Pressure regulating device for coke oven carbonization chamber and fuzzy control method thereof

A technology of pressure regulation and fuzzy control, applied in furnace safety devices, coke ovens, adaptive control, etc., can solve problems such as yellow smoke from the furnace body, leakage from the furnace wall, poor overall system stability, etc., and achieve rapid response and anti-corrosion The effect of strong interference ability and strong system robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

[0026] This embodiment provides a coke oven carbonization chamber pressure regulating device and its fuzzy control method, wherein,

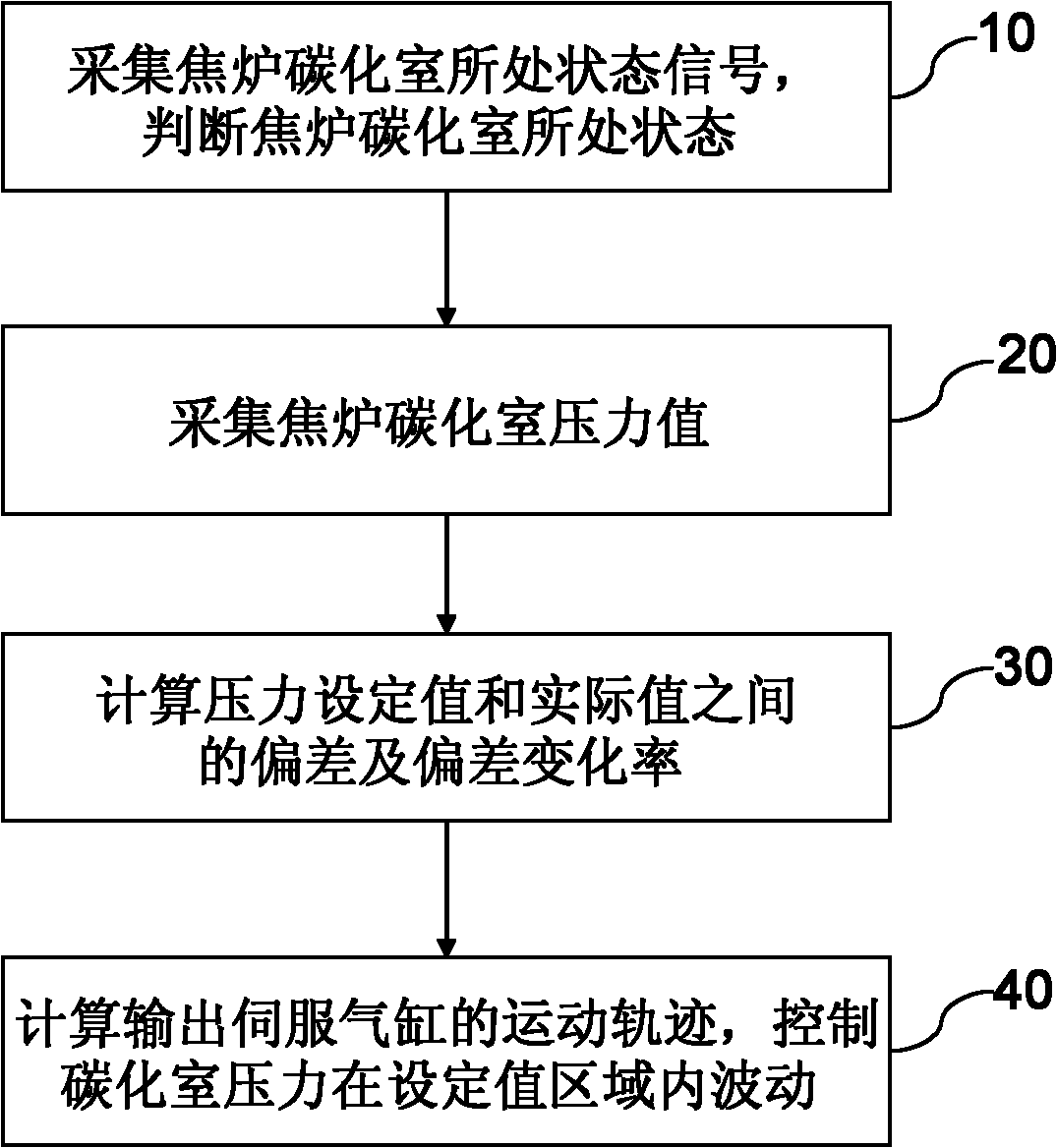

[0027] see figure 1 , is the flow of the fuzzy control method for the coke oven carbonization chamber pressure regulating device, and the method includes the following steps:

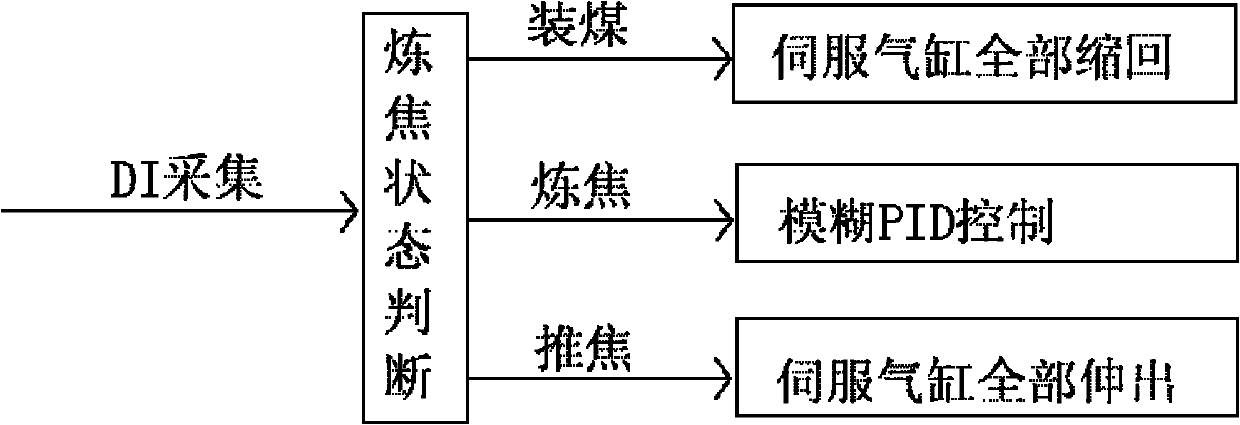

[0028] Step 10 collects the state signal of the carbonization chamber of the coke oven, and judges the state of the carbonization chamber of the coke oven;

[0029] Step 20 collects the pressure value of the carbonization chamber of the coke oven;

[0030] Step 30 calculates the deviation and deviation change rate between the pressure setting value and the actual value;

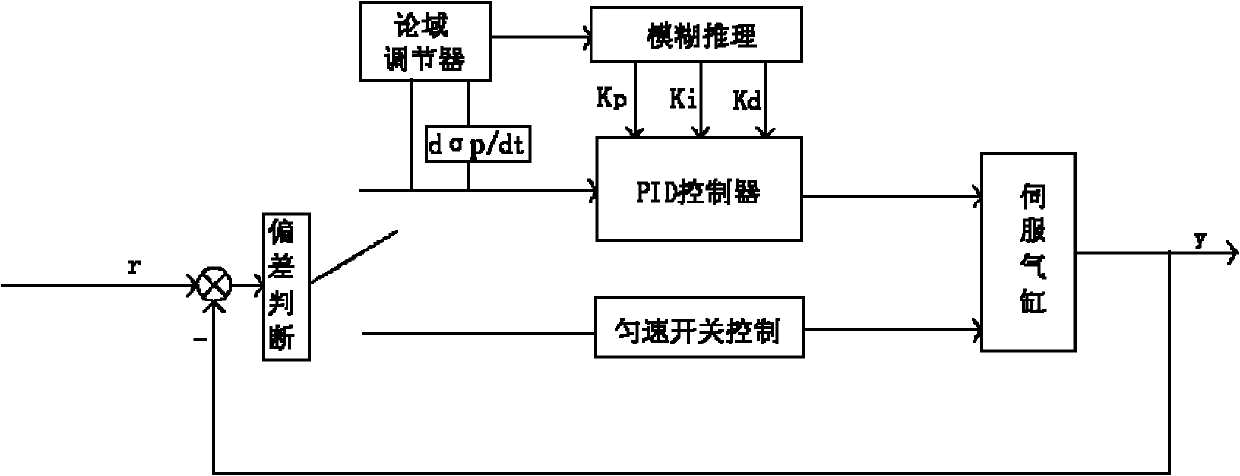

[0031] Step 40 performs fuzzy processing on the deviation and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com