Cutting machine for automatically slitting long tube stock into short tubes

A cutting machine and cutting mechanism technology, applied in the direction of metal sawing equipment, sawing machine devices, sawing machine accessories, etc., can solve the problem of not providing segmental cutting devices for long pipes with multiple diameters, and improve environmental protection and labor efficiency. The effect of protection awareness, reduction of labor intensity and reduction of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

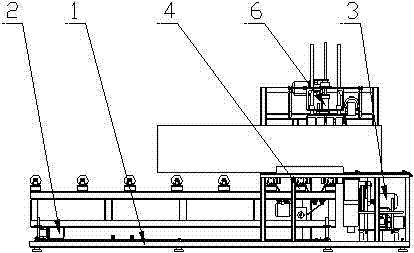

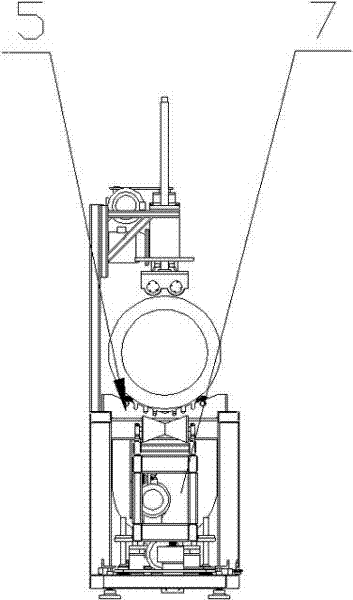

[0022] Such as figure 1 and figure 2 As shown, the present embodiment is an automatic long pipe slitter and short pipe cutting machine, which includes a frame 1, and also includes a lifting mechanism 2 and a cutting mechanism 3 arranged on the frame 1, and the cutting mechanism 3 is arranged on the lifting mechanism 2 On the right side of the lifting mechanism 2, a pipe delivery mechanism 4 is provided, a support mechanism 5 is provided above the pipe delivery mechanism 4 and the cutting mechanism 3, and a pipe transfer mechanism 6 is also provided above the support mechanism 5. There is a gap for accommodating the pipe material 8 between the pipe mechanisms 6 , and a vacuum cleaner 7 is provided on one side of the cutting mechanism 3 . The lifting mechanism can be realized by a lift.

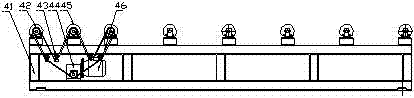

[0023] Such as image 3 As shown, the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com