Web guiding device and guiding belt separation device used for fibrous web machine and

A fiber web machine and separation device technology, which is applied in the direction of paper machine, paper machine wet end, press part, etc., can solve the problem of poor contact accuracy of the guide device, reduced success rate of web guide, and aggravated guide belt Floating and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

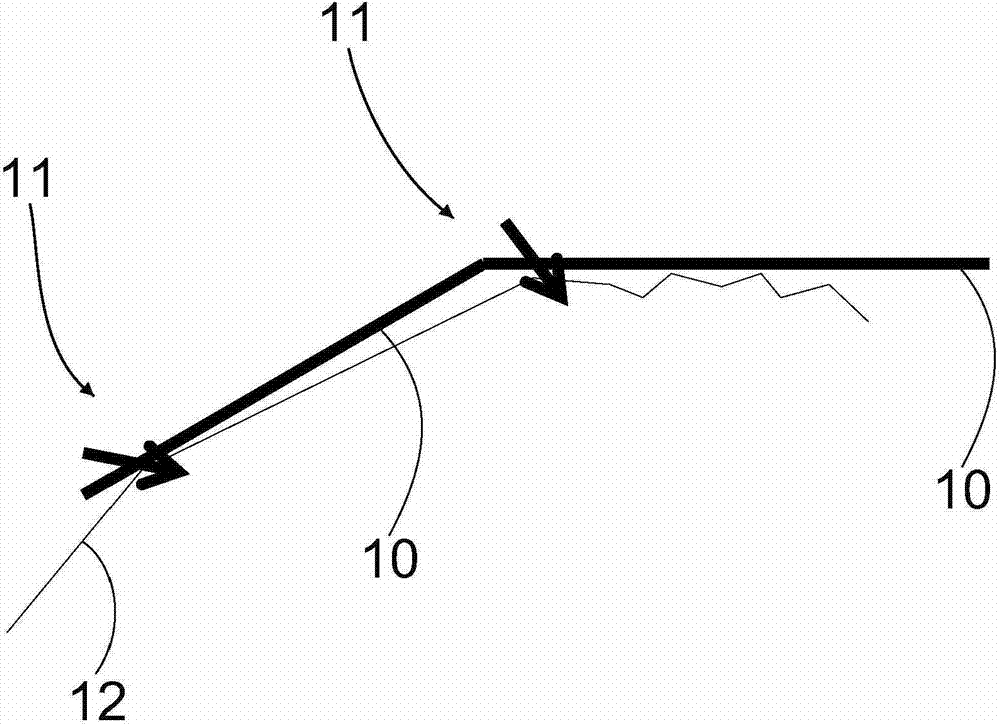

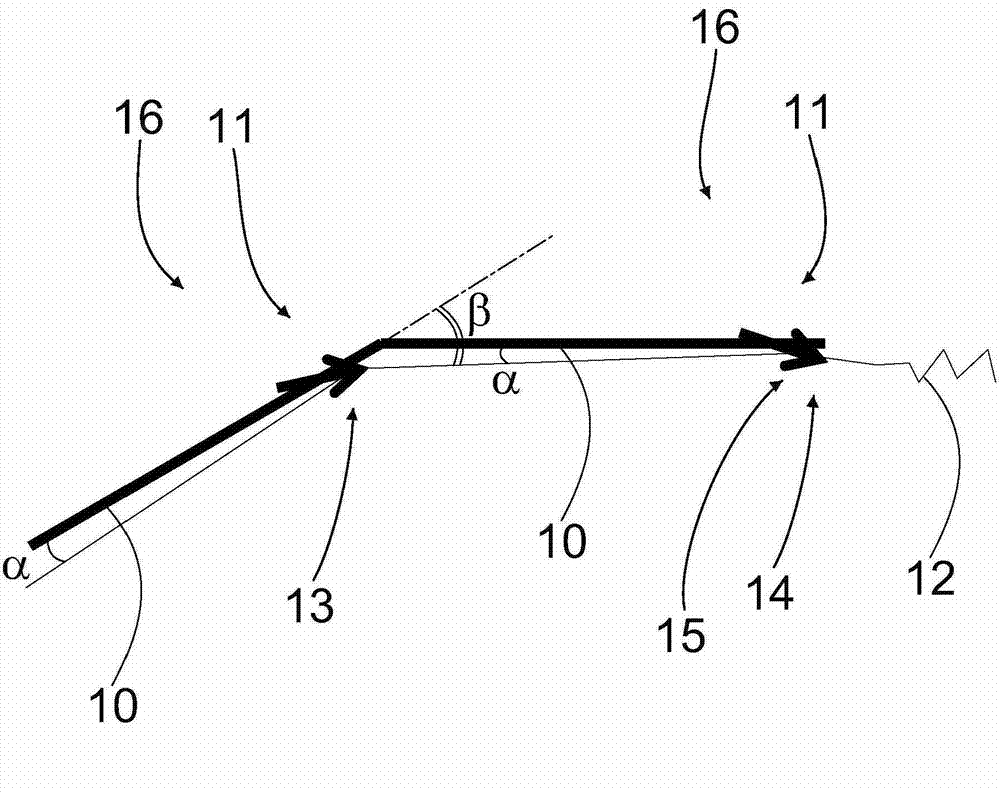

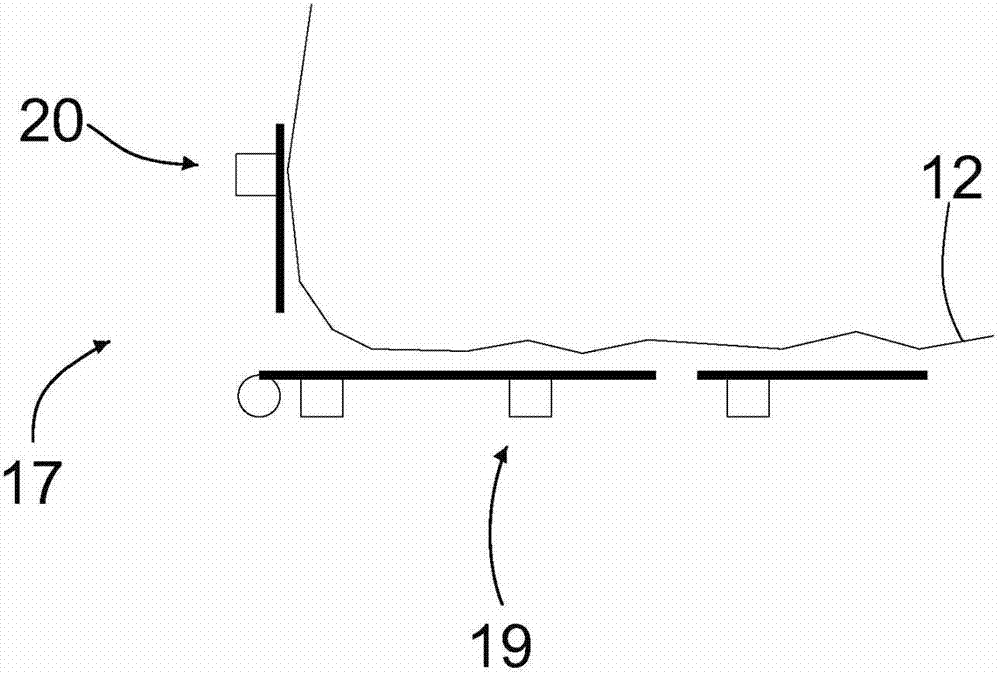

[0013] Figure 1a A part of a known web guiding arrangement for a fiber web machine is shown. The known blowing air flow for web guidance is directed from a flange, i.e. a step, to the guide surface, where the flange consists of a surface which deviates from the guide surface, which can brush against the guide belt and thus cause friction. Fiber web machines are eg paper and board machines. The guide device here comprises guide surfaces 10 , each of which is directed at a blowing air stream 11 for conveying the guide strips 12 . With the aid of this blowing air flow for guidance, the guide strip is to be attached to the guide surface and transported further. However, problems arise in this web guiding device according to the prior art. Such as Figure 1a As shown, the guide strip 12 can only follow the guide surface 10 inaccurately and flutters in an indeterminate manner. At least when the guide surfaces are angled relative to each other, the guide strip can loosen from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com