Toner supply supplementing container

A toner and container technology, which is applied in the field of toner supply and replenishment containers, can solve the problems of poor fluidity, low powder output rate and low utilization rate, and achieve the effects of reducing agglutination, improving utilization rate, and improving powder feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

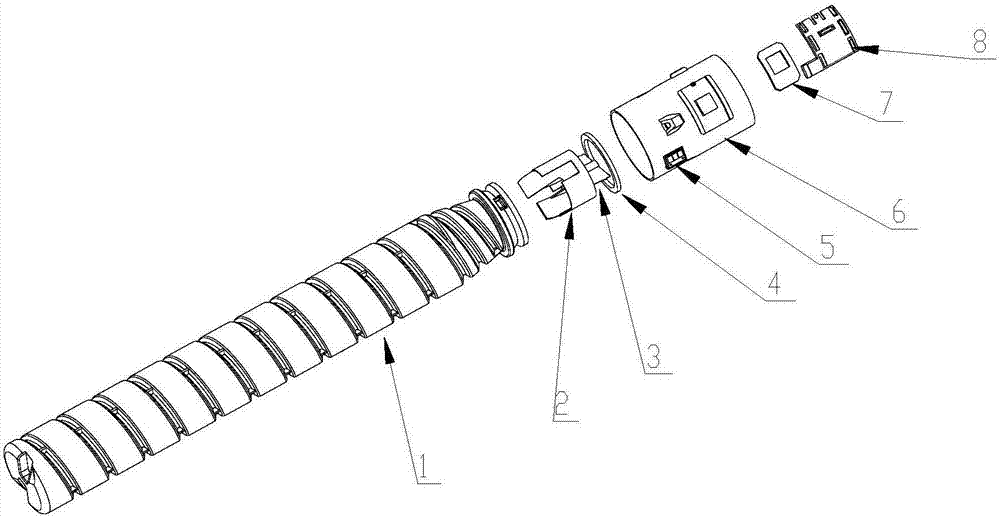

[0049] figure 1 A specific embodiment of the present invention is shown: a toner supply supplementary container, including a powder container 1, an auxiliary powder feeding frame 2, a stirring blade 3 and a container cover 6, and the stirring blade 3 is arranged in the auxiliary powder feeding frame 2, the The auxiliary powder feeding rack 2 is stuck inside the container opening 16 of the powder container 1, and the container cover 6 is set on the outside of the container opening 16 of the powder container 1. The two are connected by a buckle structure, and the auxiliary powder feeding rack 2 and the container A sealing sponge ring 4 is arranged between the covers 6, and a powder outlet 61 is provided on the container cover 6, and a powder outlet cover 8 is provided at the powder outlet 61, and a powder outlet cover 8 and a powder outlet 61 are provided with Powder outlet sponge7.

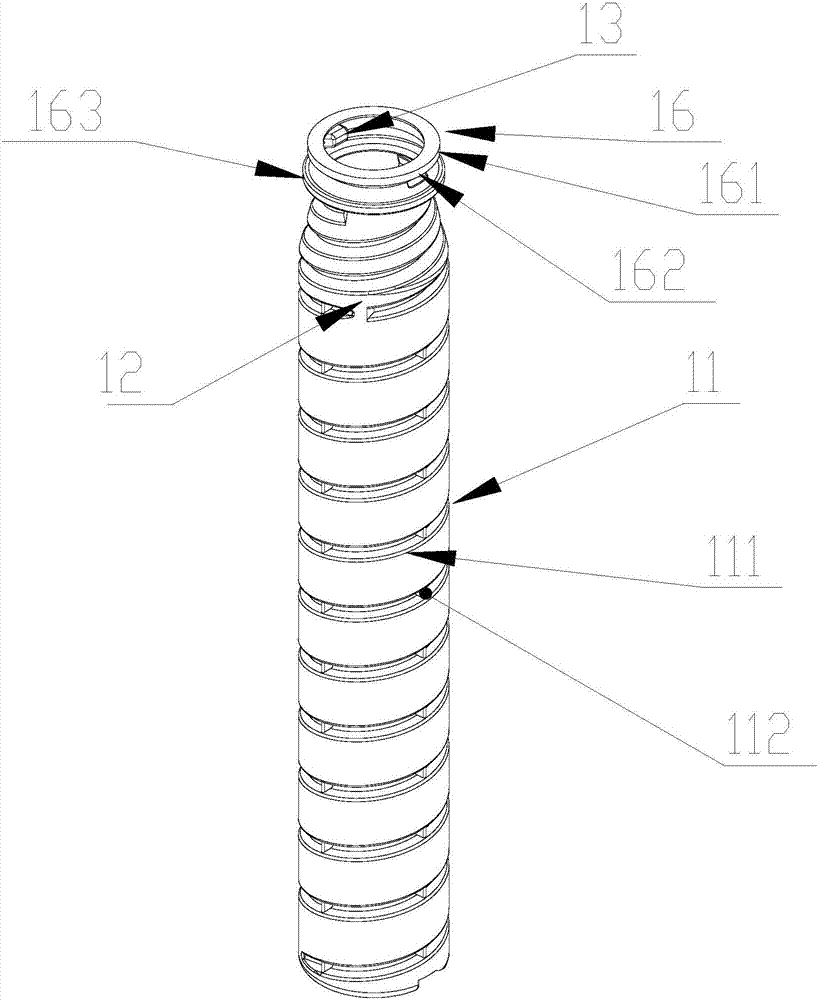

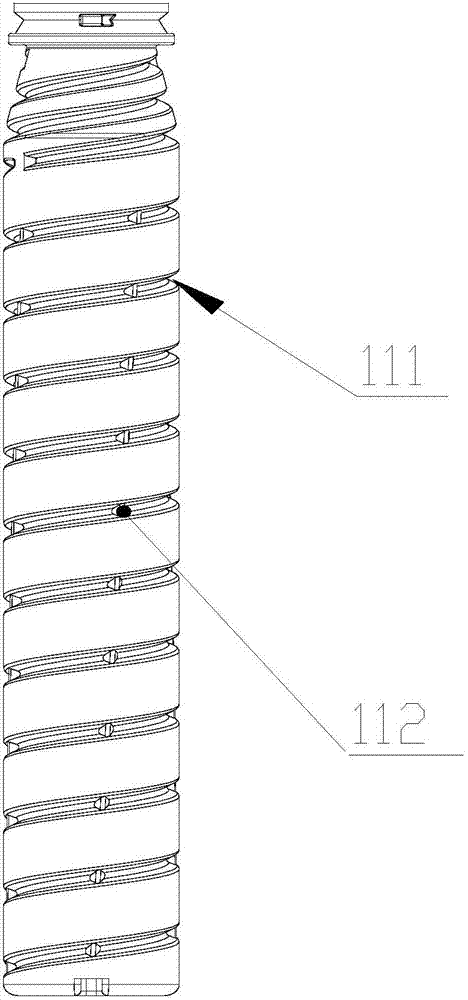

[0050] like figure 2 As shown, the extra side wall of the powder container 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com