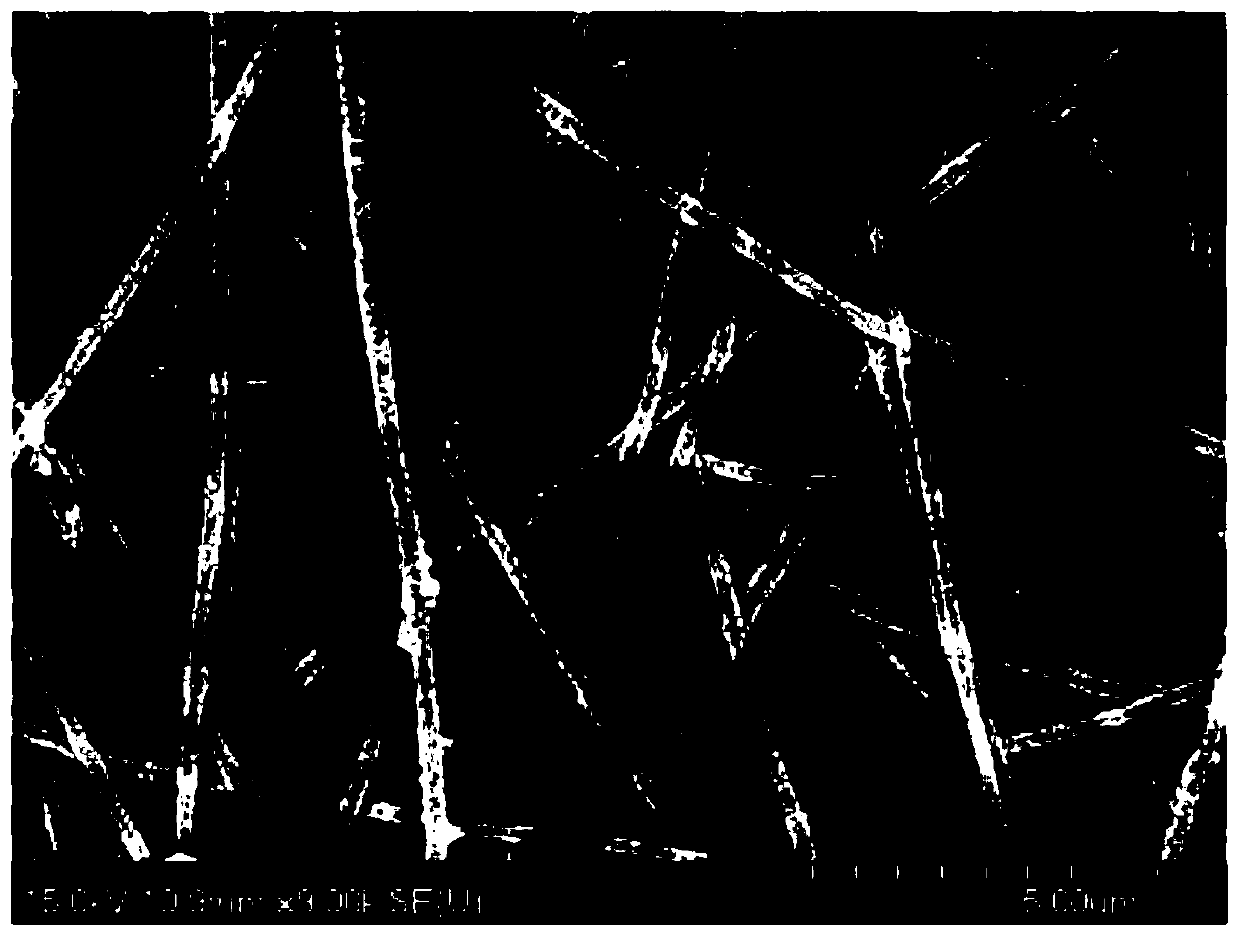

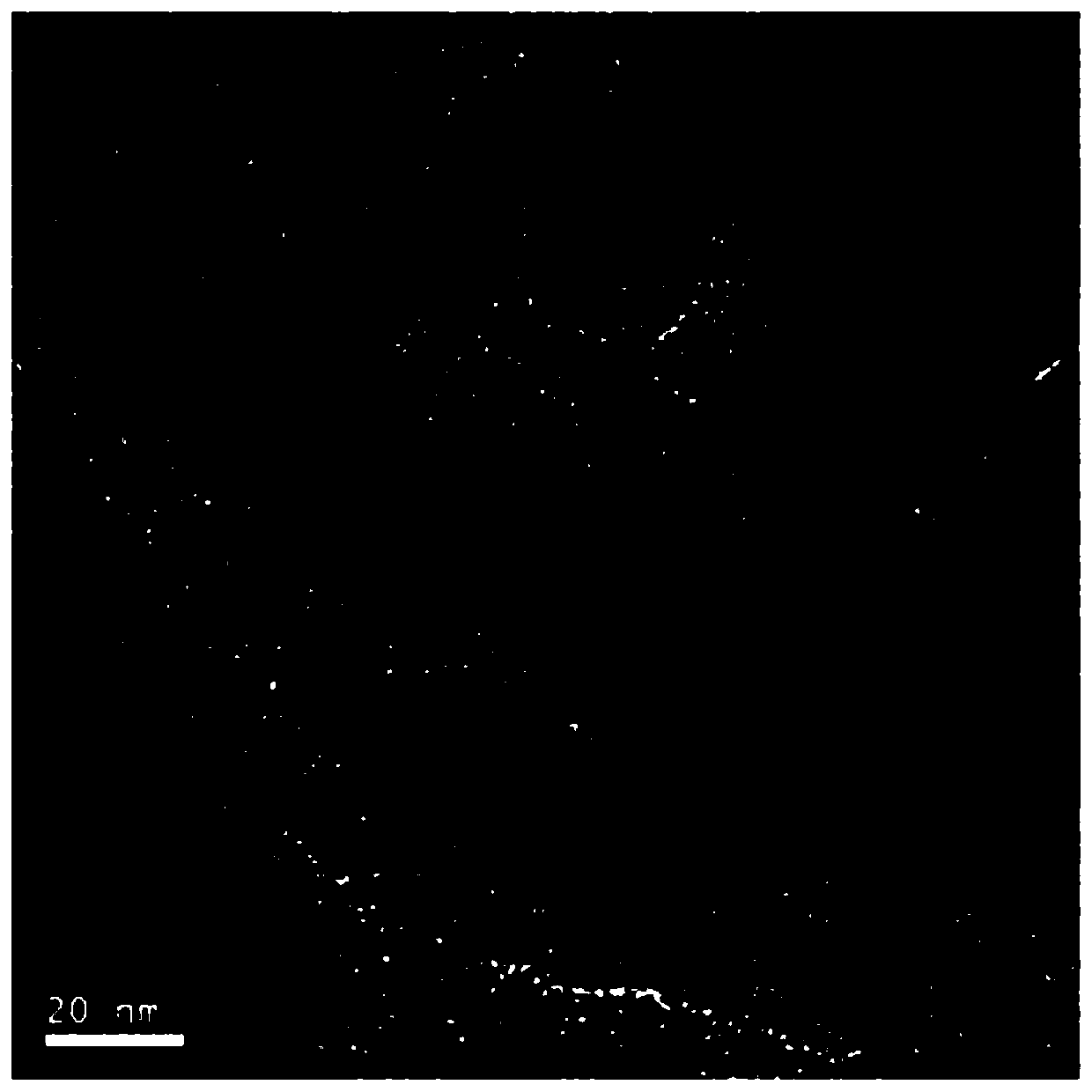

Porous boron-doped carbon-loaded platinum nanoparticle catalyst based on electrostatic spinning technology, and preparation method and application thereof

An electrospinning technology, platinum nanoparticle technology, applied in chemical instruments and methods, physical/chemical process catalysts, textiles and papermaking, etc., can solve the problems of short life, high catalyst toxicity, poor stability, etc. Simple preparation conditions and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of a flexible electrode catalyst based on boron-doped carbon supported platinum nanoparticles by electrospinning technology comprises the following steps:

[0032] 1) Dissolve 0.533 g of PVP in 180 ml of methanol, then add 6.25 ml of chloroplatinic acid aqueous solution with a concentration of 10 g / L and 13.75 ml of deionized water, and reflux in an oil bath at 100 °C for 3 h under nitrogen bubbling atmosphere conditions Afterwards, cool to room temperature first, then remove the solvent by rotary evaporation to a volume of 10ml, add acetone to the residue of rotary evaporation to obtain a cloudy mixture, and centrifuge to obtain a viscous precipitate;

[0033] 2) Take the viscous precipitate obtained in step 1), add 1 g polyacrylonitrile (molecular weight 150000), 0.5 g boric acid to 10 ml N,N-dimethylformamide, stir in an oil bath at 80 °C for 2-4 hours, and form homogeneous mixture;

[0034] 3) Transfer the mixture obtained in step 2) to a 10 mL syri...

Embodiment 2

[0044] To prepare a flexible electrode catalyst based on electrospinning technology boron-doped carbon-supported platinum nanoparticles, the preparation method steps are repeated in Example 1, the difference is: the boric acid in step 2) of Example 1 is replaced with the same quality Sodium borate, other operating steps are the same as in Example 1, and finally a porous boron-doped carbon-supported platinum nanoparticle catalyst is prepared.

[0045] Electrolysis of water to prepare ozone experiment:

[0046] During the preparation process of the membrane electrode anode in Example 1, the catalyst of Example 1 added is replaced by the catalyst prepared in Example 2 of the same quality, and the remaining operating conditions are the same as those in Example 1. The electrolysis of water produces ozone. The relationship between the ozone concentration and the reaction time is as follows Figure 4 shown.

Embodiment 3

[0048] To prepare a flexible electrode catalyst based on electrospinning technology boron-doped carbon-supported platinum nanoparticles, the preparation method steps are repeated in Example 1, the difference is: the boric acid in step 2) of Example 1 is replaced with the same quality Sodium borohydride, other operating steps are the same as in Example 1, and finally a porous boron-doped carbon-supported platinum nanoparticle catalyst is prepared.

[0049] Electrolysis of water to prepare ozone experiment:

[0050] In the preparation process of the membrane electrode anode of Example 1, the catalyst of Example 1 added is replaced by the catalyst prepared in Example 3 of the same quality, and the remaining operating conditions are the same as the electrolysis of water in Example 1 to prepare ozone. The catalytic reaction of electrolysis of water produces The relationship between the ozone concentration and the reaction time is as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com