Manufacturing method of epoxy resin pipeline

A manufacturing method and epoxy resin technology, which can be applied to devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc. The effect of avoiding gun chatter, high powder utilization, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

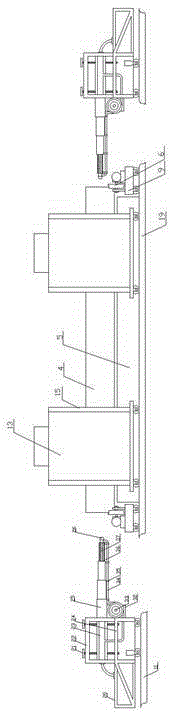

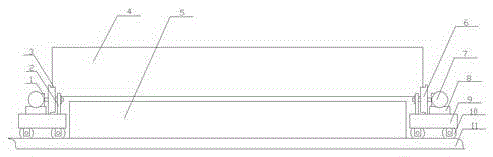

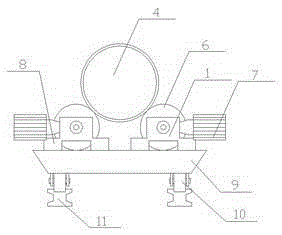

[0040] The present invention will be described below in conjunction with the accompanying drawings. Such as Figure 1-Figure 9 as shown, figure 1 It is a structural schematic diagram of the electrostatic spraying line of the present invention. figure 2 It is a structural schematic diagram of the steel pipe conveying device of the present invention. image 3 for figure 2 side view. Figure 4 It is a structural schematic diagram of the external spraying device of the present invention during operation. Figure 5 It is a structural schematic diagram of the walking box of the inner spray gun of the present invention. Image 6 It is a structural schematic diagram of the sling of the present invention. Figure 7 It is a schematic cross-sectional view of the fixing rod of the present invention. Figure 8 It is a schematic top view of the powder receiving tank of the present invention. Figure 9 It is a schematic diagram of the state of recovered powder in the powder receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com