Full-automatic powder bag stabbing and cutting machine and control method thereof

A fully automatic, bag breaking machine technology, used in packaging automatic control, packaging, packaging protection and other directions, can solve the problems of mixing powder into the production line, occupying labor efficiency, equipment damage, etc., to achieve strong operation ability, labor saving, load-bearing powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

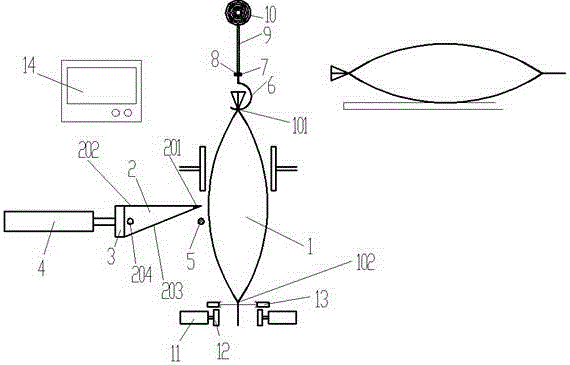

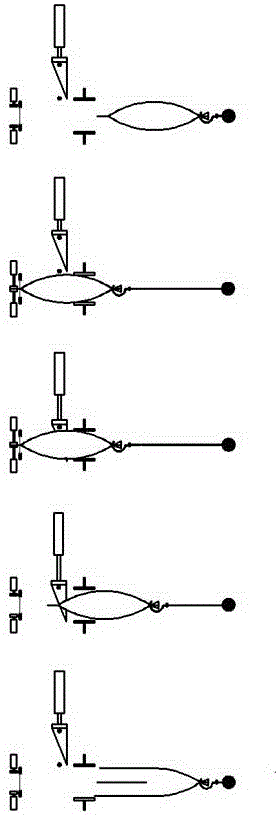

[0033] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0034] The fully automatic powder burr cutting machine includes a lifting part, a cutting knife part, a splint part and a controller 14 .

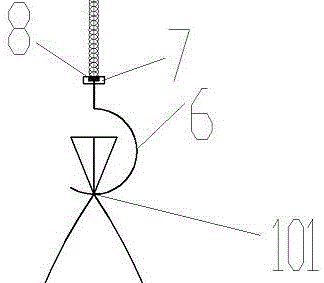

[0035] Such as figure 1 with figure 2 As shown, the lifting part includes a hook 6, a lifting chain 9, a reel 10, a lifting plate 7 and a vibrator 8, and the unqualified powder packages rejected by the production line are transported to the automatic powder cutting machine through a specific conveyor belt. The feed port of the bag breaker, the powder package in the feed port is the bag body 1, and the binding bag mouth of the bag body 1 faces the direction of the bag breaker, so that the hook 6 can hook the bag mouth 101 of the bag body 1, so the reason why the bag body is chosen to be hooked The mouth 101 is because the bundled bag mouth can bear the load during hoisting due to tightening, and in the subsequent process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com