Automatic compression joint material breaking and material changing mechanism for hygienic product coiled material and material breakage method

A technology for sanitary products and refueling mechanism, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of difficult cutting of raw materials, poor splicing reliability, and cutter replacement, etc., and achieves low manufacturing cost and operation. Convenience and reliable material breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

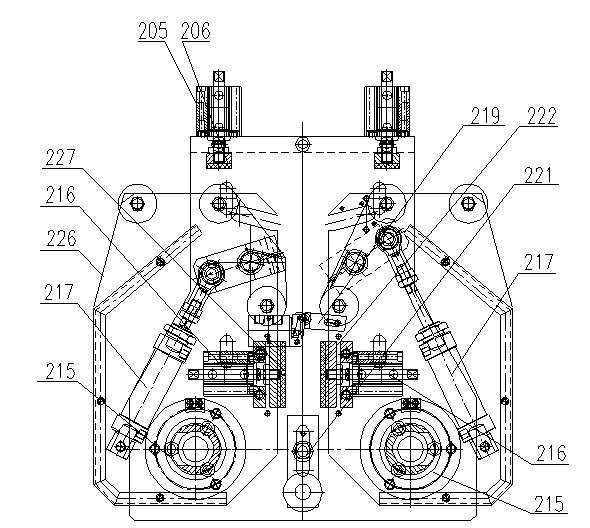

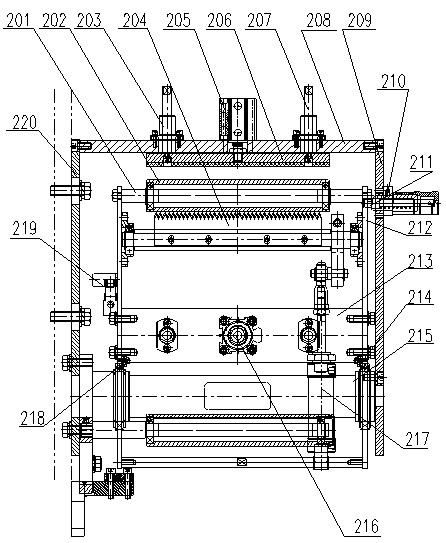

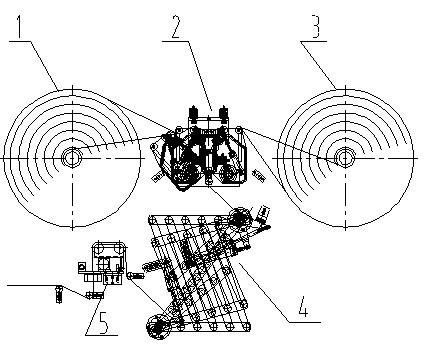

[0015] Embodiment 1: with reference to attached Figure 1-3 . A non-woven fabric automatic crimping and material breaking mechanism, which includes a left unwinding mechanism 1 and a right unwinding mechanism 3, a crimping and breaking mechanism 2, a tension control mechanism 4, a knitting mechanism 5 and a PLC controller, PLC The controller is a prior art, so it will not be described here. The left unwinding mechanism 1 and the right unwinding mechanism 3 are composed of left and right coil roll shafts respectively driven by left and right motors. The gap between the roller (spare coil) and the working material roll (running coil) is both the working material roll and the spare material roll, both of which can realize cutting and receiving of materials; It is composed of two sets of cutting assemblies, and the pressing assembly is located in the middle of the two sets of cutting assemblies; the crimping surface of the crimping plate 227 in the pressing assembly 213 is oppos...

Embodiment 2

[0016] Embodiment 2: On the basis of embodiment 1, a kind of material cutting method of the automatic crimping material breaking and changing mechanism of hygienic products roll material, it comprises PLC controller, and left unwinding mechanism 1 and right unwinding mechanism 3 are installed respectively There are normal running coils and spare coils. When the diameter of the running coils reaches the set refill diameter, the PLC processor instructs the spare coils to prepare for operation. Since the materials in the running coils pass through two crimping plates 227 and It is opposite to the spare coil head, so after the pressing assembly 213 receives the PLC command, the crimping cylinder 216 in the pressing assembly 213 drives two crimping plates 227 to squeeze and crimp the spare coil head and the running coil , the spare roll pressing cylinder 205 lifts up the pressing plate 206, the running roll motor stops running, the PLC controller instructs the piston in the cut off ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com