Underwater cutting releasing mechanism

A release mechanism and underwater cutting technology, which is applied in the direction of shearing devices, shearing machine equipment, metal processing equipment, etc., can solve the problems of communication buoys that cannot surface normally and the floating speed is small, and achieve reliable release and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

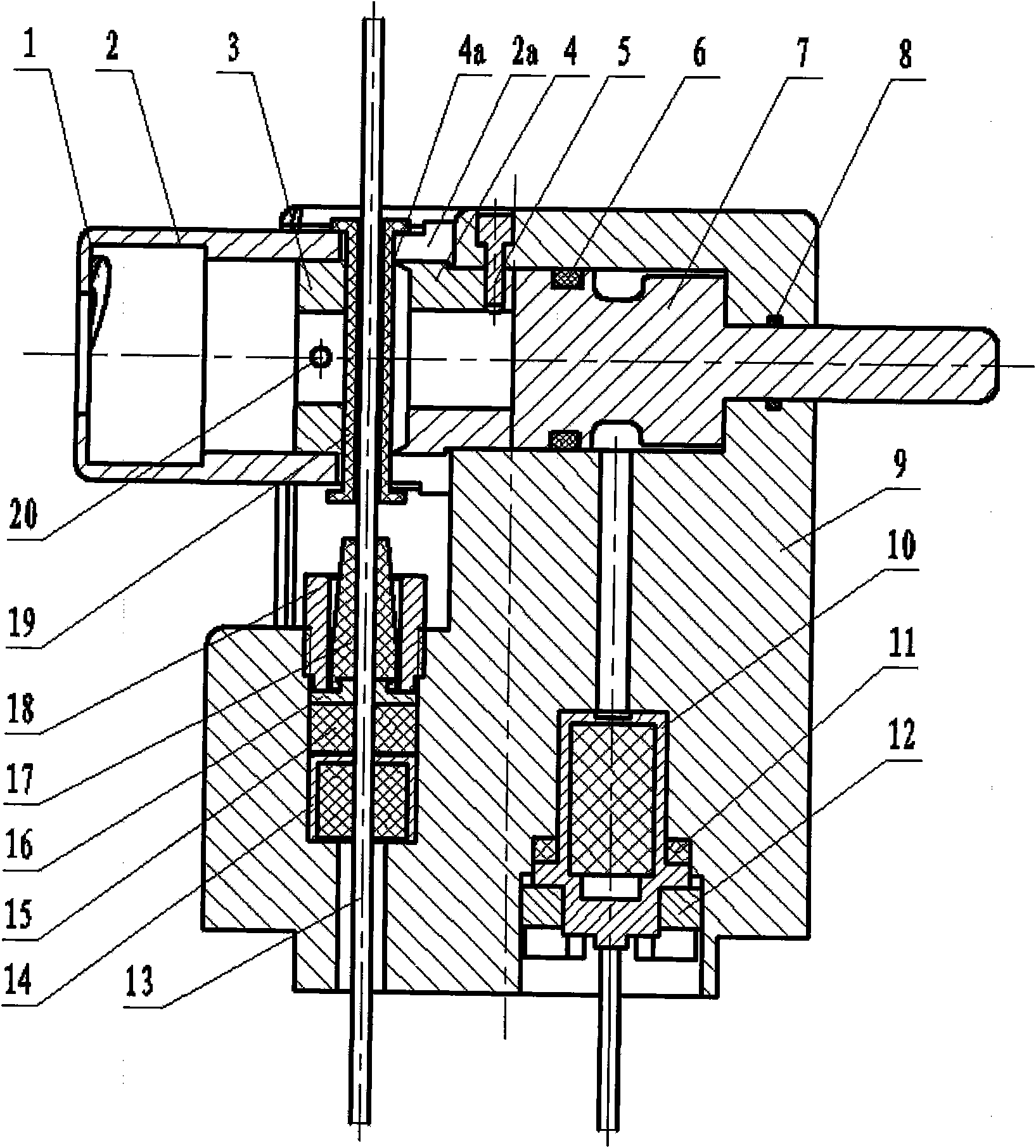

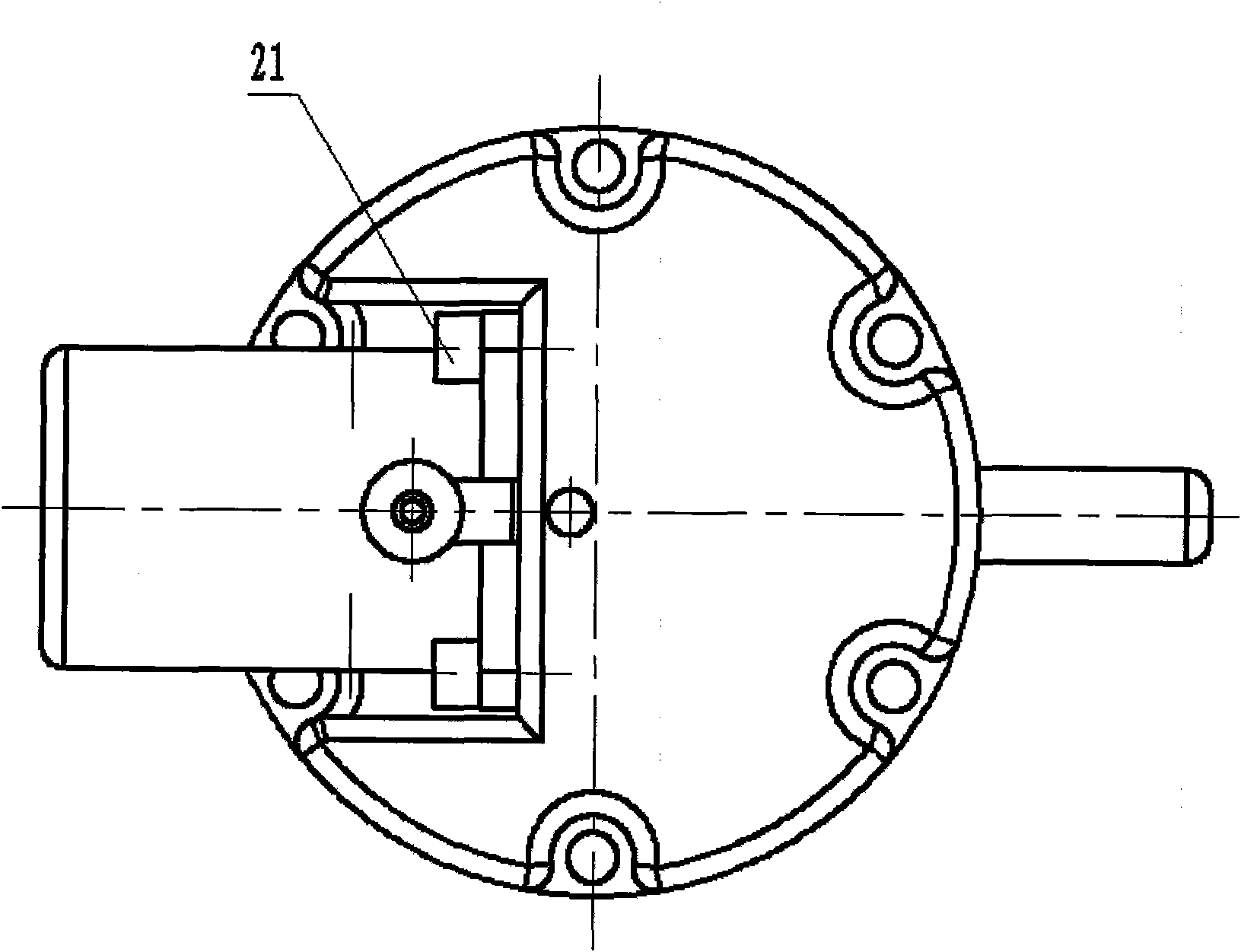

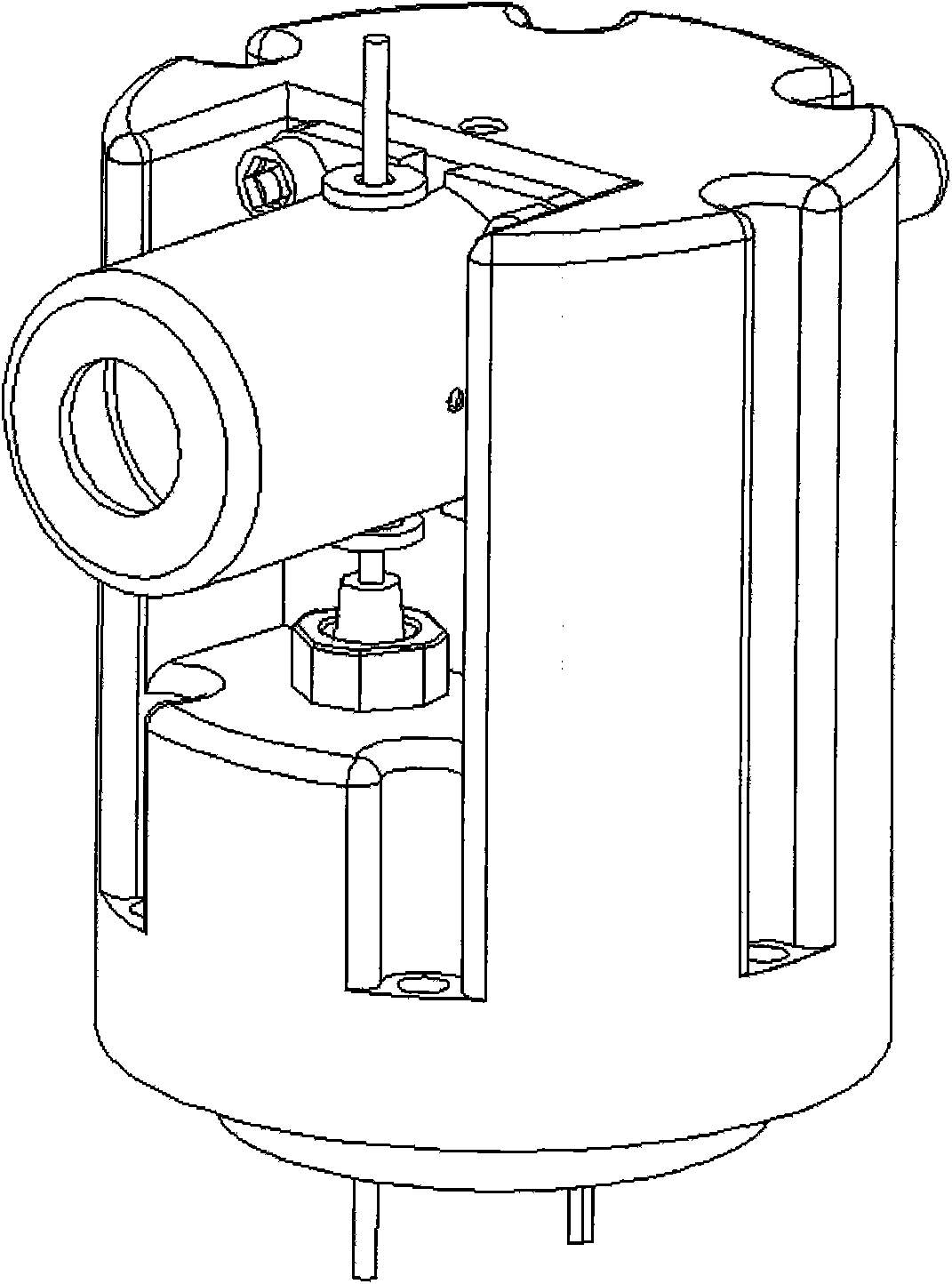

[0025] Such as Figure 1 ~ Figure 4 As shown, the present invention mainly consists of a guide plate 1, a cutter chamber 2, an opening groove 2, a retaining ring 3, a cutter 4, a breakable pin 5, a sealing ring 6, a piston-type pulling pin 7, a sealing ring 8, a substrate 9, Igniter 10, sealing ring 11, pressure ring 12, communication cable 13, watertight joint 14, sealing gasket 15, gasket 16, sheath 17, pressure ring 18, sheath 19, breakable pin 20, screw 21, communication buoy 22 and so on.

[0026] The base body 9 has a cylindrical structure and a smooth surface, and the outer edge is evenly distributed with screw mounting holes, and one side is opened with a Π-shaped groove, facing the hole on the vertical surface of the Π-shaped groove, and a piston-type pull pin 7 with a sealing ring 6 Install from here, and then install the cutter 4, with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com