Full-automatic unstacking and unpacking system

A fully automatic depalletizing machine technology, which is applied in the field of unpacking, unloading, and solid powder material depalletizing. It can solve the problems of high labor costs, high labor intensity, and different pallet sizes, and improve work efficiency. , Realize the effect of reducing staff and increasing efficiency, and ensuring the workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

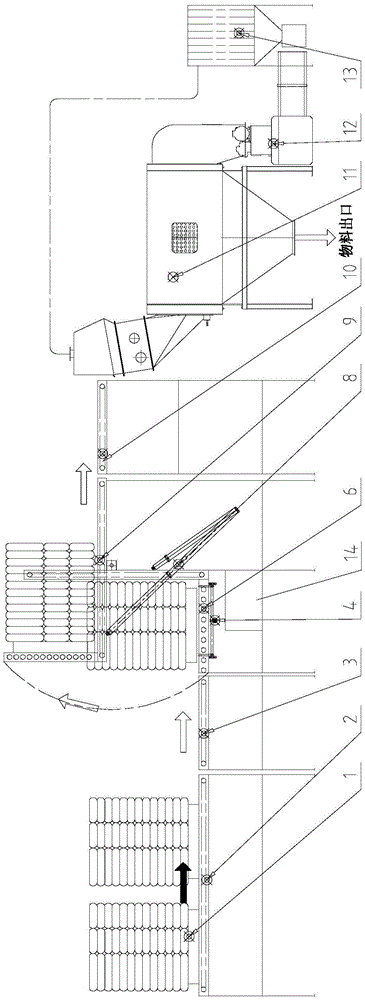

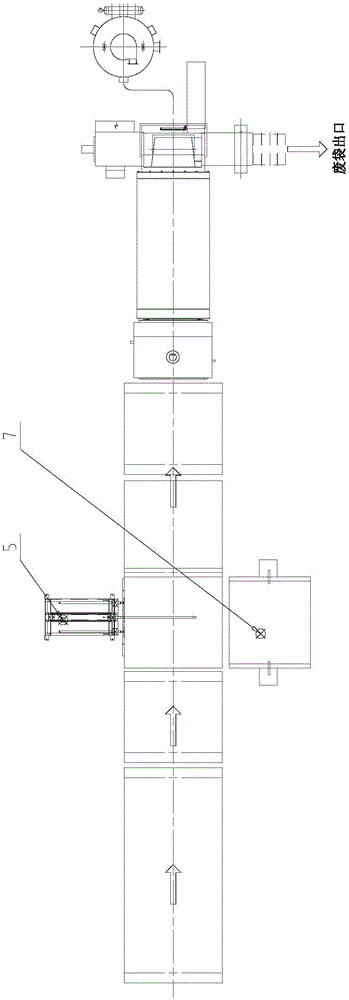

[0029] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0030] As shown in the accompanying drawings, the present invention includes: chain plate conveyor, hydraulic flipping and unstacking equipment, packaging bag conveyor 10, fully automatic unpacking machine 11, fully automatic packing machine 12 and pulse dust collector 13, and a forklift for solid pallet 1 Place it directly on the chain-slab conveyor, the output end of the chain-slab conveyor is connected to the input end of the hydraulic flipping and unstacking equipment, the output end of the hydraulic flipping and unstacking equipment is connected to the input end of the packaging bag conveyor 10, and the packaging bag conveyor 10 is connected to the On the support frame of the hydraulic flipping and unstacking equipment, the output end of the packaging bag conveyor 10 is connected to the automatic bag unpacking machine 11. Packing machine 12, fully automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com