Manufacturing device of schistosome egg detection filter membrane

A technology for manufacturing devices and schistosomes, which is applied in membrane technology, semi-permeable membrane separation, metal processing, etc., can solve the problems of low manual cutting efficiency, low production efficiency of filter membranes, and affecting the degree of filtration, so as to prevent wire drawing and prevent heat Too high, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

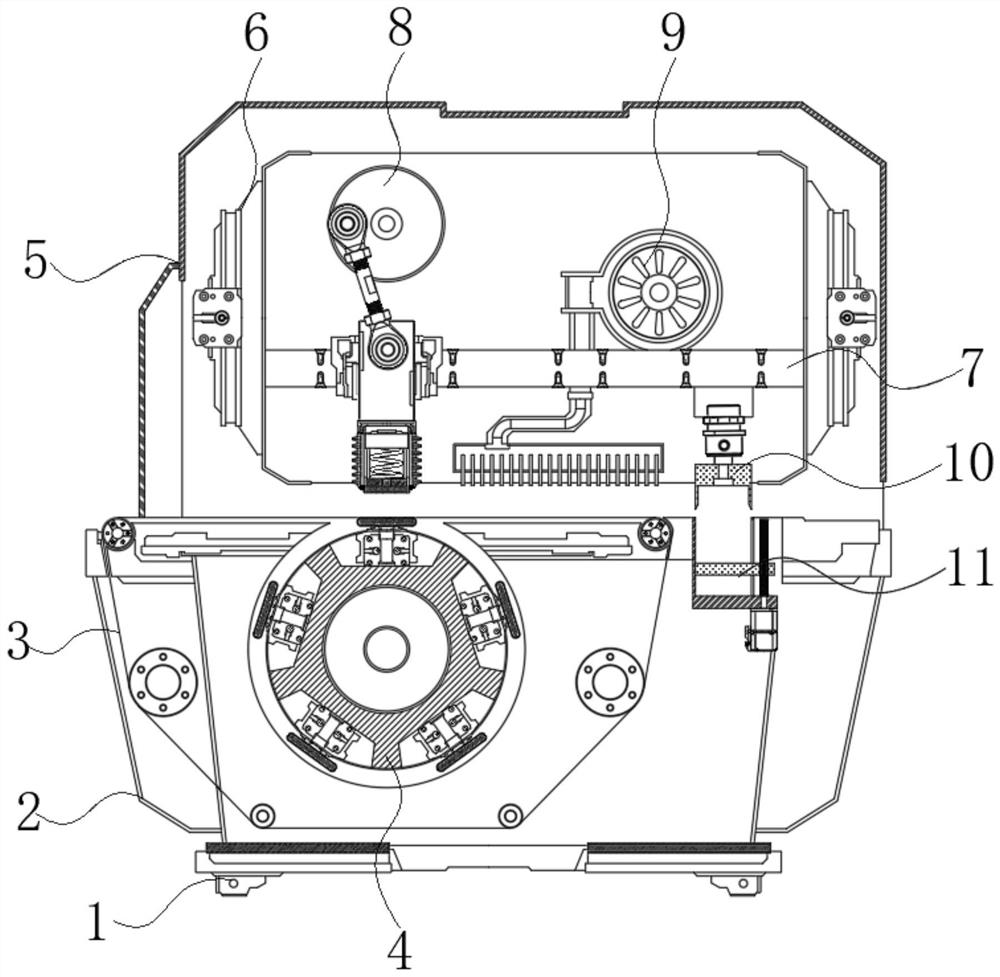

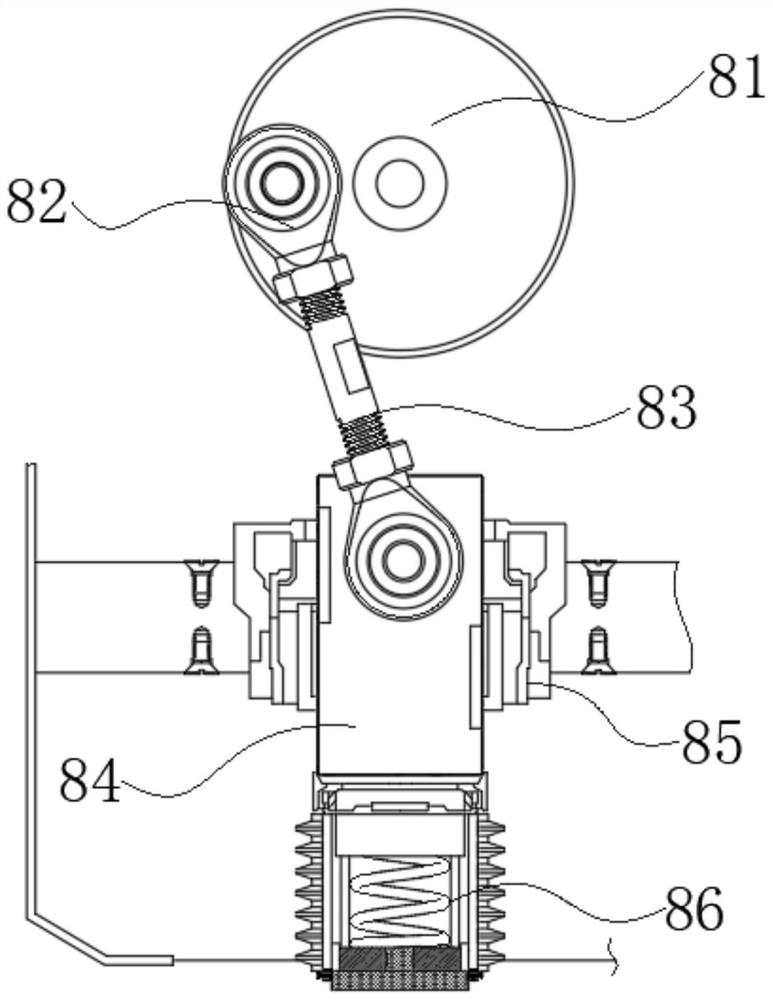

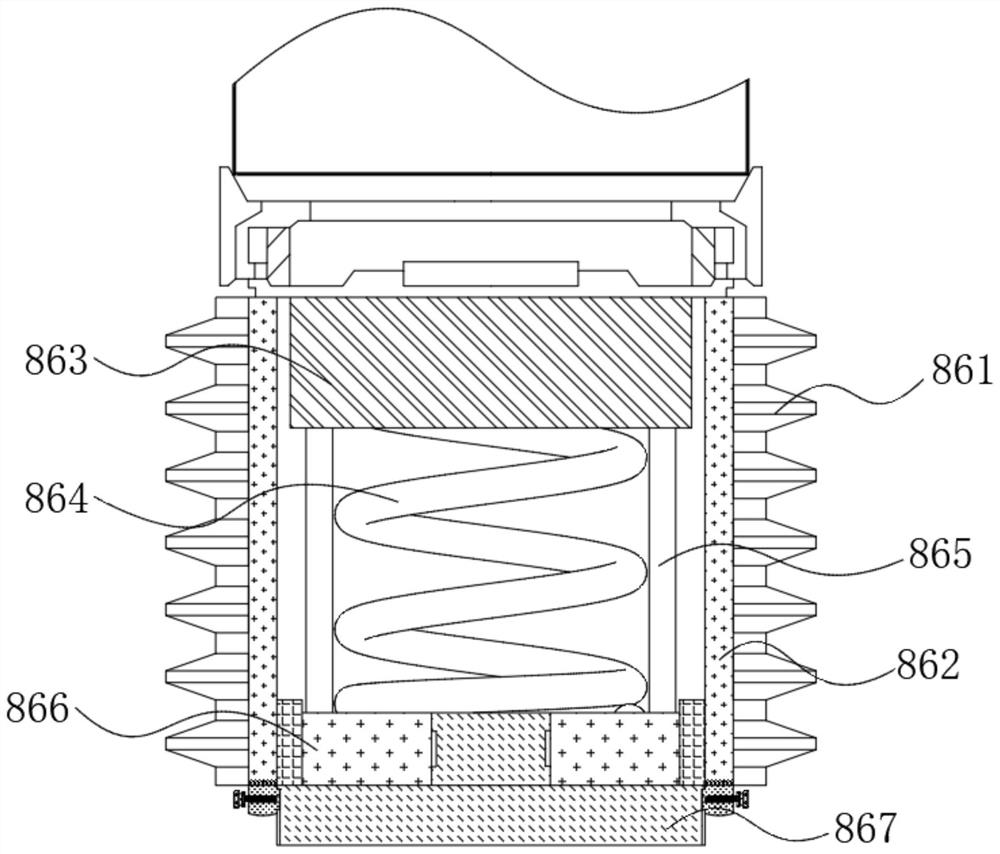

[0032] refer to Figure 1-7 , the present invention provides a technical solution: a manufacturing device for schistosome egg detection filter membrane, including a base 1, a lower frame 2, an auxiliary pressing assembly 4, an upper frame 5, a hot pressing assembly 8, a cooling assembly 9, and a cutting assembly 10 and the storage assembly 11, wherein, the upper end surface of the base 1 is fixed with a lower frame 2;

[0033] The lower frame 2 is rotatably provided with an auxiliary pressing assembly 4, and the auxiliary pressing assembly 4 is provided with a conveyor belt 3 outside, which is used to continuously transport the filter membrane to be cut. The surface of the conveyor belt 3 is provided with a plurality of avoidance grooves That is to say, a plurality of said avoidance grooves can make the hot pressing assembly 8 contact with the auxiliary pressing assembly 4, preventing damage to the conveyor belt 3;

[0034] The upper end surface of the lower frame 2 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com