A holey core photonic crystal fiber with nano-air holes for light transmission

A photonic crystal fiber, air hole technology, applied in cladding fiber, optical waveguide light guide, microstructure fiber, etc., can solve the problems of high loss, no light intensity distribution in the central air hole, and light intensity reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

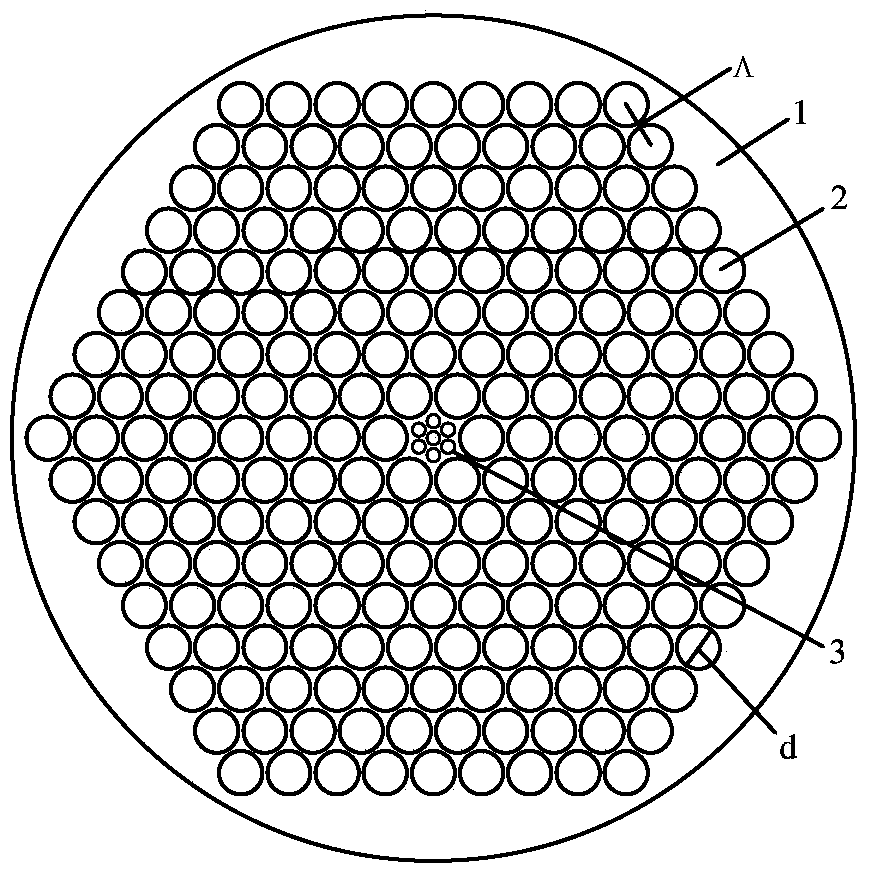

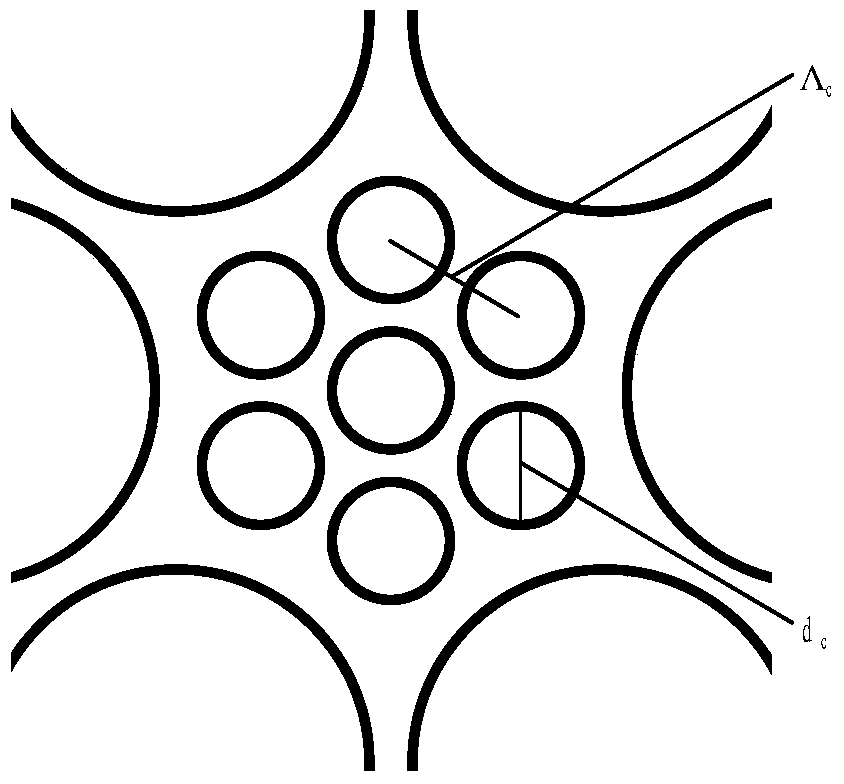

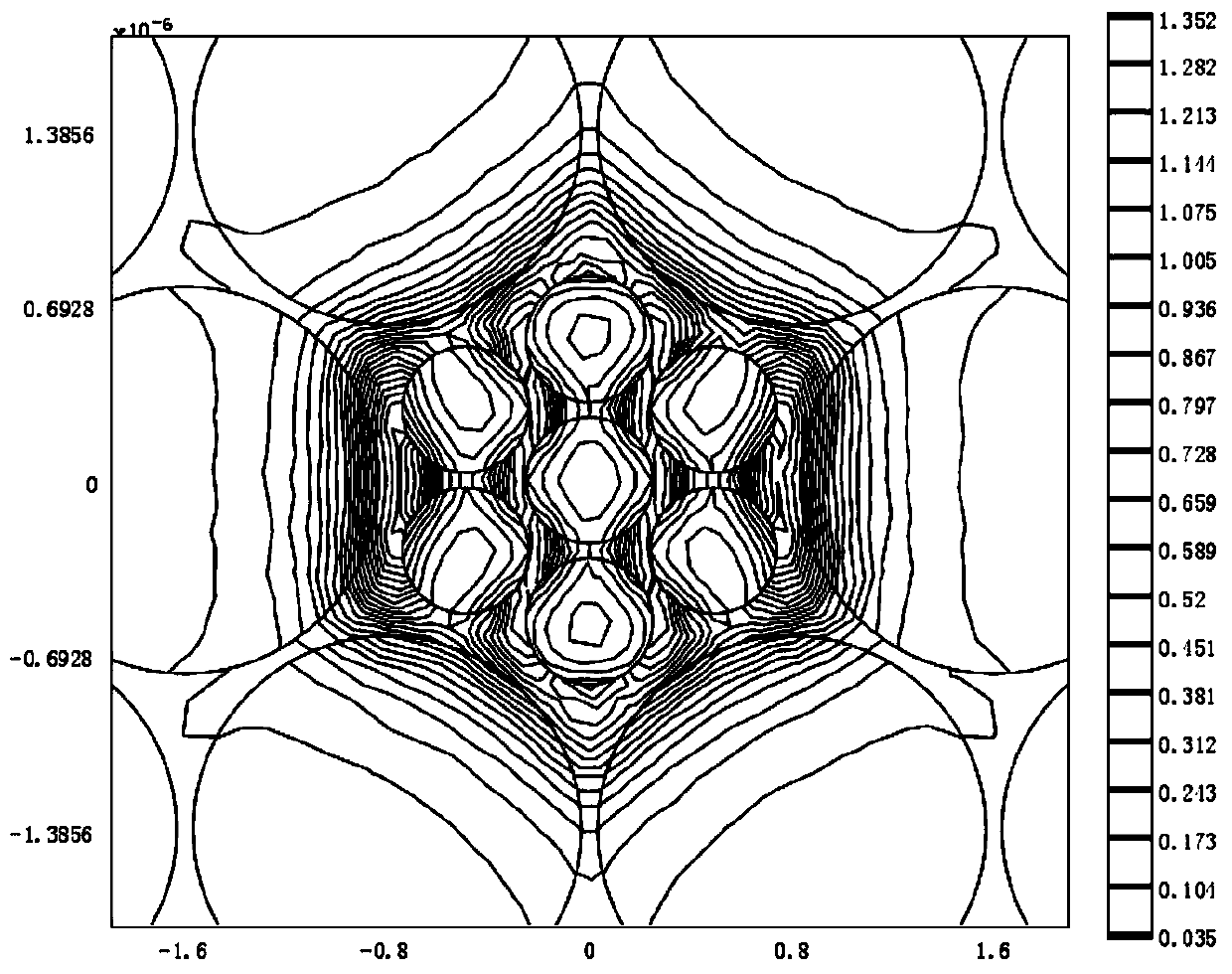

[0027] Such as figure 1 and 2 As shown, the optical fiber is composed of core air holes 3, cladding air holes 2, and matrix material 1; a columnar quartz matrix is used as the matrix material, and at least one core air hole is processed in the center of the matrix material to form a core part; in the matrix material, the cladding air holes are processed around the core to form the cladding part, and the cladding air holes are processed according to the regular hexagonal multi-layer close arrangement structure, and the spacing of the cladding air holes is equal; the aperture of the cladding air holes It is larger than the aperture of the core air hole; the air filling rate of the core part is smaller than that of the cladding, and the equivalent refractive index of the core part is greater than that of the cladding.

[0028] The core part is to introduce 7 circular core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com