Infrared encoded positioning based automatic operation control system for four machines of cokery

A technology of positioning technology and control system, which is applied in the field of automatic operation control system of the four major locomotives of coke oven, and can solve the problems of not fully satisfying the automatic production operation and computer management of the four major locomotives, the contact of the coke pusher with the furnace wall, and the decrease in reliability, etc. problems, to achieve timely communication and operation control, reduce labor intensity, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further explain in detail in conjunction with accompanying drawings;

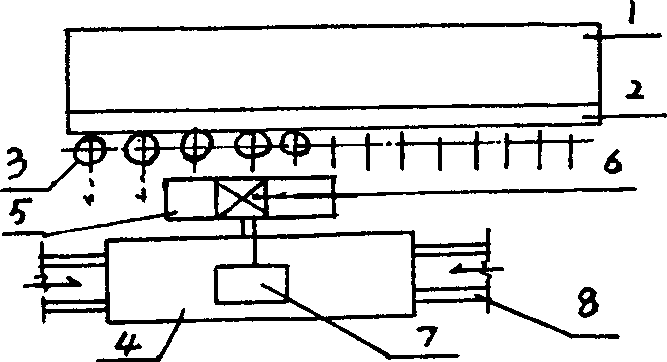

[0014] Such as Figure 1 As shown, the device composition of the locomotive position detection system is as follows: a fixed scale 2 that is consistent with the locomotive 4 and the furnace number is installed on the coke oven body 1, and an infrared light source 3 is installed on it at a certain distance. There is a matching movable scale 5, which is equipped with an infrared processor 6 for receiving and demodulating infrared codes, and is connected with the vehicle-mounted PLC7; Figure 1 , the arrow represents the running direction of the locomotive 4, and 8 shows the running track of the locomotive 4;

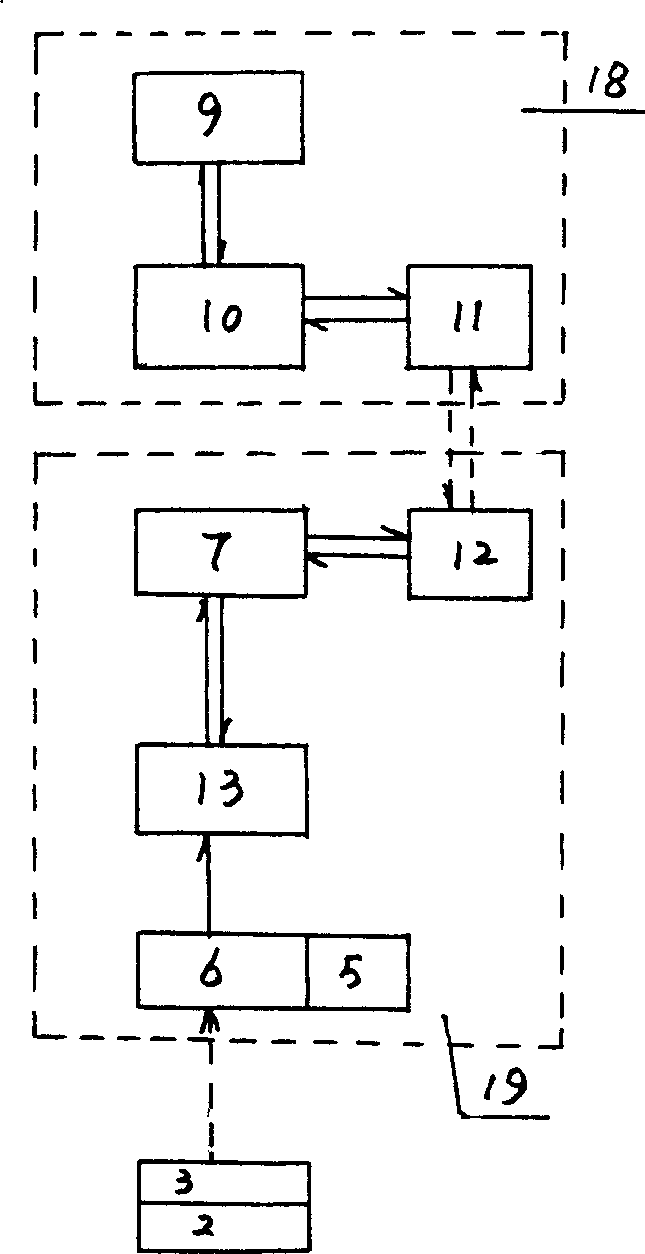

[0015] The function of the locomotive position detection system is mainly to upload the position information of the locomotive to the vehicle-mounted PLC 7 for processing and display in time, and finally to automatically control the operation of the locomotive 4 .

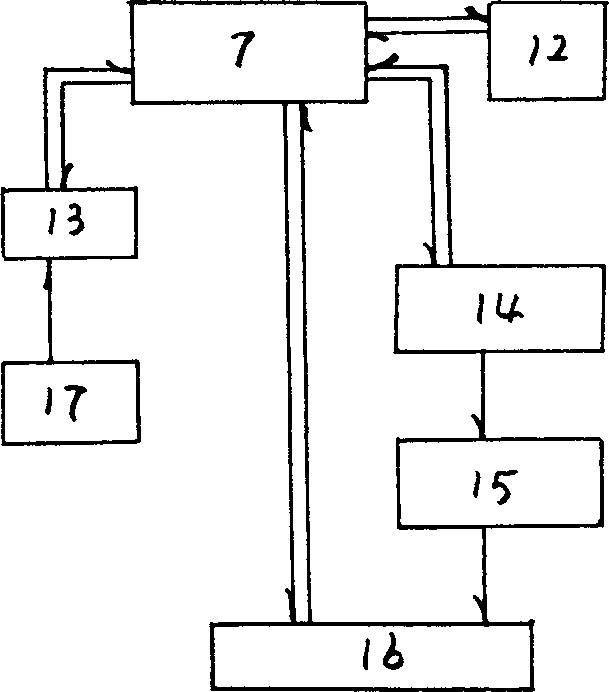

[0016] Such as Figure 2 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com