Bag opening machine for large bag

A bag unpacking machine and large bag technology, applied in the field of machinery and equipment, can solve the problems of dust pollution, health hazards of workers, and high labor intensity, and achieve the effects of energy saving, labor intensity reduction, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

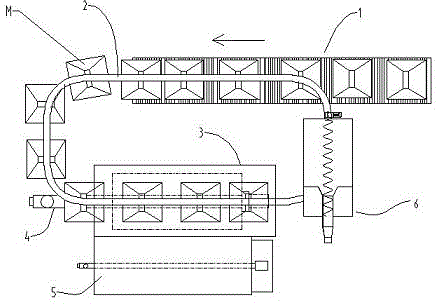

[0035] Examples such as figure 1 As shown, the large bag unpacking machine includes an annular conveying mechanism 2, and a bag-loading conveying mechanism 1 is arranged below the circular conveying mechanism 2. The bag-loading conveying mechanism 1 is used to guide the packaging bag M containing materials into the circular conveying mechanism 2, and the packaging The bag M moves circularly under the drive of the circular conveying mechanism 2. The circular conveying mechanism 2 is provided with a bag unpacking mechanism 3 for dismantling the packaging bag M. The material output mechanism 4 that flows out of the material inside, and the empty bag collection mechanism 6 that collects the packaging bags are also provided on the ring conveying mechanism 2 .

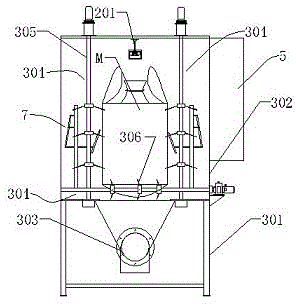

[0036] Such as Figure 4 As shown, the circular conveying mechanism 2 includes a ring track 201, the ring track 201 is supported by a gantry frame, the gantry frame is fixed on the ground, and several sliders 202 are slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com