Automatic pressure regulating method and device for coke oven chamber

An automatic adjustment and carbonization chamber technology, applied in furnace safety devices, coke ovens, petroleum industry, etc., can solve the problems affecting the stable operation of the system, complexity, difficulty in use and maintenance, etc., and achieve low operation and maintenance requirements, simple equipment structure, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing description and embodiment:

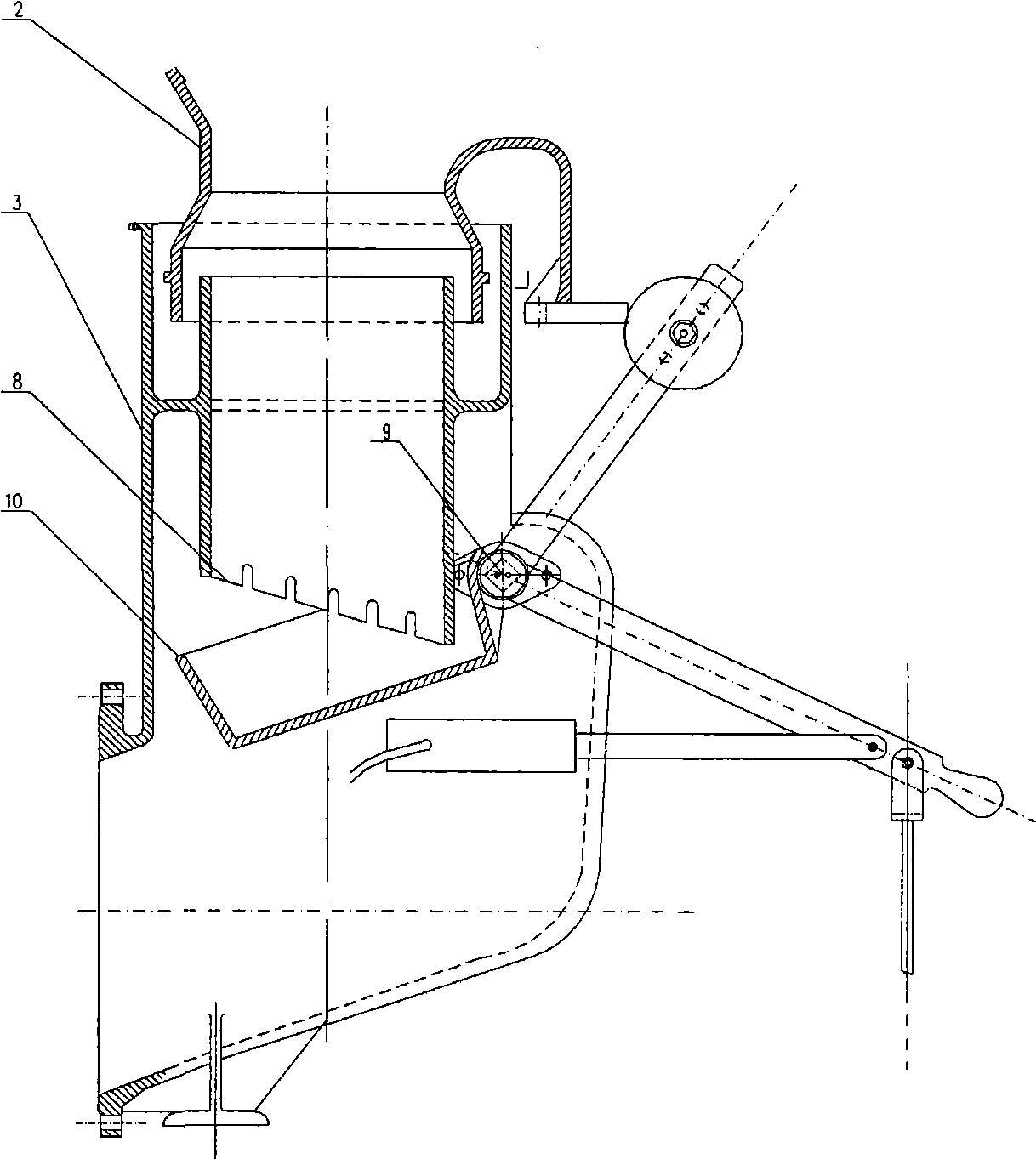

[0027] A method for automatically adjusting the pressure of a coke oven carbonization chamber. The method controls the flow of raw gas by controlling the opening of the water seal valve disc to change the size of the passage section of the raw gas in the water seal valve device of the bridge tube, thereby achieving control of coke. The purpose of furnace carbonization chamber pressure.

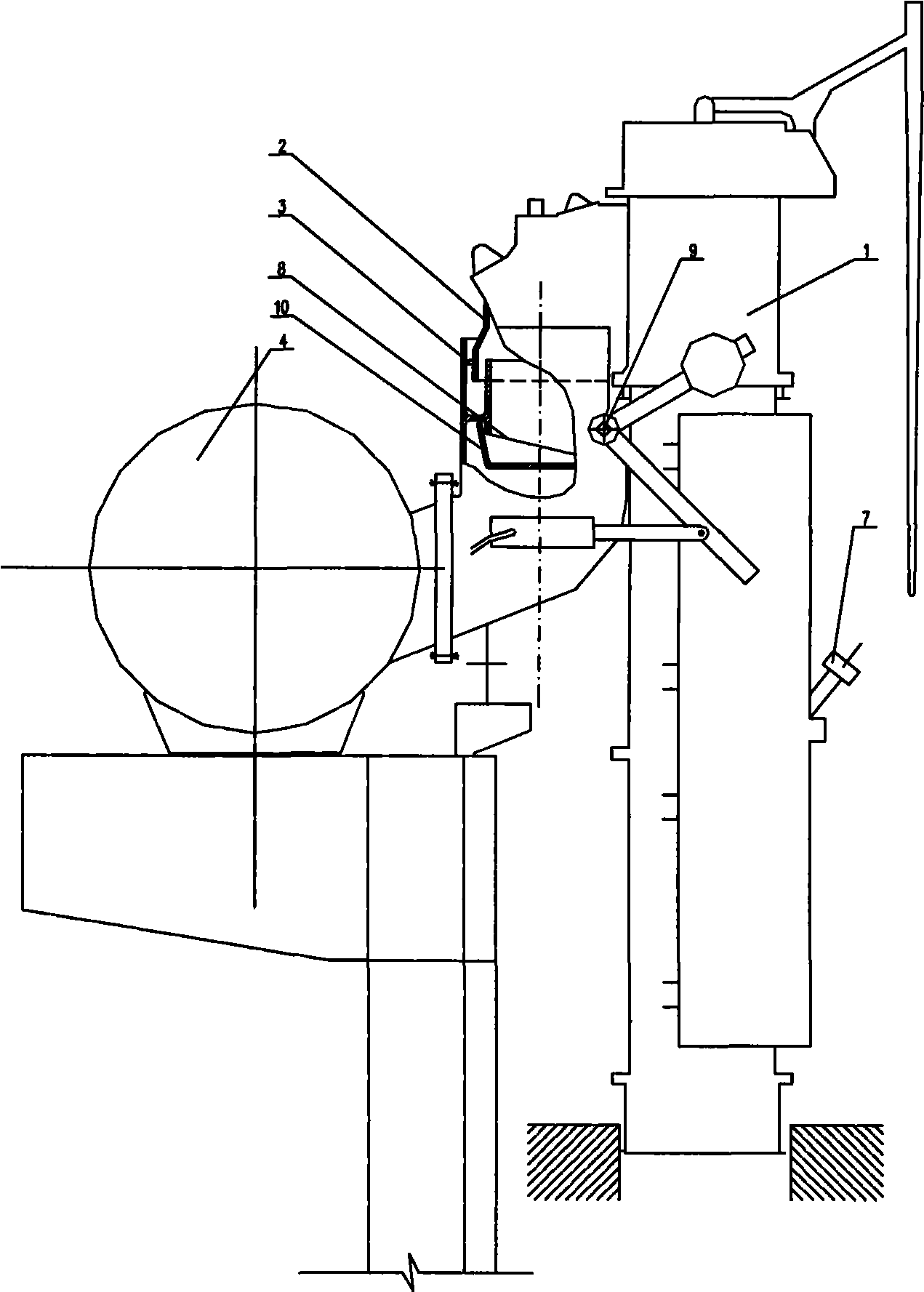

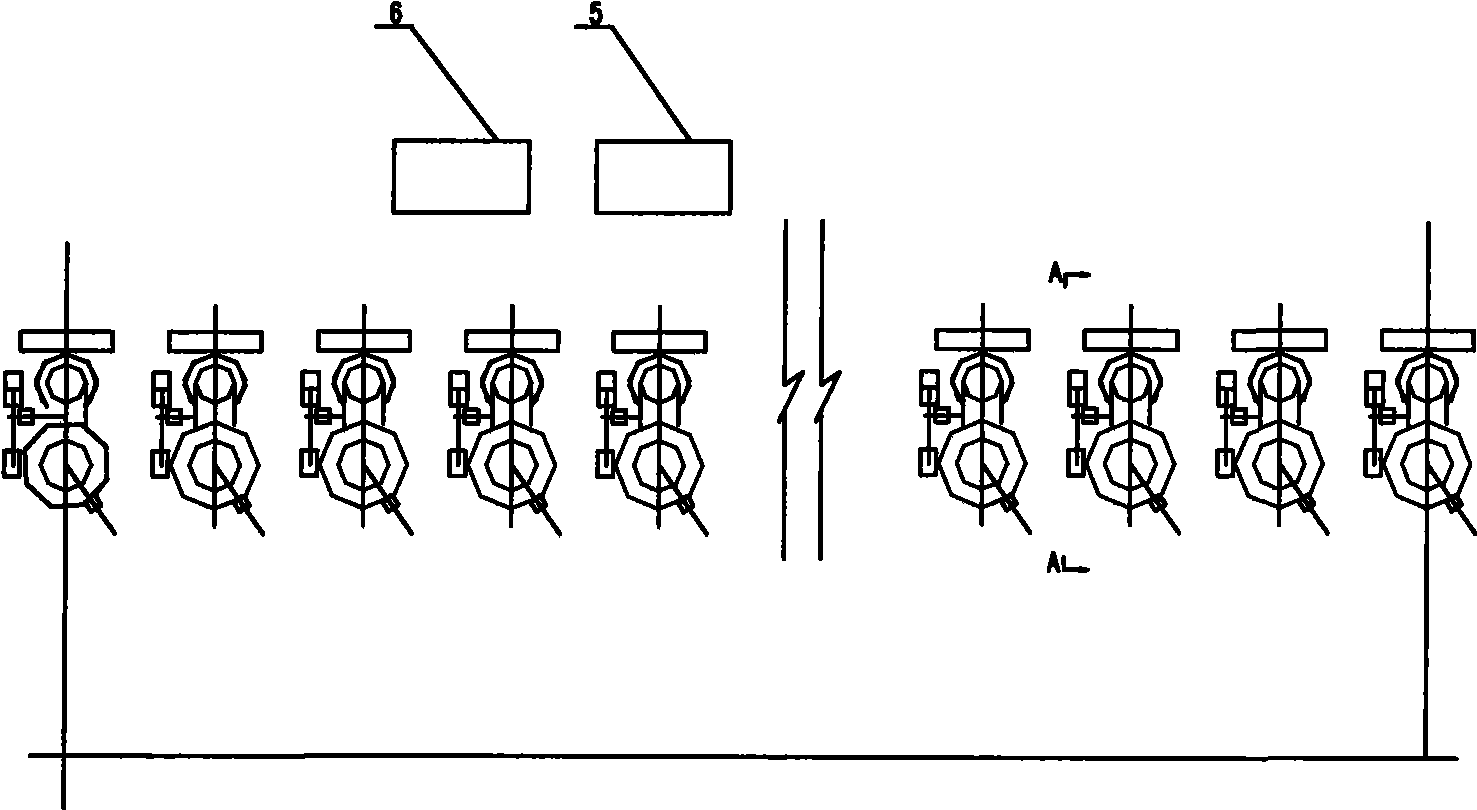

[0028] See figure 1 , figure 2 , image 3 , coke oven carbonization chamber pressure automatic adjustment device, including rising pipe 1, bridge pipe valve body 2, bridge pipe water sealing valve device 3, gas collecting pipe 4, computer control system 5, pressure control device 6, pressure measuring device 7, rising pipe 1 is located at the upper part of the coke oven carbonization chamber, the upper part of the rising pipe 1 is connected to the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com