Beverage packaging bag recycling and processing system

A recycling processing and packaging bag technology, applied in the field of beverage packaging bag recycling processing system, can solve the problems of breeding bacteria, polluting the environment, costing large labor costs and time costs, etc., and achieves easy assembly and disassembly, improved utilization rate, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

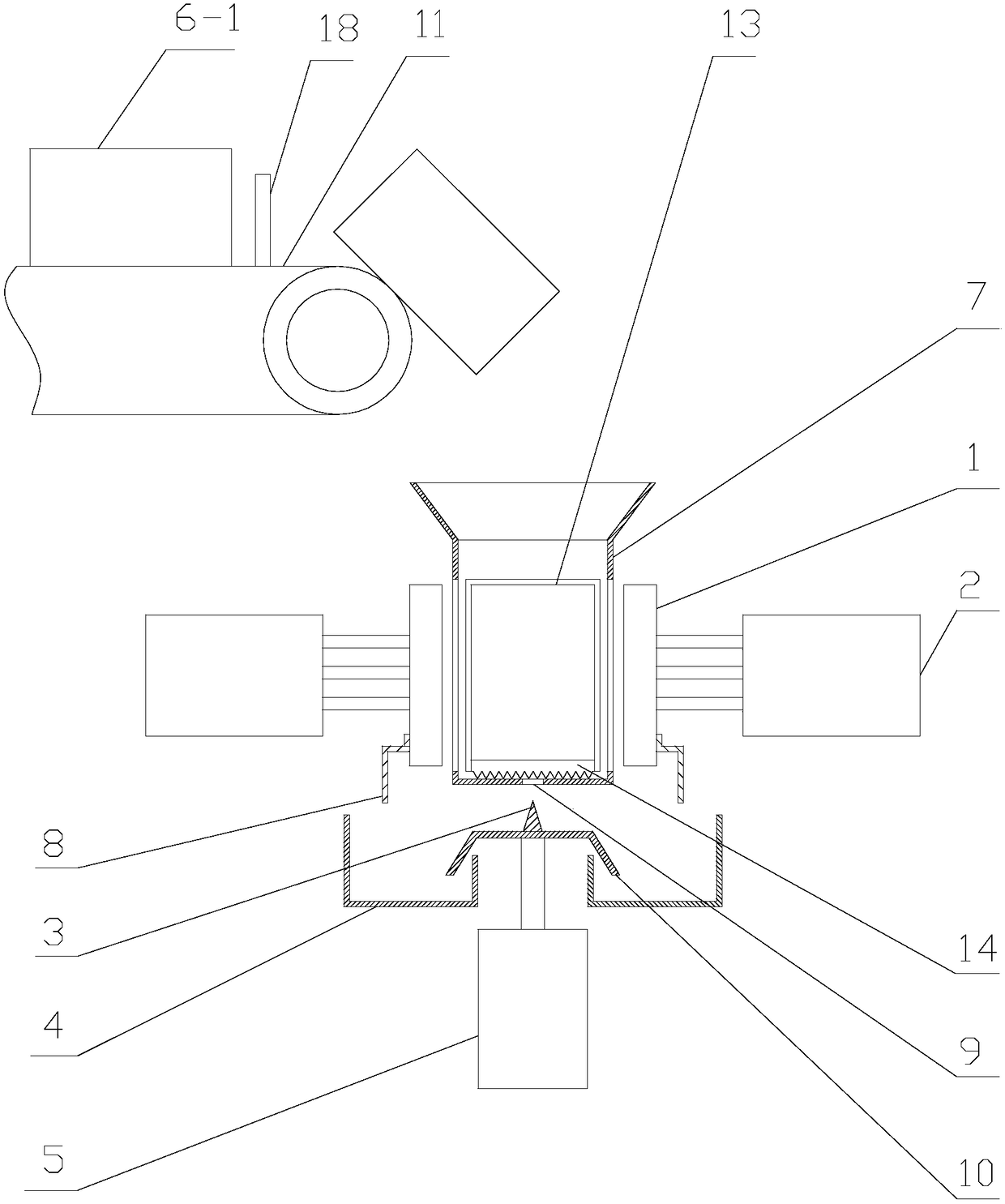

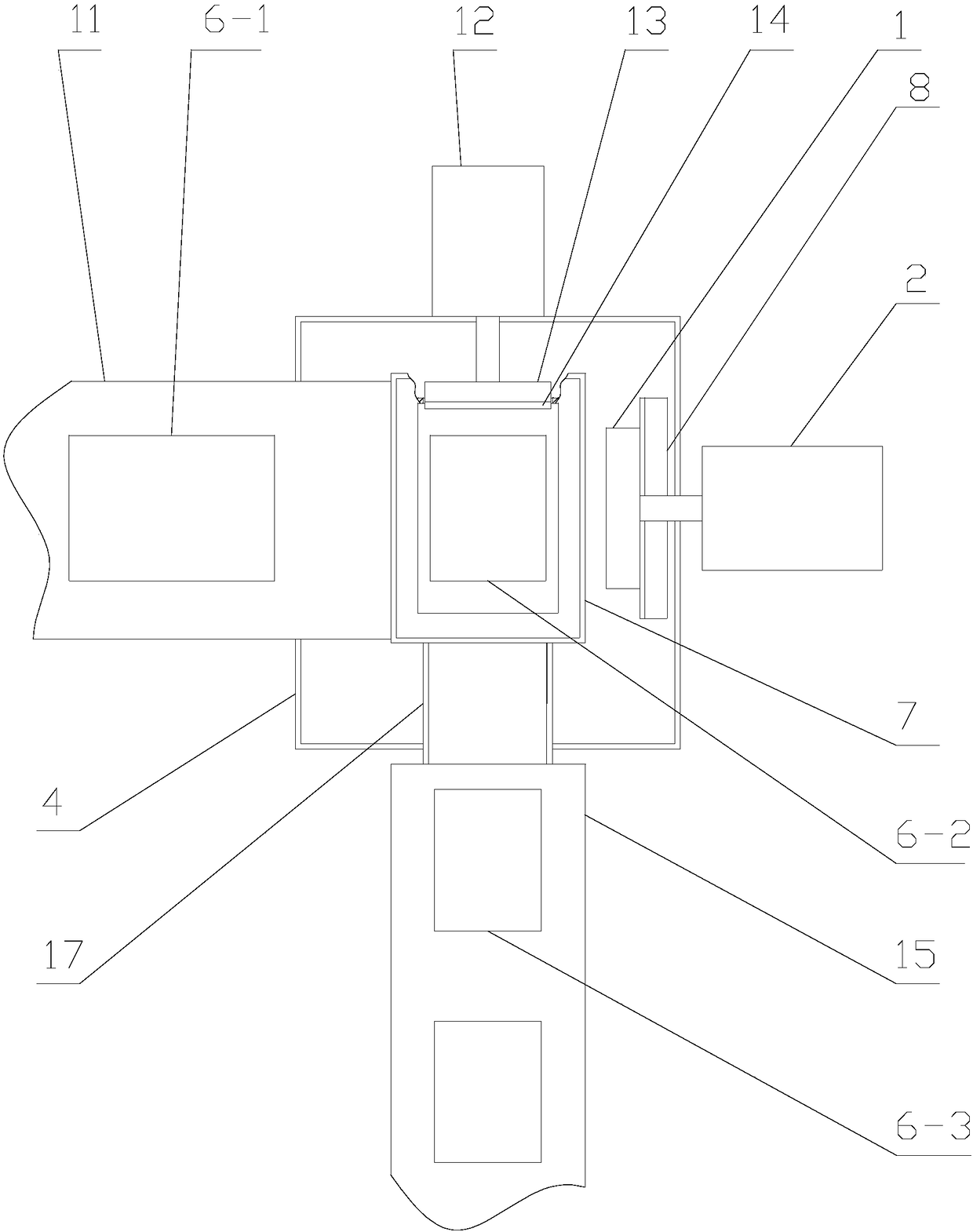

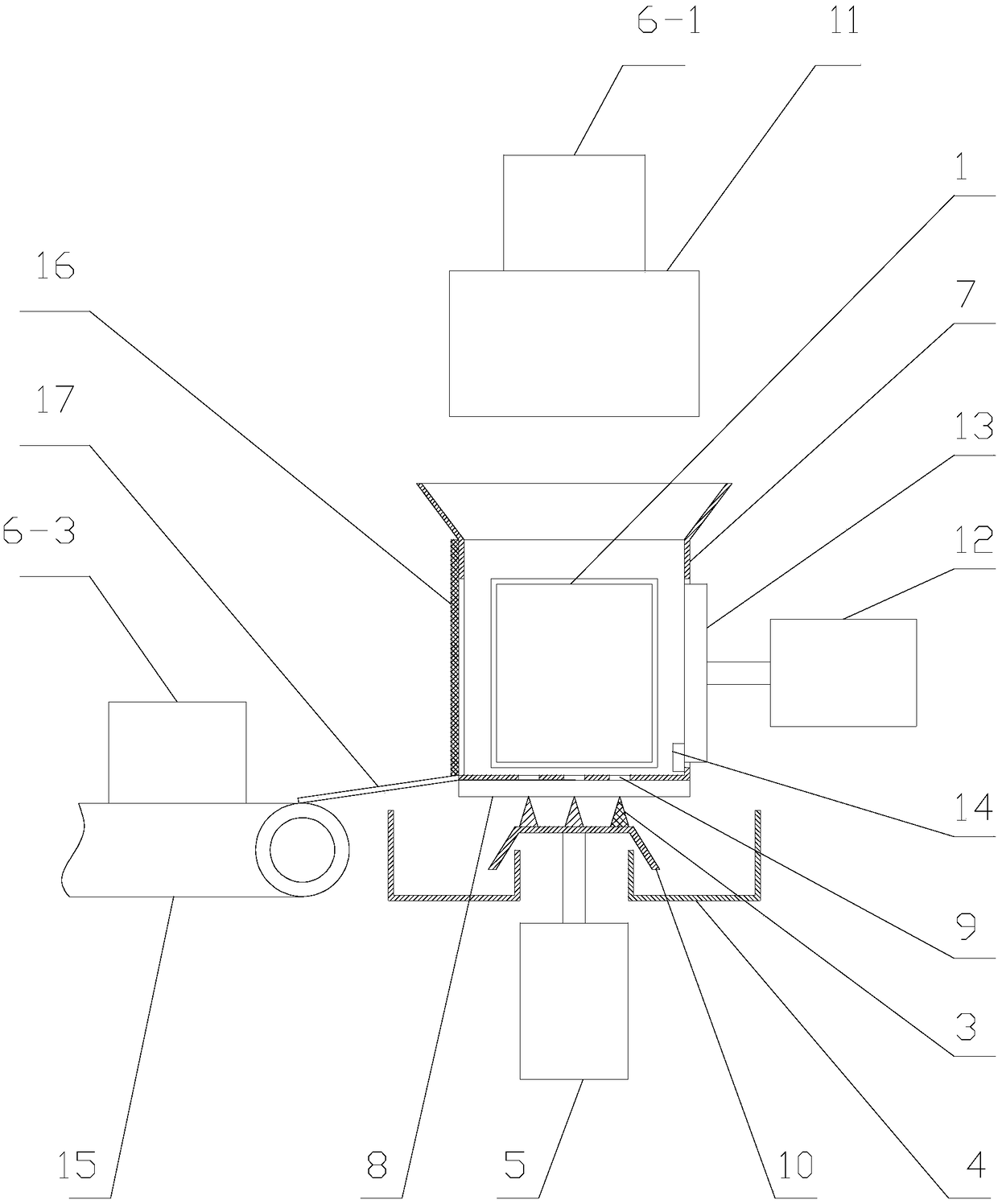

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0020] See Figure 1 ~ Figure 3 , a recycling processing system for beverage packaging bags, comprising a recovery platform, a left extrusion unit, a right extrusion unit, a piercing unit, a liquid collection tank 4 and a pushing unit; the recovery platform is provided with a chassis with a sieve hole 9, the The four sides of the chassis are provided with coaming panels 7 and form a material inlet. The coaming panels 7 include a front panel, a rear panel, a left panel and a right panel; the left extruding unit and the right extruding unit, They are respectively located on the left and right sides of the recovery platform, and they all include an extruding cylinder 2 and an extruding plate 1 driven by the extruding cylinder 2 to move left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com