Clamping piece forging equipment for automobile bent arm

A technology of bending arms and clips, which is applied in the field of forging of auto parts, can solve the problems of cumbersome disassembly and assembly of molds and poor fastening, and achieve the effect of strong installation fastening, convenient disassembly and assembly, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0034] see Figure 1-Figure 9 In order to make the technical means, technical features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

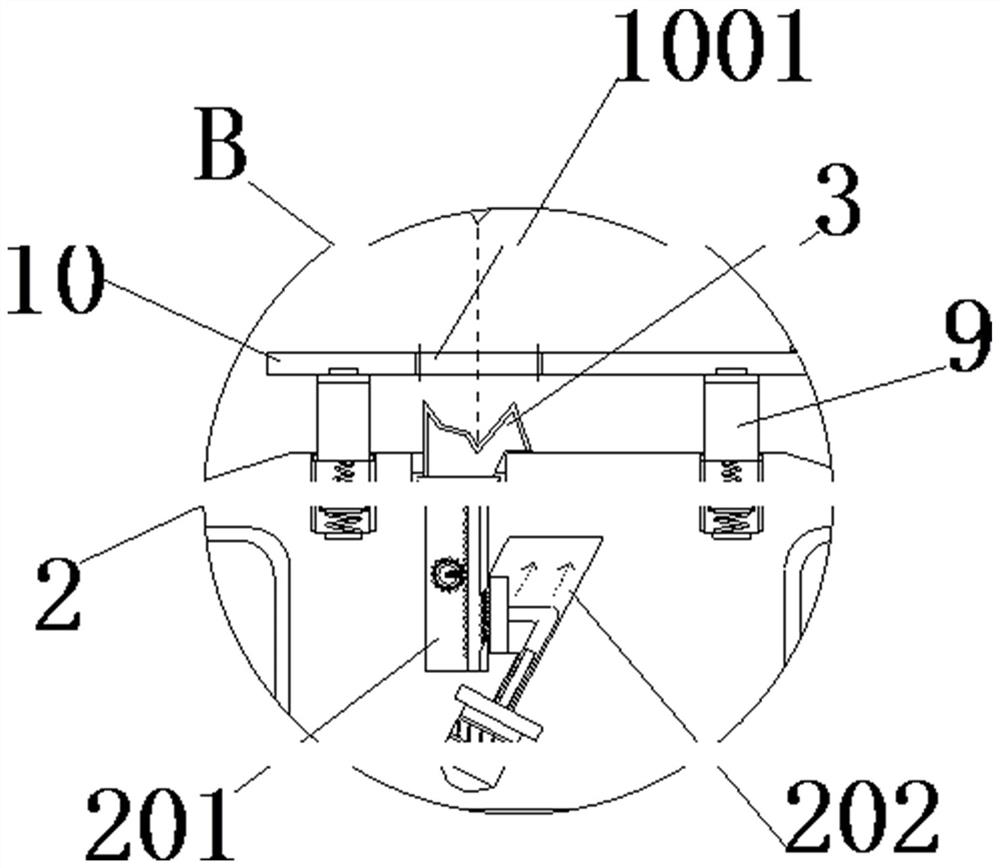

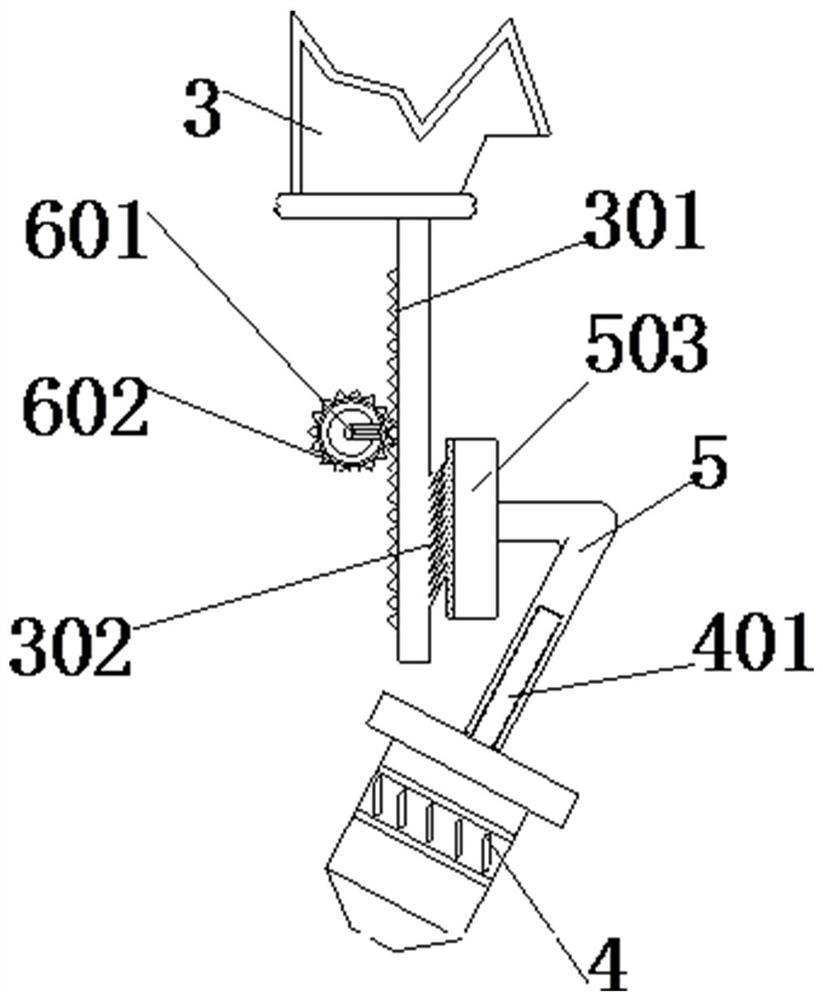

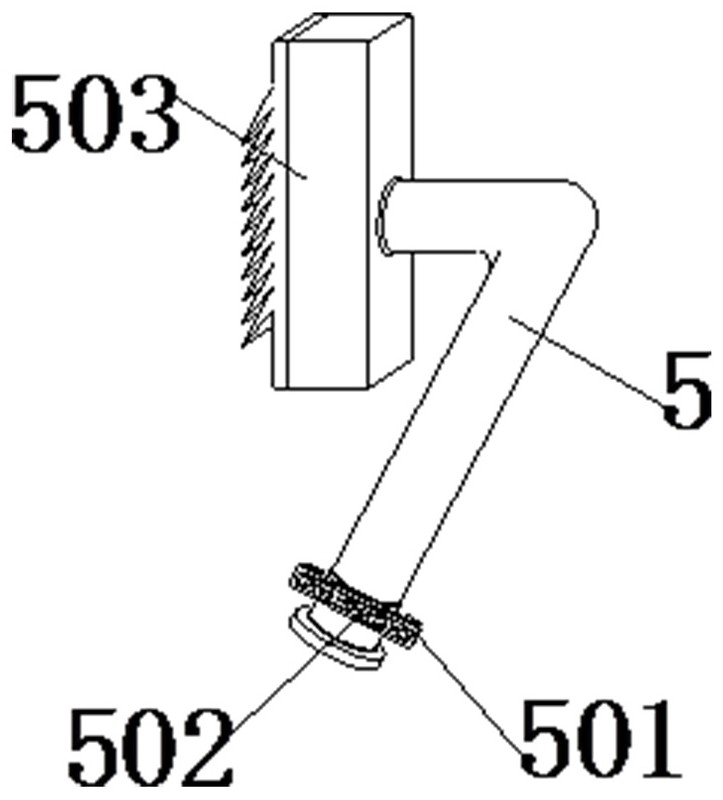

[0035] A clamp forging equipment for a bending arm of an automobile, comprising an equipment box 1;

[0036] There is a forging cavity 101 inside the equipment box 1, and a forging bracket 2 is embedded in the bottom wall of the forging cavity 101, and slots 203 are opened on the left and right sides of the top of the forging bracket 2, and the left and right sides of the inner wall of the slot 203 Both sides are provided with rails 204, the bottom wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com