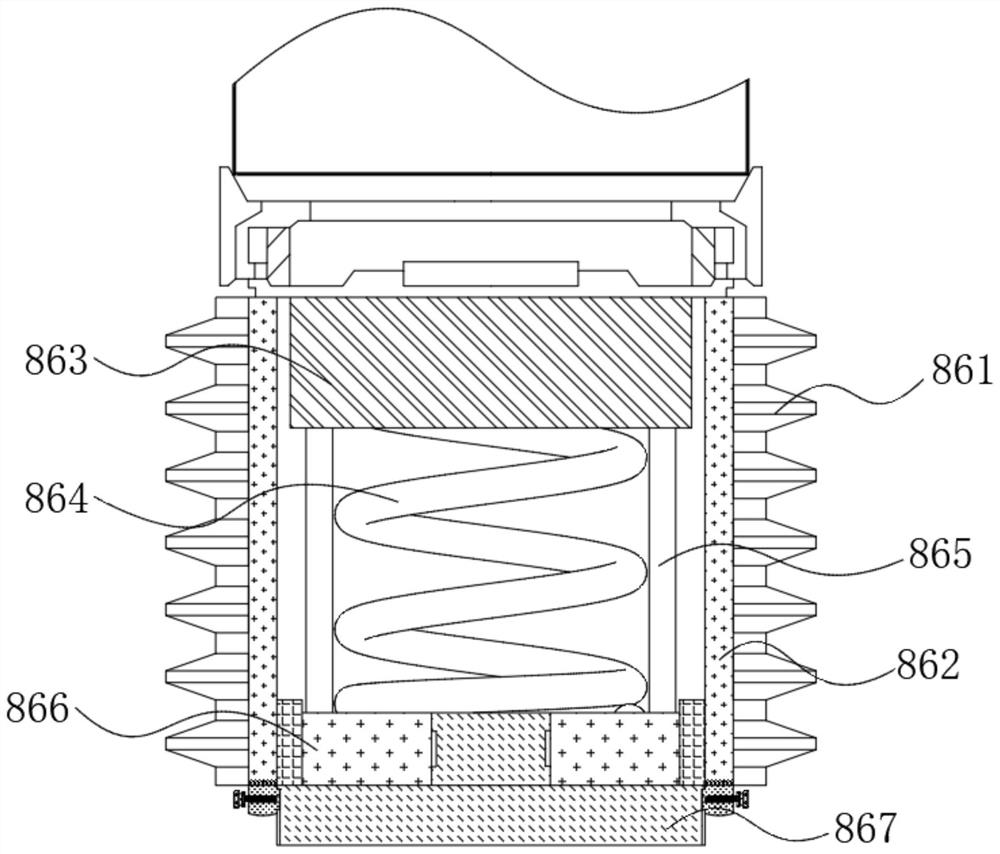

Automatic reset switch system for furniture

ActiveCN103742017AReduce handleFew stepsBuilding locksWing fastenersEngineeringMechanical engineering

An automatic reset switch system for furniture comprises a fixed part and a moving part. The fixed part or the moving part is provided with a pressing bounce device, and the pressing bounce device is provided with a heart-shaped groove and slides along the heart-shaped groove and stay at an opening position by pressing the moving part. The pressing bounce device is in matched connection with one end of a rope, cable or strip through the acting part, and matches with a pulling device arranged on the fixed part or the moving part through the other end of the rope, cable or strip at least when the moving part opens continuously so as to allow the pressing bounce device to be at a closing position. The pulling device is separated from the rope, cable or strip when the moving part opens continuously, so that the rope, cable or strip resets automatically through a provided elastic member. By the optimization of the structure, a handle on the moving part is omitted, production cost is reduced, steps for a user to open and close the moving part are reduced, convenience of usage is provided to users, user experience is improved, and practicality is high.

Owner:伍志勇

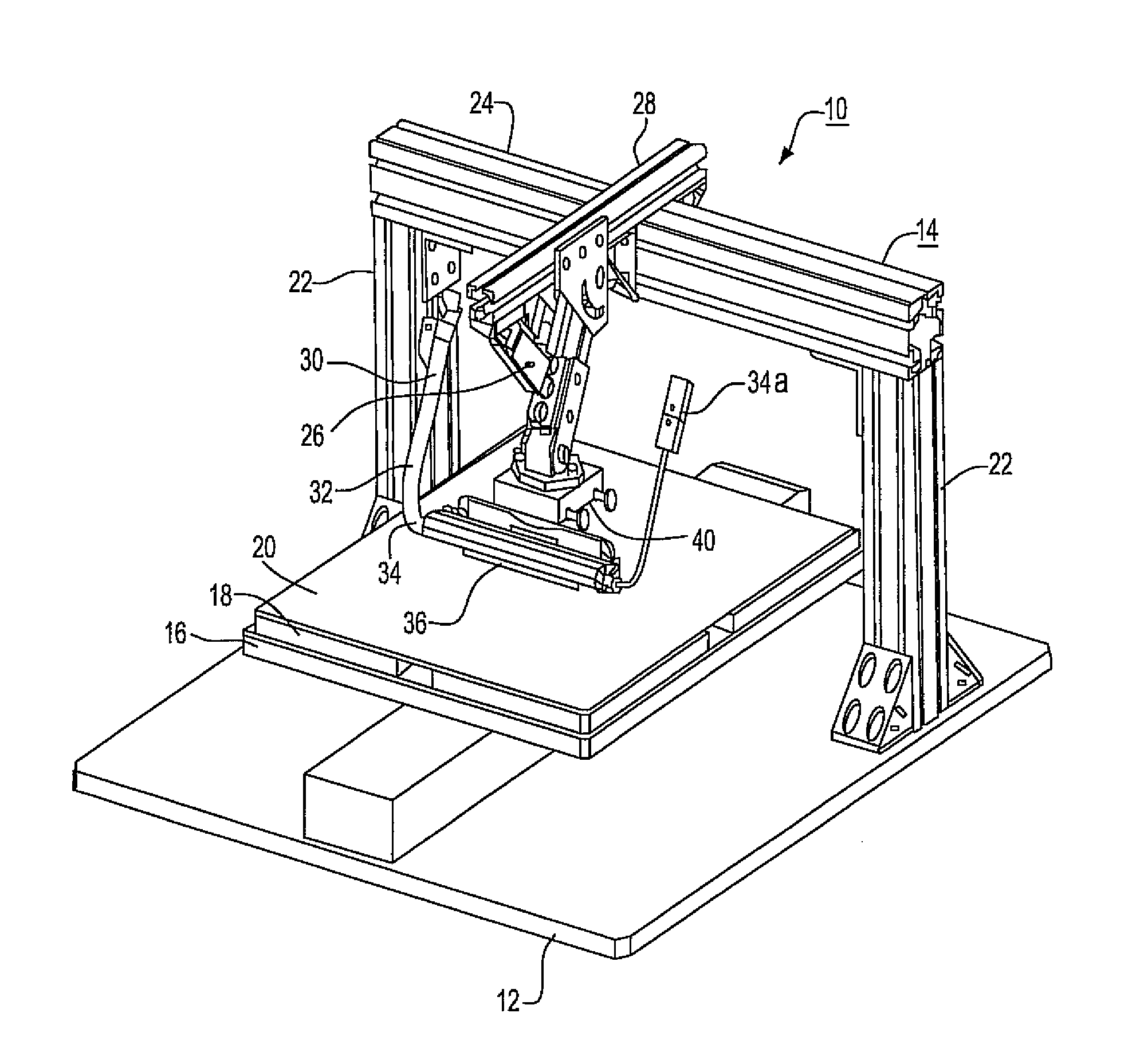

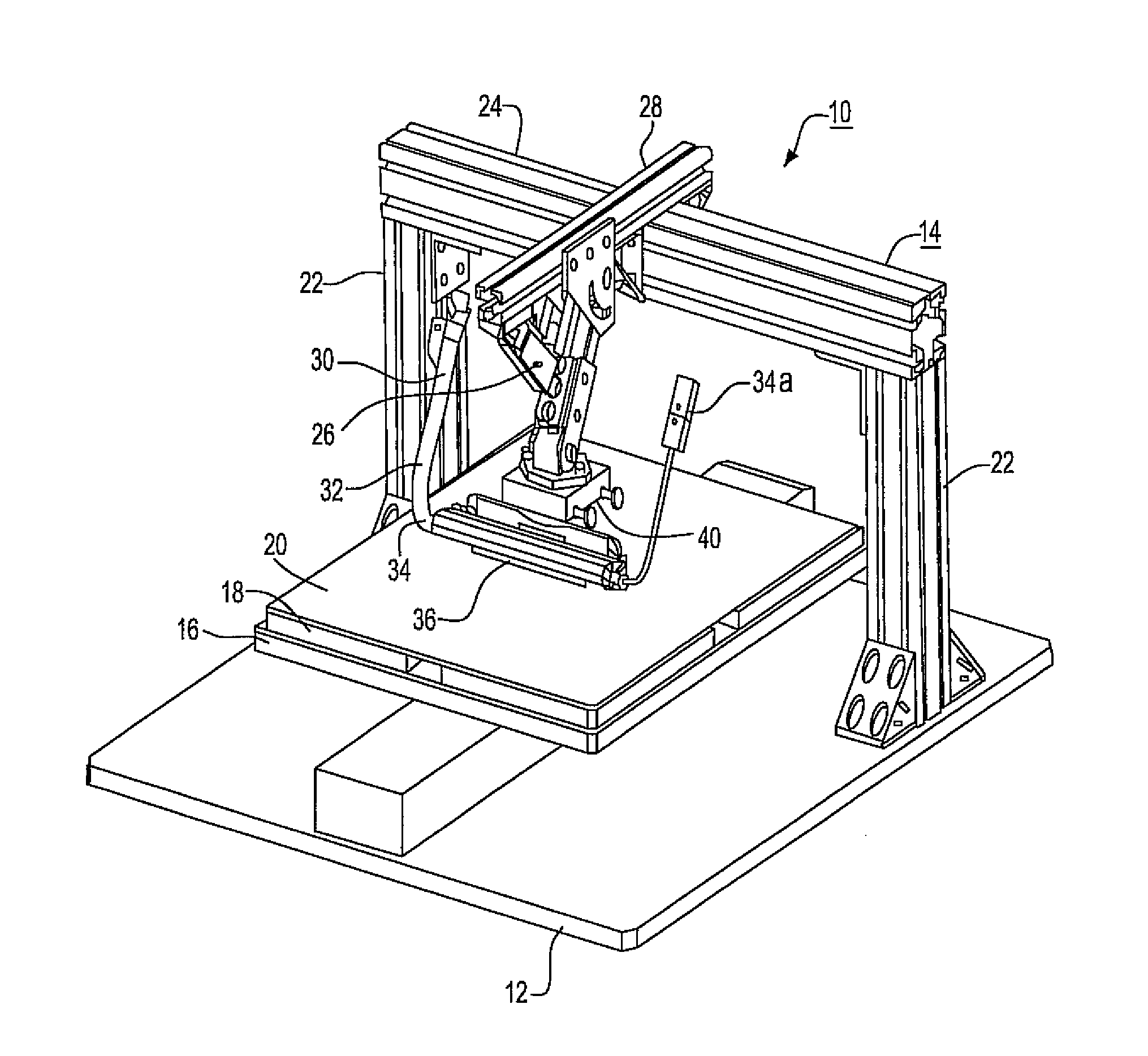

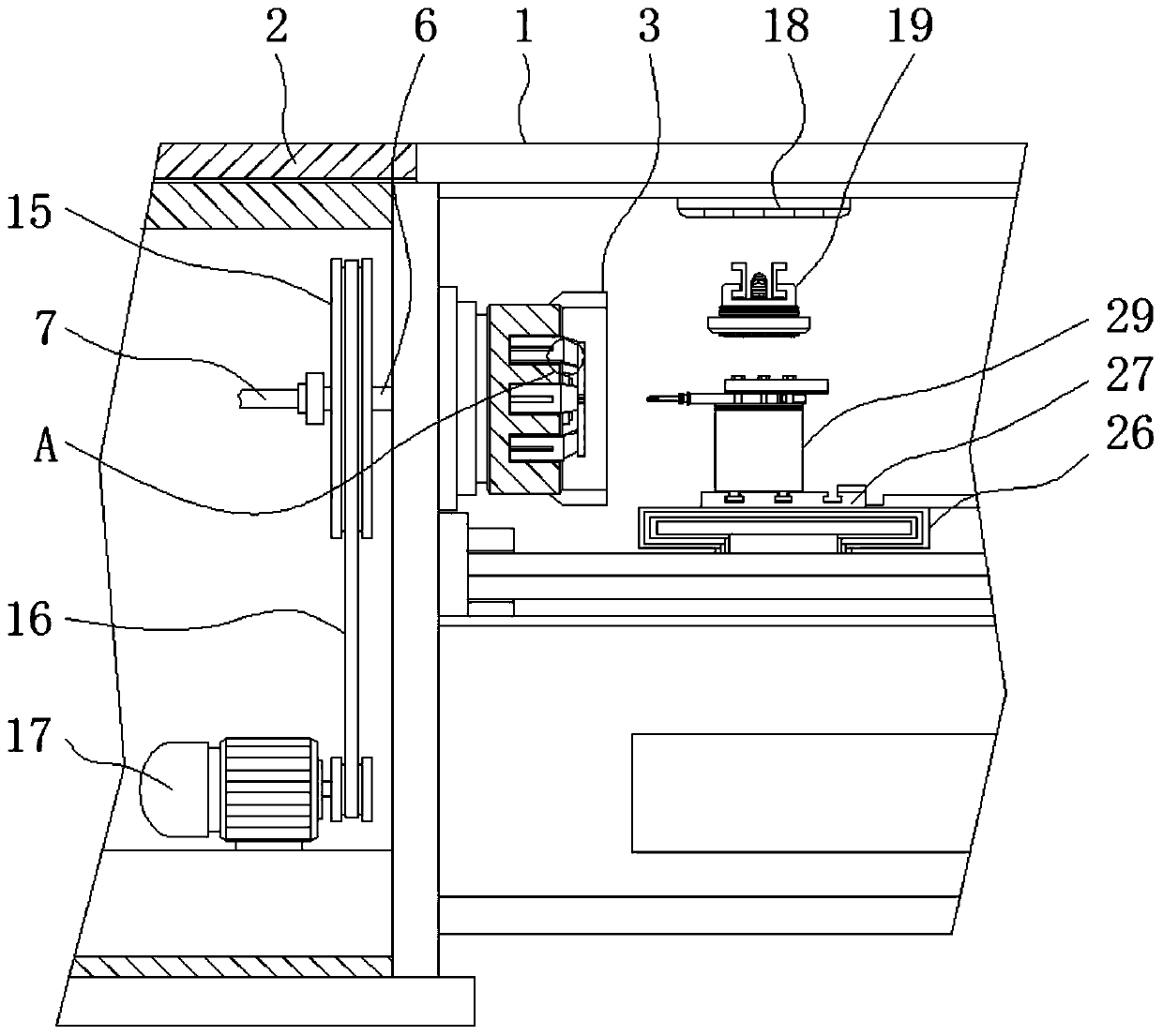

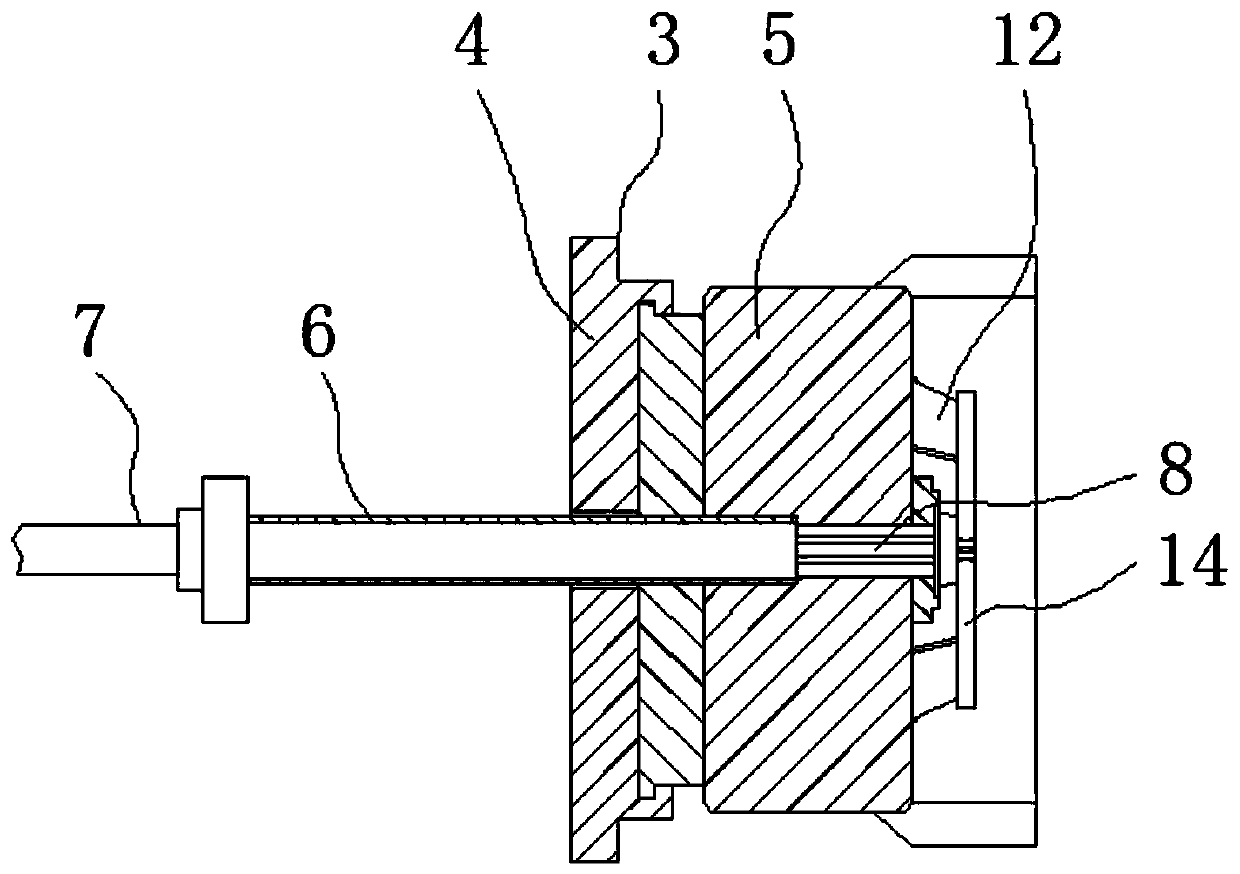

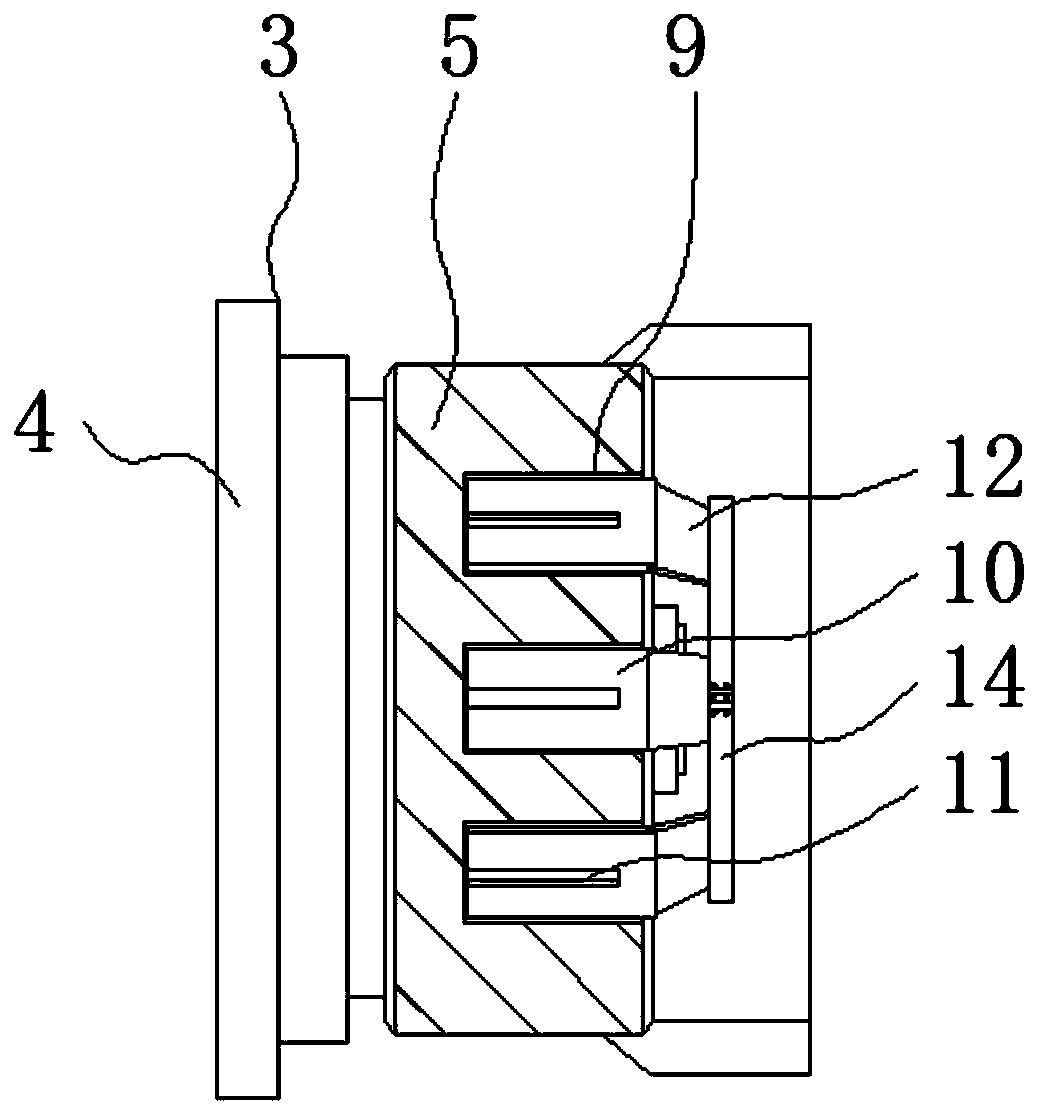

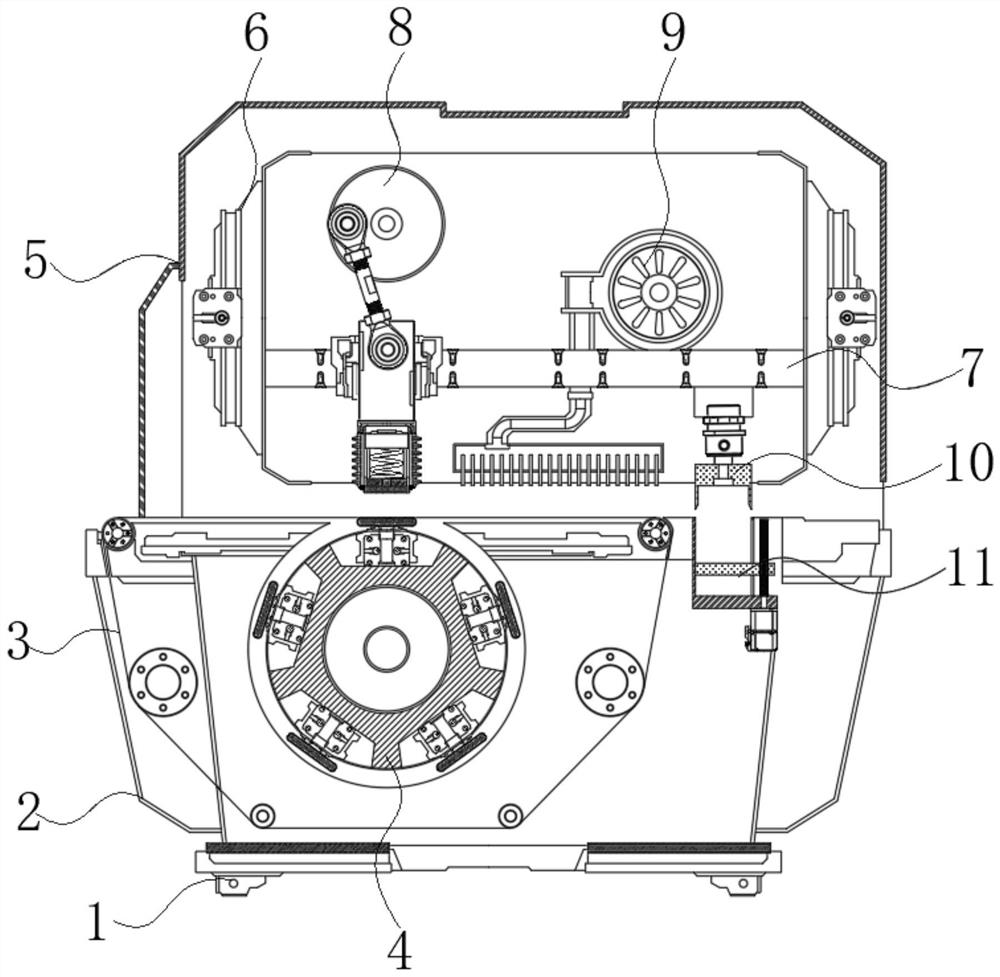

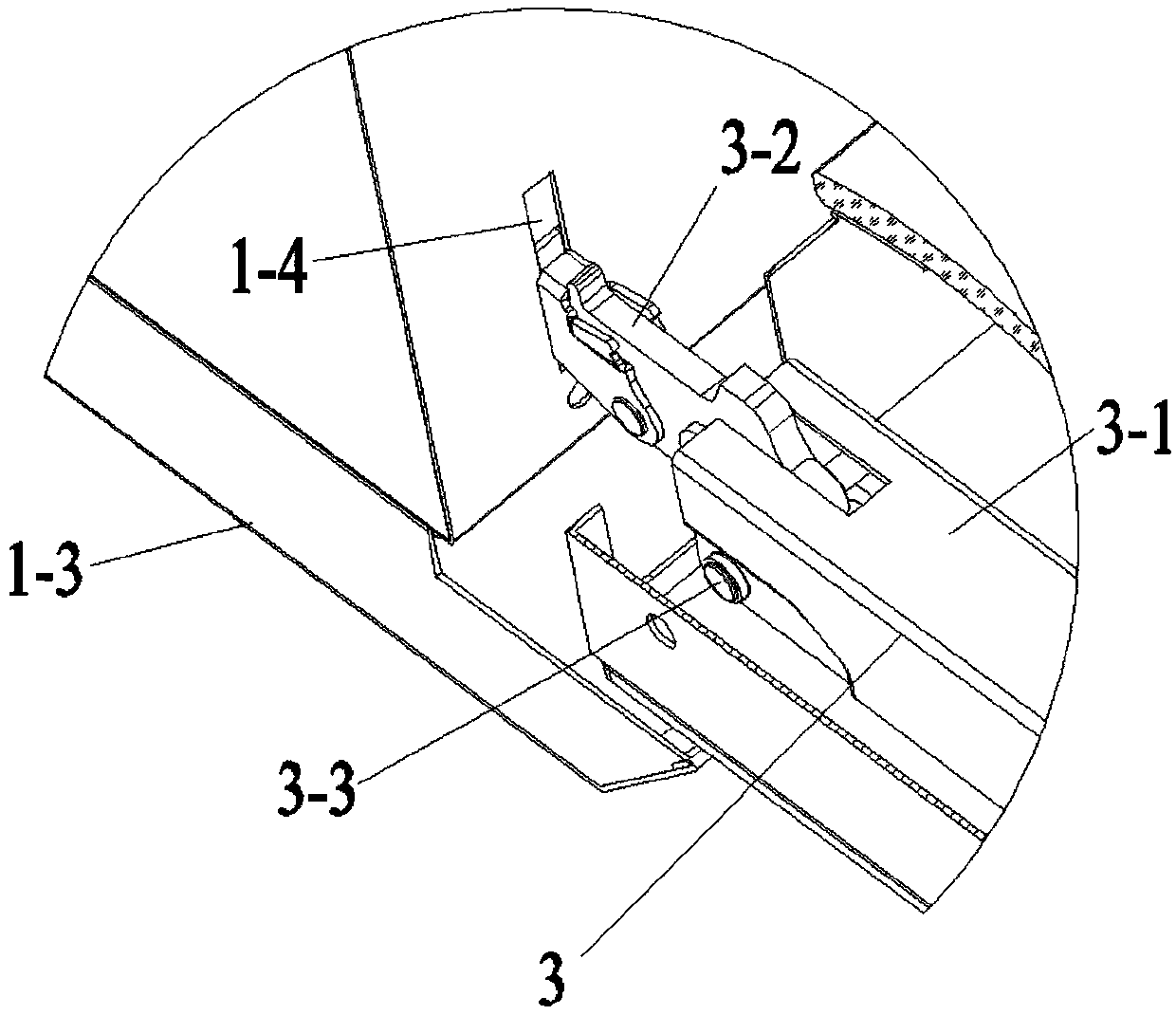

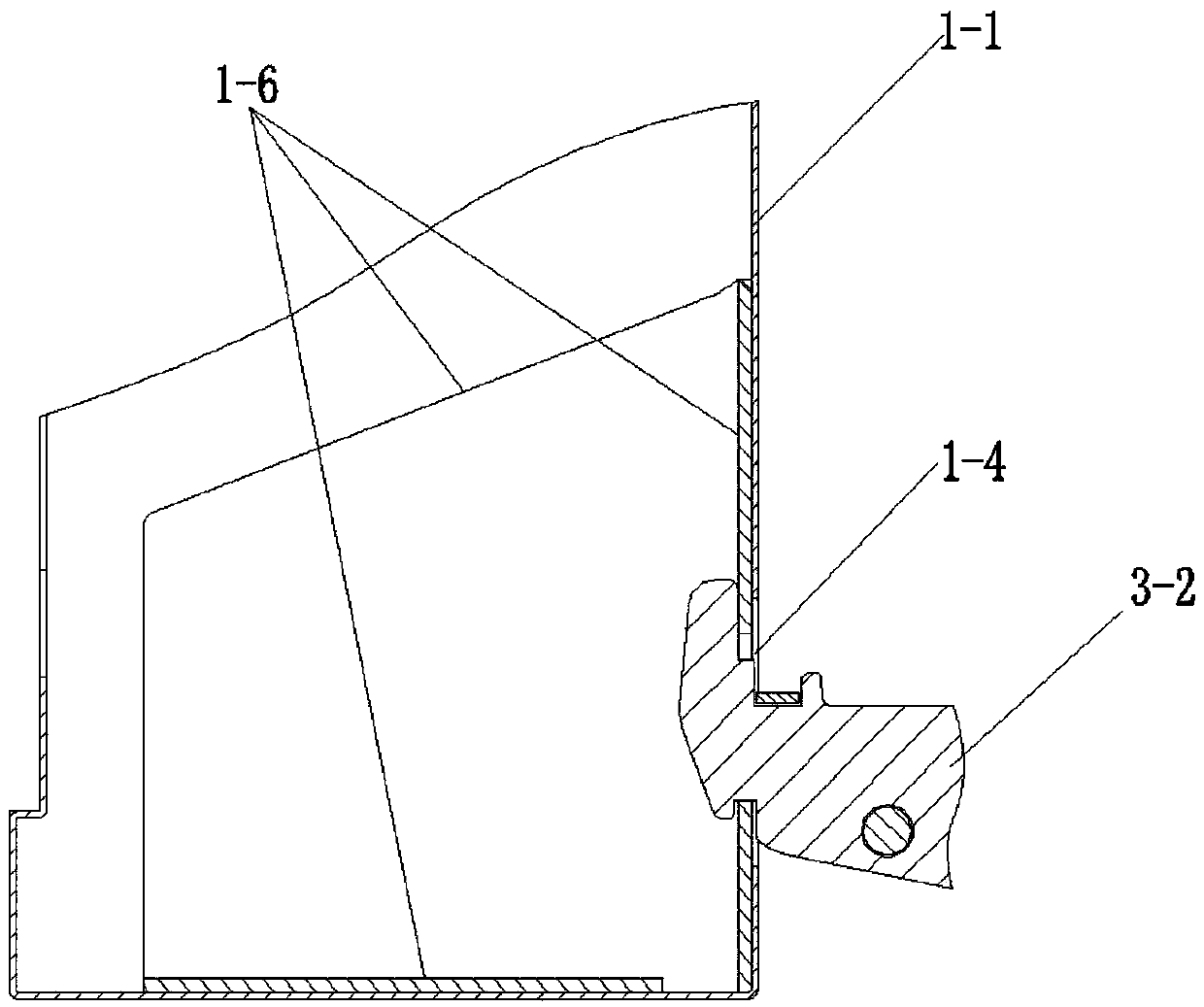

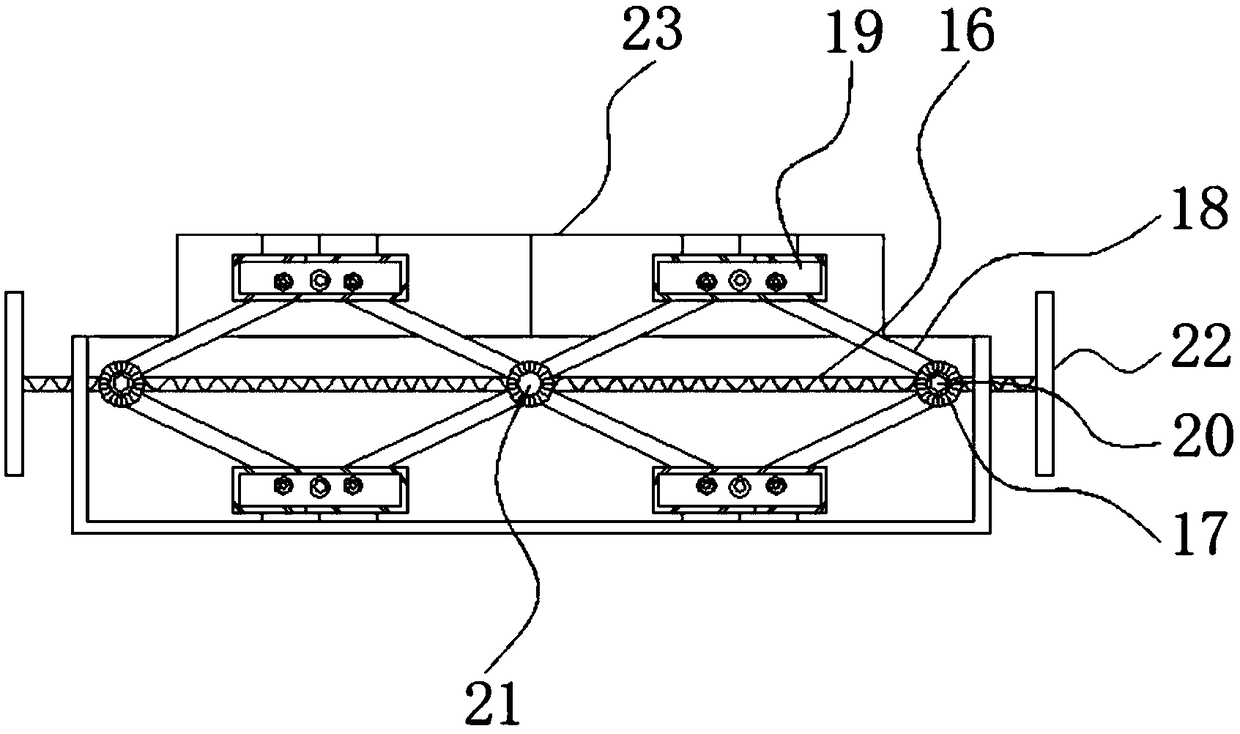

Machining equipment for large tapered roller pin hole and machining process thereof

ActiveCN110270835AHigh concentric precisionLower skill requirementsOther manufacturing equipments/toolsBoring/drilling machinesTransmission beltEngineering

The invention discloses machining equipment for a large tapered roller pin hole and a machining process thereof and relates to the technical field of machining of large tapered roller pin holes. The machining equipment particularly comprises a machine tool, a clamping body, a chip cleaning mechanism and a distance adjusting rod set. A sliding door is installed outside the machine tool. The clamping body is arranged on one side in the machine tool. A hollow rotary shaft penetrates through one side of the clamping body. The outer side of an end of the hollow rotary shaft is sleeved by a belt wheel. A transmission motor is installed at the other end of a transmission belt. The chip cleaning mechanism is transversely arranged on the upper portion in the machine tool. The distance adjusting rod set is clamped between a cutter clamping seat and a cutter clamping plate. According to the machining equipment for the large tapered roller pin hole and the machining process thereof, an original common drill bit is changed to a U drill, thus a workpiece can be punched once, a boring cutter for finish turning of an inner hole is changed to a shakeproof long rod boring cutter, and boring of the inner hole is completed once. Through the machining process, a gear mark of the inner hole of the workpiece is avoided, turning-round secondary drilling and boring are not needed, and concentric accuracy of the inner hole and a conical face is improved.

Owner:WUXI YITONG PRECISION MACHINERY

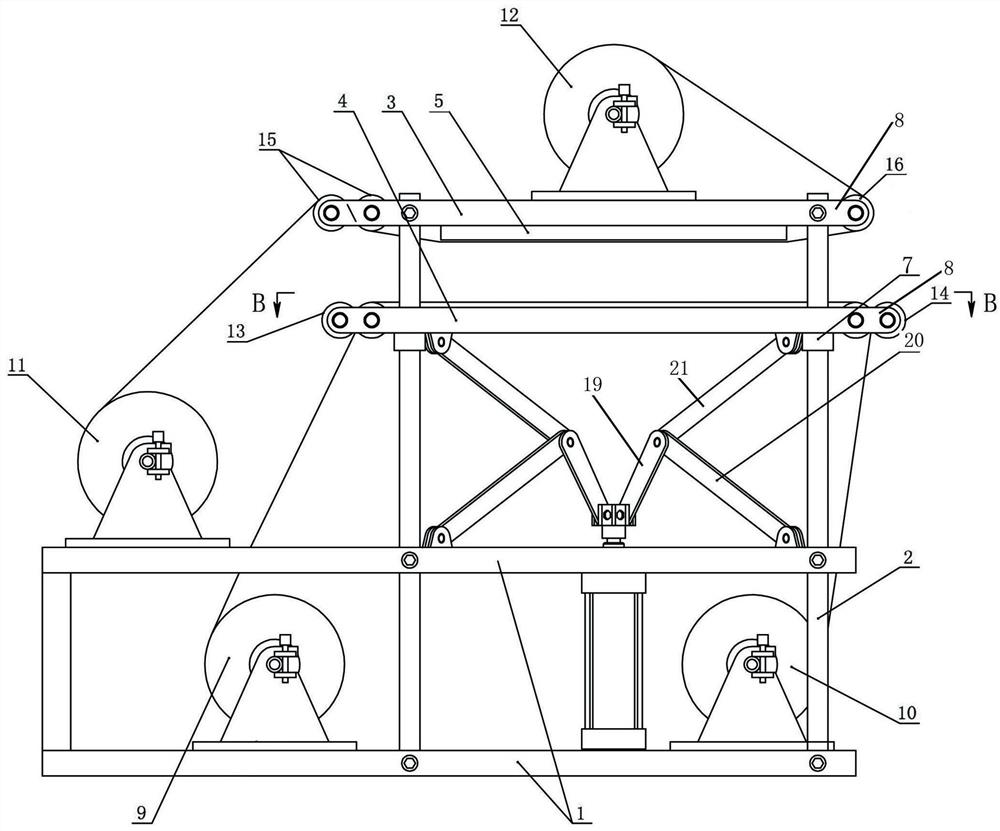

Manufacturing device of schistosome egg detection filter membrane

ActiveCN113043342AQuality improvementImprove integritySemi-permeable membranesMetal working apparatusHot pressManufacturing engineering

The invention discloses a manufacturing device of a schistosome egg detection filter membrane. The manufacturing device comprises a base, a lower frame, an auxiliary pressing assembly, an upper frame, a hot pressing assembly, a cooling assembly, a slitting assembly and a storage assembly, wherein the lower frame is fixed to the upper end surface of the base, and the auxiliary pressing assembly is rotatably arranged in the lower frame; a conveying belt is arranged outside the auxiliary pressing assembly, a plurality of avoiding grooves are formed in the surface of the conveying belt, the upper frame is fixed to the upper end face of the lower frame, a supporting frame is fixed to the interior of the upper frame, and a fixing plate is horizontally fixed to the position, close to the bottom, of the inner part of the supporting frame; and the hot pressing assembly, the cooling assembly and the slitting assembly are sequentially arranged on the fixing plate from left to right, and the storage assembly is arranged under the slitting assembly and fixed in the lower frame. The manufacturing device can rapidly and completely cut the detection filter membrane, and the production efficiency of the detection filter membrane is improved.

Owner:HUNAN NORMAL UNIVERSITY

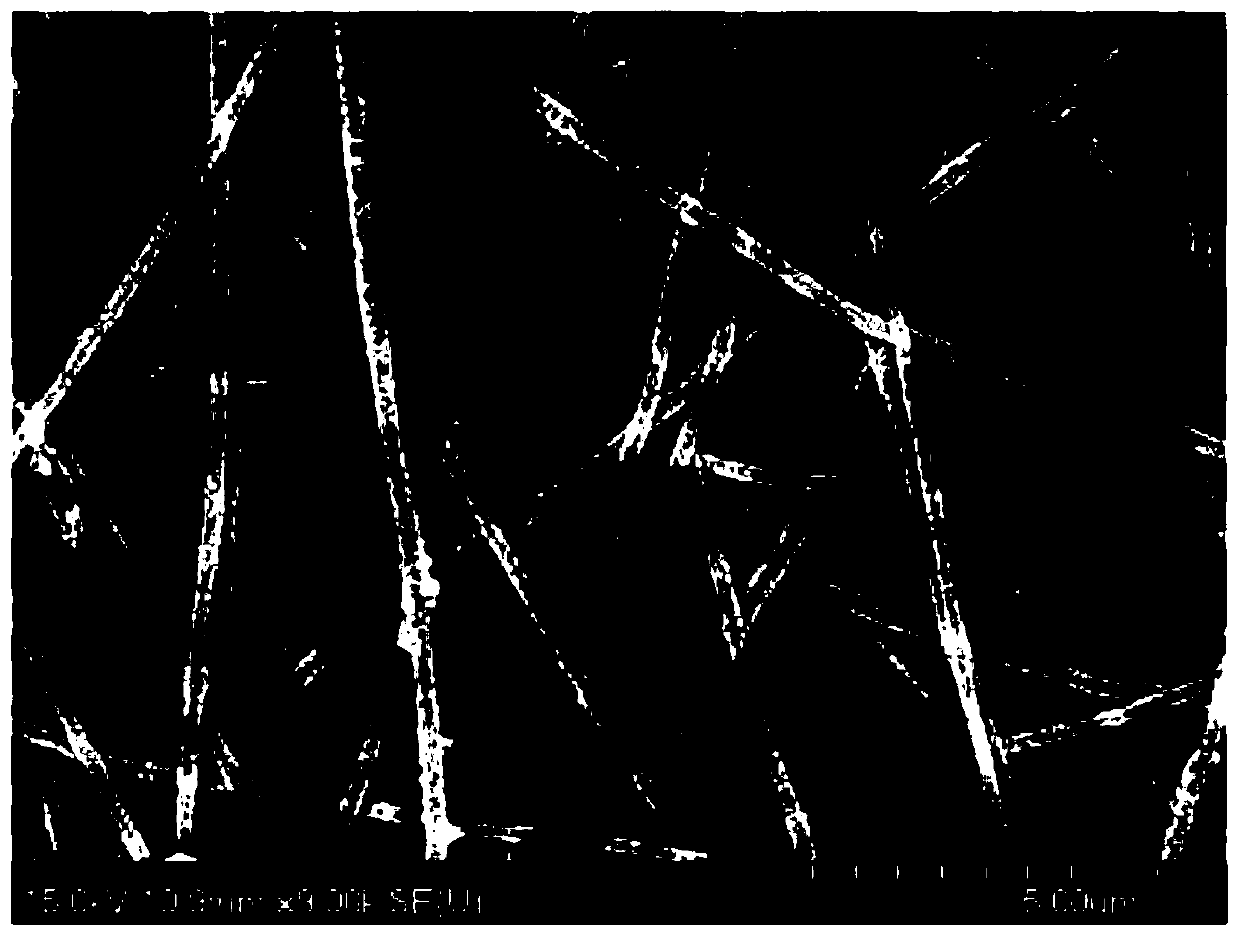

Porous boron-doped carbon-loaded platinum nanoparticle catalyst based on electrostatic spinning technology, and preparation method and application thereof

InactiveCN110508311AImprove electrocatalytic activityImprove current efficiencyPhysical/chemical process catalystsFilament/thread formingAir atmosphereBoron doped carbon

The invention discloses a porous boron-doped carbon-loaded platinum nanoparticle catalyst based on an electrostatic spinning technology, and a preparation method and application thereof. The preparation method of the catalyst comprises the following steps: adding a surfactant coated with platinum nanoparticles, a boron-containing compound and a high-molecular polymer into an organic solvent, and carrying out stirring at 60-80 DEG C for 2-4 hours to form a viscous mixed solution; transferring the obtained viscous mixed solution into an injector, and carrying out spinning under the conditions that a voltage is 14-18 kV and a propelling speed is 1-2.5 mL / h to obtain a blocky spun material; and oxidizing the obtained blocky spun material in an air atmosphere at 180-250 DEG C for 1-3 hours, andcarrying out high-temperature calcination on the obtained oxidized material in a high-purity gas atmosphere at 700-1000 DEG C for 2-4 hours so as to obtain the catalyst disclosed by the invention. The catalyst provided by the invention is low in preparation cost, has relatively high electrocatalytic activity and super-strong stability when applied to preparation of ozone through electrolysis of water, and obviously improves the current efficiency of the preparation of ozone through electrolysis of water.

Owner:ZHEJIANG UNIV OF TECH

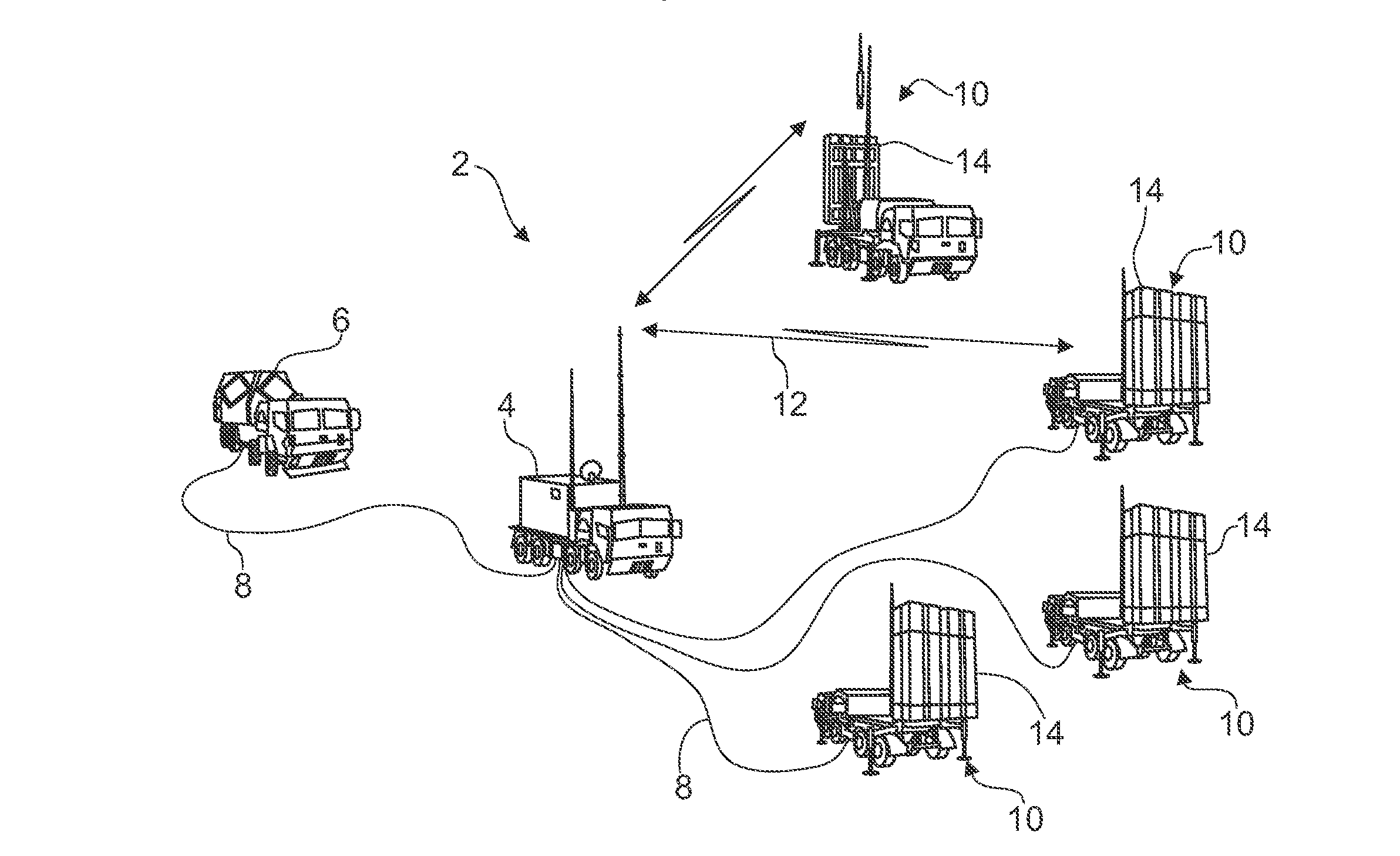

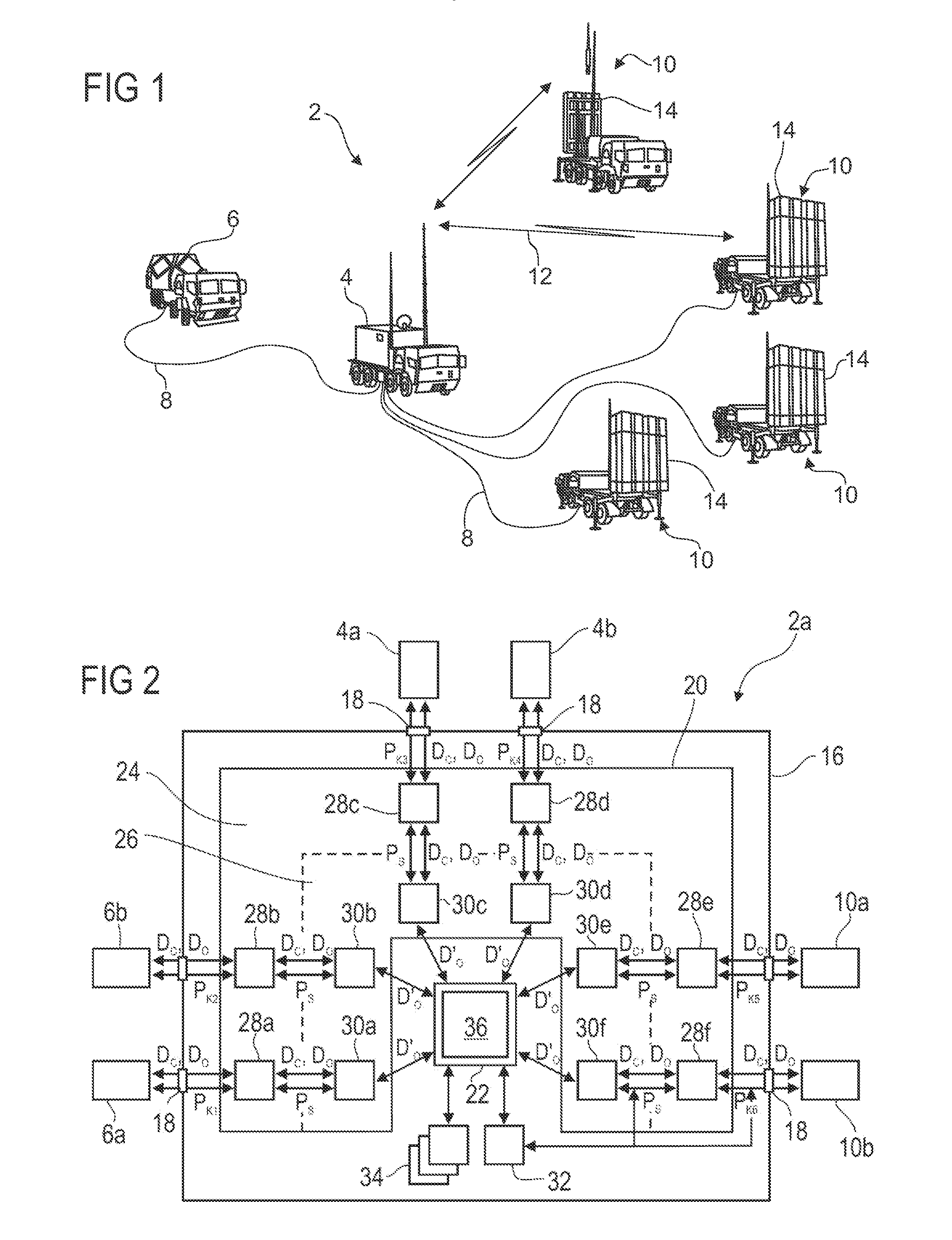

Ground-based Anti-aircraft system and method for operating the system

ActiveUS20160047633A1Reduced integrityFirmly connectedDefence devicesDirection controllersOperational systemDistributor

A method for operating a ground-based anti-aircraft system includes providing a group of main system components containing a sensor system, a tactical operation control and an effector system. Combat target sensor data are passed from the sensor system to the tactical operation control, processed therein and passed in processed form from the tactical operation control to the effector system, using the data to combat the target. A central integration module having a converter unit and a central data distributor allows differently constructed main system components to be connected. Data from all main system components are routed to the central data distributor by the converter unit and converted therein from component protocol into system-internal data protocol, and passed from the central data distributor to one or more main system components, through the converter unit, converting the distributed data back from system-internal data protocol into component protocol.

Owner:DIEHL DEFENCE GMBH & CO KG

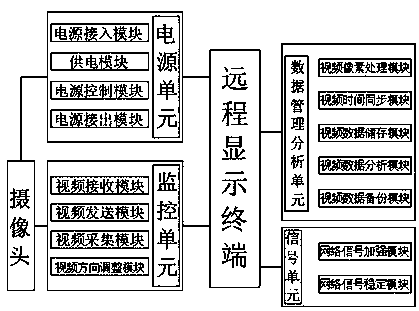

Video monitoring platform for power transmission and transformation equipment

InactiveCN110519482AImprove accuracyAvoid lossTelevision system detailsColor television detailsElectric power transmissionVideo monitoring

The invention discloses a video monitoring platform for power transmission and transformation equipment. The system comprises a remote display terminal, a data management and analysis unit, a signal unit, a power supply unit, a monitoring unit and a camera, the remote display terminal is electrically connected with the data management and analysis unit, the signal unit, the power supply unit and the monitoring unit. A video pixel processing module capable of adjusting video pixels is arranged in the data management and analysis unit, wherein the video time synchronization module can be used for determining time, the video data storage module can be used for video storage, the video data analysis module can be used for improving the accuracy of data information, and the video data backup module can prevent data loss. The system is reasonable in design, does not need to arrange lines, can reduce the cost required by monitoring, can guarantee the stability and transmission speed of videotransmission through a 5G or WIFI network, and avoids the impact on the integrity of video data transmission caused by the instability of the network.

Owner:STATE GRID CORP OF CHINA +1

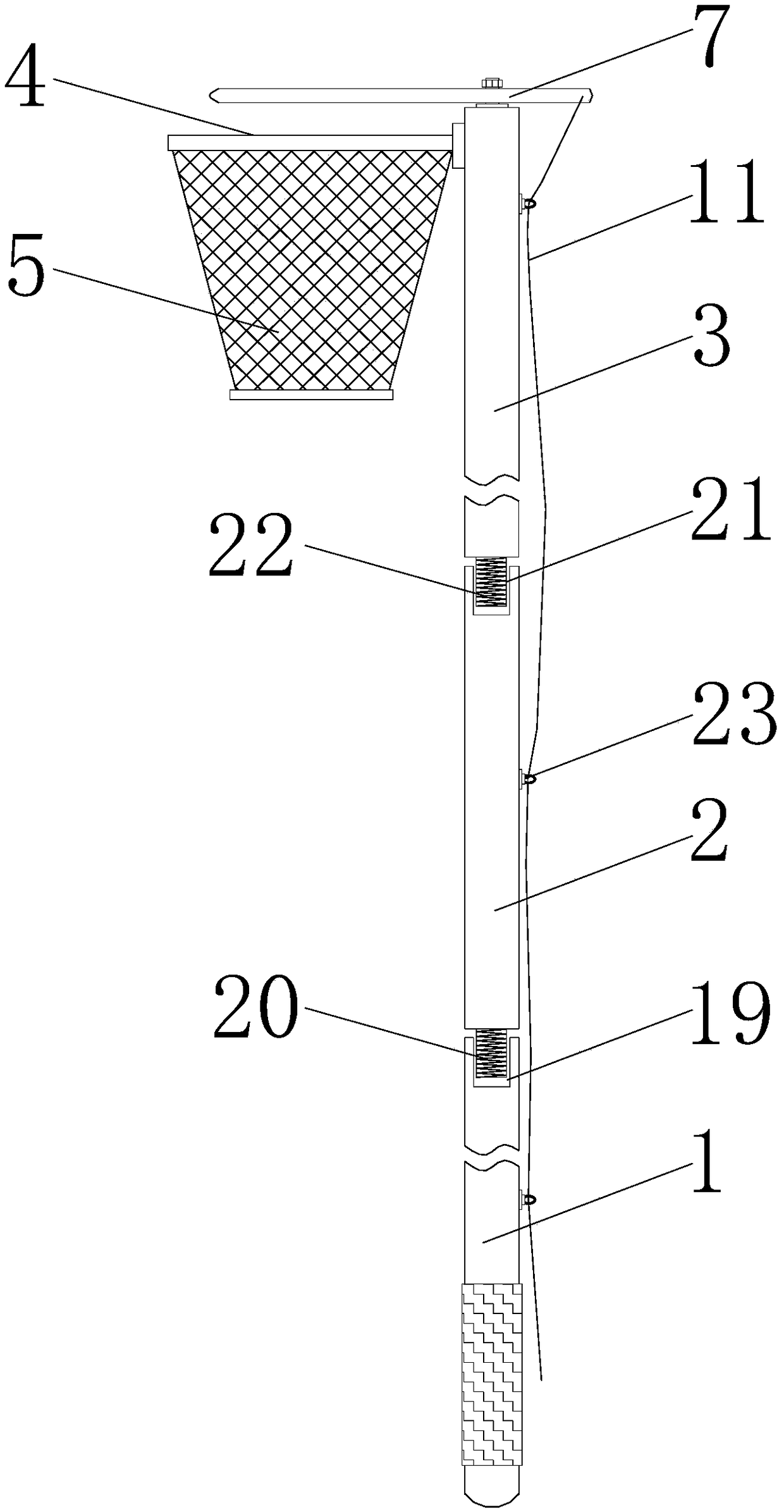

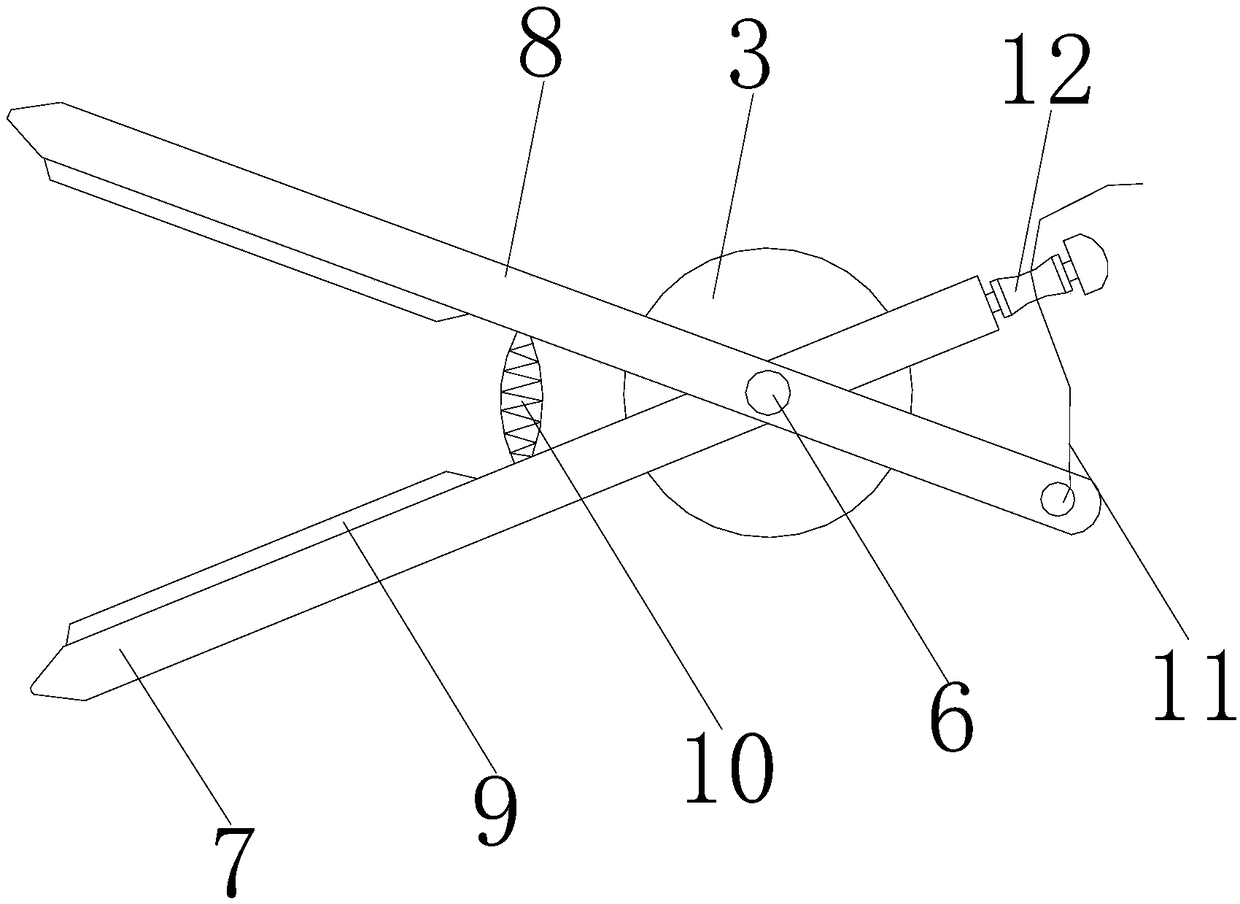

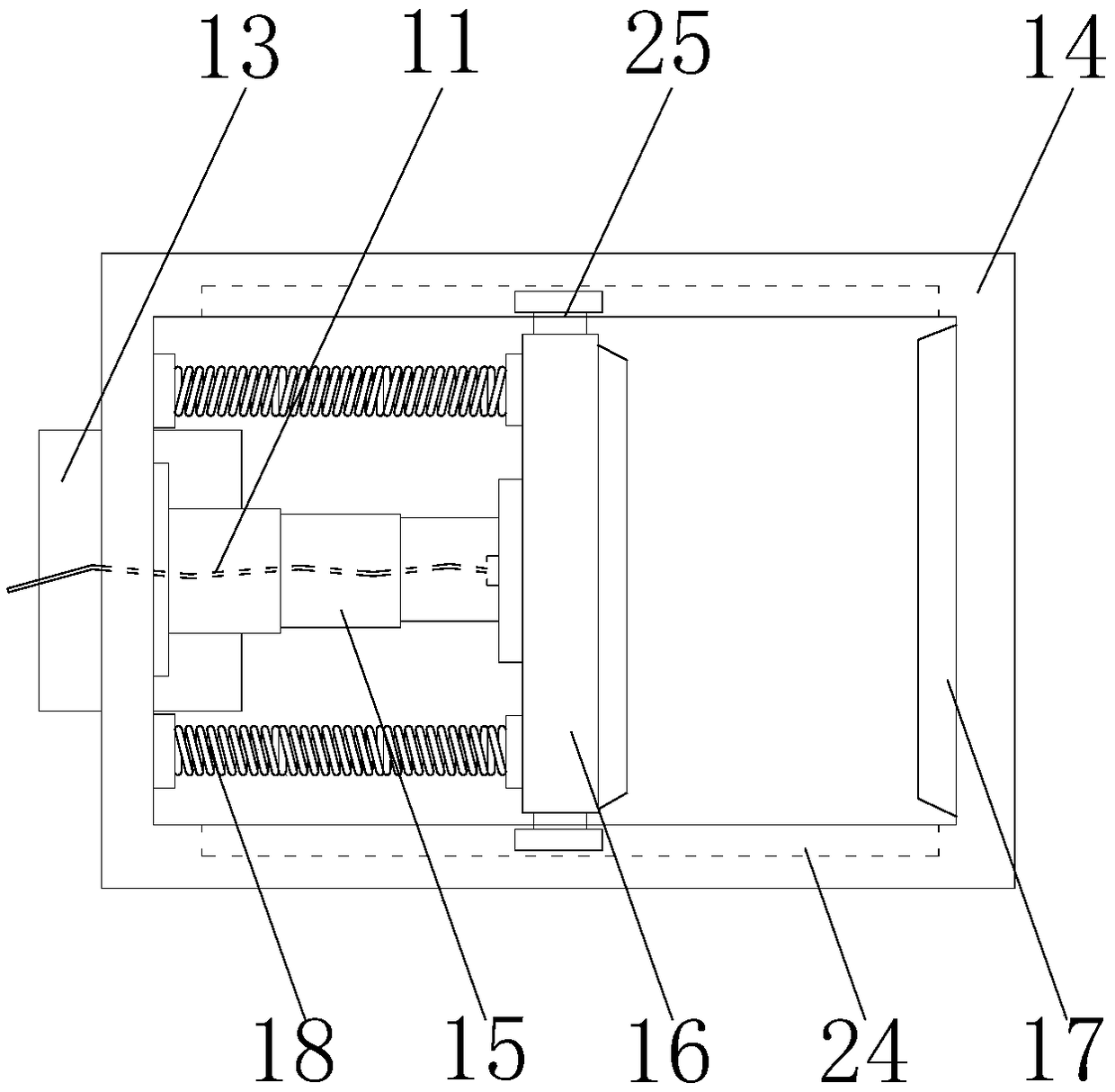

Practical fruit-bearing forest fruit picking device

The invention discloses a practical fruit-bearing forest fruit picking device which comprises a bottom rod. The top end of the bottom rod is connected with a connecting rod in a threaded manner, the top end of the connecting rod is connected with an ejector rod in a threaded manner, one side of the top of the ejector rod is fixedly connected with a fixing frame, and the bottom of the fixing frameis fixedly connected with a fruit net bag. According to the practical fruit-bearing forest fruit picking device, by coordination of a first knife handle, a second knife handle, a knife edge, a limit spring, a pull rope, a shear frame, a telescopic sleeve, a plate, a blade and a supporting spring, the problem of generally single structure of fruit picking equipment used in the current market is solved, practicability of the fruit picking equipment is greatly improved, better use effects are achieved, great effects on completeness of fruits is avoided, attractiveness of the appearance of the fruits is ensured, sale level is improved, use of people is more effectively facilitated, fruit picking efficiency is improved, and working time is shortened.

Owner:盱眙启睿矿业有限公司

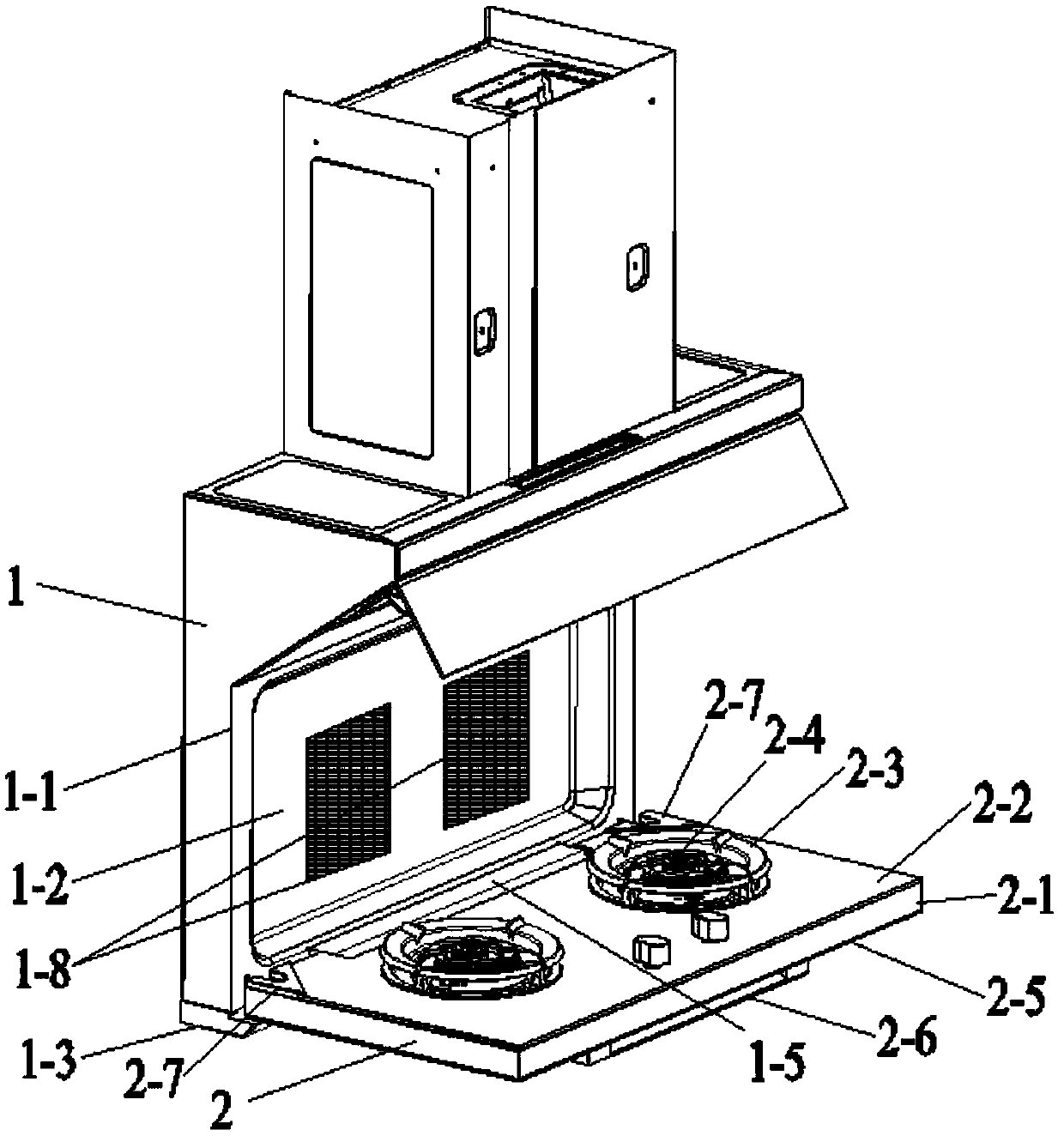

Range hood and gas stove all-in-one machine

PendingCN110578938AAffect integritySave spaceStoves/ranges foundationsDomestic stoves or rangesCombustorExhaust fumes

The invention discloses a range hood and gas stove all-in-one machine. The range hood and gas stove all-in-one machine includes a range hood and a turnover gas stove, the range hood includes an exhaust fume collecting hood and a vertical panel arranged below the exhaust fume collecting hood, the hearth of the gas stove is hinged to the lower end of the vertical panel, an oil collecting box is arranged below the bottom wall of the vertical panel, and the front side wall, the left side wall and the right side wall of the vertical panel extend downwards to enclose a facade stretch cavity of the exhaust fume collecting hood. According to the range hood and gas stove all-in-one machine, burners and gas pipelines do not need to be arranged in cabinets like the prior art, the space in a kitchen is saved, a cabinet below the gas stove can be used for other purposes, the available space is enlarged, the arrangement of the vertical panel takes advantage of the viscous effect of oil fume, in theprocess of rising of the oil fume, the oil fume is attached to the front wall of the vertical panel to rise upwards, the facade stretch cavity formed by the front wall, the left side wall and the right side wall of the vertical panel and the exhaust fume collecting hood can improve the effect of oil fume collecting, and the oil fume absorption effect is enhanced.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

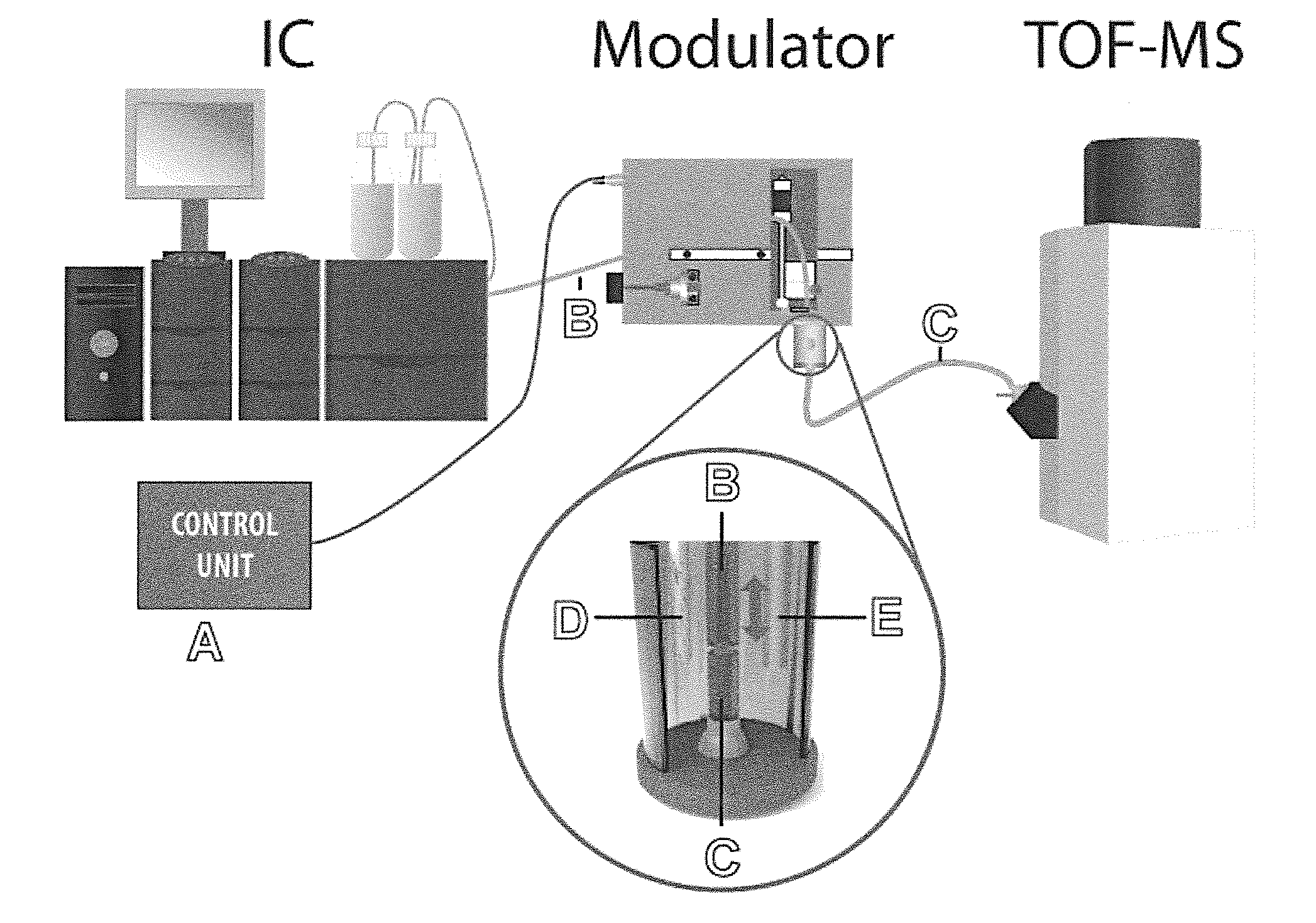

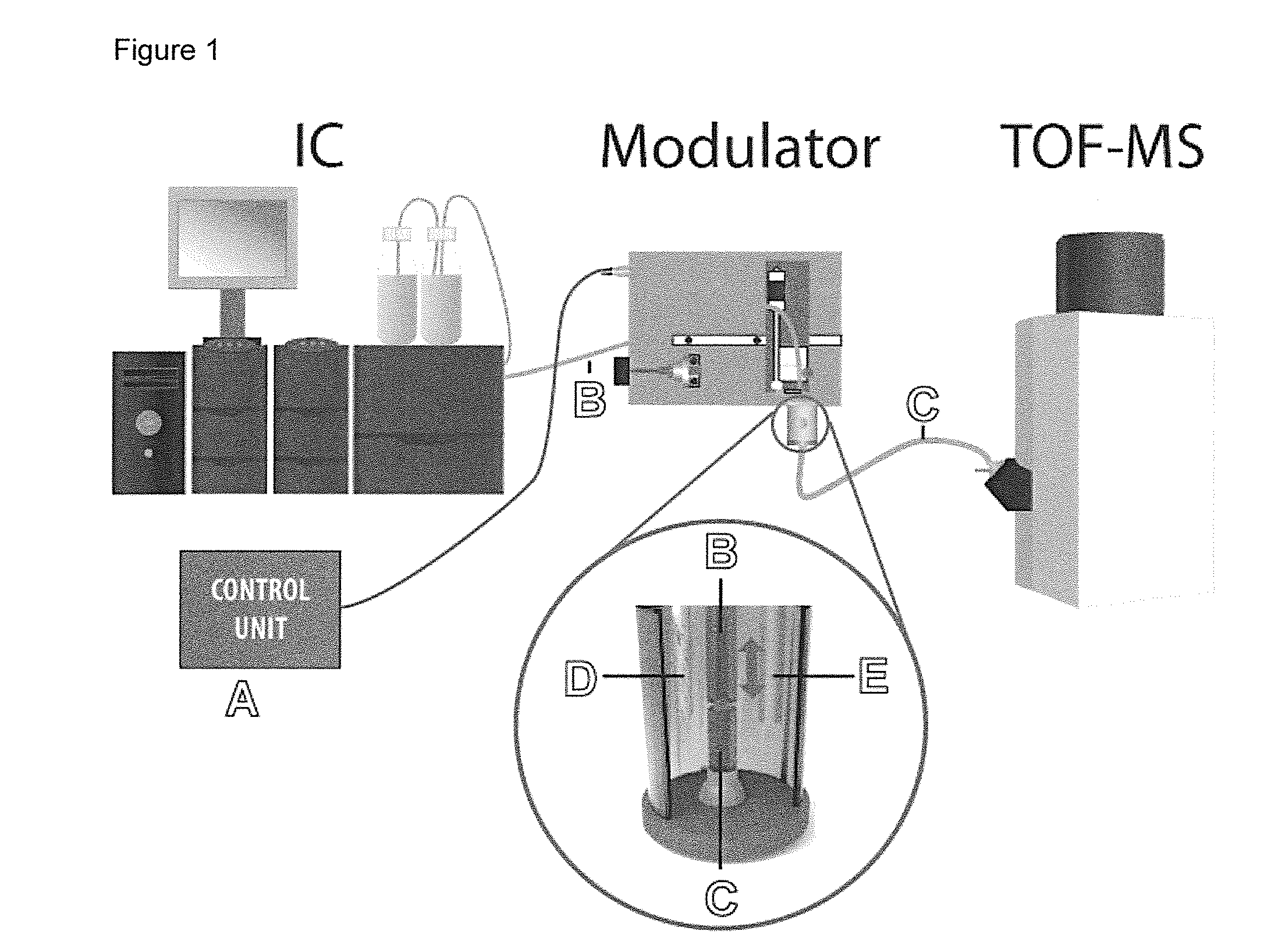

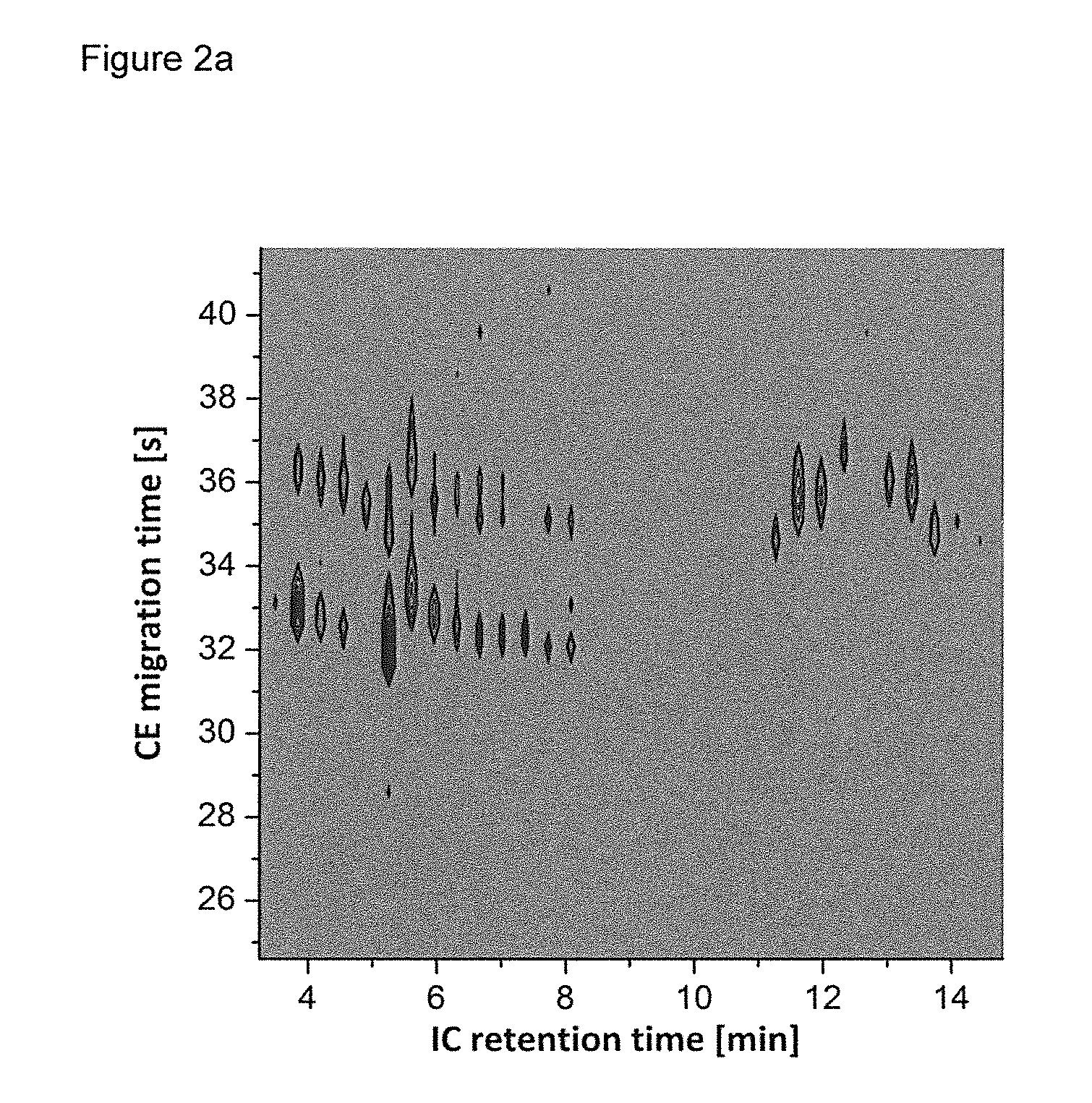

Method and device for two-dimensional separation of ionic species

ActiveUS20170030860A1Higher electrophoretic mobilityLess frictionCation exchanger materialsComponent separationIonElectrophoresis

The invention relates to a method which realizes a two-dimensional separation of ionic species on the basis of the online coupling of ion chromatography (IC) and capillary electrophoresis (CE). A device for IC×CE coupling, its implementation in terms of two alternatives, the connection to a mass spectrometric detector, and corresponding application are described.

Owner:UNIV REGENSBURG

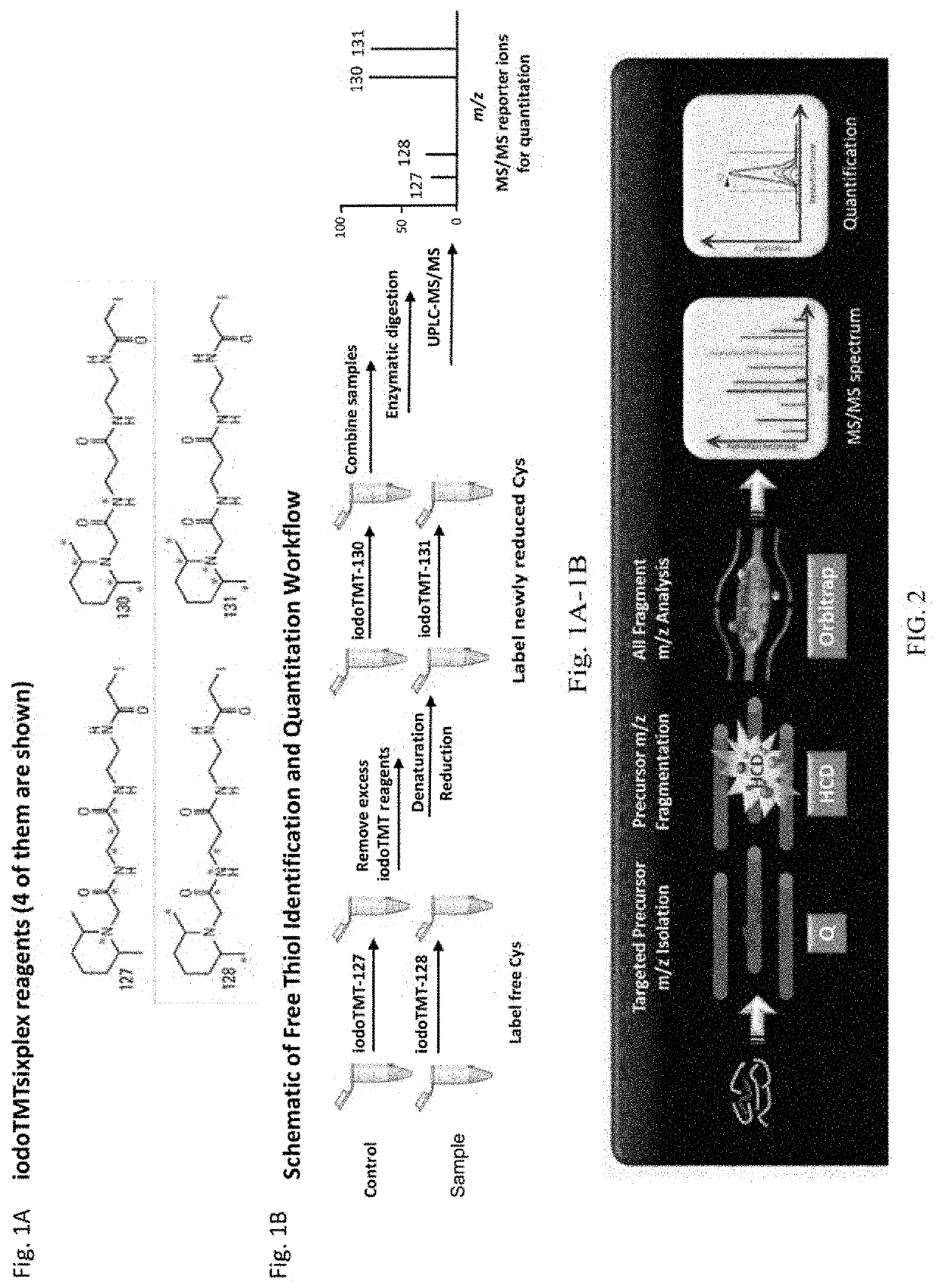

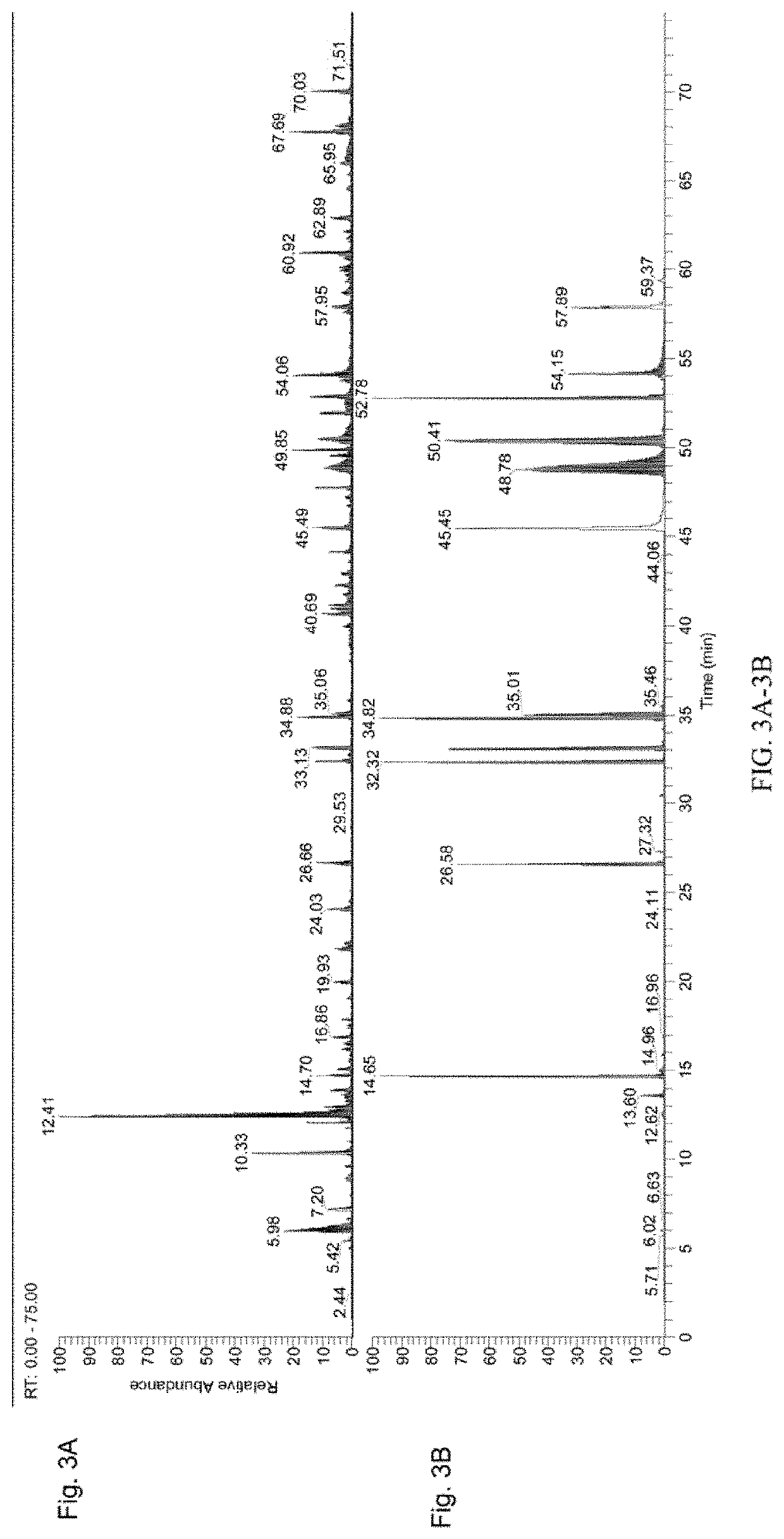

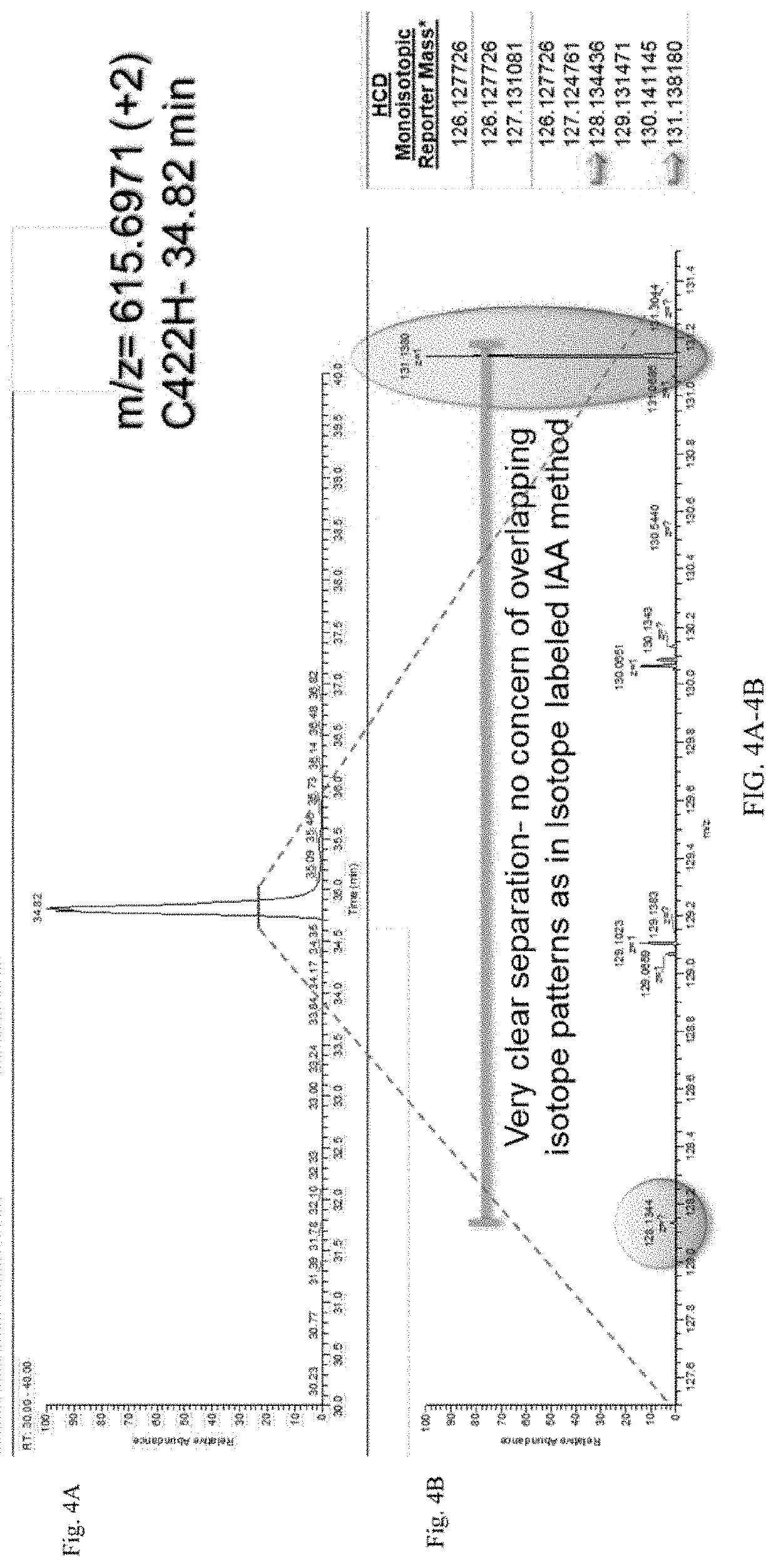

Methods for identifying free thiols in proteins

ActiveUS20200225245A1Reduced thermal stabilityAffect biological functionComponent separationPreparing sample for investigationDisulfide bondingProtein composition

Compositions and methods for identifying free thiols in protein are provided. An exemplary method labeling peptides with a tag to identify free thiols and a tag to identify native disulfide bonds and analyzing the tags using targeted MS2. In one embodiment, the method provides complete coverage of all 32 cysteine residues in an IgG molecule. In other embodiments the method covers the 16 cysteine residues on the heavy and light chains in an IgG molecule. In another embodiment, the method covers the 5 cysteine residues on each light chain of an IgG molecule. In another embodiment, the method covers the 11 cysteine residues on each heavy chain of an IgG molecule.

Owner:REGENERON PHARM INC

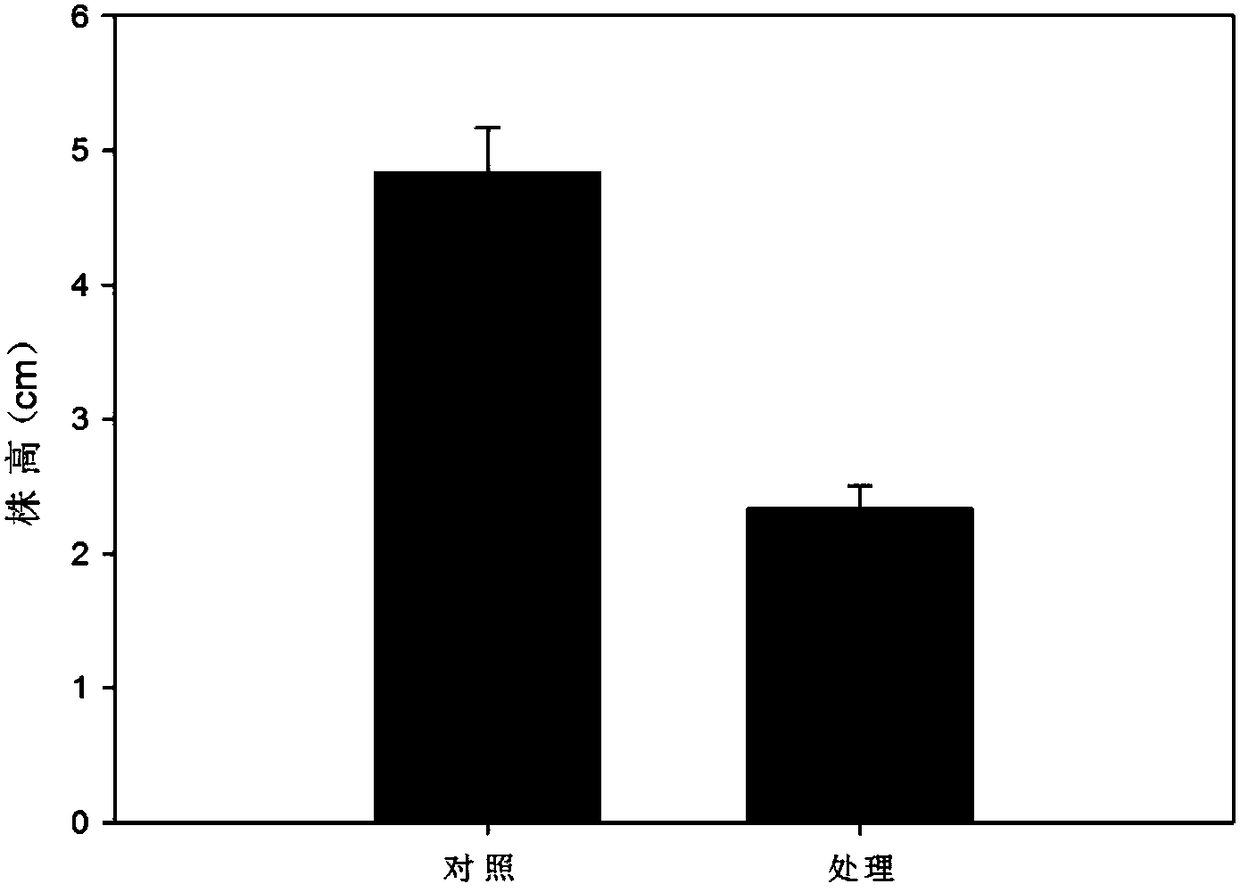

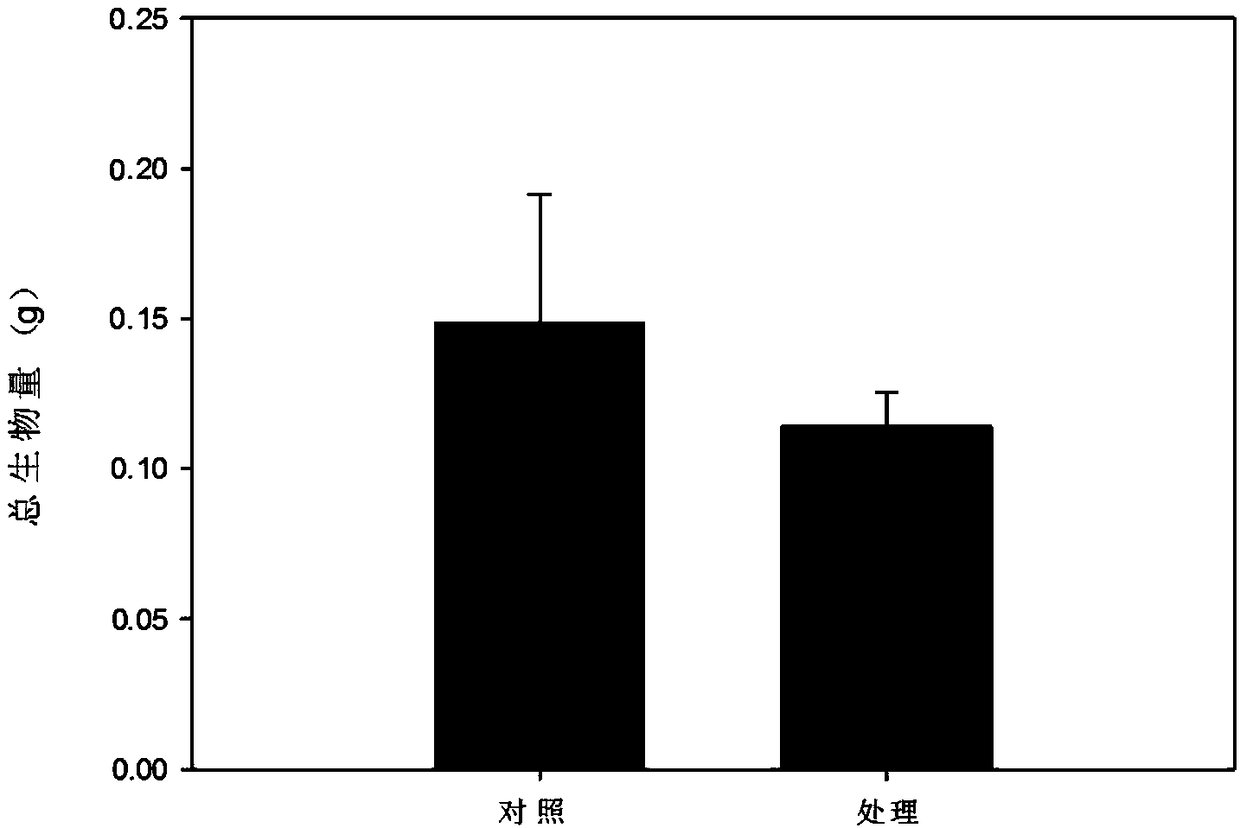

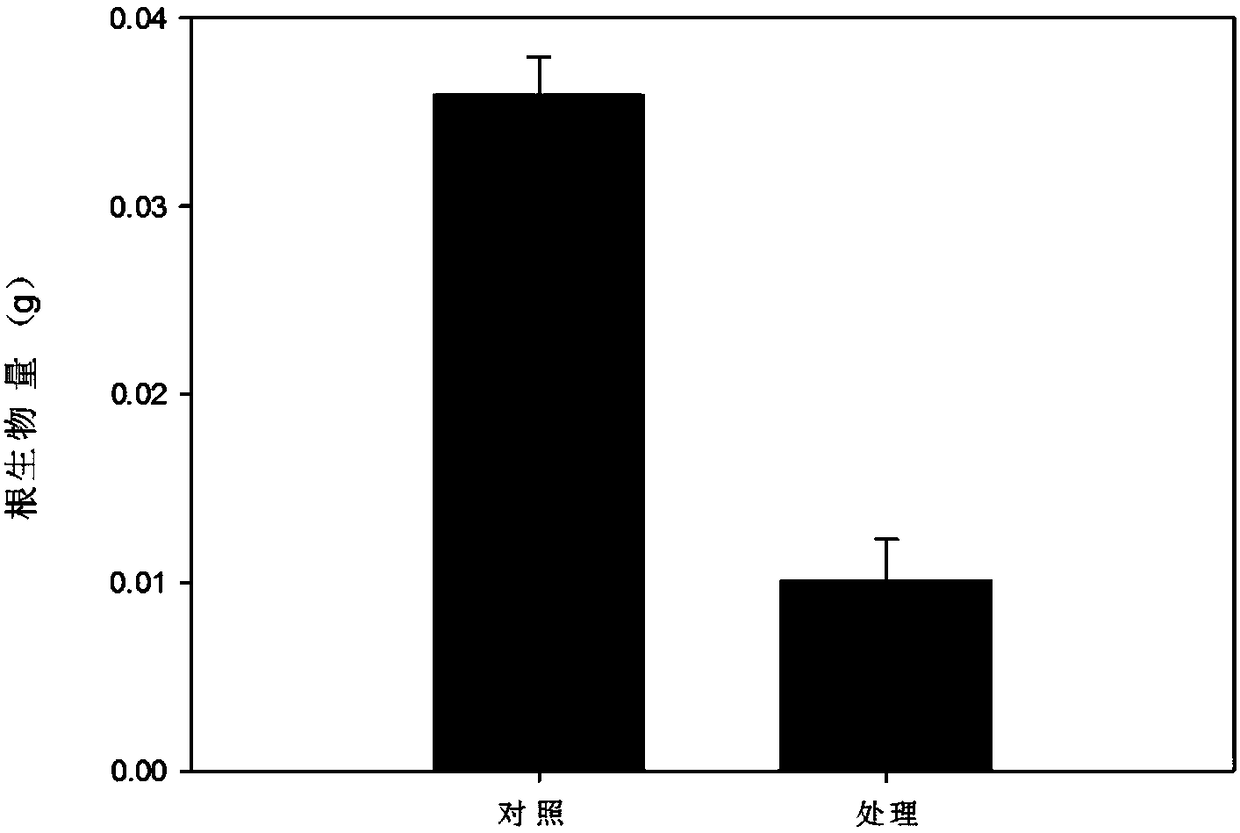

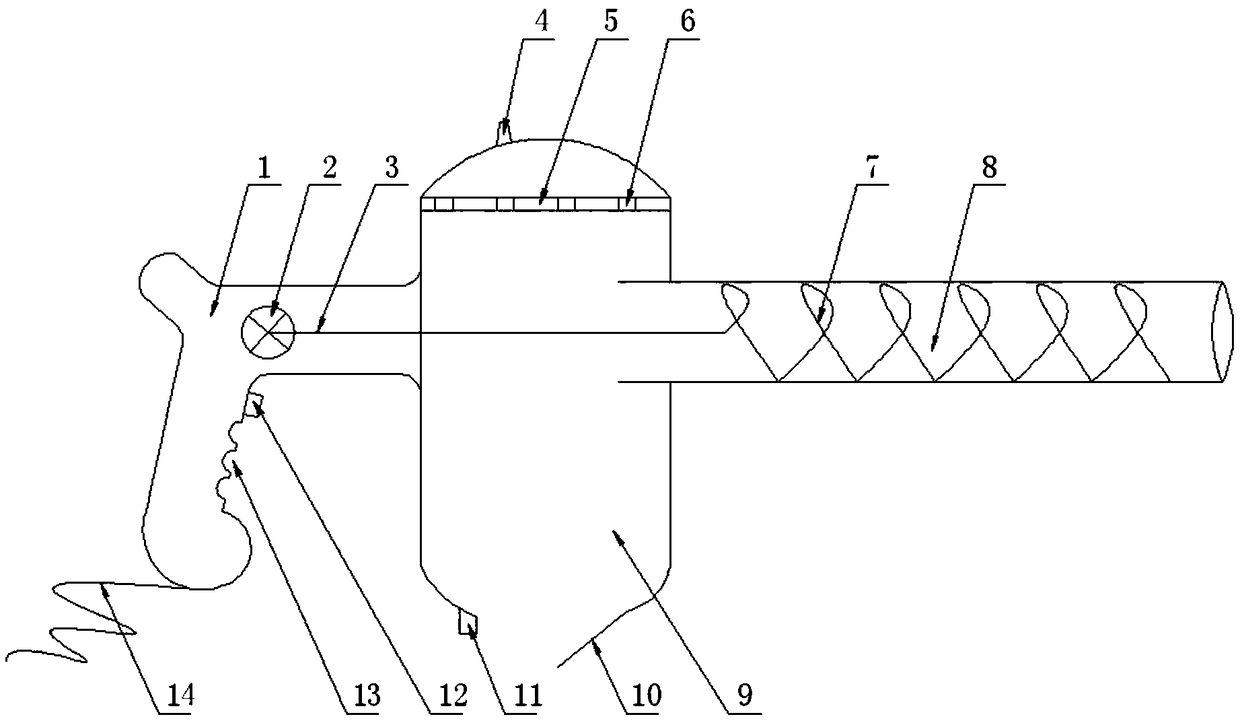

Biological preparation and method for inhibiting growth of foreign species of solidago canadensis L.

ActiveCN108576080AAvoid absorptionAvoid damageBiocidePlant growth regulatorsBristlegrassesAqueous extract

The invention relates to a biological preparation and method for inhibiting growth of foreign species of solidago canadensis L., and belongs to the technical field of ecological prevention and controland biological agents for weed control. The invention provides the biological preparation and method for inhibiting growth of foreign species of solidago canadensis L. to avoid the harm and limitation of an existing inhibitor. The biological preparation contains an aqueous extract of green bristlegrass, and green bristlegrass adopted for the aqueous extract of green bristlegrass is the herbs of green bristlegrass. The method comprises the step of adopting the biological preparation containing the aqueous extract of green bristlegrass for watering an area in which solidago canadensis L. is grown, wherein green bristlegrass adopted for the aqueous extract of green bristlegrass is the herbs of green bristlegrass. The preparation is capable of inhibiting the absorption of nutrients by solidago canadensis L. and damaging a photosynthesis system of solidago canadensis L., so that the plant height and total biomass of solidago canadensis L. are inhibited, and the effect of effectively inhibiting the growth is achieved.

Owner:TAIZHOU UNIV

Negative-pressure rotary cut specimen extractor used for laparoscopic surgery

InactiveCN109009252AIntegrity guaranteedTake it out smoothlySurgeryVaccination/ovulation diagnosticsEngineeringLarge size

The invention relates to a negative-pressure rotary cut specimen extractor used for laparoscopic surgery. The extractor is characterized by comprising a handle, a specimen collecting chamber and a rotary cut sleeve pipe. One end of the specimen collecting chamber is fixedly provided with the handle, the other end of the specimen collecting chamber is fixedly provided with the rotary cut sleeve pipe, a power motor is installed in the handle, a rotating shaft of the power motor is connected with a rotary cut blade through a connection rod, the rotary cut blade is located in the rotary cut sleevepipe, the power motor is connected with an external power supply through a wire, and the top of the specimen collecting chamber is provided with a negative-pressure device connection opening. The extractor is scientific and reasonable in design, a large-size specimen can be smoothly taken out, after the specimen is orderly taken out from the body, the original structure of the specimen still canbe restored, and the follow-up pathological study is facilitated.

Owner:刘胜来

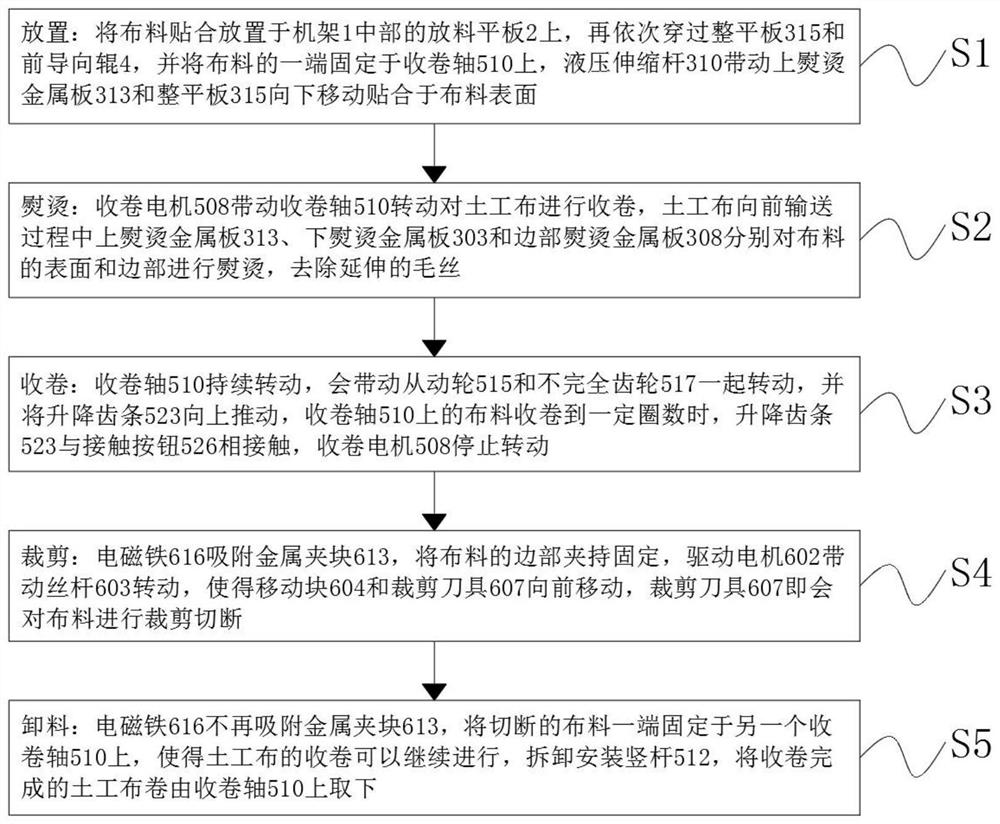

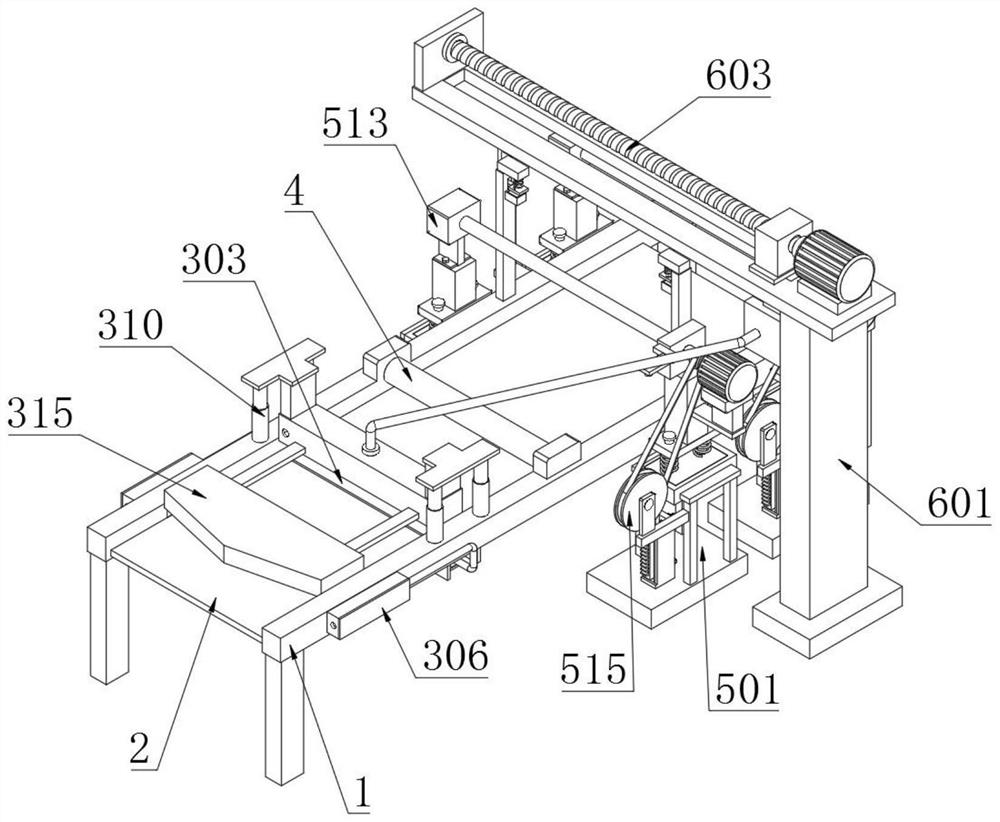

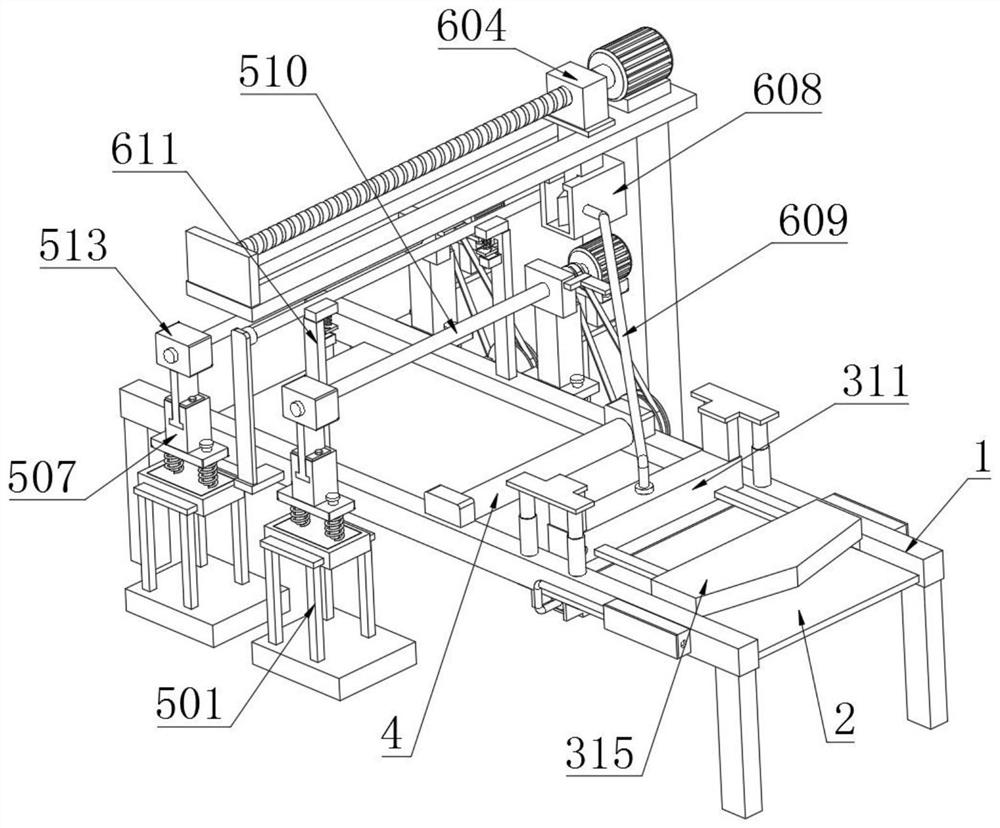

Durable geotechnical cloth preparation process

ActiveCN113564860AImprove structural strengthExtended service lifeSingeingSevering textilesForeign matterSoil science

The invention discloses a durable geotechnical cloth preparation process. The durable geotechnical cloth preparation process comprises the following steps that S1, placing is carried out, specifically, cloth is placed on a material placing flat plate in the middle of a machine frame in a fitting mode; then the cloth sequentially penetrates through a leveling plate and a front guide roller, and one end of the cloth is fixed to a rolling shaft; and an upper ironing metal plate and the leveling plate are driven to move downwards by a hydraulic telescopic rod to be fitted on the surface of the cloth. A lower heating plate and an upper heating plate are used for heating a lower ironing metal plate and an upper ironing metal plate at the same time, geotechnical cloth passes through the space between the lower ironing metal plate and the upper ironing metal plate when being conveyed forwards, and the geotechnical cloth can be ironed through the lower ironing metal plate and the upper ironing metal plate; residual broken filaments on the surface of the geotechnical cloth in the geotechnical cloth manufacturing and weaving process are removed at high temperature, so that the surface of the geotechnical cloth is kept flat, and the broken filaments or thread residues are prevented from protruding; and the situation that the geotechnical cloth is torn due to the fact that the thread residues and the broken filaments are prone to being hung on foreign matter in the use process is avoided, and the service life of the geotechnical cloth is effectively prolonged.

Owner:无锡中水土工新材料有限公司

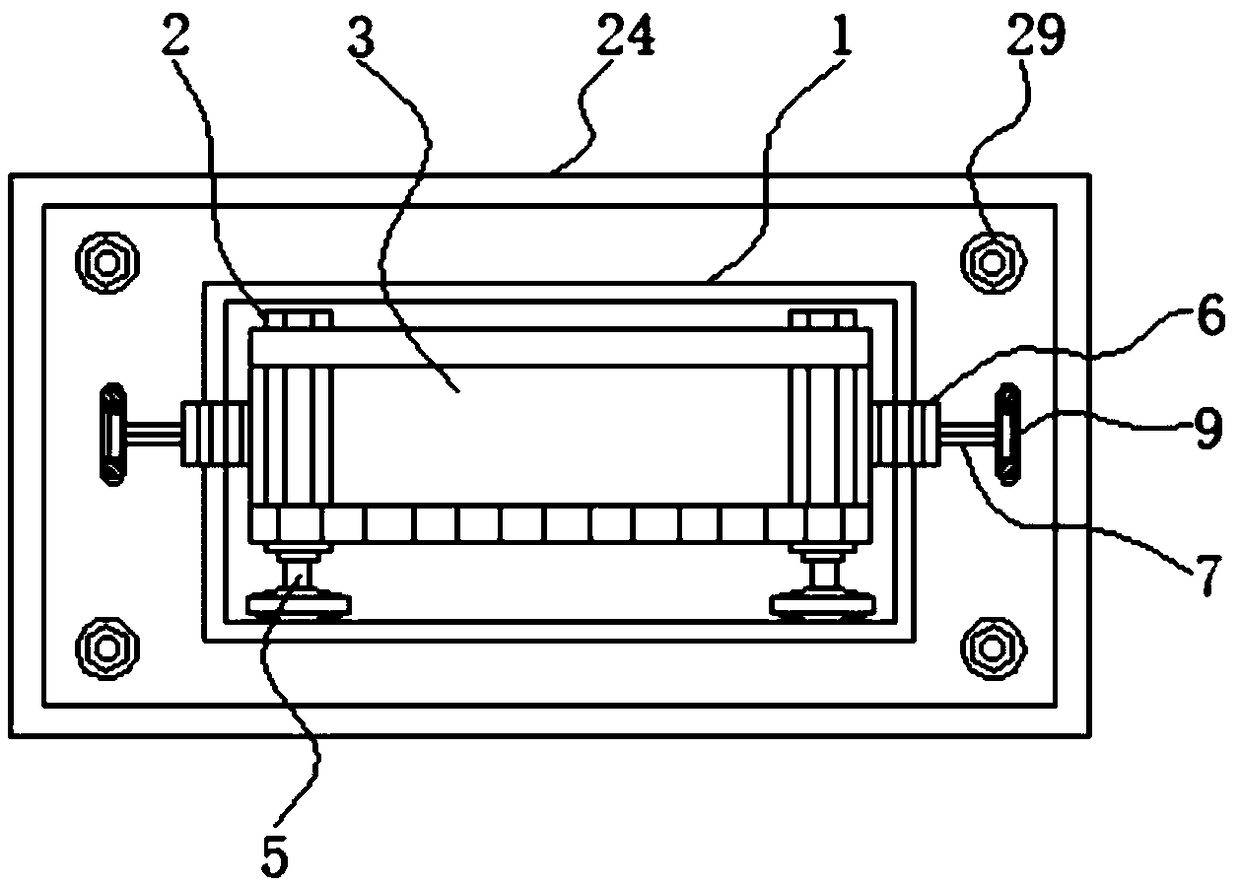

Flatness calibration and detection device for aluminum product processing

ActiveCN110986742AAvoid random movementSolve the deformation effectAngles/taper measurementsAluminium preparationsMetallurgy

The invention discloses a flatness calibration and detection device for aluminum product processing, and relates to the technical field of flatness calibration and detection devices for aluminum product processing. The flatness calibration and detection device for aluminum product processing comprises a rectangular block. Firstly, an aluminum plate is inserted into a rear transverse groove. Then the aluminum plate is drawn forwards. At the moment, the aluminum plate drives the rolling shaft at the rear end to roll. then the rolling shaft rolls on the surface of the aluminum plate, the bulges on the surface of the pressing plate are pressed, the front end of the aluminum plate is forwards drawn into the front transverse groove. Through tension of the tension spring, the transverse block moves downwards, and then the rolling shaft is driven to move downwards to clamp the aluminum plate, so that the aluminum plate is prevented from moving at will, the aluminum plate can be fixed through the arrangement, and the problems that after the aluminum plate is manufactured, a certain deformation effect is achieved, the aluminum plate is likely to be concave inwards or bent, the aluminum plateis not prone to being flatly laid manually in the measurement process, and consequently the subsequent measurement process is affected are solved.

Owner:江西华宇铝业有限公司

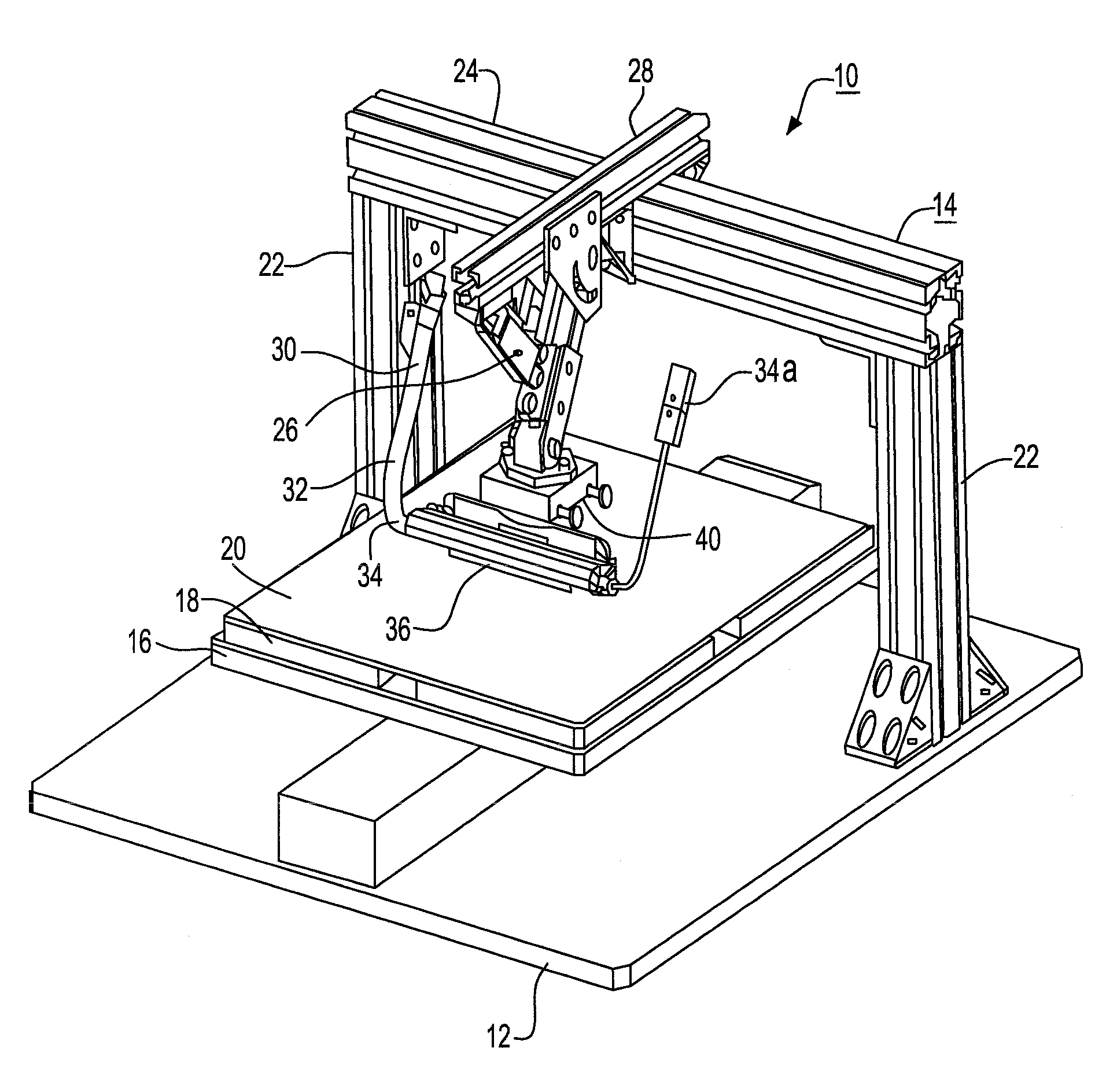

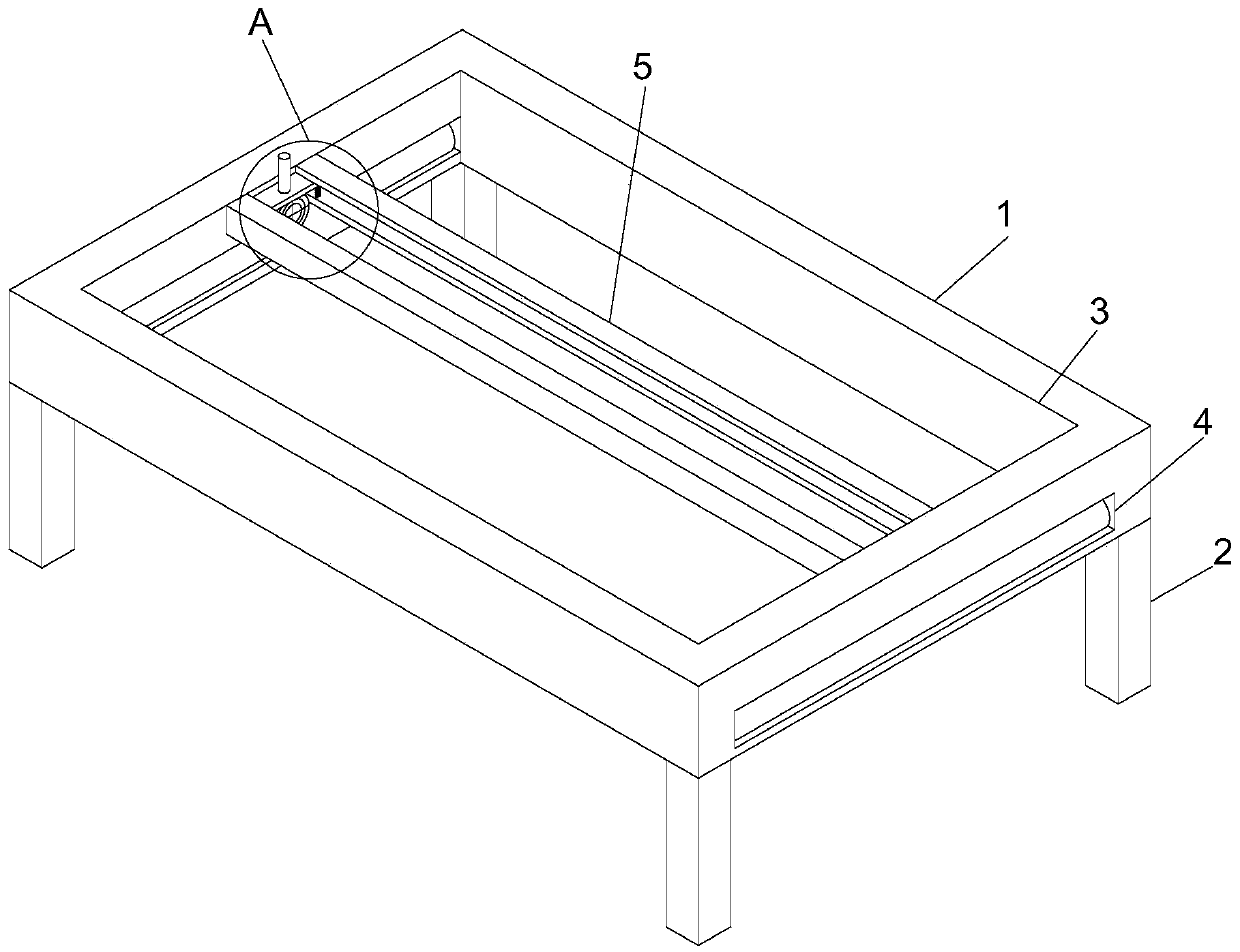

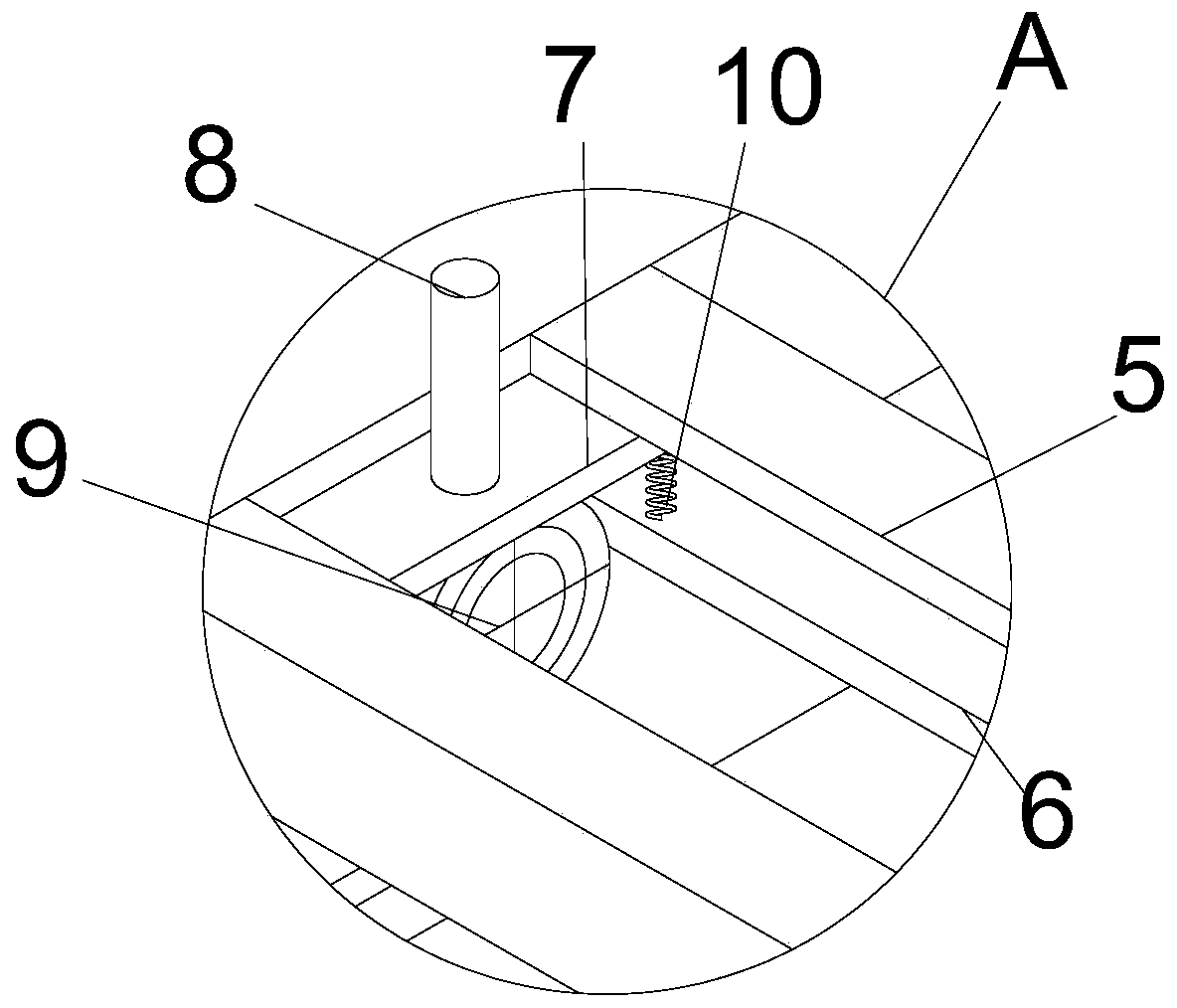

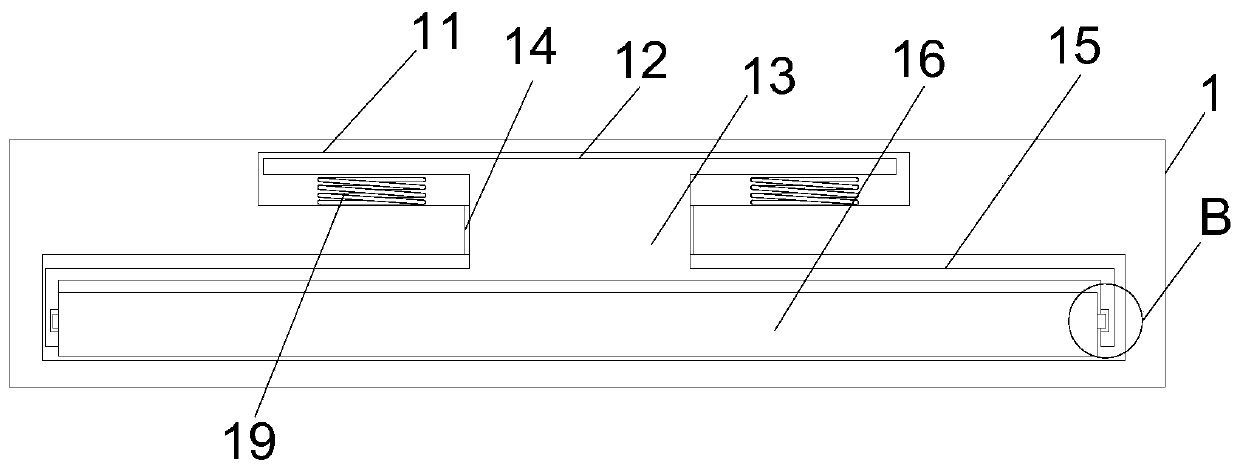

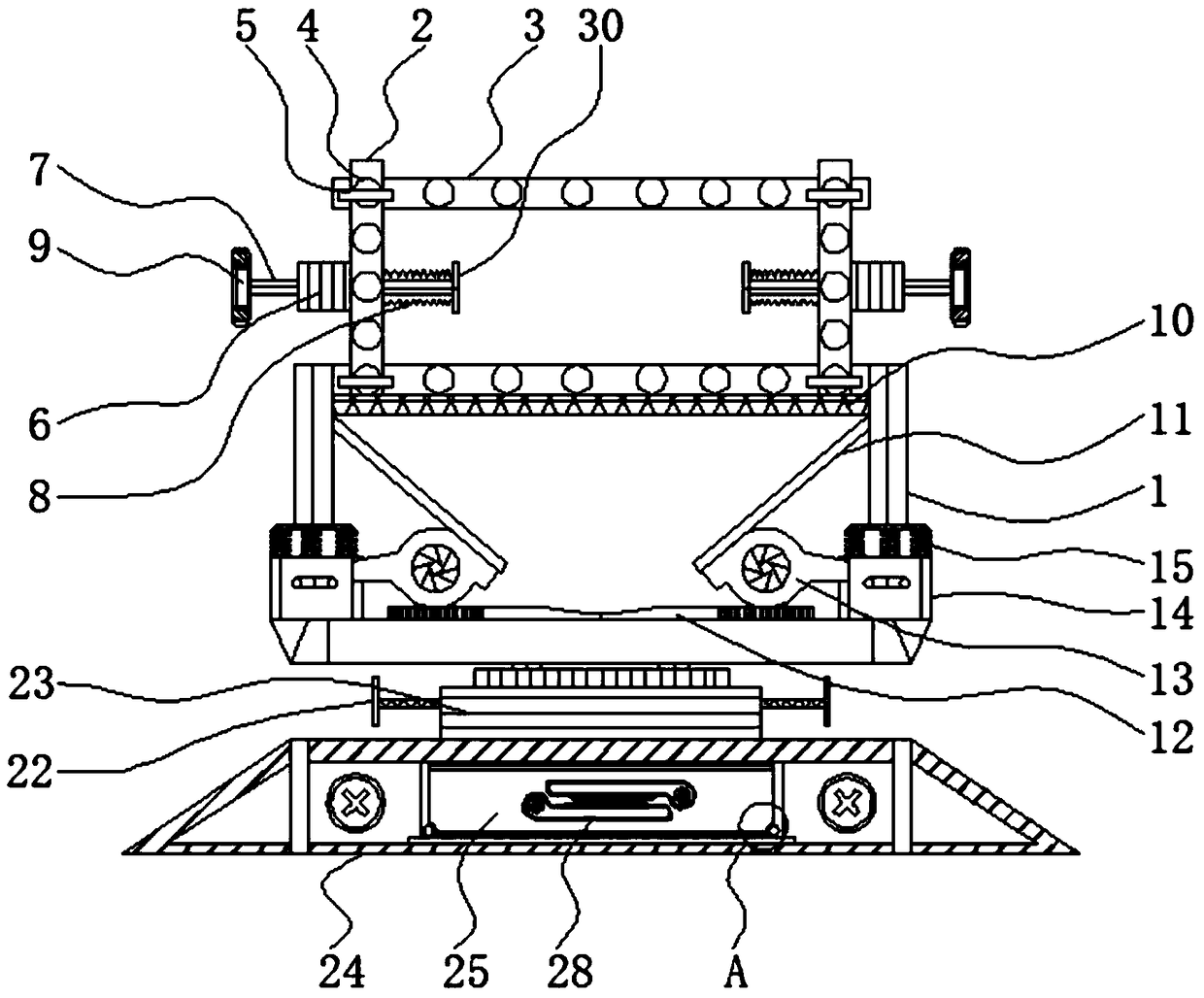

Engraving table capable of intelligently adjusting size and provided with dust sucking structure

ActiveCN109435553AAffect integrityEasy to fixDirt cleaningOther artistic work equipmentsStationary caseEngineering

The invention relates to an engraving table capable of intelligently adjusting the size and provided with a dust sucking structure. The engraving table comprises a main body, a fixed box, a fixing plate and a telescopic column; a fixed column is mounted above the main body, and the main body and the fixed column are connected in a welded mode; a first clamping plate is mounted on the right side ofthe fixed column, a circular hole is formed in the fixed column in a penetrating mode, and the circular hole and the fixed column are connected in a welded mode; and the fixed box penetrates into theleft side of the fixed column, and the fixed box and the fixed column are fastened through nuts. The engraving table capable of intelligently adjusting the size and provided with the dust sucking structure has the beneficial effects that a top box is arranged, and by moving a movable column penetrating into a sliding rod, the movable column drives the top box to ascend or descend through a connecting rod; and then after adjusting is completed, the top box is fixed by rotating bolts, thus the engraving table can be adjusted to a certain extent according to the height of an engraver, the engraver reaches the optimal engraving height, and it is ensured that an object is embodied more perfectly.

Owner:阜南县中泰工艺品有限公司

Mold shave apparatus and injection molded soldering process

InactiveUS8162199B2Easy to disassembleWeak degree of adherenceLiquid surface applicatorsInking apparatusSiliconSoldering process

An apparatus for the removal of excess solder or contaminant, which are encountered on the surfaces of injection mold prior to the transfer of a solder on a silicon wafer. More particularly, there is provided an apparatus for the removal of excess solder, which may be present on a mold surface, without removing any solder, which is located in cavities formed in the mold, and wherein the solder is applied through an injection molded soldering process.

Owner:INT BUSINESS MASCH CORP

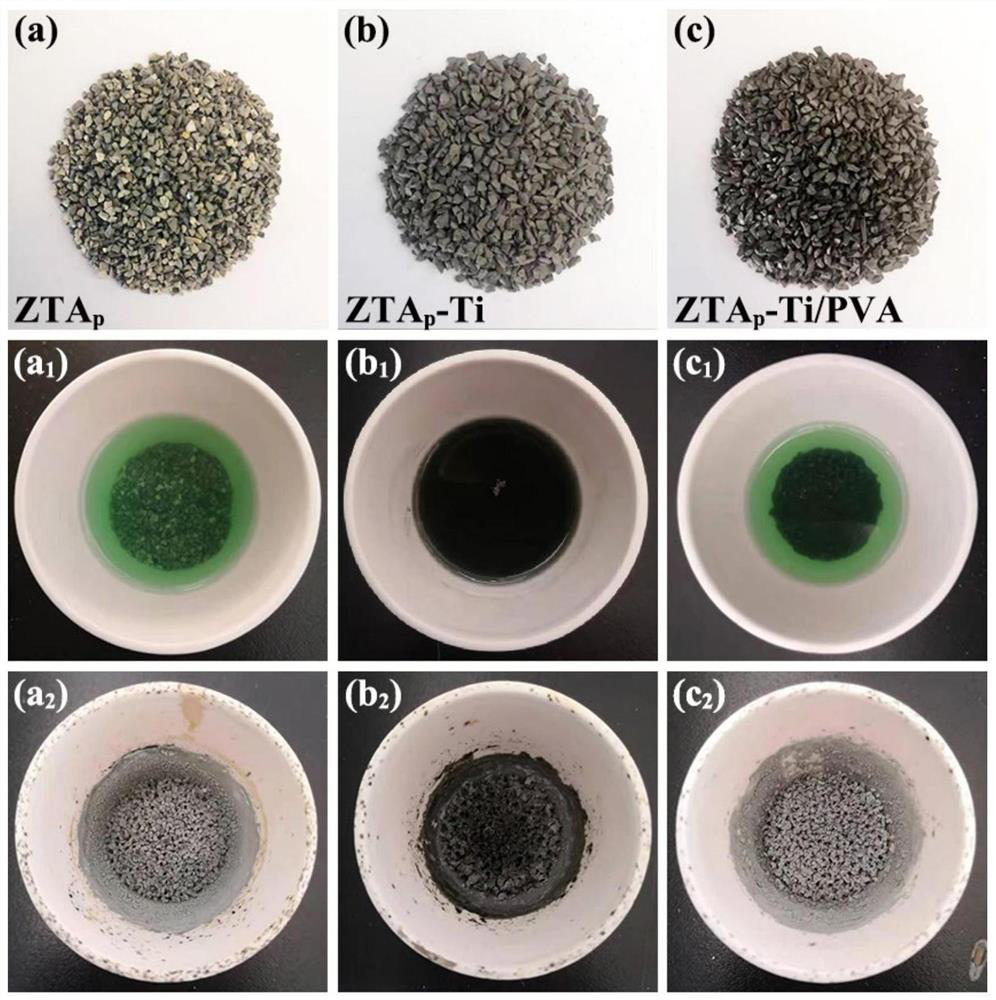

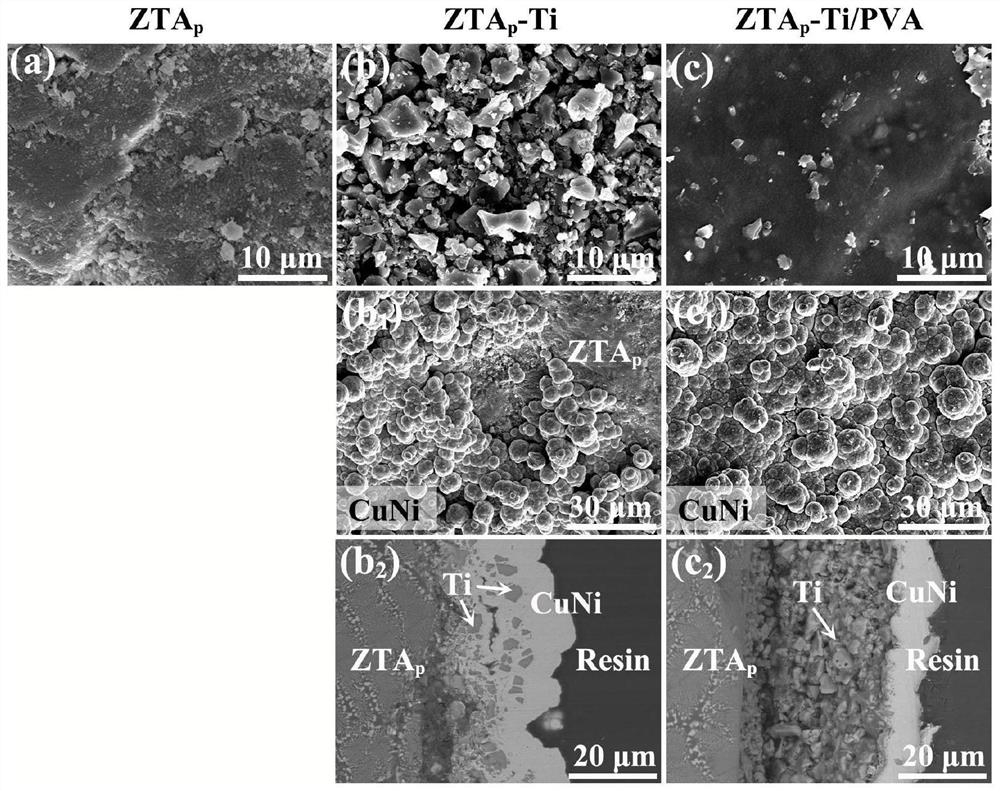

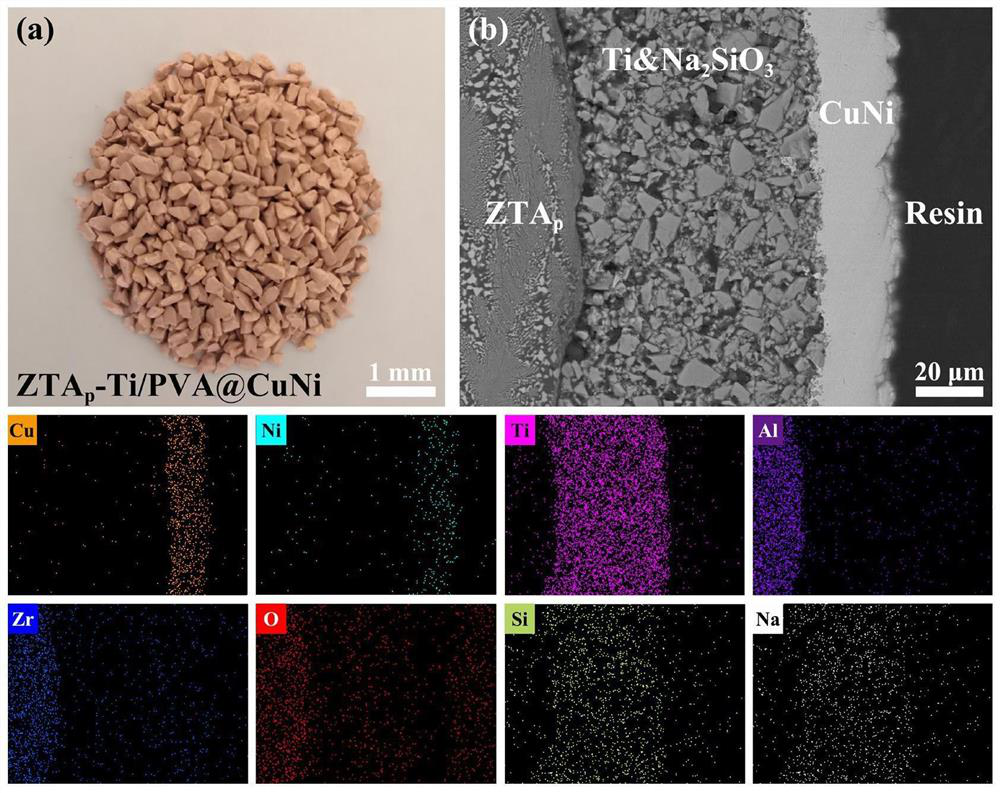

Ceramic particle coating method and composite material preparation method

PendingCN114850472AAvoid distractionAffect integrityTransportation and packagingMetal-working apparatusChemical platingCeramic particle

The invention provides a method for coating ceramic particles and a preparation method of a composite material. The coating method comprises the following steps: mixing ceramic particles with an adhesive, adding coating powder, and stirring to obtain ceramic particles coated with the coating powder; mixing the ceramic particles coated with the coating powder with polyvinyl alcohol, and drying to obtain ceramic particles with the coating powder and the polyvinyl alcohol attached to the surfaces; and activating the ceramic particles of which the surfaces are attached with the coating powder and the polyvinyl alcohol, and carrying out chemical plating by using a plating solution after activation to obtain the ceramic particles coated with the coating powder-metal coating. The preparation method of the composite material comprises the following steps: preparing coating powder-metal coating coated ceramic particles; and carrying out pressureless infiltration treatment on the ceramic particles coated with the coating powder-metal coating and the metal matrix to obtain the composite material. According to the method, the surfaces of the ceramic particles can be better coated with the coating powder through the protection layer formed by the polyvinyl alcohol, a reaction type interface can be better formed in the compounding process of the ceramic particles and a metal matrix, and the bonding performance is better.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com