Uniform-feeding rice impurity removing equipment

A uniform and rice technology, applied in sieves, grilles, and the separation of solids from solids by air flow, etc., can solve the problems of affecting the quality of rice, poor stone removal effect, and cumbersome steps, and achieve good dust removal effect. Avoid repeated processing and ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

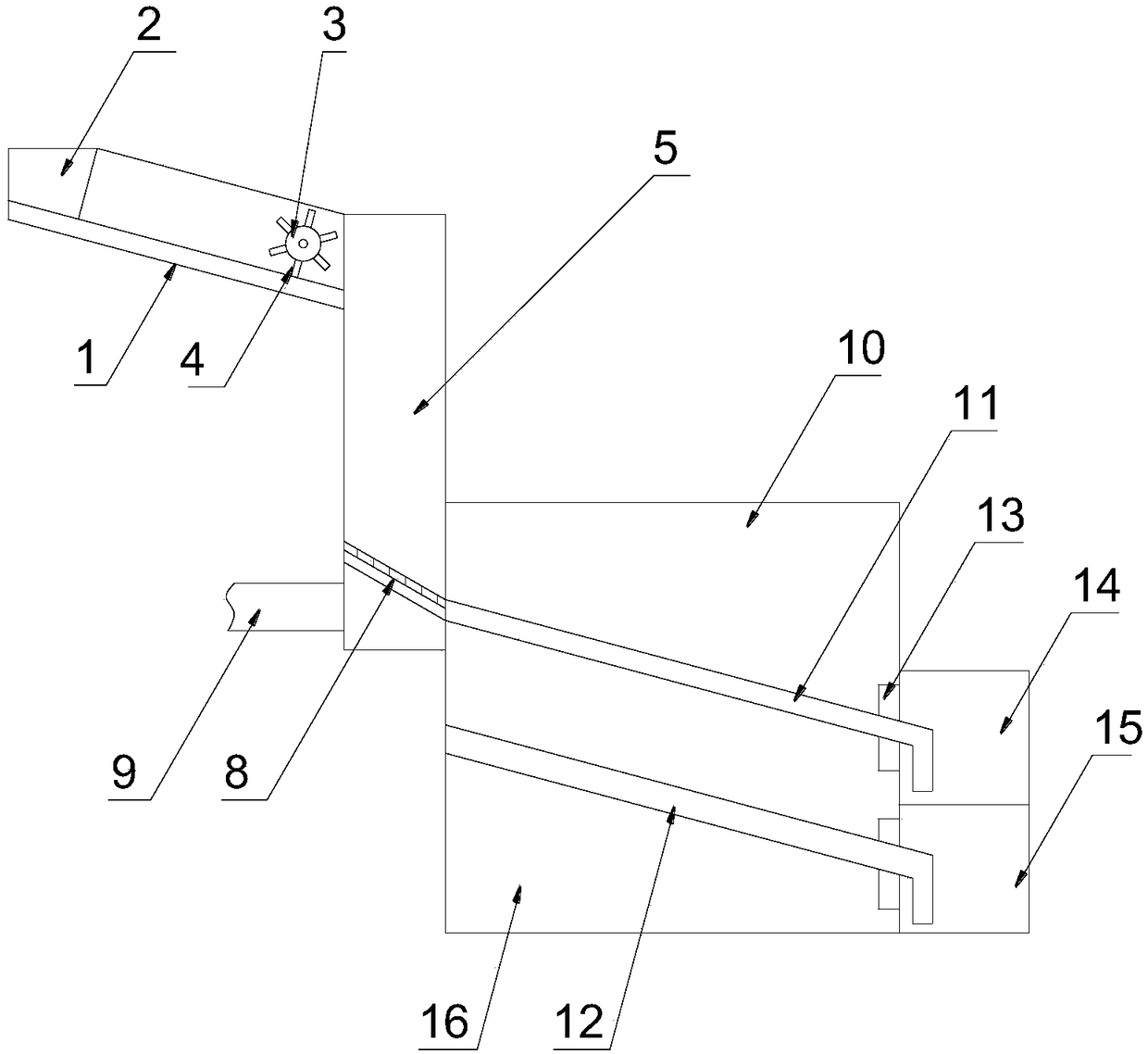

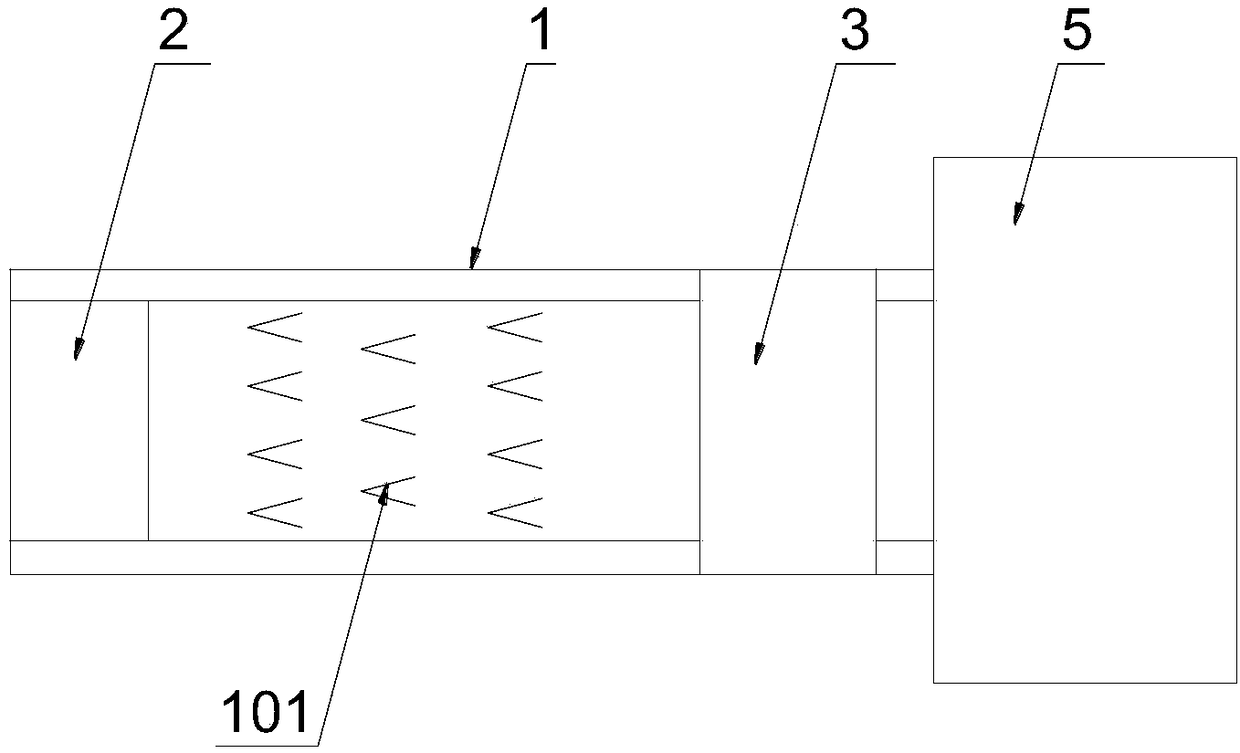

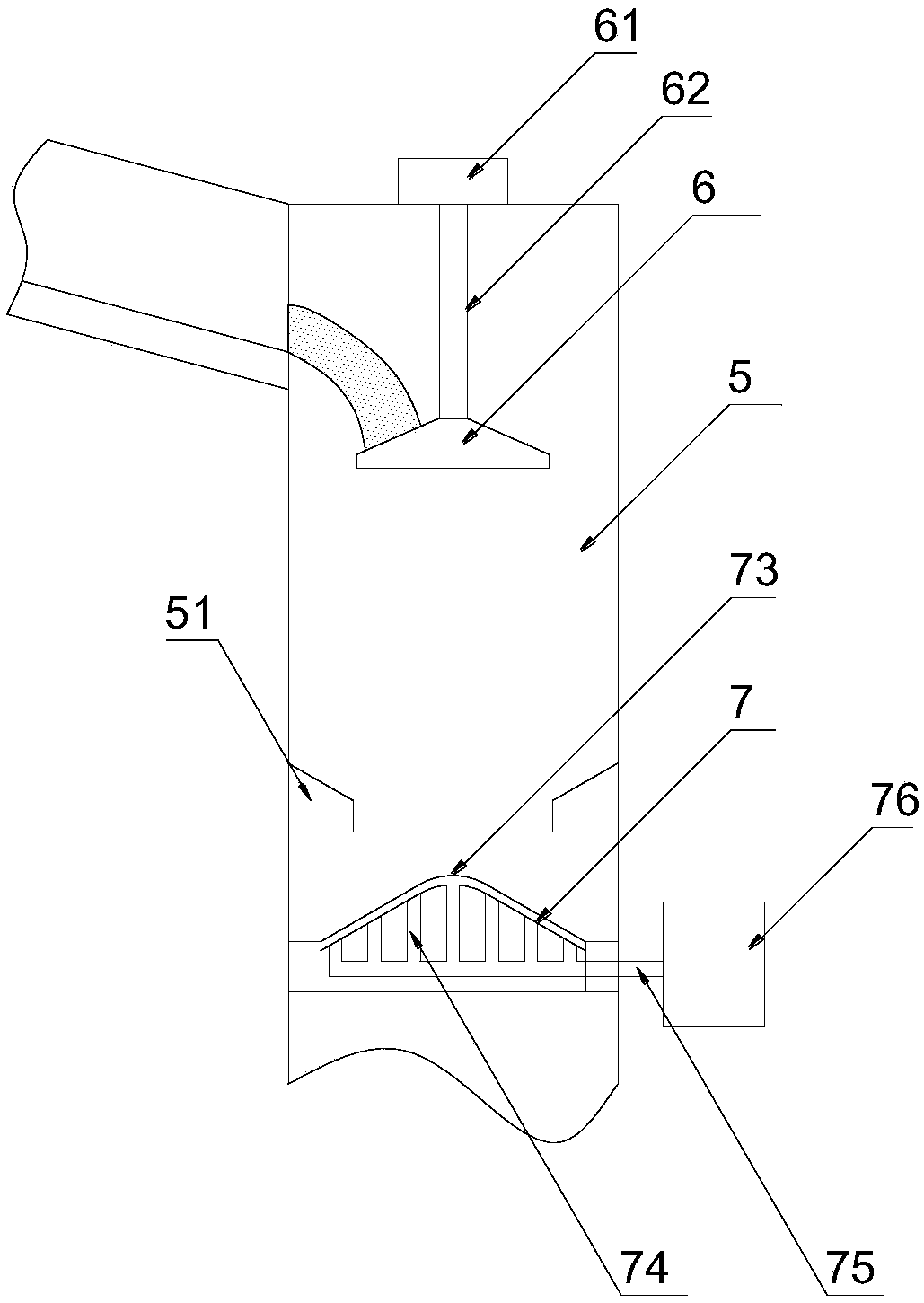

[0025] Such as Figure 1-4 as shown, figure 1 It is a structural representation of a uniform rice impurity-removing device for a kind of feed that the present invention proposes, figure 2 Partial structural representation of the even rice impurity-removing equipment for feeding that the present invention proposes, image 3 It is a schematic diagram of the internal structure of the blanking channel in the uniform rice impurity removal equipment for feeding that the present invention proposes, Figure 4 It is a structural schematic diagram of the dust removal assembly in the uniformly fed rice impurity removal equipment proposed by the present invention.

[0026] refer to Figure 1-4 , a kind of feeding uniform rice impurity removal equipment that the present invention proposes, comprises feed board 1, blanking channel 5, dust removal assembly 7, cabinet 10, first vibrating screen 11, second vibrating screen 12, recovery box 14, rice bin 15 and waste bin 16;

[0027] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com