Automatic monitoring system for oven drying temperature of coke oven

An automatic monitoring and oven technology, used in thermometers, coke ovens, furnace safety devices, etc., can solve the problems of large system errors and manual reading errors, inability to grasp the temperature situation in time, and long temperature collection cycles, and achieve data statistics. Analyze the effect in time, improve oven quality and efficiency, and avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

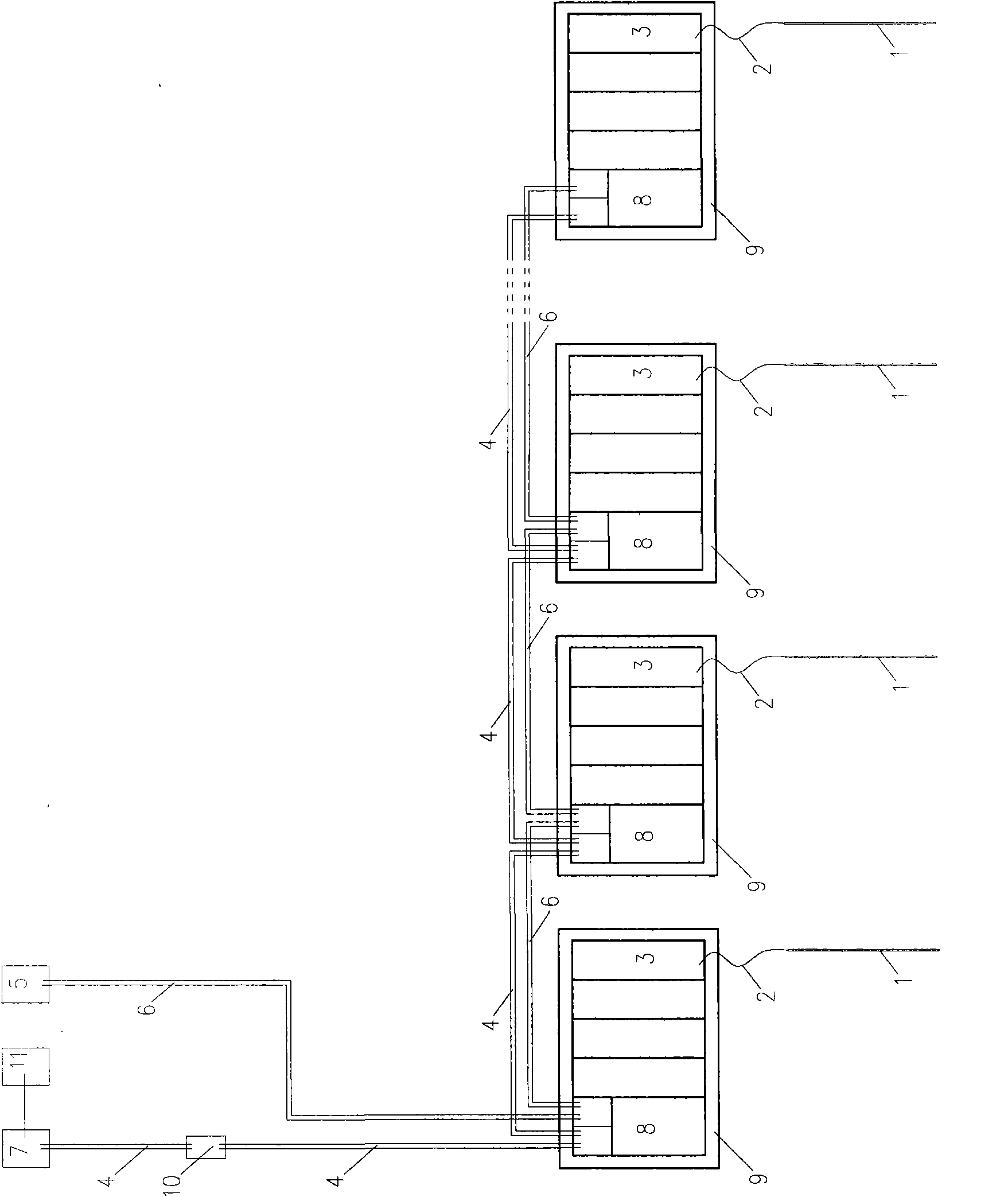

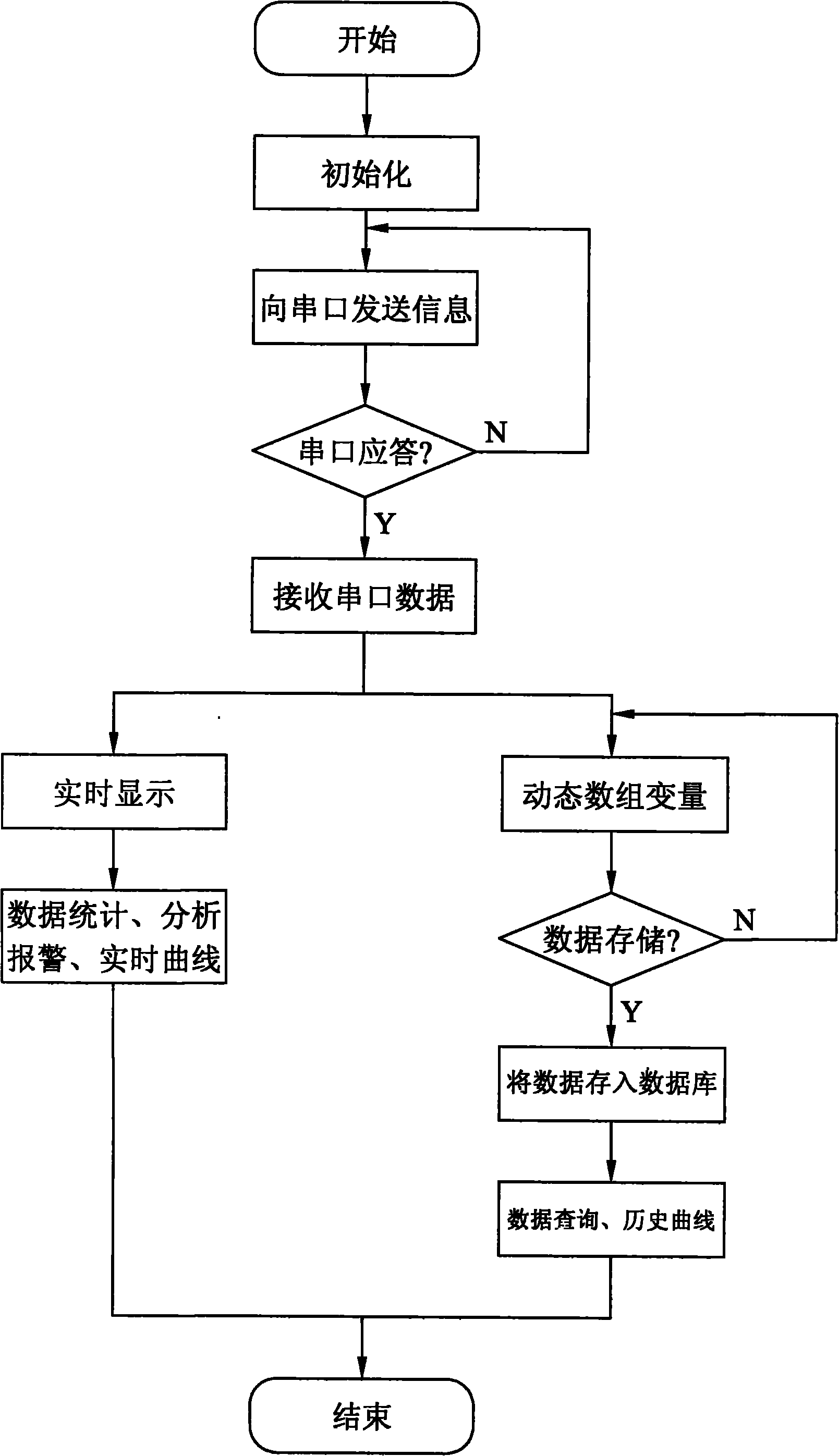

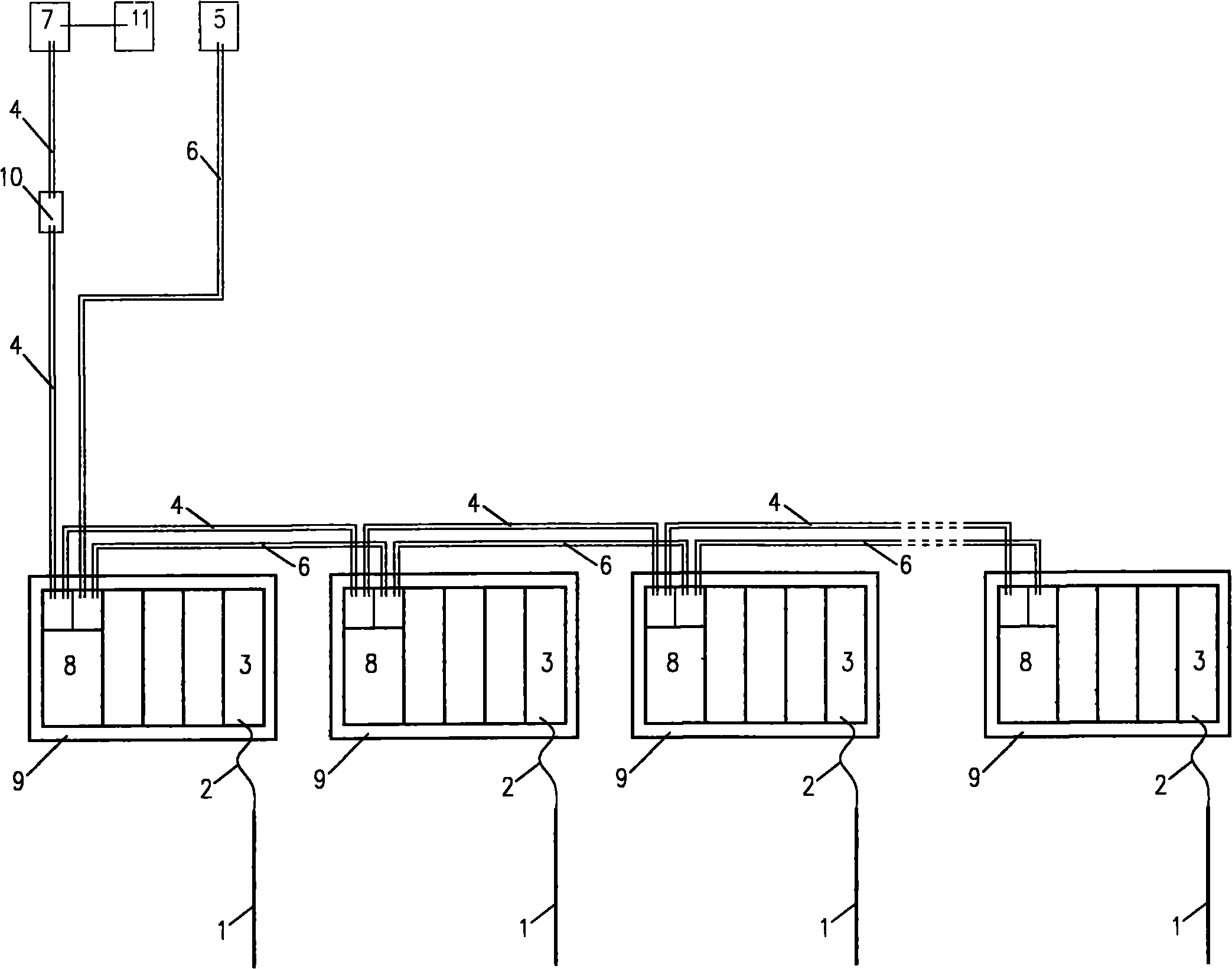

Method used

Image

Examples

Embodiment 1

[0015] Taking the 75-hole 5.5m tamping coke oven gas fuel oven as an example, the whole furnace is equipped with 18 standard combustion chambers and 4 horizontal wall combustion chambers, and each standard combustion chamber is equipped with 8 standard vertical fire channels. See Table 1 for point settings.

[0016] Table 1 Setting of temperature monitoring points in 5.5m tamping coke oven with 75 holes

[0017] serial number

monitoring project

Monitoring points

Monitoring frequency

1

Manage flue temperature

1, 2, 6, 11, 16, 21, 26, 31, 36,

41, 46, 51, 56, 61, 66, 71, 75,

1, 3, 8, 14, 20, 25 of 76# combustion chamber,

31, 32# Lihuo Road

times / 5min

2

straight temperature

The 8th and 25th vertical fire passages of each combustion chamber of the whole furnace

ditto

3

cross wall temperature

All standing fires of 11, 26, 51, 66# combustion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com