Control method and system for coke oven riser pipe

A control system and coke oven technology, applied in the coke oven field, can solve the problems of poor manual operation environment and high labor intensity, and achieve the effect of improving operation accuracy, meeting automation requirements and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

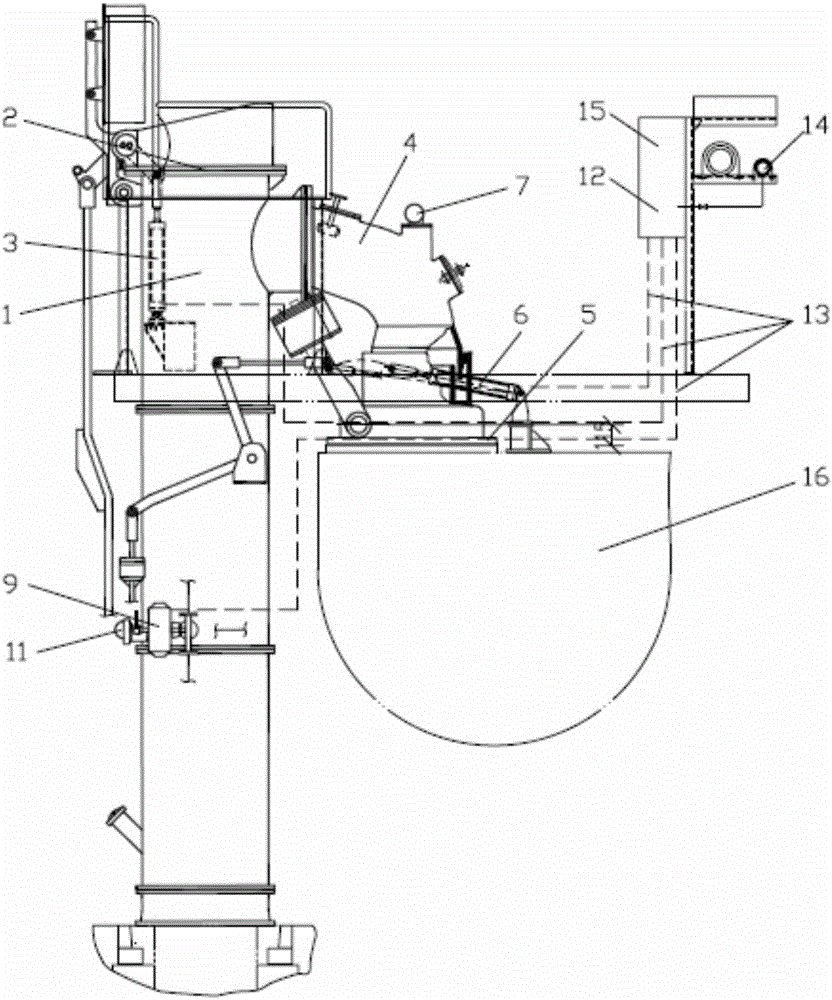

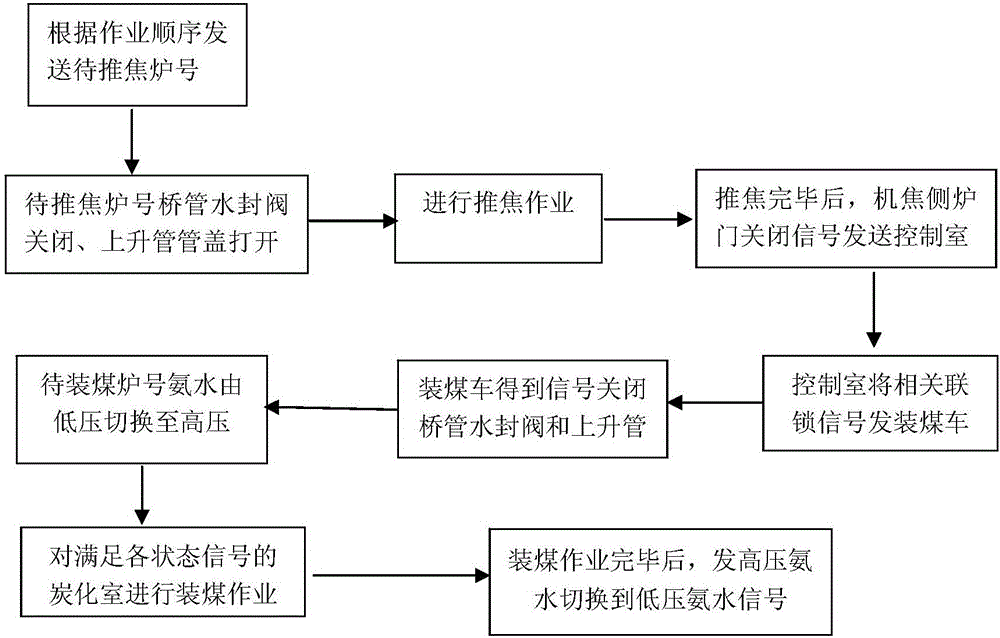

[0021] see figure 1 , figure 2 , the control system of the coke oven riser of the present invention, which includes,

[0022] The riser pipe 1 is a three-way pipe, and its upper port is provided with an openable and closed pipe cover 2 and a pipe cover driving cylinder 3;

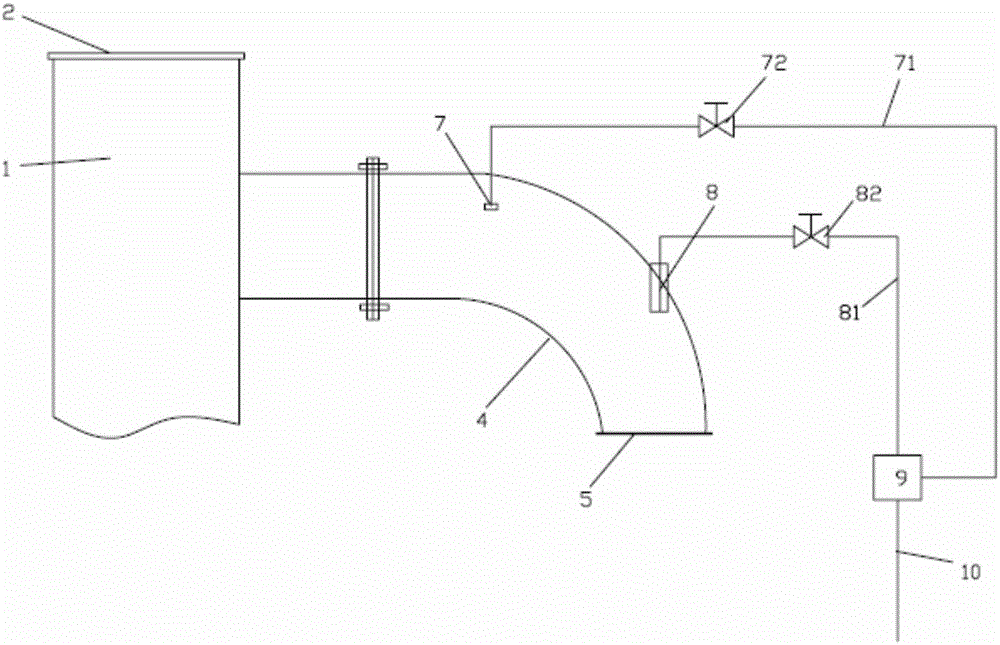

[0023] The bridge pipe 4 is connected to the port on one side of the riser pipe 1 through a flange; the bridge pipe 4 is a downwardly bent pipe, and the lower end of the bridge pipe 4 is provided with a water seal valve 5 and a water seal valve driving cylinder 6;

[0024] Low-pressure ammonia water nozzle 7, high-pressure ammonia water nozzle 8 and corresponding low-pressure ammonia water pipeline 71 and low-pressure ammonia water valve 72, high-pressure ammonia water pipeline 81 and high-pressure ammonia water valve 82;

[0025] The low-pressure ammonia water nozzle 7 is arranged on the junction of the bridge pipe 4 and the riser pipe 1; the high-pressure ammonia water nozzle 8 is arranged below the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com