Gravel filling and simulation system and method in hydrate mining well pipe

A technology of gravel filling and simulation system, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., to achieve the effect of true and reliable measurement, optimization of construction parameters, and optimization of gravel size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

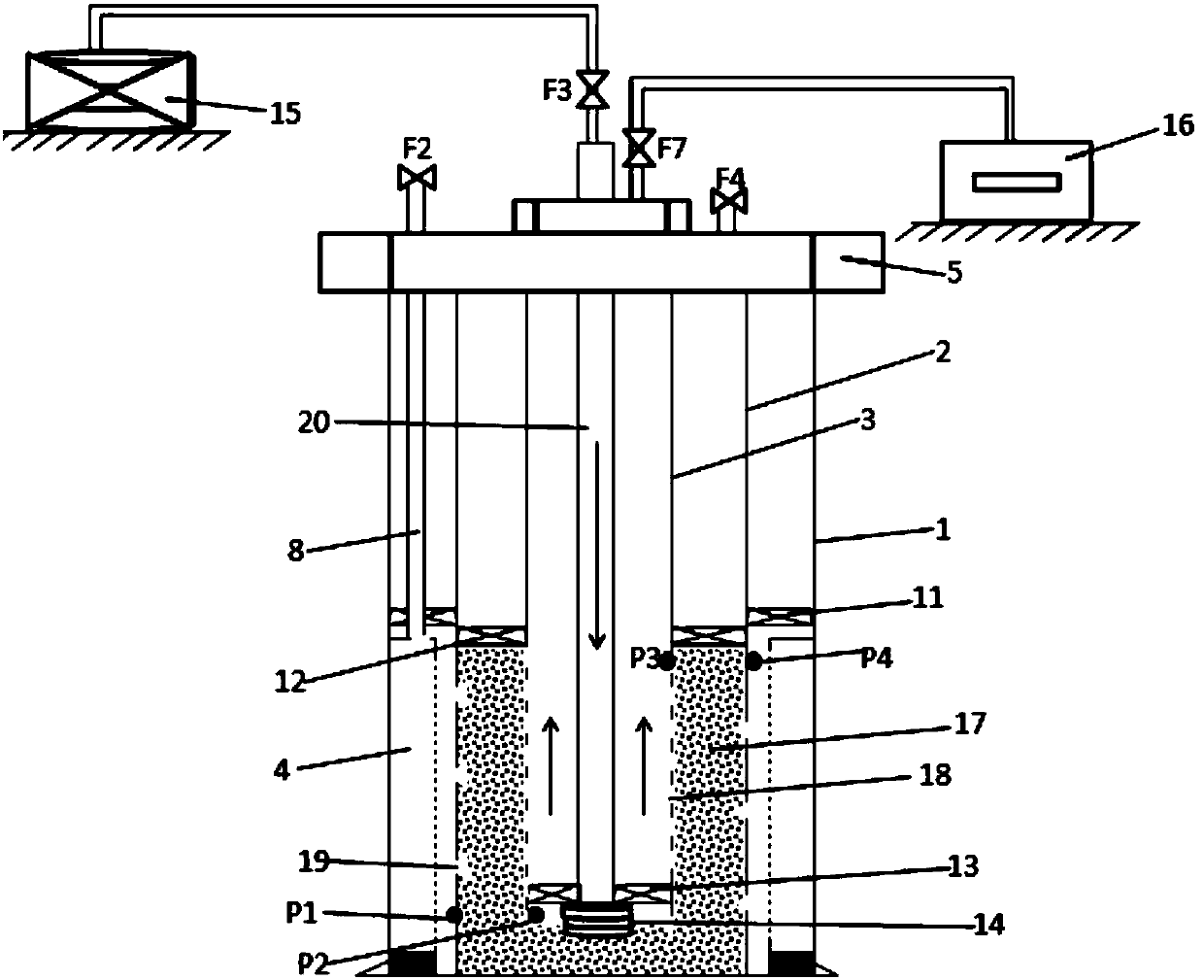

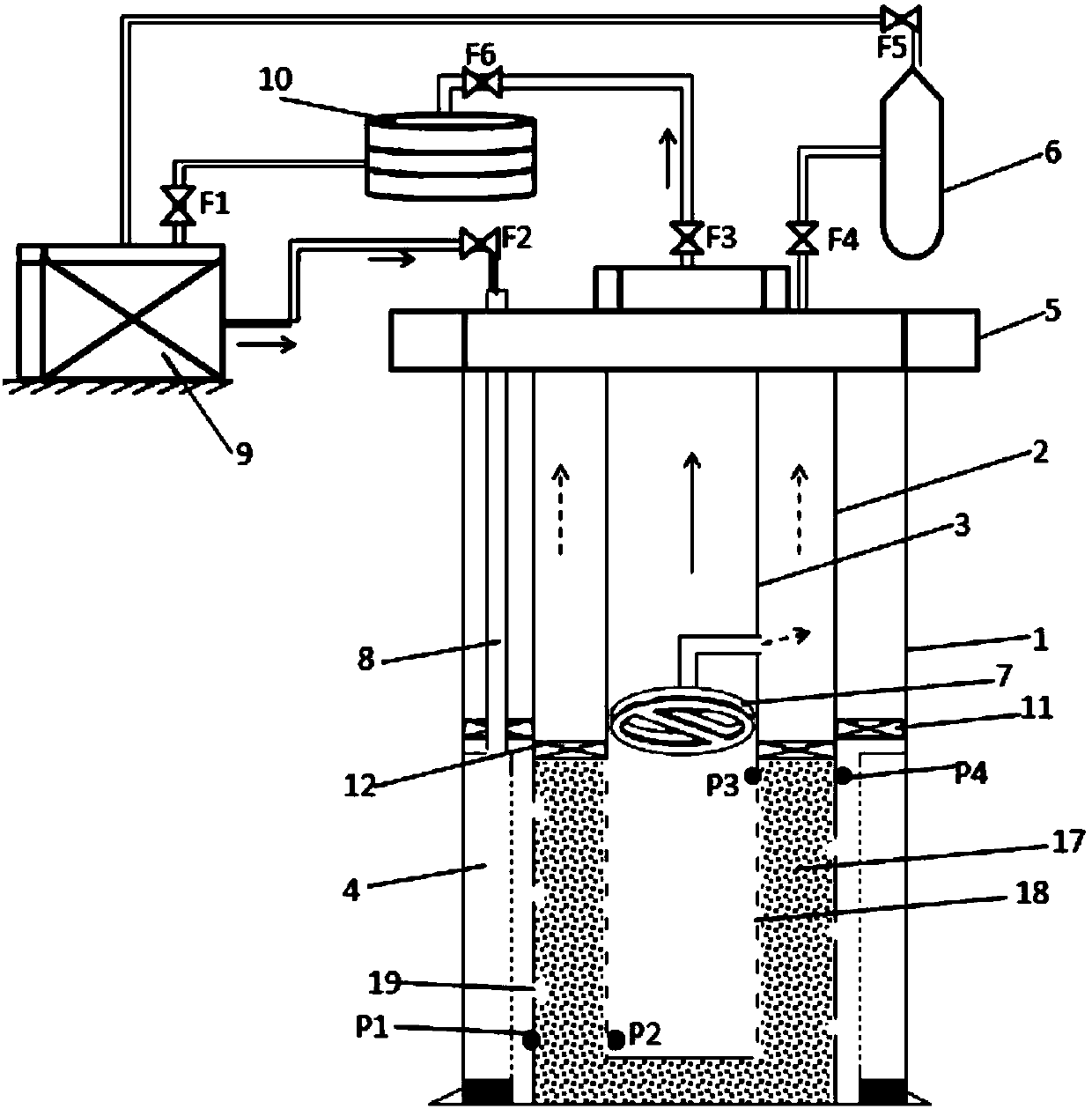

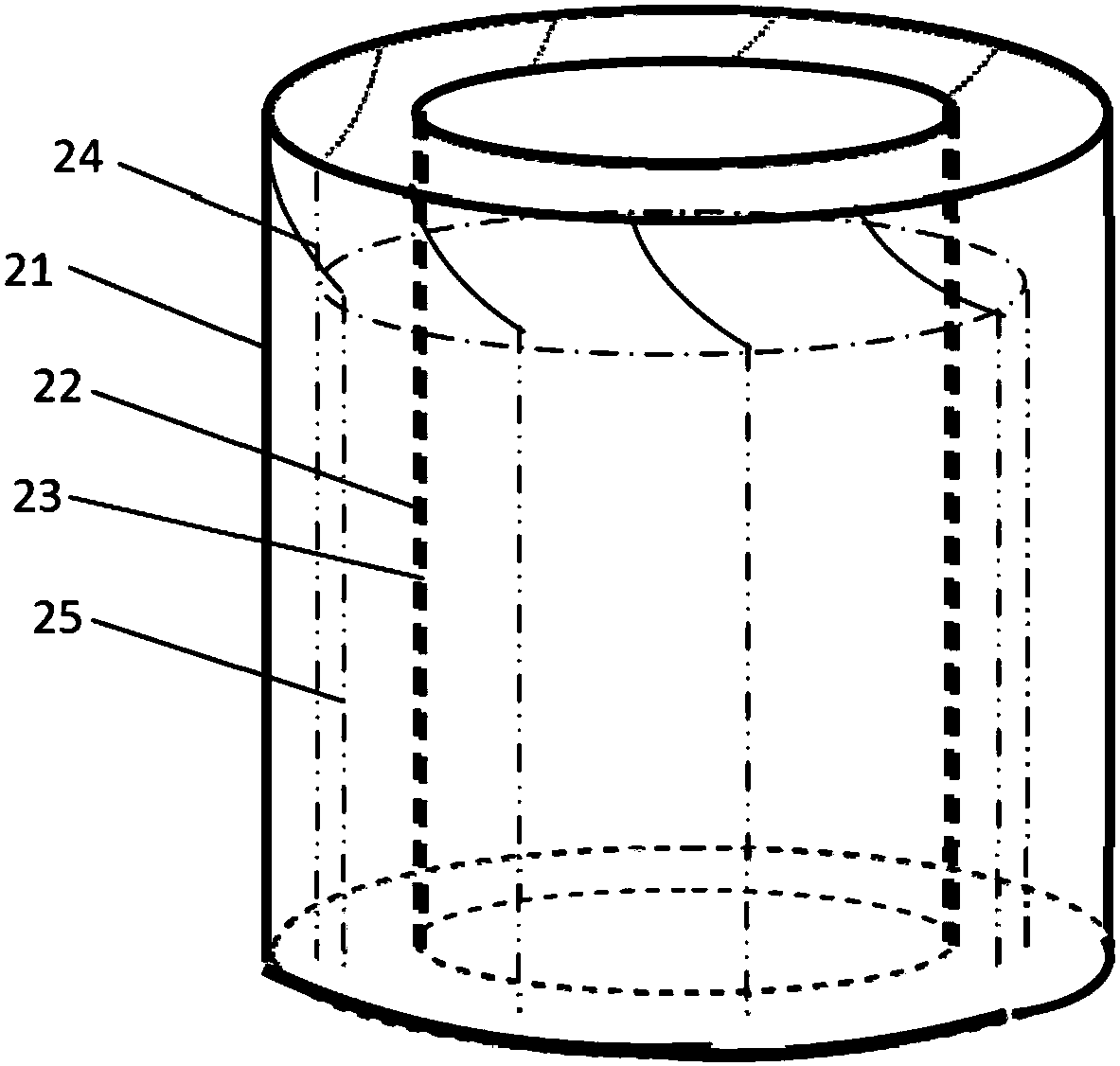

[0043] Example 1. A simulation system for gravel packing in a hydrate mining well tube has a 1:1 correspondence with the actual gravel packing tool, which satisfies the full-scale gravel packing tool entry and gas hydrate reservoir depth conditions, and the simulation results are highly reliable , Strong engineering practice, including test well subsystem, simulation filling subsystem and filling quality inspection subsystem.

[0044] reference figure 1 The test well subsystem includes a simulated wellbore 1, a simulated casing 2, a simulated tubing 3, a three-phase injection pipeline 8 and a mechanical screen 18. The wellhead of the simulated wellbore 1 is provided with a wellhead blowout prevention gate 5; the depth of the simulated wellbore The wellhead blowout ram is a bridge between the test well subsystem and the simulated filling subsystem. It is the main component of the test well to maintain the high pressure system. The pressure resistance is 15Mpa. The wellhead blowout ...

Embodiment 2

[0049] Embodiment 2, based on the simulation system described in embodiment 1, this embodiment also proposes a method for simulating gravel packing in hydrate mining well pipes, refer to Figure 5 , Including the following steps:

[0050] A. Install the wellbore string according to the actual wellbore structure, check the tightness of each sealing position, fill the simulation subsystem and perform the filling operation simulation;

[0051] B. The lower filling quality inspection subsystem monitors the filling quality and judges whether the filling quality is qualified. If it is unqualified, the filling operation simulation will be performed again; if it is qualified, the mixed gas, liquid, and mud will be injected to simulate the production process, and the sand production will be monitored in real time Happening;

[0052] C. Determine whether the sand control effect is qualified. If the sand control effect is unqualified, adjust the filling process parameters and re-run the fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com