Automatic detection and analysis system for temperatures at multiple points of coke oven baking

An automatic detection and multi-point temperature technology, which is applied to thermometers, coke ovens, and parts of thermometers, etc., can solve the problems of inconsistent expansion rate and design predetermined value, out-of-control coke oven temperature measurement, poor stability, etc., to improve system stability Sexuality and data accuracy, elimination of interference and error, good effect of interference and error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, the specific implementation manner, The structure, characteristics and functions are described in detail.

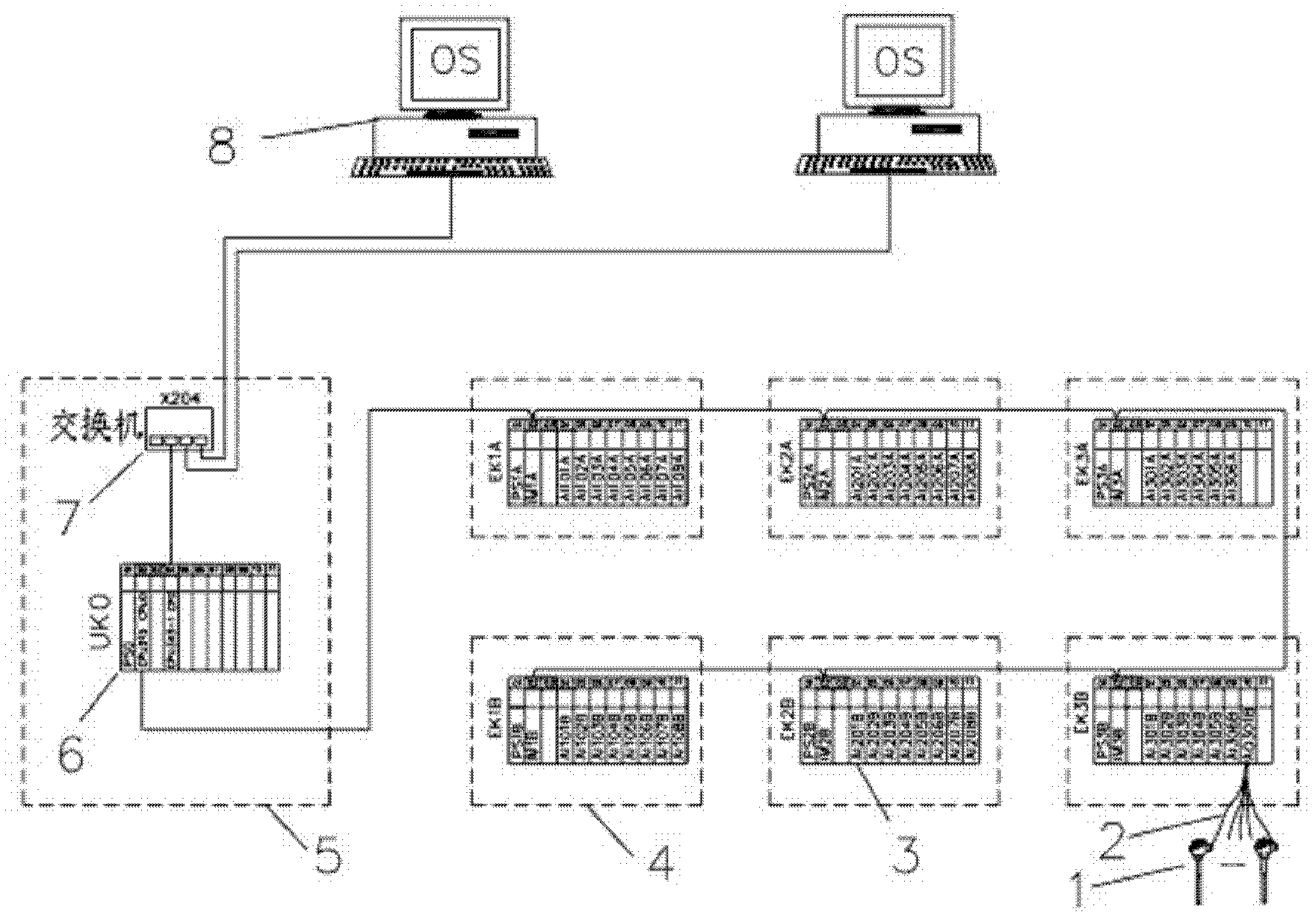

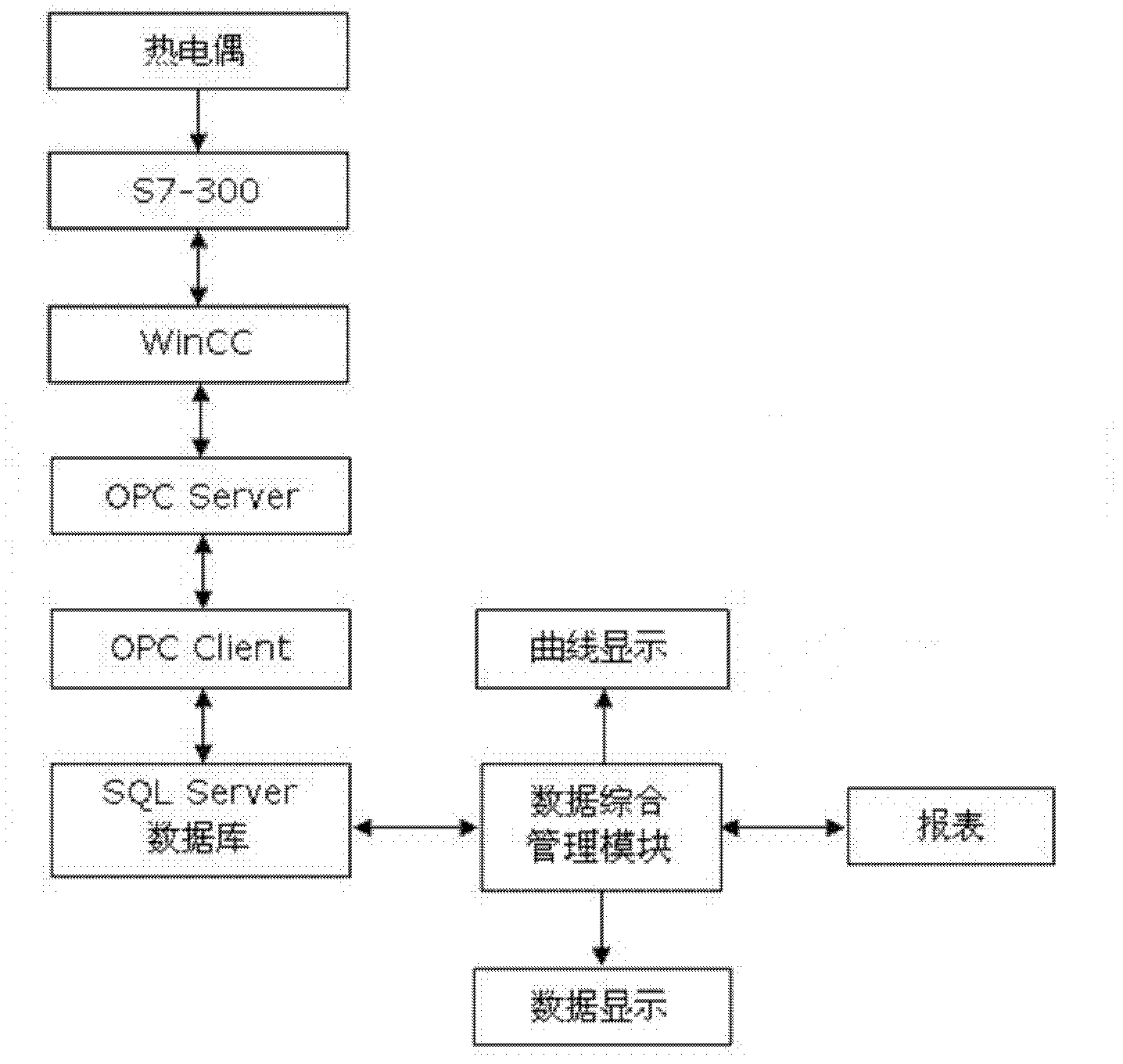

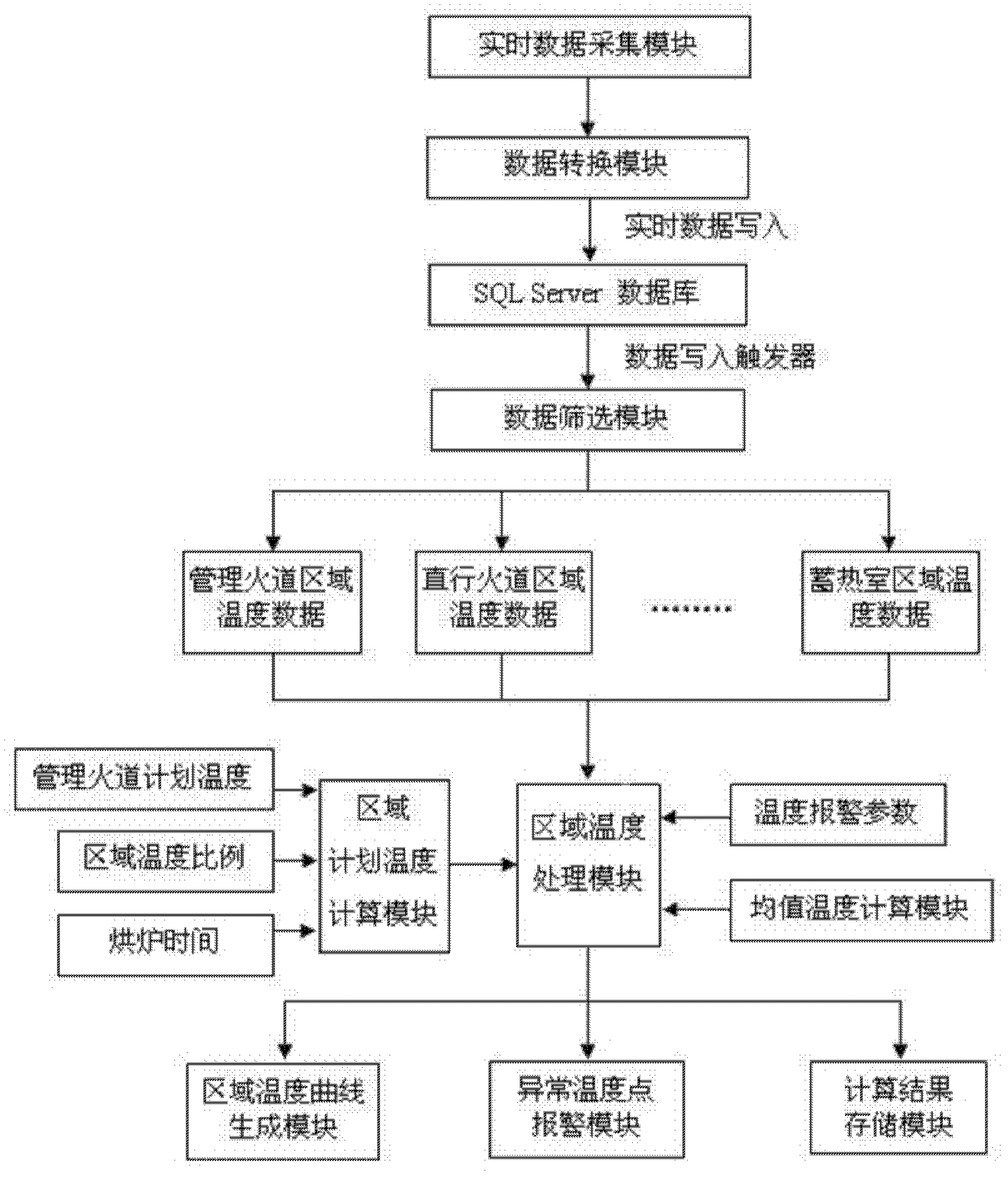

[0042] Such as figure 1 The structure schematic diagram of the embodiment of the present invention is shown. The present invention combines the latest technologies in the field of automation, communication, and computer, and adopts thermocouple 1, compensation wire 2, lower computer, switch 7, and upper computer 8 to connect. The temperature of more than 300 points inside the coke oven is converted into electrical signals by the thermocouple 1, the compensation wire 2 and the temperature acquisition template 3 of the lower computer, and then transmitted to the lower computer for processing, and then the data is transmitted through the communication module and the switch 7 on the lower computer Give the upper computer 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com