Durable geotechnical cloth preparation process

A preparation process and geotextile technology, which is applied in the cutting, singeing, textile and papermaking of textile materials, etc., can solve problems such as easy to get caught in wool and thread ends, and affect the normal use of geotextiles, so as to improve the service life and improve the quality of geotextiles. The effect of using efficiency and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

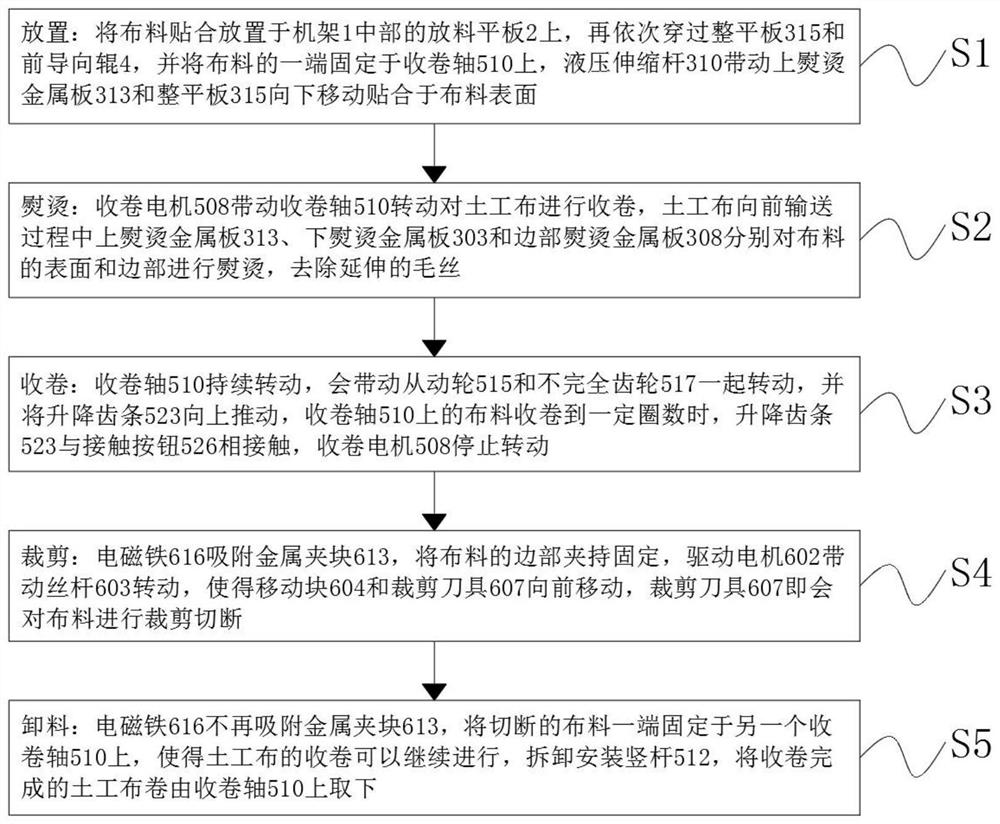

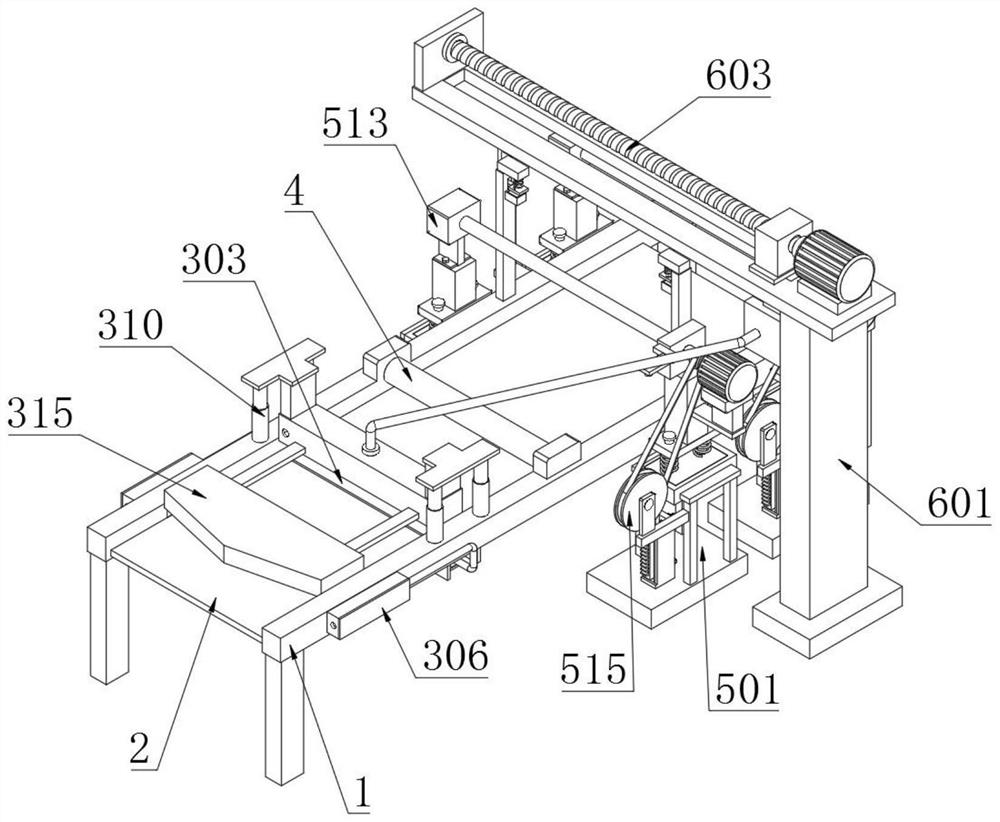

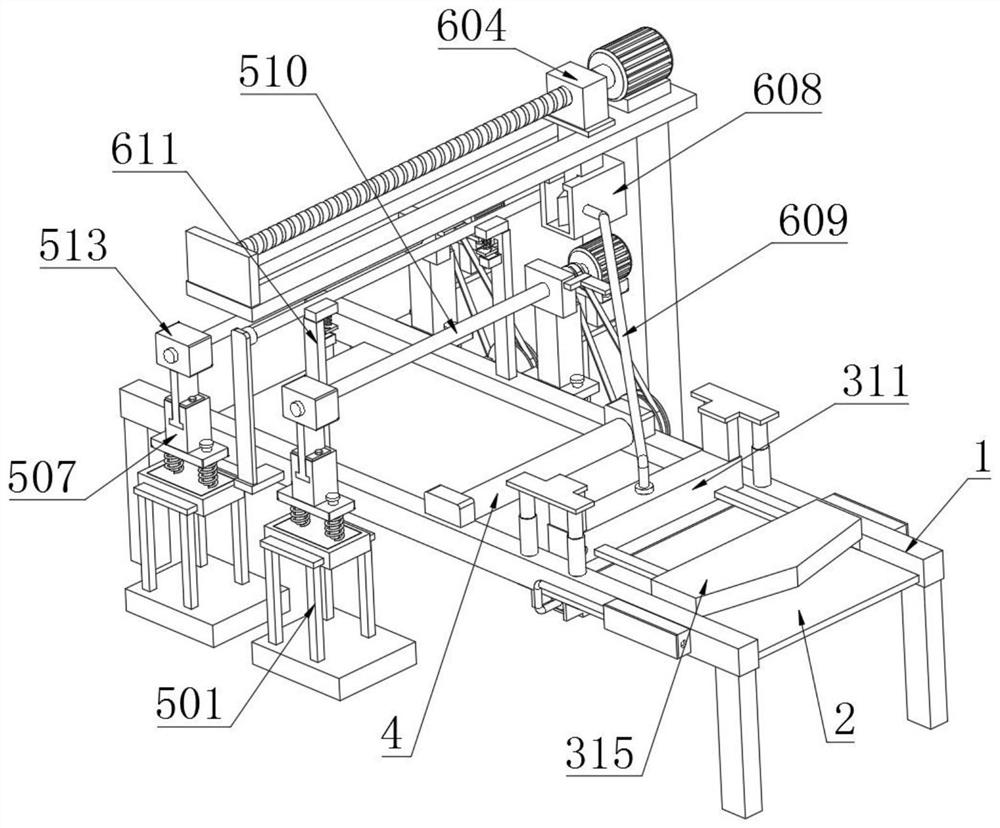

[0040] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a preparation process of a durable geotextile, comprising the following steps:

[0041] S1: Placement: Place the fabric on the discharge flat plate 2 in the middle of the frame 1, then pass through the leveling plate 315 and the front guide roller 4 in turn, and fix one end of the fabric on the winding shaft 510, and the hydraulic telescopic rod 310 Drive the upper ironing metal plate 313 and the screed plate 315 to move downwards to fit on the surface of the fabric;

[0042] S2: Ironing: the winding motor 508 drives the winding shaft 510 to rotate to wind the geotextile, and the upper ironing metal plate 313, the lower ironing metal plate 303 and the side ironing metal plate 308 are respectively Iron the surface and edges of the fabric to remove extended hair;

[0043] S3: Winding: The continuous rotation of the winding shaft 510 will drive the driven wheel 515 and the incomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com