Automatic unpacking and blanking device

An automatic, packaging bag technology, applied in packaging, transportation and packaging, unsealing of packaging objects, etc., can solve problems such as occupational diseases and adverse effects on the human body, and achieve the effect of reducing dust, reducing labor input, and improving the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

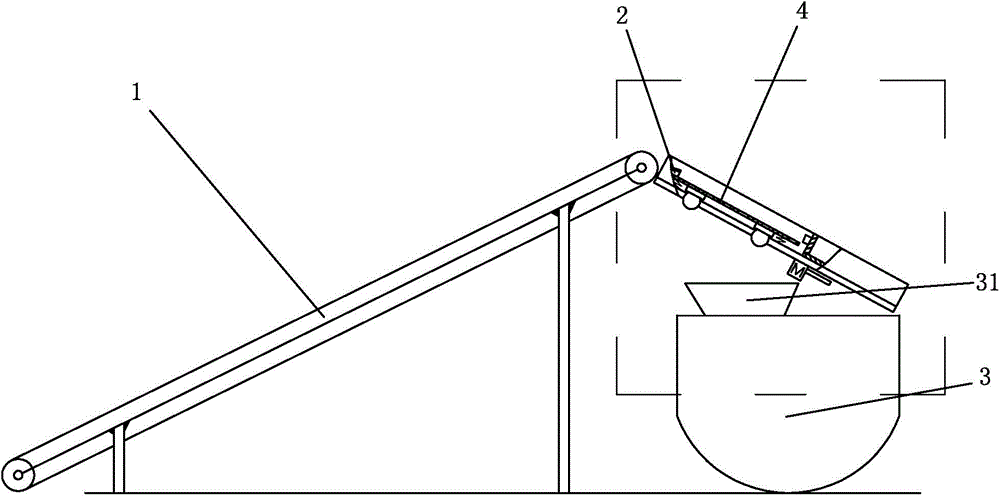

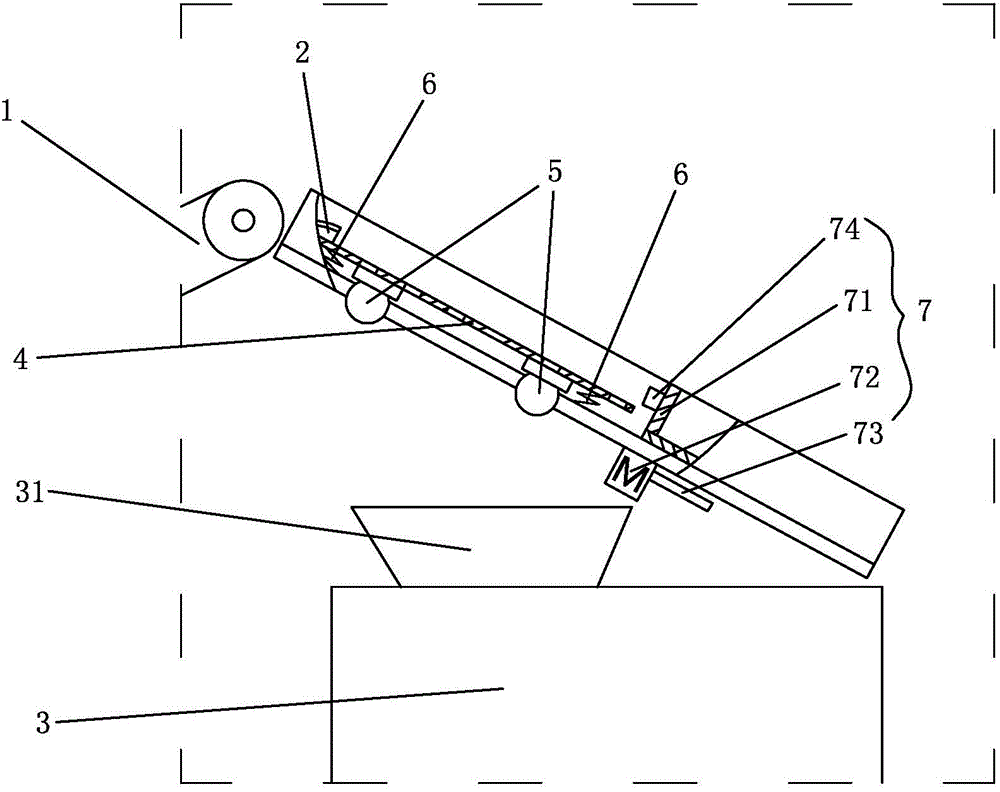

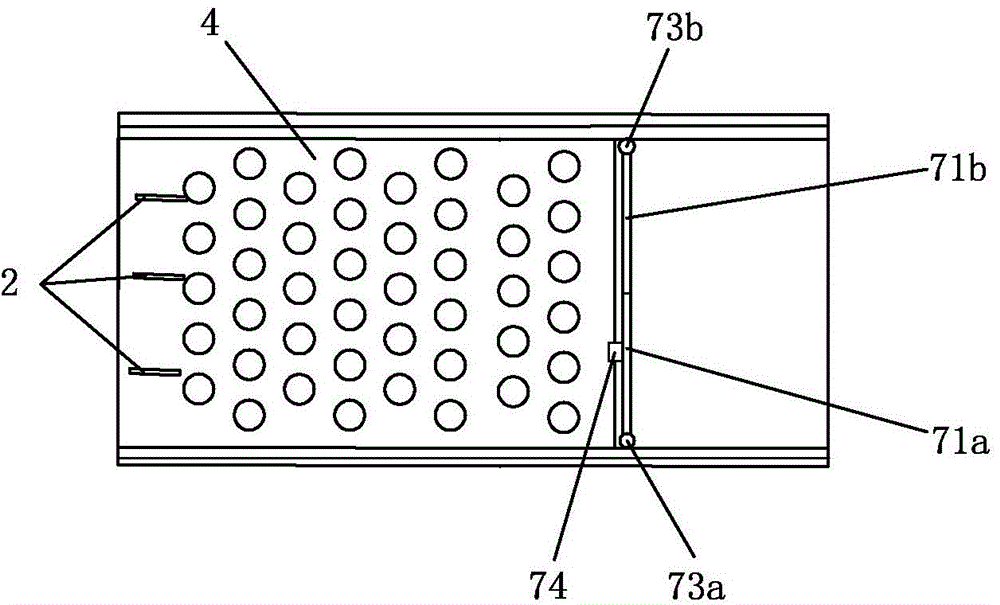

[0025] See Figure 1 to Figure 3 As shown in the figure, an automatic unpacking and unloading device of the present invention includes a conveying mechanism 1, a cutting mechanism 2 and a storage bin 3. The bagged solid raw materials are transmitted from one end of the conveying mechanism 1 to the other end. The mechanism 1 drives the bagged solid raw materials to pass through the cutting mechanism 2, so that the solid raw materials enter the storage bin 3 after the packaging bag is broken, and also includes a sieve plate 4. The other end of the conveying mechanism 1 is connected to one end of the sieve plate 4. Adjacent, so that the bagged solid raw material enters one end of the sieve plate 4 through one end of the conveying mechanism 1, and the cutting mechanism 2 is arranged at one end of the sieve plate 4 to cut the packaging bag of the bagged solid raw material. , the solid raw material falls into the storage bin 3 through the mesh of the sieve plate 4 .

[0026] Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com