Small-sized intelligent automatic unpacking system

An intelligent and small technology, which is applied in the directions of packaging, transportation and packaging, and unsealing of packaged objects, etc., can solve the problems of inability to use large-scale automatic unpacking machines, high degree of harm to workers, inability to replace manual operation automation, intelligent miniaturization, Unmanned production and other issues, to achieve the effect of reducing staff and increasing efficiency, occupying a small area, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

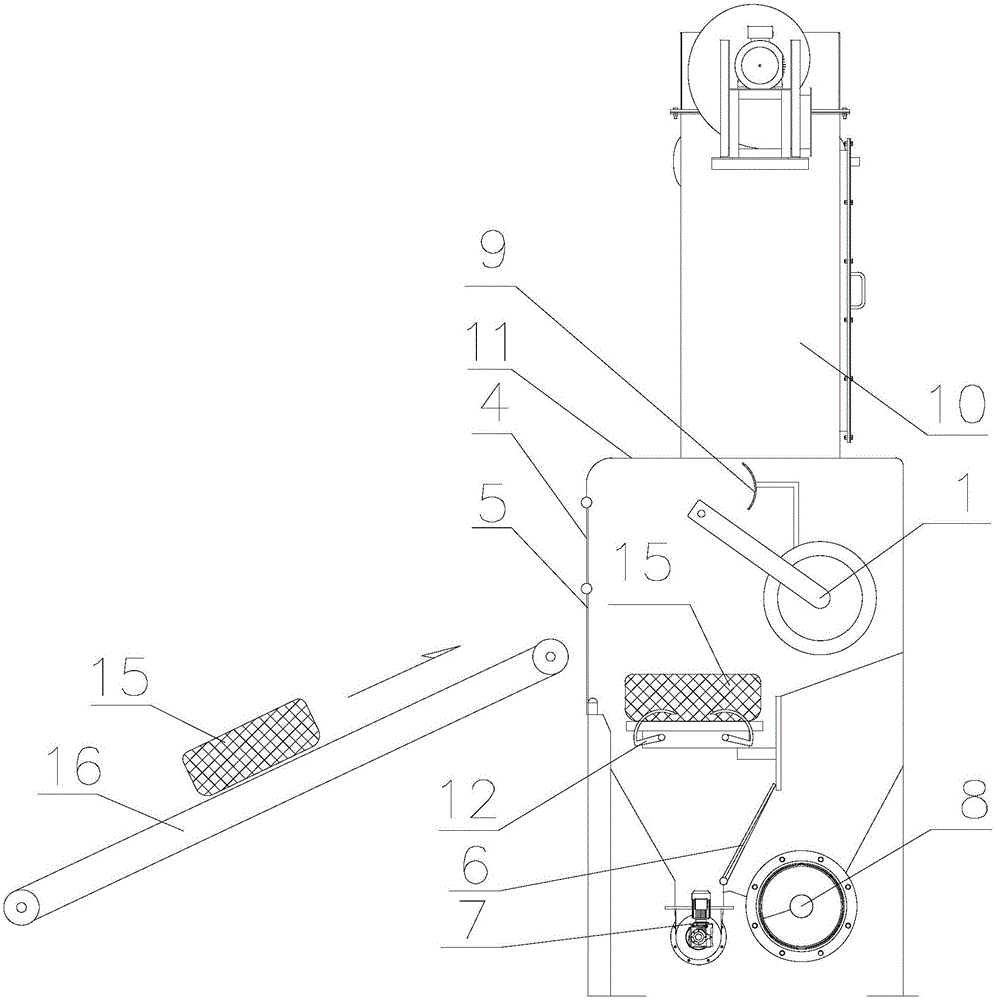

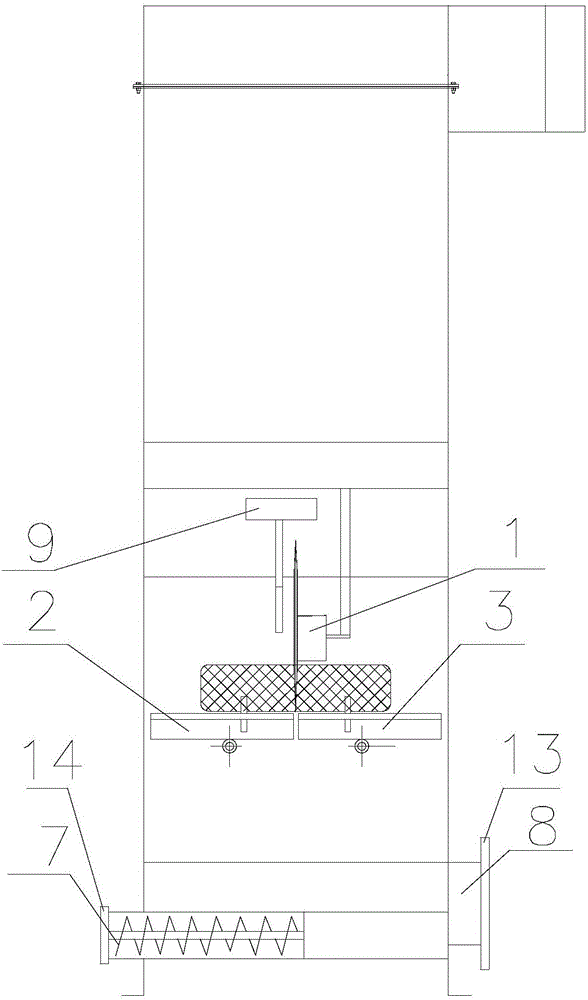

[0038] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0039]As shown in the drawings, the present invention includes: a bag cutting mechanism 1, a turning and discharging mechanism, a safety door mechanism, a blanking / waste bag switching mechanism 6, a waste bag screw conveying mechanism 7, a powder particle spiral conveying mechanism 8, and a claw mechanism 12. The box 11 and the PLC control system, the box 11 is provided with a bag inlet, the bottom of the box 11 is provided with a waste bag mouth 13 and a material discharge port 14, and a safety door mechanism is installed at the bag inlet, and the safety door mechanism is used for To realize the opening or closing of the bag inlet, the box body 11 is located below the bag inlet and is provided with an overturning and unloading mechanism, and a gripper mechanism 12 is provided under the overturning and unloading mechanism, and the gripper mechanism 12 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com