A method for detecting coke-free in coke tank

A detection method and coke technology, applied in the field of coke ovens, can solve problems such as difficult judgment, equipment loss, personal injury, etc., and achieve the effect of avoiding safety accidents of coke falling off the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

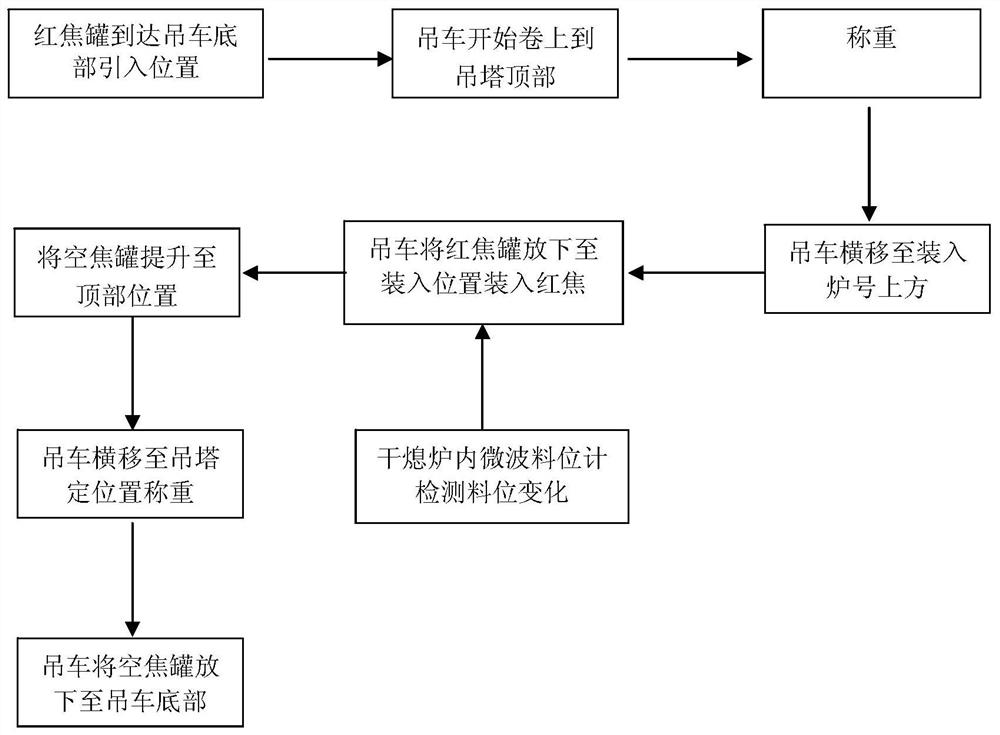

[0014] see figure 1 , a coke-free detection method provided by the invention, which comprises,

[0015] a) A number of material level gauges are evenly installed along the circumferential direction on the top of the CDQ furnace. After the CDQ crane loads the red coke into the CDQ furnace, the material level value of the coke in the CDQ furnace can be obtained through the detection of the material level gauge. , every time it is loaded, the height of coke in the CDQ furnace will rise by 500mm. If the height of the material level in the CDQ furnace rises less than 300mm after red coke is loaded, an alarm signal will be issued to remind the operator to check whether there is residual red coke in the coke tank. coke;

[0016] b) When the crane rises to the top of the hanging tower, it will stop for a few seconds, and the crane will use the weighing system to weigh the total weight and save it. Then, when the crane has filled the red coke cans and returned to the top of the hangin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com