Multi-stage perforation supercharging method

A technology of perforating and perforating gun, applied in the field of TCP tubing transmission perforation in oil and gas wells, can solve the problems of reliability, poor safety, high working intensity, low reliability, etc. Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

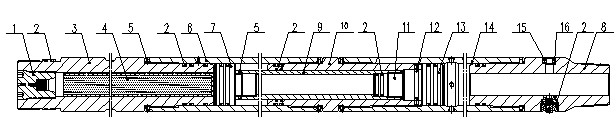

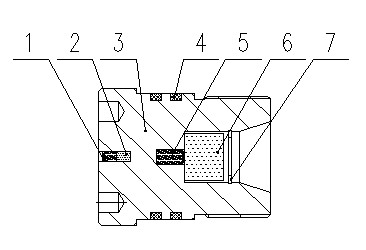

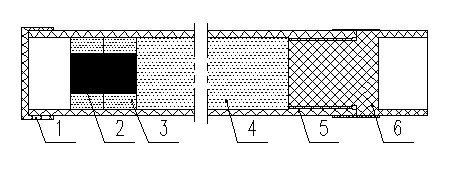

[0035]A multi-stage perforation boosting method, including the following process: a multi-stage perforation booster device is connected to the tail of the upper-stage perforating gun, and after the upper-stage perforating gun is detonated, the perforating gun sends the detonation wave Transfer to the supercharging device, detonate the diaphragm igniter of the supercharging device, the diaphragm igniter ignites the supercharged powder mechanism, and the supercharged propellant mechanism generates high-pressure gas to drive the supercharged piston to move, cut the copper shear pin, and push the piston to squeeze the interlayer The liquid in the oil pipe increases the pressure in the interlayer oil pipe, cuts off the shear pin of the next-stage pressure detonator, detonates the next-stage pressure detonator and perforating gun, and completes the perforation operation of the next layer. The pressure detonation device in the present invention can adopt the pressure detonation device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com