Molten iron dephosphorization device and dephosphorization method for smelting stainless steel

A stainless steel and molten iron technology, applied in the field of iron and steel metallurgy, can solve the problems of large space occupied by oxygen lances and spray guns, affecting the use effect of powder, and large loss of powder, saving space, shortening dephosphorization treatment time, and reducing smelting costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

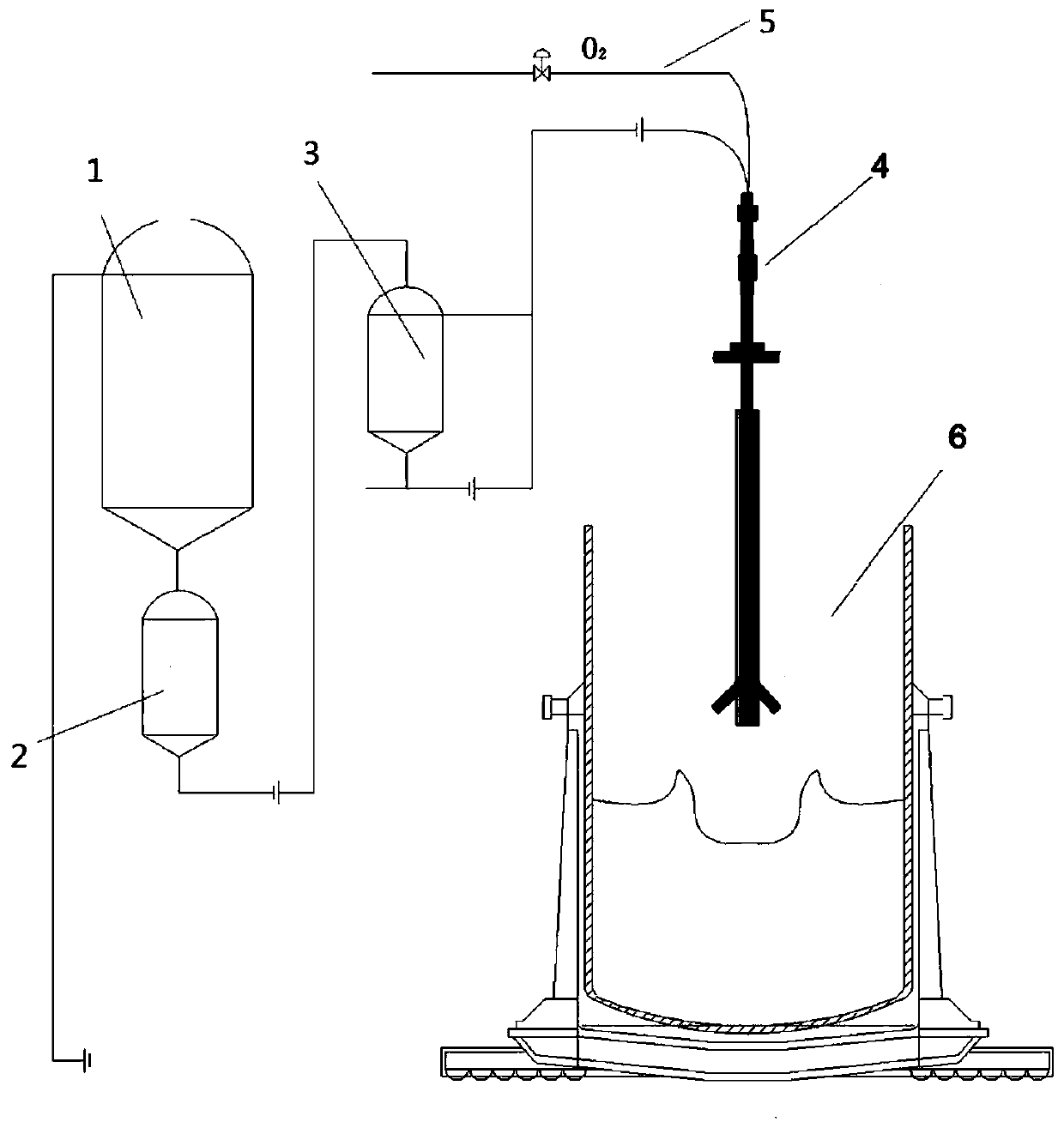

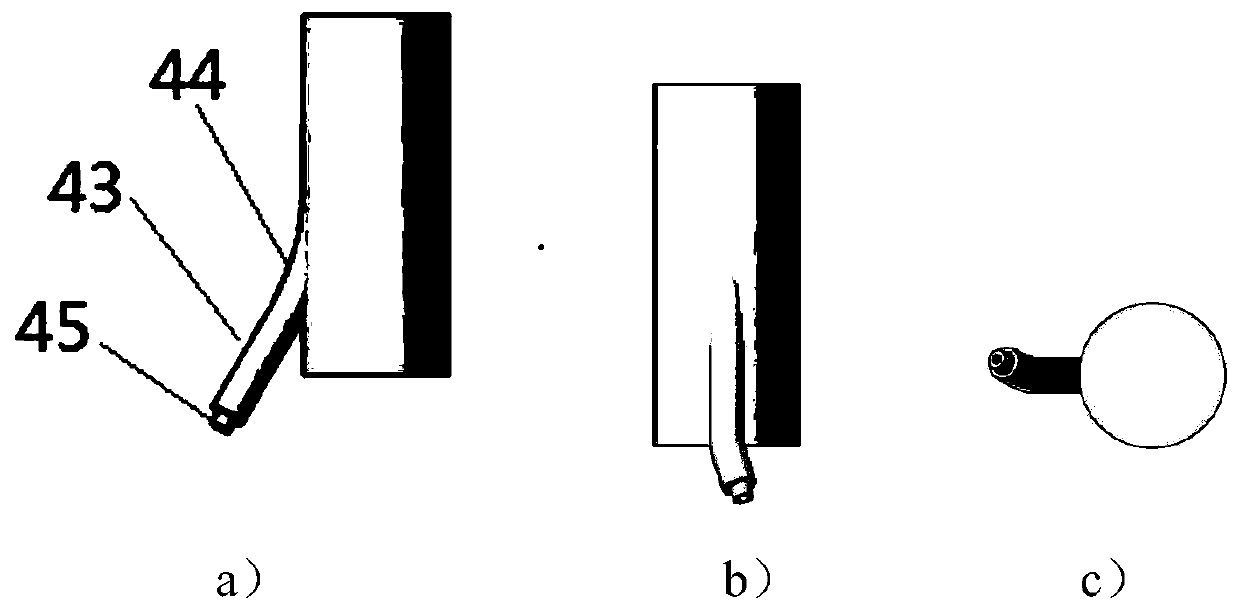

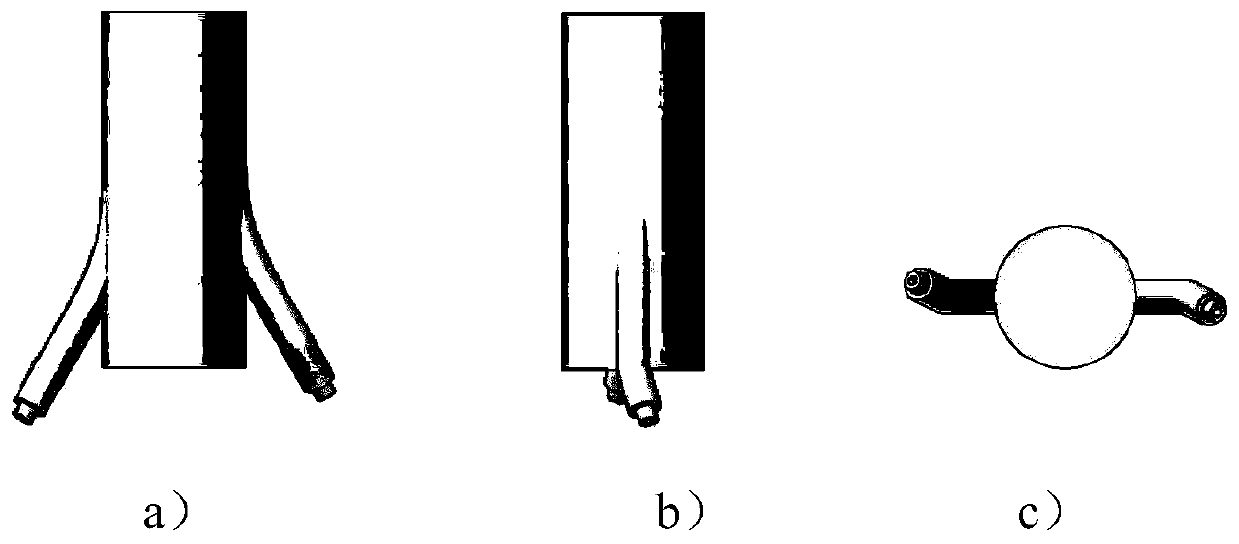

[0041] This embodiment discloses a hot metal dephosphorization device for smelting stainless steel, such as figure 1 As shown, the molten iron dephosphorization device includes a storage tank 1, a delivery tank 2, a blow tank 3, a spray gun 4, an air pipe 5 and a ladle 6, the storage tank 1 is connected with the blow tank 3 through the delivery tank 2, and the blow tank 3 and The ventilation pipes 5 are respectively connected with the spray guns 4; the spray guns 4 include a first pipe 41 and a second pipe 42, the first pipe 41 is provided with a support bearing or the first pipe 41 is composed of a flexible connecting pipe, and the first pipe 41 is telescopically arranged Inside the second pipe 42; the second pipe 42 is provided with N spray gun outlets, N≥1, the spray gun outlet is a streamlined rotating structure, and the spray gun outlet includes a connecting elbow 43 separated from the axis by the second pipe, along the circumference To the rotating connecting section 44 ...

Embodiment 2

[0050] This embodiment discloses a method for dephosphorizing molten iron for smelting stainless steel. This method uses the device for dephosphorizing molten iron in Example 1. The principle is that during the dephosphorization process of molten iron, the oxygen emitted from the spray gun reacts with the phosphorus in the molten iron Generate P 2 o 5 , react with the added lime powder to generate calcium phosphate, as shown in the reactions (1) and (2), the purpose of dephosphorization is achieved after entering the slag, when the slag is melted to form slag, the iron oxide in the slag and the iron Phosphorus reacts as shown in reaction (3).

[0051] 2P+5O 2 =2(P 2 o 5 ) (1)

[0052] (CaO)+(P 2 o 5 )=3CaO·P 2 o 5 (2)

[0053] 2P+5(FeO)+3(CaO)=3CaO·P 2 o 5 +5[Fe] (3)

[0054] The molten iron dephosphorization method for smelting stainless steel provided by the present embodiment comprises the following steps:

[0055] Step S1, desiliconizing the molten iron, scr...

Embodiment 3

[0062] This embodiment is aimed at the dephosphorization treatment of 50t molten iron, adopts the molten iron dephosphorization device such as embodiment 1, and the molten iron dephosphorization device comprises a storage tank 1, a delivery tank 2, a spray tank 3, a spray gun 4, an air pipe 5 and a ladle 6, and stores The tank 1 is connected with the spray tank 3 through the delivery tank 2, and the spray tank 3 and the ventilation pipe 5 are respectively connected with the spray gun 4; A tube 41 is telescopically arranged inside the second tube 42; the second tube 42 is provided with a spray gun outlet, and the spray gun outlet is a streamlined rotating structure, such as figure 2 As shown in a-2c, the outlet of the spray gun includes a connecting elbow 43 separated from the axis by the second pipe, a connecting section 44 rotating in the circumferential direction, and a nozzle 45. The diameter of the second pipe 42 is Φ260mm, and the diameter of the connecting elbow is The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com