Method for calculating thermal property of coke and control method therefor

A control method and technology of thermal properties, applied in the field of coal chemical industry, can solve the problems of large fluctuation of coal quality, shortage of high-quality coking coal, lack of effective utilization of coking coal resources, control of thermal properties of coke, and low-cost coal blending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

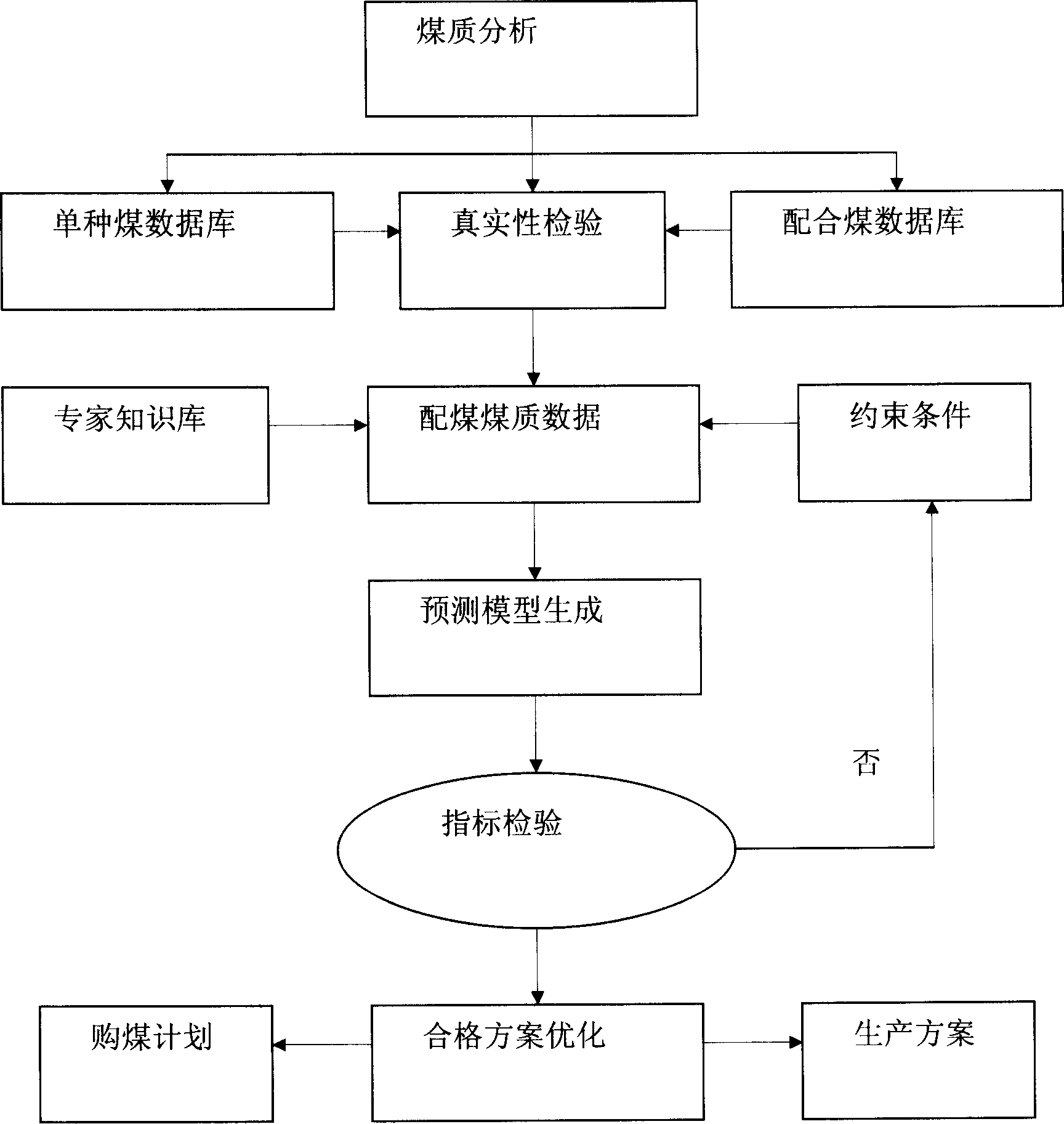

Method used

Image

Examples

Embodiment Construction

[0041] In order to better illustrate the actual effect of the present invention, the implementation process of the method will be described below in conjunction with the coking production experiment process of a certain enterprise. Specific requirements are put forward according to the quality of coke produced in the blast furnace, and the crushing strength M 40 ≥82%, wear resistance M 10 ≤7%, coke reactivity CRI≤30%, coke post-reaction strength CSR≥60%, coke ash A d ≤12.50%, sulfur S t,d≤0.5%. The enterprise's metallurgical coke production capacity is 3.6 million tons per year. Among the commonly used coal types, there are 4 types of gas coal, 3 types of coking coal, 2 types of fat coal, 1 type of lean coal and 1 type of non-caking coal. This method is used to count the historical data of the above-mentioned coal types in the past five years, and the volatility and coking performance of each single type of coal are obtained. Therefore, the adjustment plan for the used coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com