Ceramic particle coating method and composite material preparation method

A technology of ceramic particles and composite materials, which is applied in metal material coating process, transportation and packaging, liquid chemical plating, etc. It can solve the problems of rapid volatilization and shedding of adhesives, affecting the integrity and uniformity of coating layers, etc. , to achieve good bonding performance and improve bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Another aspect of the present invention provides a method for preparing a composite material. In an exemplary embodiment of the composite material preparation method of the present invention, the following steps may be included:

[0032] S100, the ceramic particles are mixed with the binder, the coating powder is added, and after stirring, the ceramic particles coated by the coating powder are obtained.

[0033] S101, the ceramic particles coated with the coating powder are mixed with polyvinyl alcohol, and after drying, the ceramic particles coated with the coating powder and the polyvinyl alcohol are obtained.

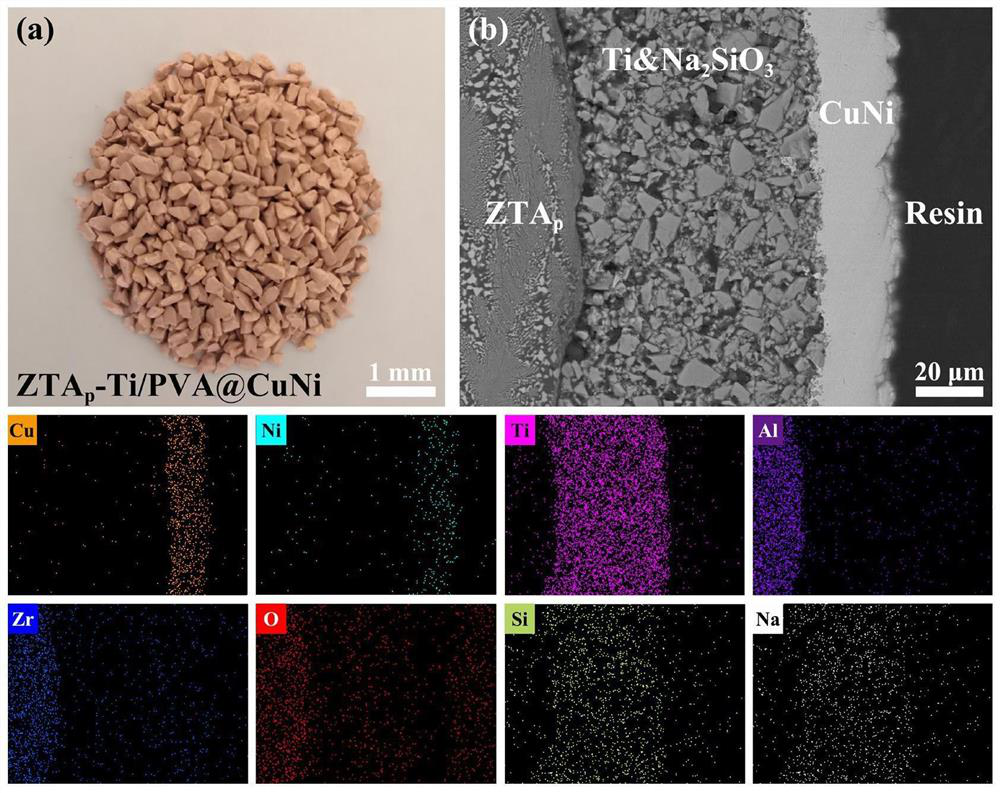

[0034] S102 , activating the ceramic particles coated with the coating powder and polyvinyl alcohol, and performing electroless plating with a metal-containing plating solution to obtain ceramic particles coated by the coating powder-metal coating.

[0035] S103 , casting the ceramic particles and the metal matrix coated with the coating powder-metal coating ...

example 1

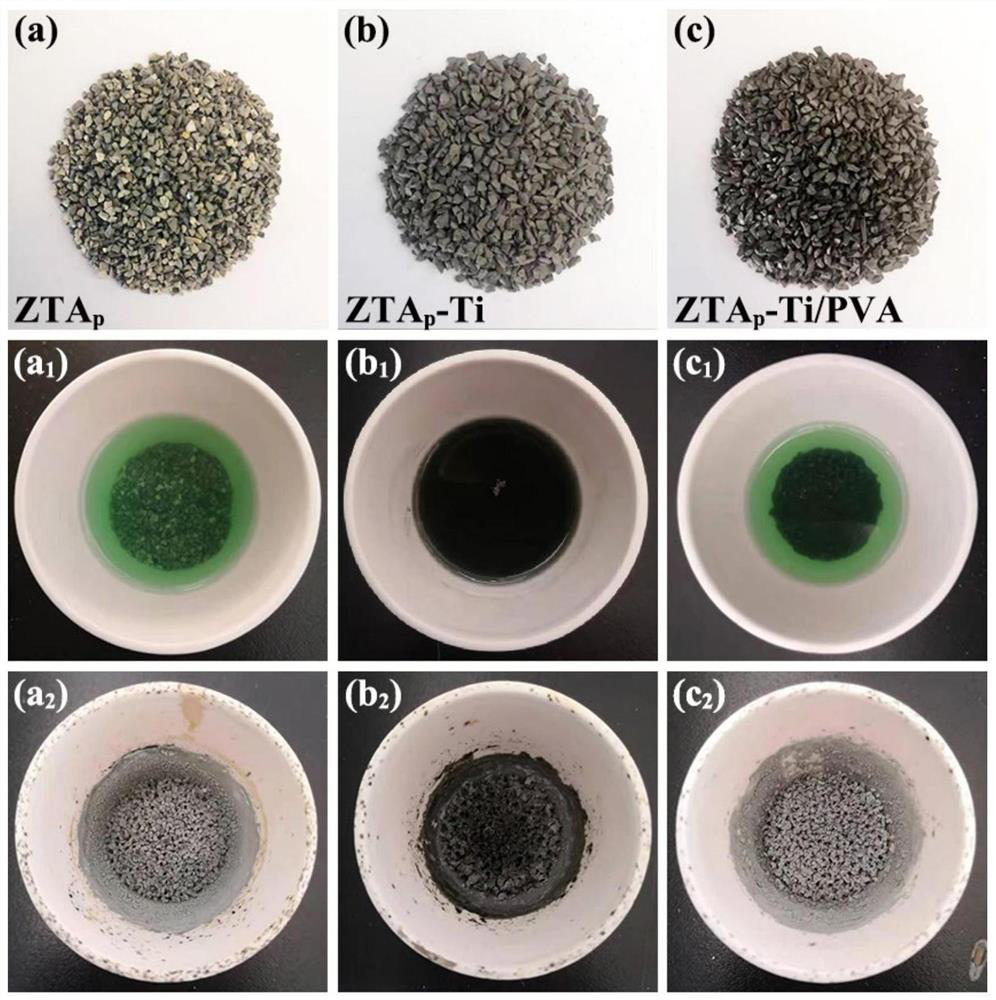

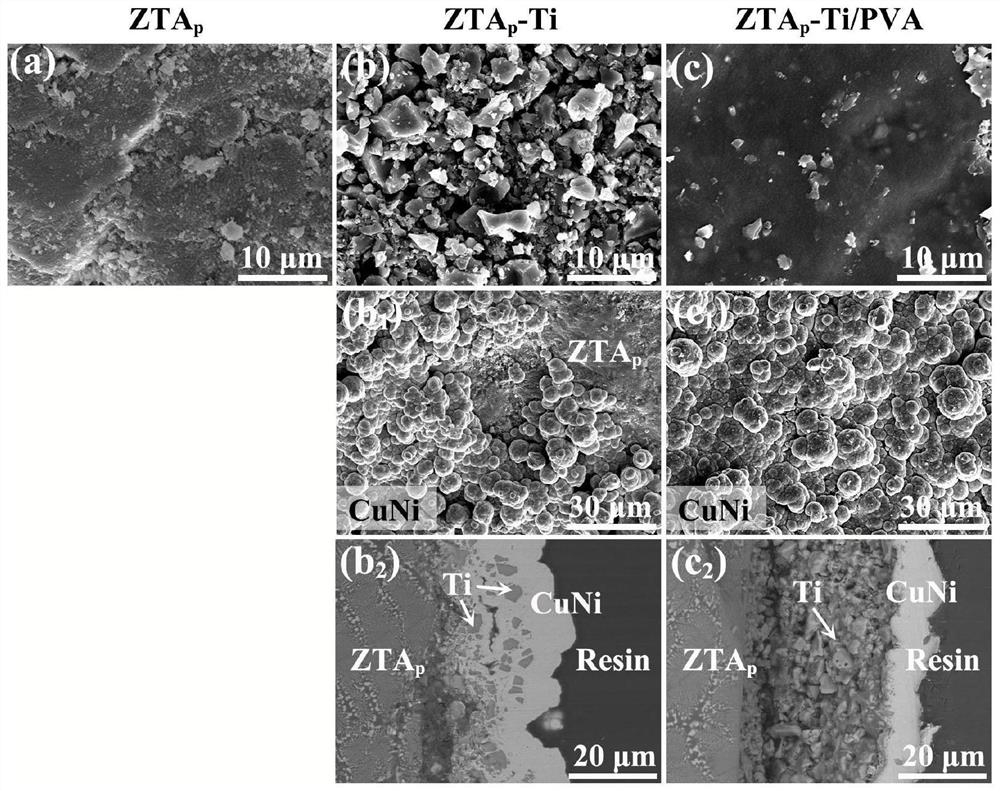

[0041] Step 1, the ZTA pellets (ZTA p ) and water glass binder, add Ti powder with a particle size of 4 μm, and mechanically stir to obtain ZTA particles coated with coated powder Ti, namely ZTA p -Ti.

[0042] Step 2, place the ZTA p -Ti was mixed with PVA with a mass concentration of 3%, and dried at 60 °C for 1 min to obtain coated powder Ti and PVA coated ZTA p , namely ZTA p -Ti / PVA.

[0043] Step 3, place the ZTA p -Ti / PVA and Ni(Ac) 2 The activation solution was mixed and activated at 170 °C for 25 min to obtain activated ceramic particles ZTA p -Ti / PVA / Ni 2+ , where Ni(Ac) 2 The activation solution is Ni(Ac) 2 , NaH 2 PO 2 , C 2 H 6 O and H 2 O mass concentration ratio of 1:1:15:2 activation solution.

[0044] Step 4, configure CuNi plating solution. Nickel sulfate (NiSO 4 ·6H 2 The concentration of O) is 30g / L, copper sulfate (CuSO 4 ·5H 2 O) concentration can be 30g / L, sodium citrate (C 6 H 5 Na 3 O 7 • 2H 2 O) concentration can be 30g / L, sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com