Range hood and gas stove all-in-one machine

A technology for gas stoves and range hoods, which is used in the removal of range hoods, household stoves, heating fuels, etc., can solve the problem of range hoods failing to function, and achieve the effects of improving user experience, saving space, and preventing pollution to the kitchen environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

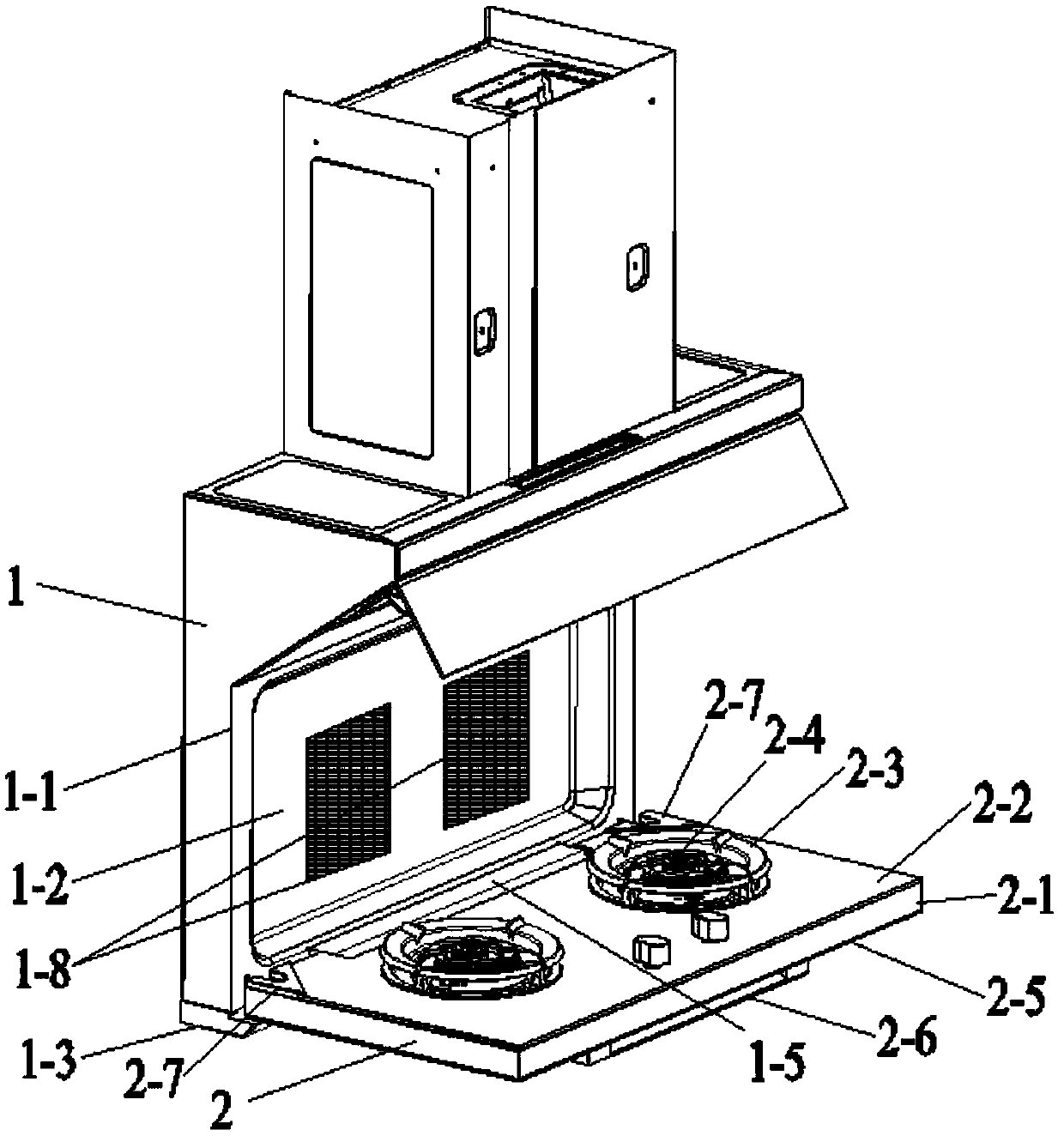

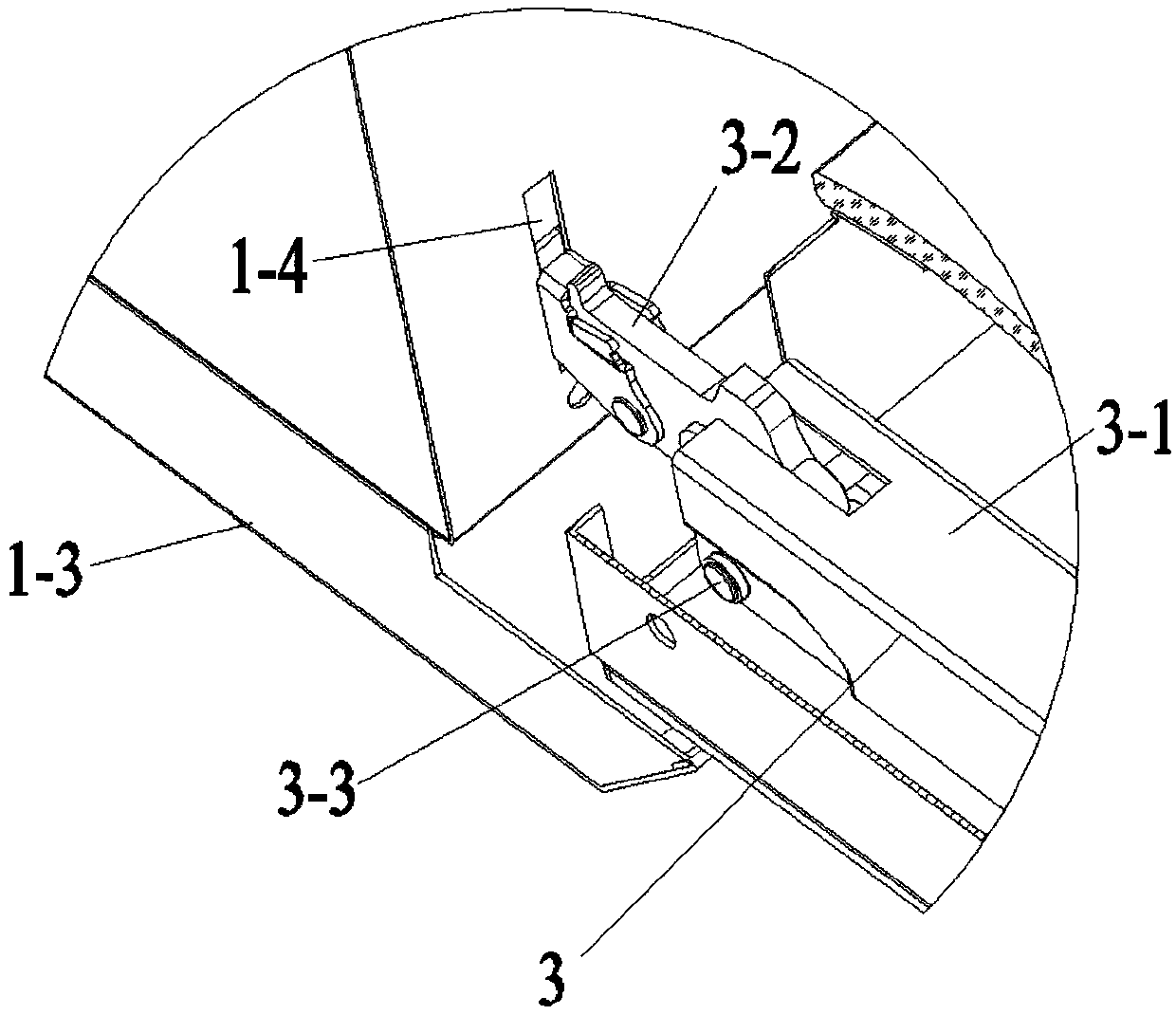

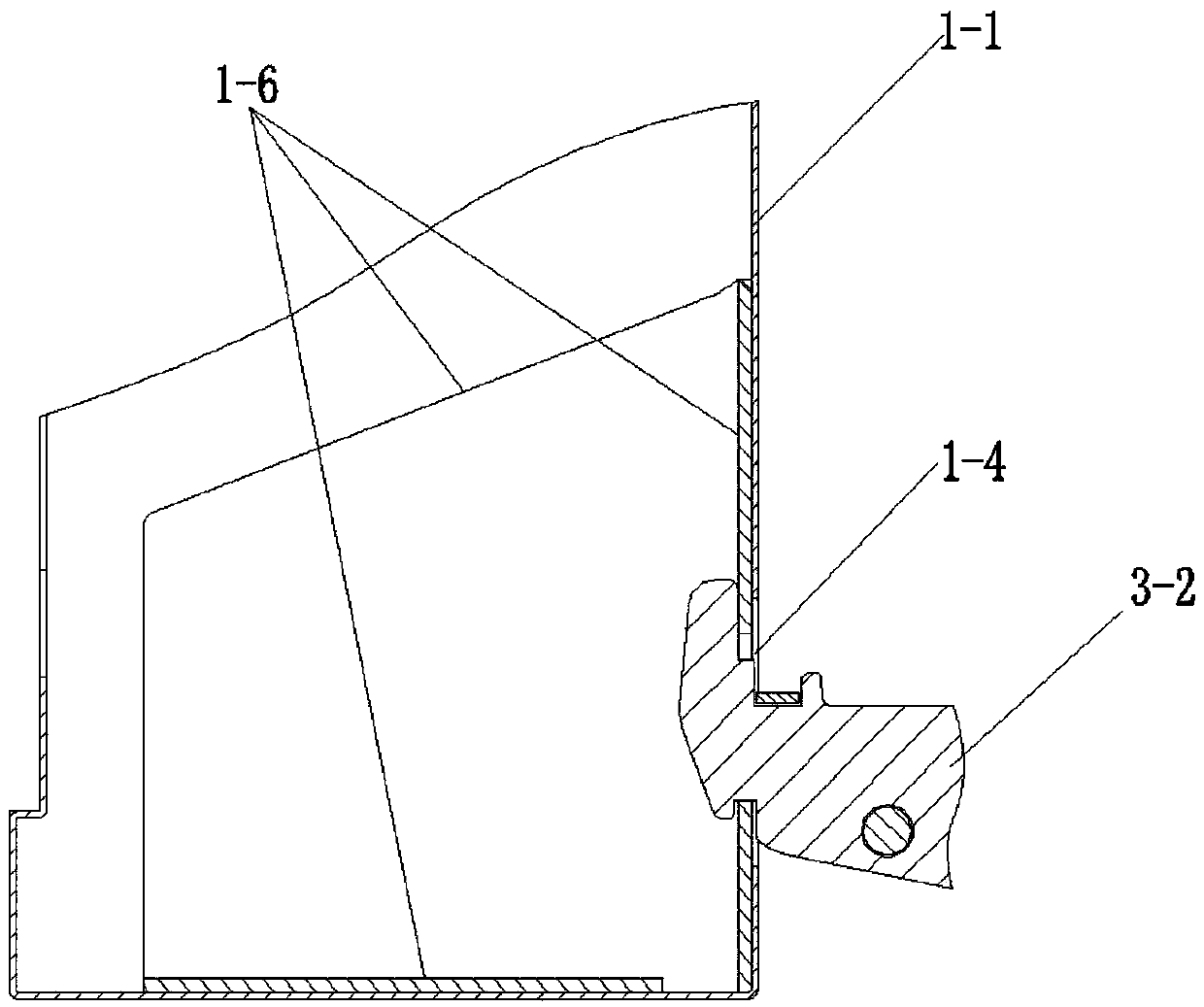

[0036] Such as figure 1 , 2In the example shown in , 3, the present invention is a range hood and gas stove integrated machine, which includes a range hood 1 and a reversible gas stove 2, and the range hood 1 includes a smoke collection hood and a set under the rear wall of the smoke collection hood The vertical panel 1-1, the stove 2-1 of the gas stove 2 are hinged to the lower end of the vertical panel 1-1, and an oil collection box 1-3 is arranged below the bottom wall of the vertical panel 1-1, and the bottom wall of the vertical panel 1-1 The front side wall and the left and right side walls enclose the façade stretch chamber 1-2 of the smoke collecting hood.

[0037] In the present invention, the gas cooker 2 is hinged on the lower end of the front wall of the vertical panel 1-1 of the range hood 1 through the integrated machine of the range hood and gas cooker to form a reversible gas cooker 2. Turning the gas stove 2 up as a whole does not need to set burners and gas...

Embodiment 2

[0041] Such as figure 1 , 2 As shown in . and 3, the present invention is an integrated range hood and gas stove, which includes a range hood 1 and a reversible gas stove 2. The range hood 1 includes a smoke collection hood and a facade panel 1- 1. The cooktop 2-1 of the gas stove 2 is hinged to the lower end of the vertical panel 1-1, and a long groove-shaped oil collection box 1-3 is arranged below the bottom wall of the vertical panel 1-1, and the front of the vertical panel 1-1 The side walls and the left and right side walls enclose the façade stretch chamber 1-2 of the fume collecting hood.

[0042] The reversible setting of the cooktop can turn the gas stove 2 down when in use, and turn the gas stove 2 up when not in use. There is no need to set burners and gas pipelines in the cabinet as in the prior art, which saves In the space in the kitchen, the cabinet under the gas stove 2 can be used for other purposes, which increases the available space; at the same time, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com