Coke oven temperature and pressure automatic monitoring oven control system

A coke oven and pressure technology, which is applied in the field of oven control system for automatic monitoring of coke oven temperature and pressure, can solve the problem of insufficient utilization and statistical analysis of data, loss of timeliness and accuracy of detection data, and failure of automatic pressure monitoring. Detection and control and other issues, to achieve the effect of rich and colorful screen monitoring forms, complete and comprehensive statistical algorithms, and saving oven operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

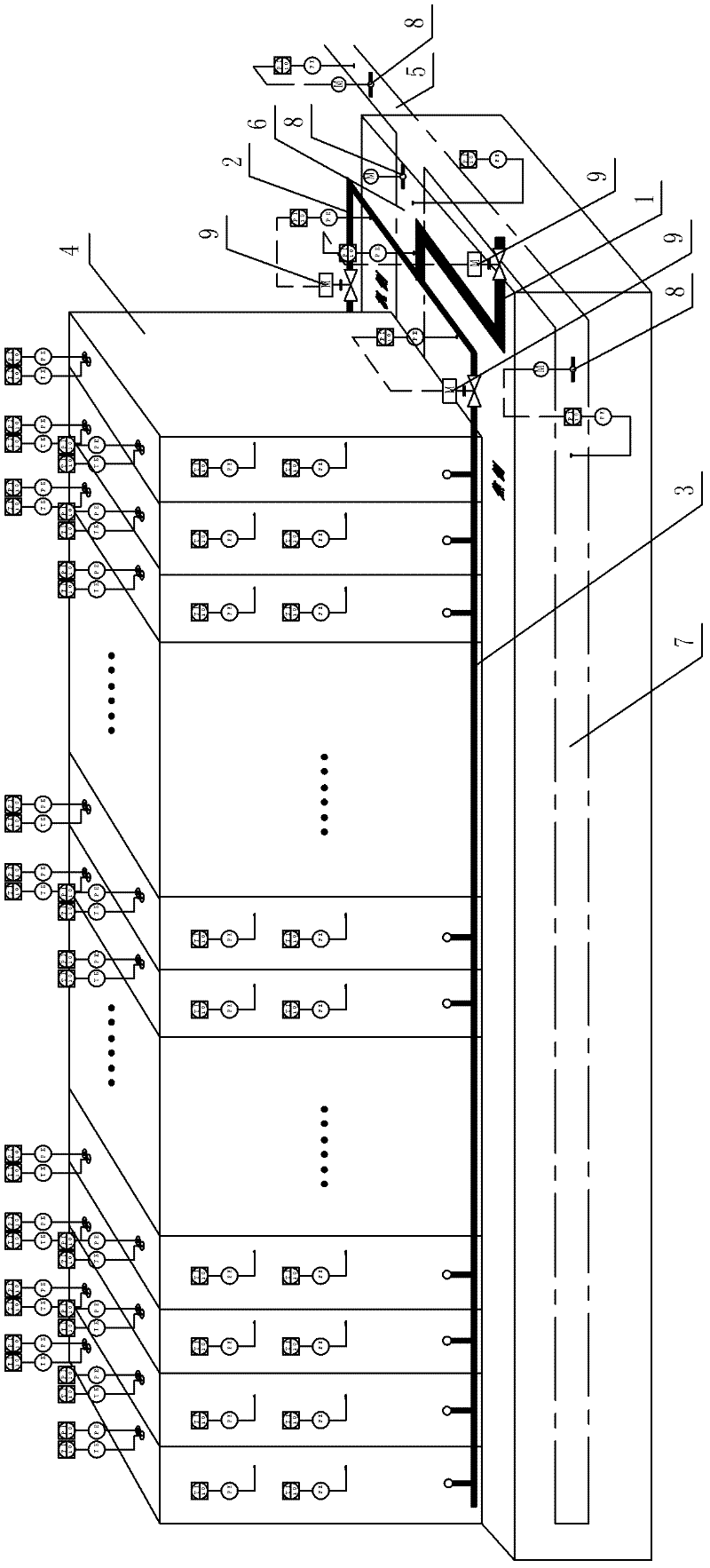

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

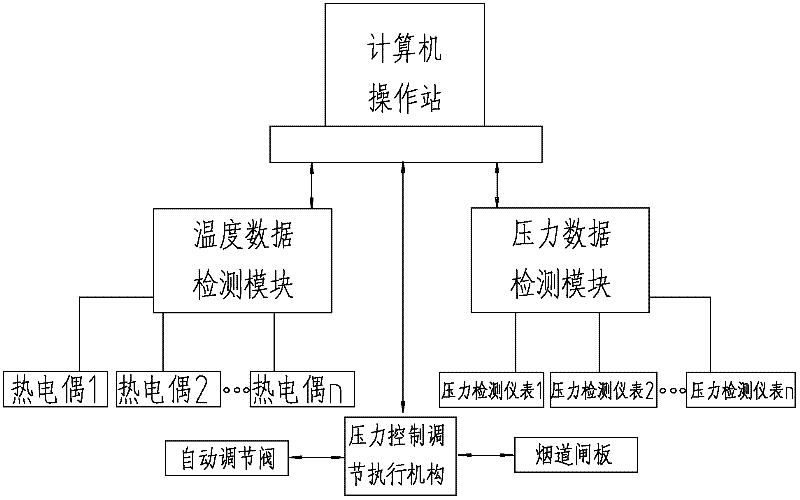

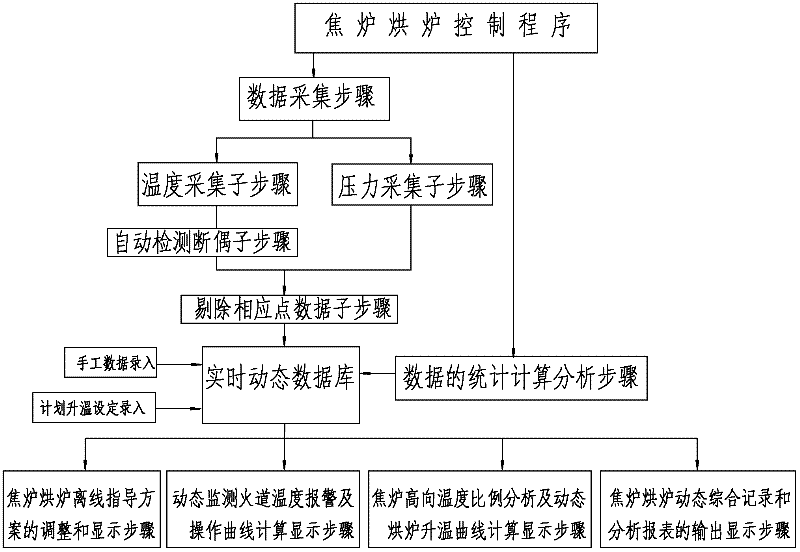

[0030] See figure 1 , which is a schematic diagram of the hardware configuration of the oven control system for automatic monitoring of coke oven temperature and pressure in the present invention, including a temperature data detection module, a pressure data detection module, a computer operation station and a pressure control and adjustment actuator. The computer operation station is equipped with a real-time dynamic database, The computer operation station is respectively connected with the temperature data detection module, pressure data detection module, and pressure control adjustment actuator. The computer operation station executes the online guidance and control strategy of the oven, which can automatically adjust the gas pressure and flue suction control and give guidance offline Adjustment plan; the temperature data detection module is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com