Remote intelligent decoking program control device

A remote control system technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problem of not being able to see the danger, shorten the decoking time, reduce energy consumption, and improve coke cutting efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with specific embodiments, and the given examples are only for clarifying the present invention, not for limiting the scope of the present invention.

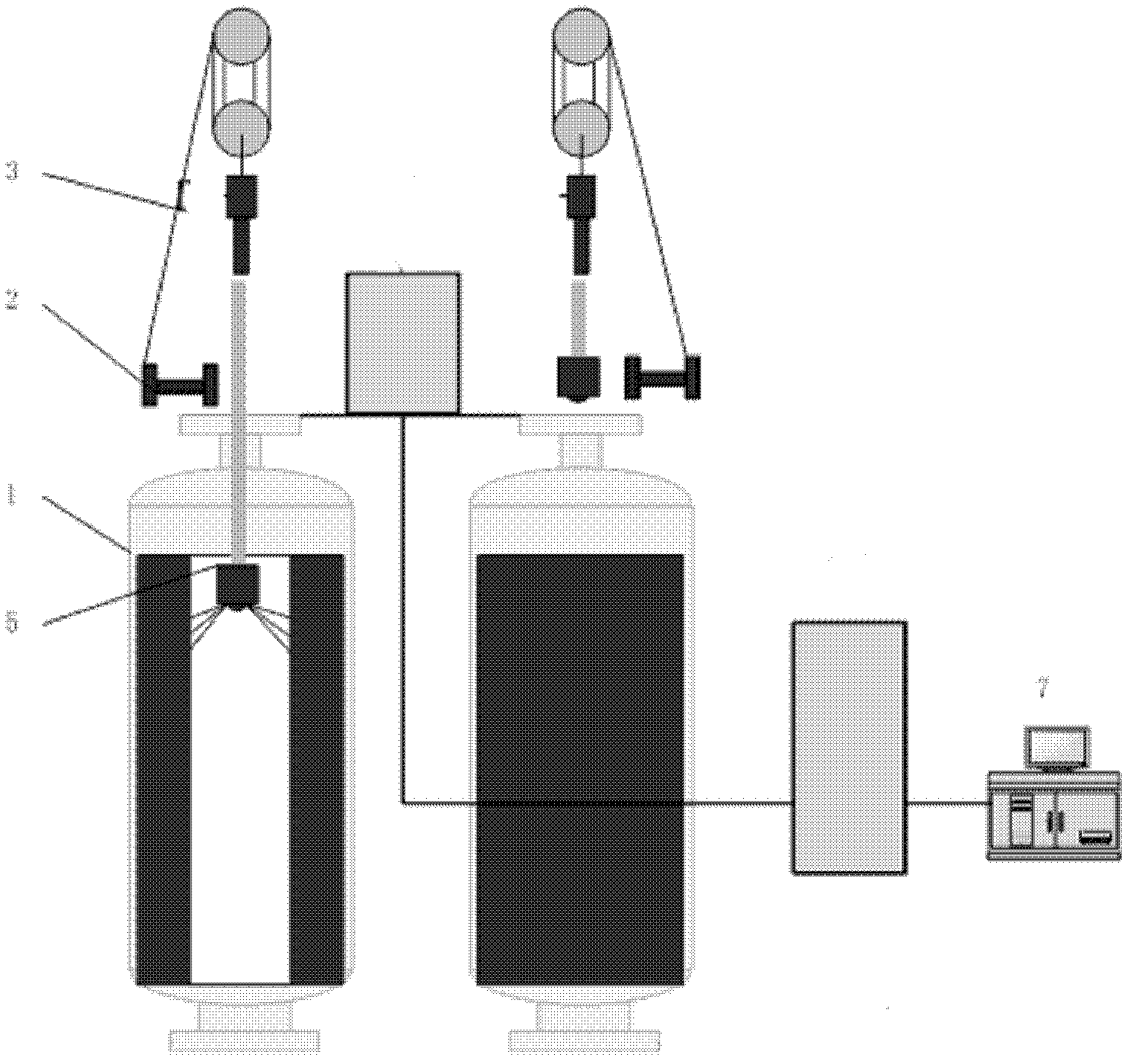

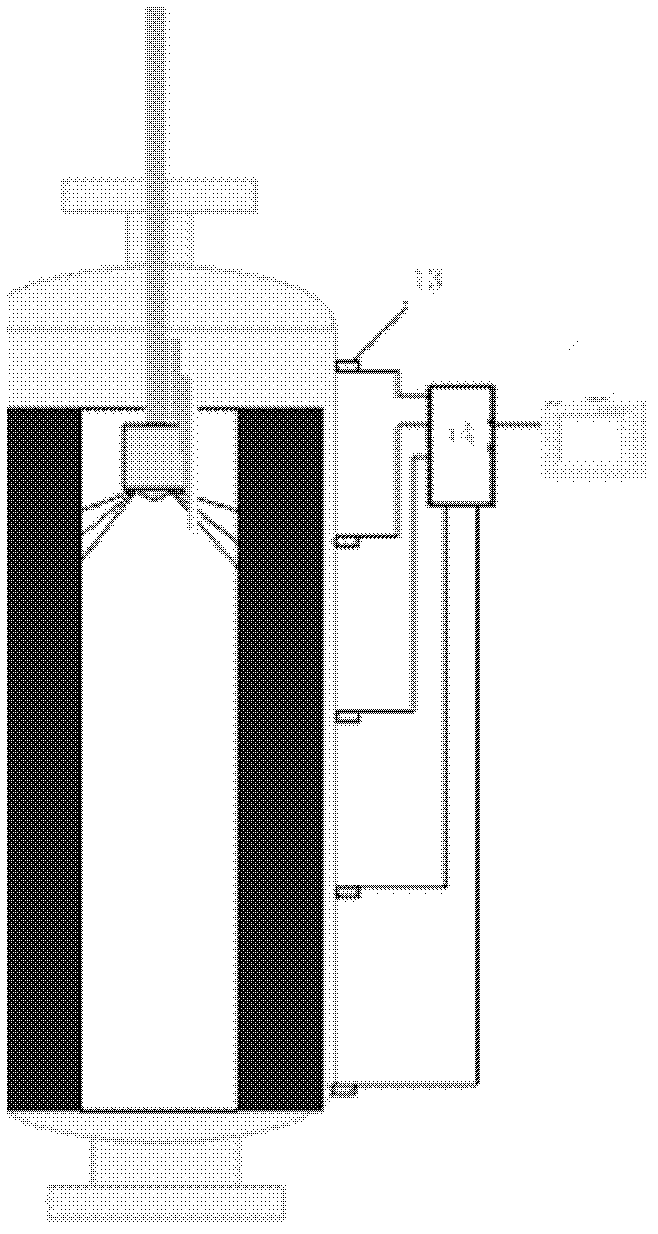

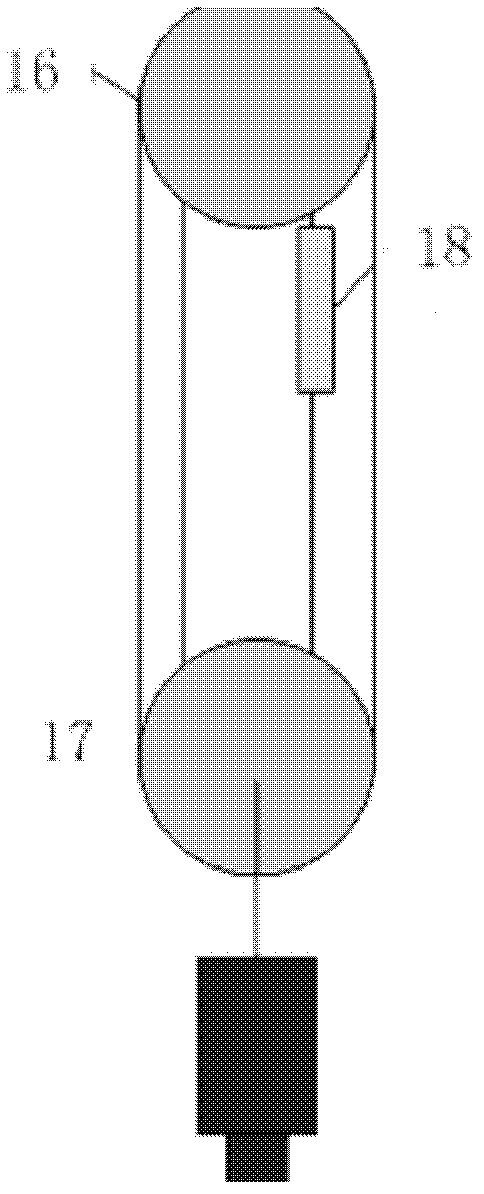

[0017] The following combined with the accompanying drawings figure 1 , figure 2 , image 3 and Figure 4 And embodiment, the present invention is described in detail as follows:

[0018] A remote intelligent decoking program-controlled device includes: man-machine terminal equipment, a PLC control system (programmable control system), an actuator system, a motion detection system and a data analysis system.

[0019] This device contains 2 sets of independent PLC systems. The control objects and testing instruments of the PLC system are respectively:

[0020] The actuator system includes:

[0021] (1) High pressure pump outlet valve, high pressure water pump unit.

[0022] (2) Drilling tool motion control equipment: such as figure 1 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com