Reduction Furnace Sequence Control Method Based on DCS System of Polysilicon Production Plant

A technology of DCS system and production equipment, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve the problems of unfavorable production equipment stable operation, stable product quality improvement, large difference in reduction furnace operation, cumbersome operation, etc., to achieve The effect of reducing the operating frequency and labor intensity of employees, continuous and stable feeding, and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

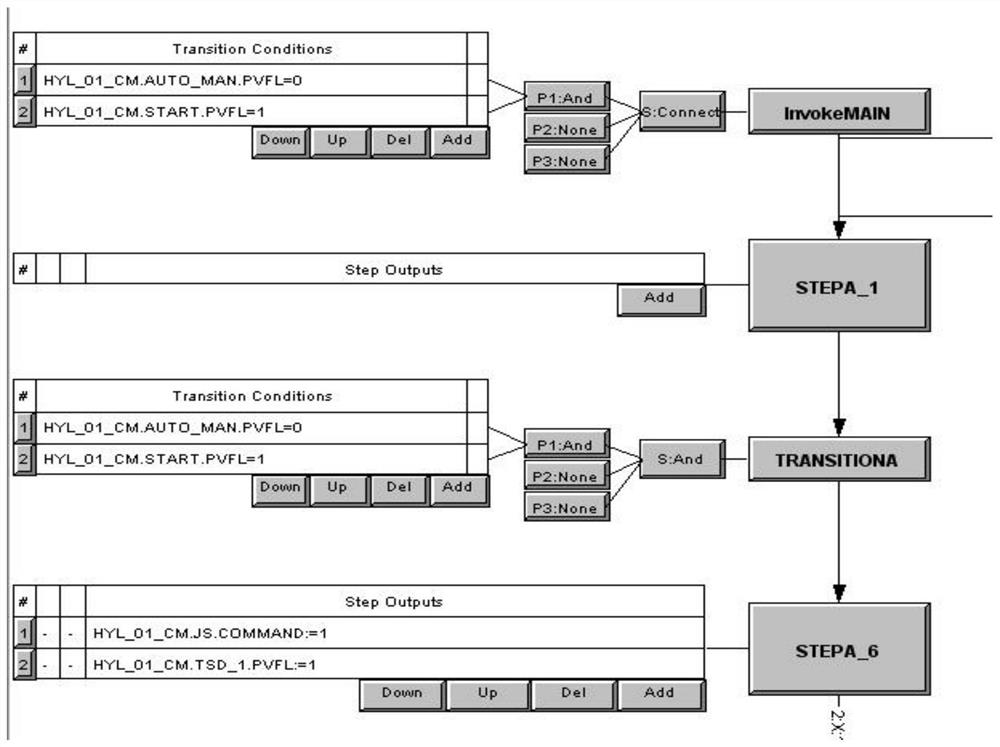

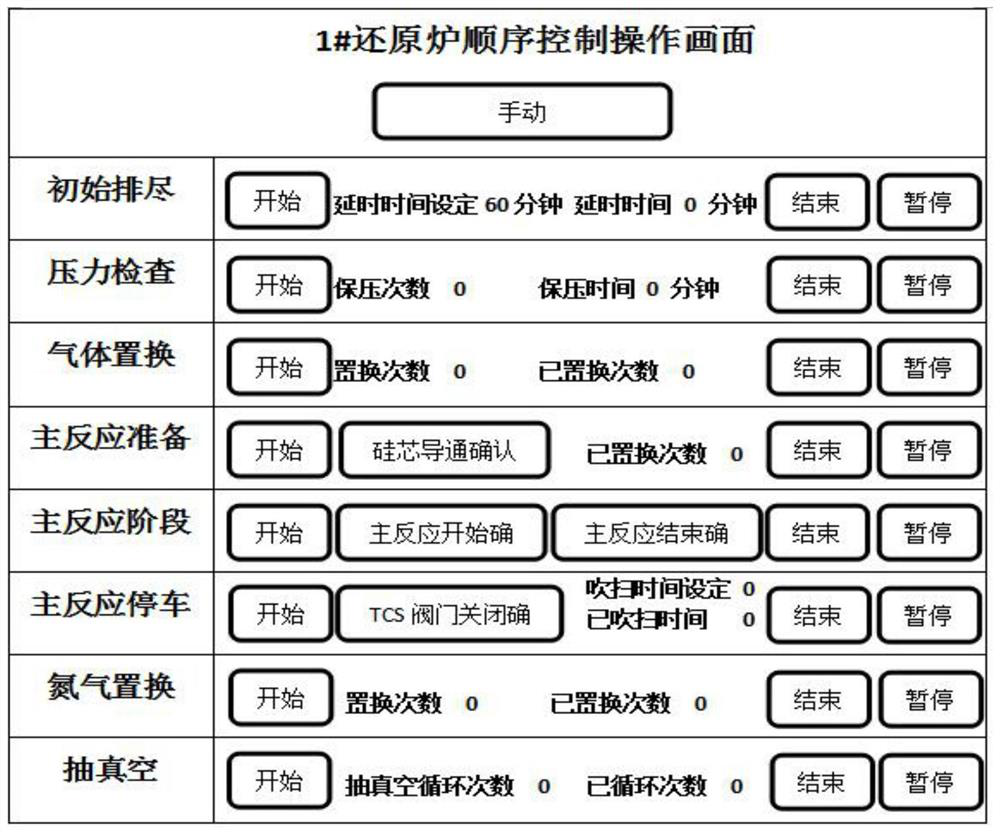

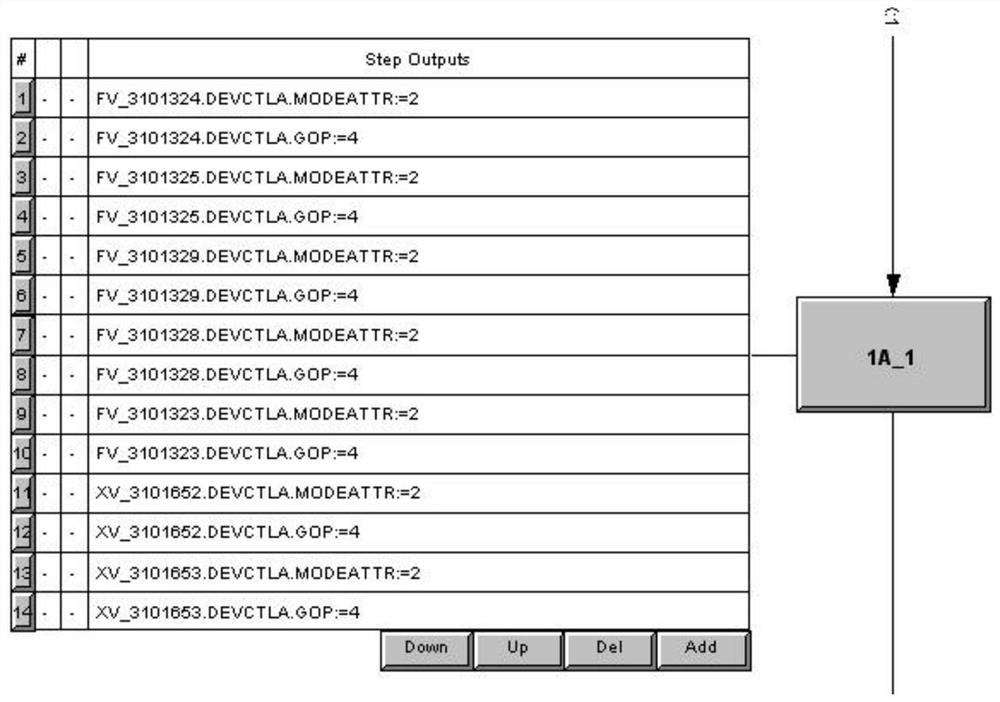

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0026] refer to Figure 1-10 , based on the reduction furnace sequence control method of the DCS system of the polysilicon production device, the specific program operation steps are:

[0027] S1, the initial cleaning sequence control program: the program automatically opens the relevant valves to evacuate to the specified pressure, within the specified time, the specified pressure remains unchanged or does not drop, the program automatically runs the next step or is operated by the operator;

[0028] S2, pressure check sequence control program: the program automatically opens the relevant valve to pressurize to the specified pressure, within the specified time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com