Extruding machine

An extruder and barrel technology, applied in the field of extruders, can solve the problems of affecting the quality of finished products, easy to block the internal pipes of the extruder, and high energy consumption, so as to increase the processing speed and processing quality, and enhance the plasticizing shear. The effect of cutting effect and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

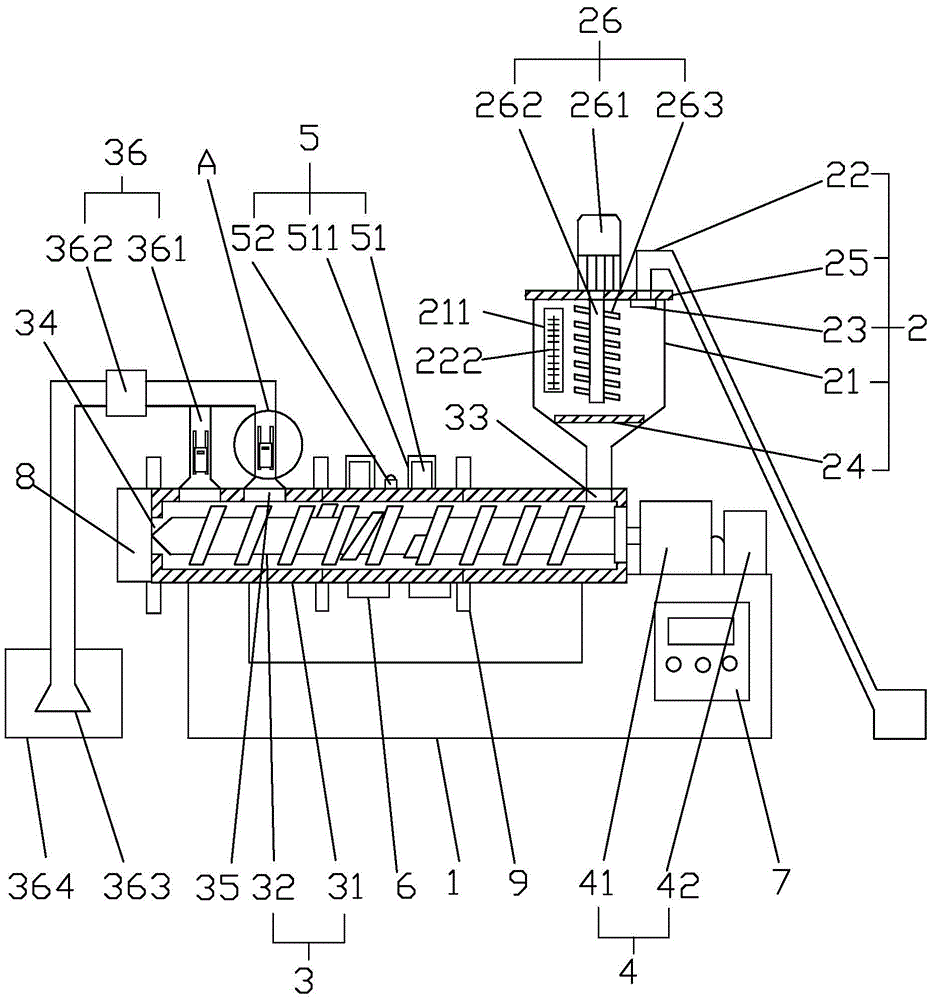

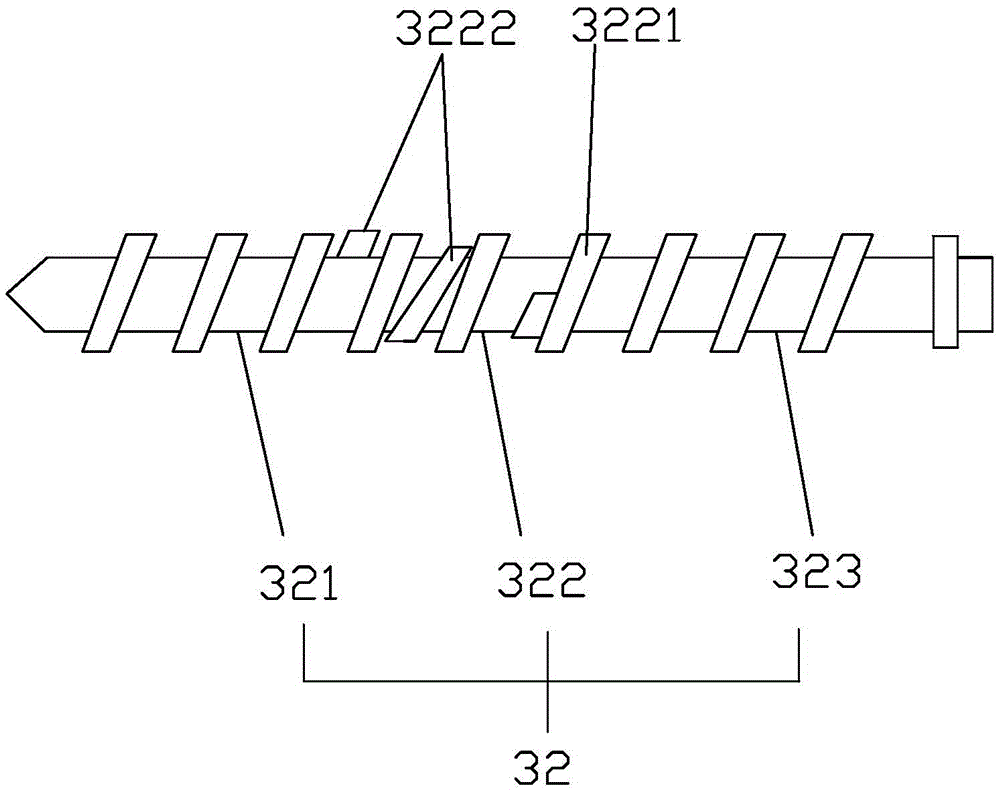

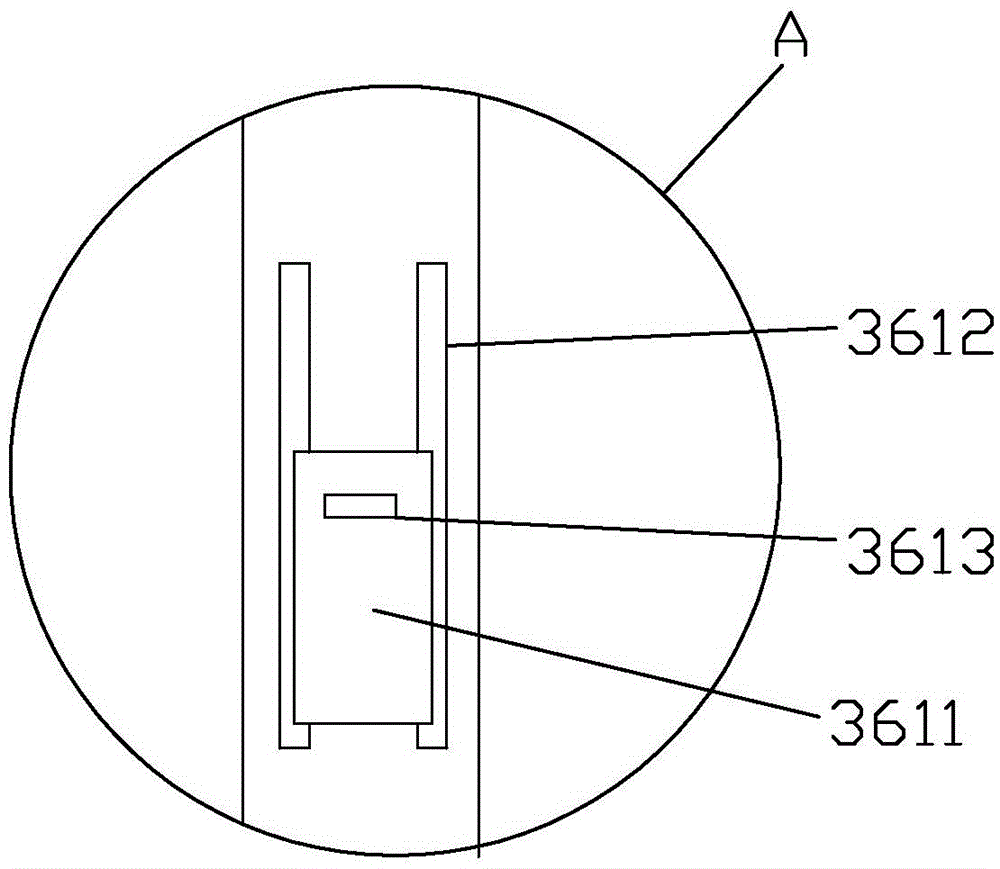

[0018] Such as Figure 1-3 Described a kind of extruder comprises machine base 1, feeding system 2, extruding system 3, transmission system 4, heating system 5, cooling system 6, electric control system 7 and machine head 8, and described feeding system 2 includes a hopper 21 and a feeding screw 22, the hopper 21 adopts a conical hopper 21, a transparent window 211 is provided on the outside of the hopper 21, and a scale line 222 is provided on the transparent window 211, and the Material balance, you can add materials in time. The feeding screw 22 is connected to the hopper 21, which can automatically feed materials to save manpower. The connection between the feeding screw 22 and the hopper 21 is provided with a filter screen 23 for filtering impurities, and the bottom of the hopper 21 is provided with an opening and closing door 24....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com