Internal wireless self-cooled continuous automatic temperature measurement method in coke oven and spectrogram device thereof

A coke oven and self-cooling technology, applied in measuring devices, furnace safety devices, coke ovens, etc., can solve problems such as frequent failures, deformation, deterioration and damage of thermometers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

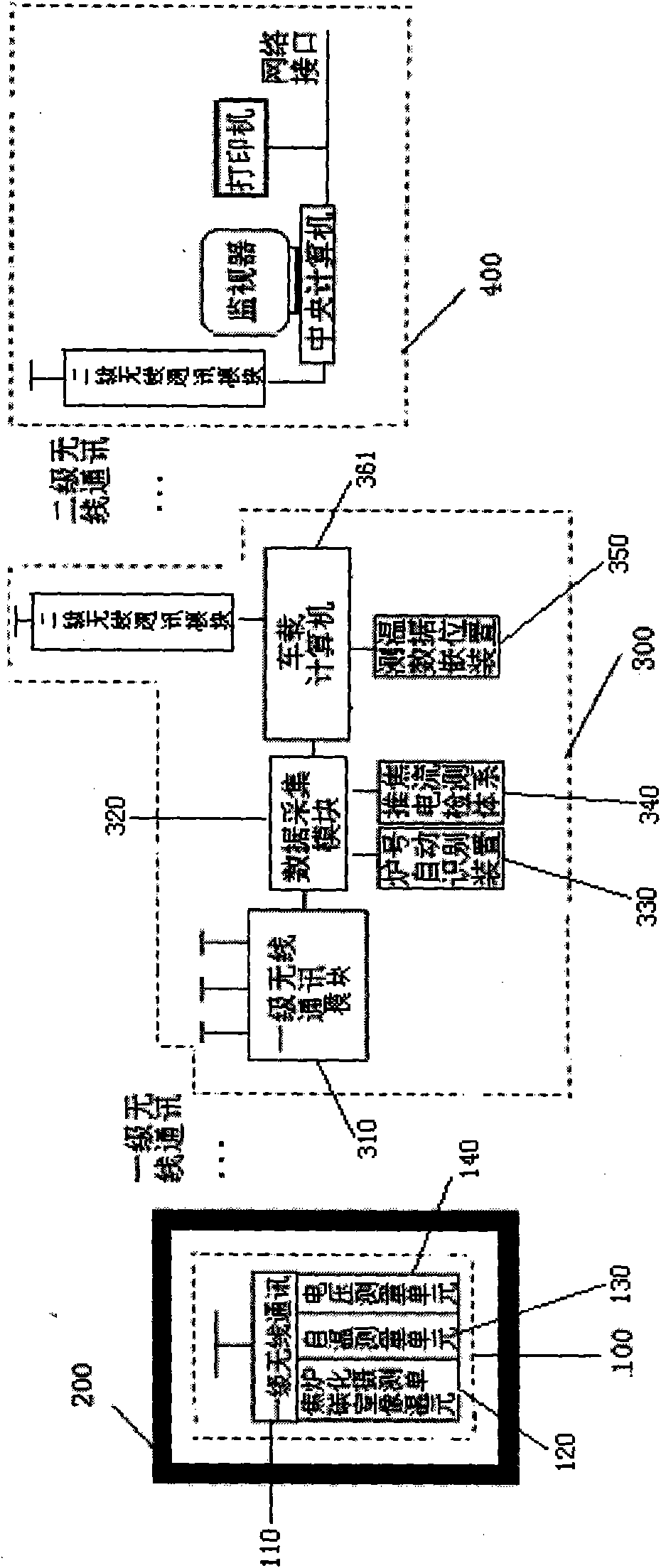

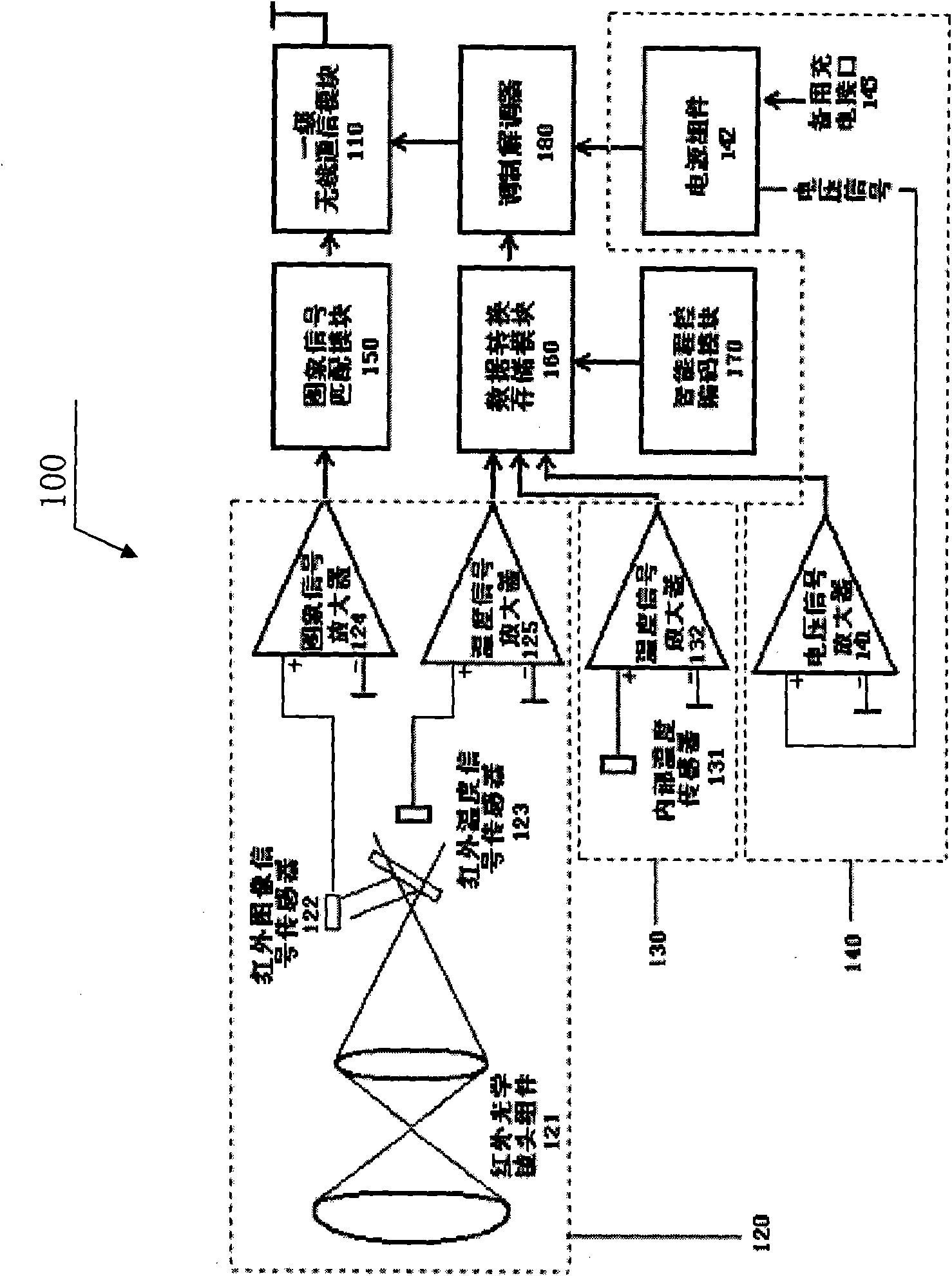

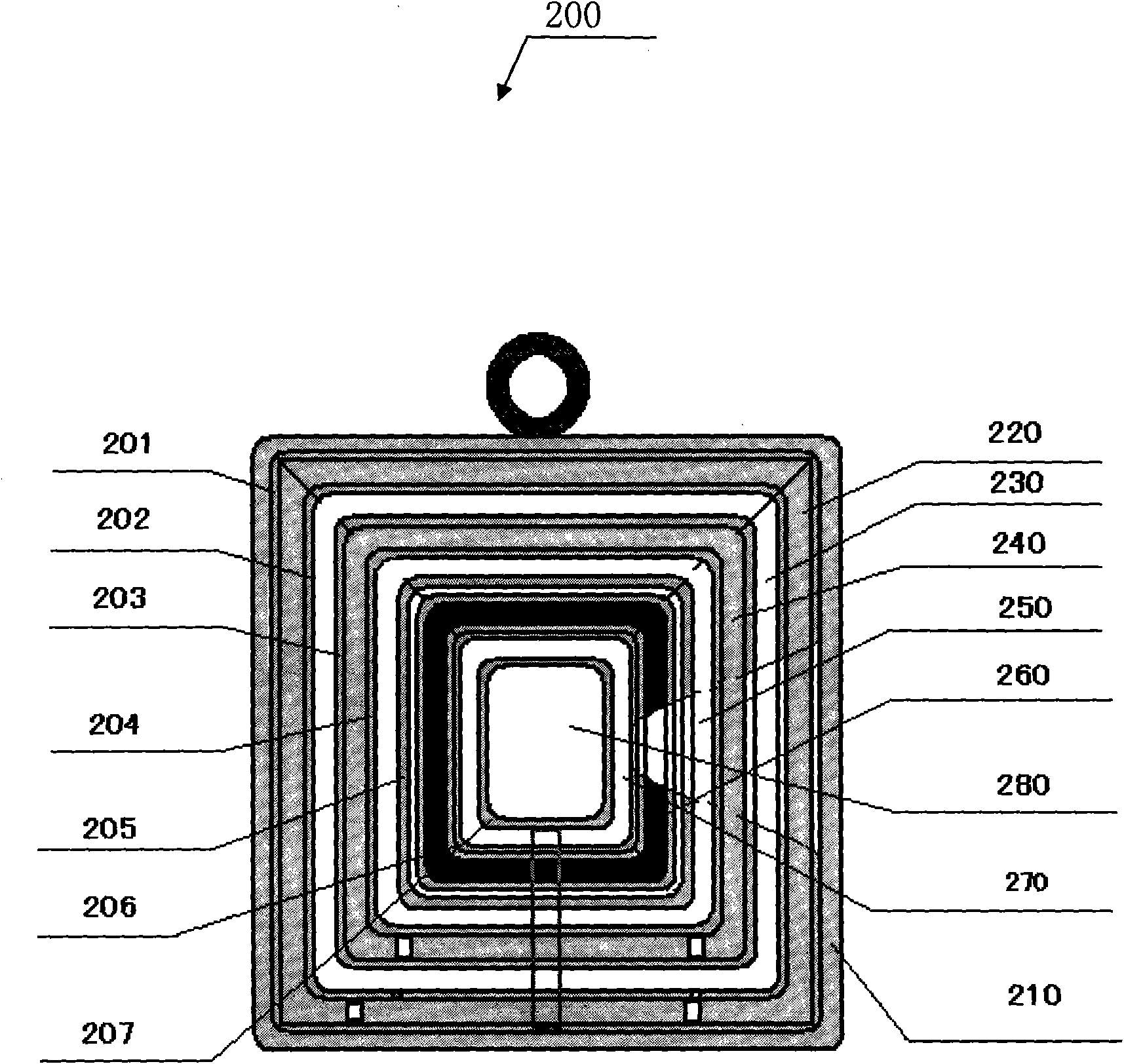

[0144] Such as Figure 1 to Figure 10 A wireless self-cooling continuous automatic temperature measurement method inside a coke oven and a spectrogram recording device are shown. See figure 1 As shown, the device includes: three intelligent wireless data acquisition and transmission devices 100, three bionic anti-high temperature protection devices 200, a vehicle-mounted computer workstation 300, and a base central computer workstation 400.

[0145] A bionic anti-high temperature protection device 200 is provided outside each of the smart wireless data acquisition and transmission devices 100;

[0146] Said set of three intelligent wireless data acquisition and transmission devices 100 are respectively connected with three first-level wireless communication modules 310 on the vehicle-mounted computer workstation 300 through the first-level wireless communication module 110 thereon to transmit information;

[0147] Said vehicle-mounted computer workstation 300 communicates with a s...

Embodiment 2

[0368] See Picture 11 As shown, this embodiment is based on the device structure and method of the first embodiment, using three intelligent wireless data acquisition and transmission devices 100, a bionic anti-high temperature protection device 200, a vehicle-mounted computer workstation 300, and a base central computer workstation 400. The internal structure and data signal transmission mode of the three intelligent wireless data acquisition and transmission devices 100, a bionic anti-high temperature protection device 200, an on-board computer workstation 300, and a base central computer workstation 400 are basically the same as those in the first embodiment.

[0369] In this embodiment, tin is filled into the filling heat storage layer 240 in the bionic anti-high temperature protection device 200. The effective volume (referring to the net added volume) of the liquid nitrogen container 260 in the bionic anti-high temperature protection device 200 is 10 liters, and the thermal...

Embodiment 3

[0373] See Picture 12 As shown, this embodiment is based on the device structure and method of the first embodiment, using six intelligent wireless data acquisition and transmission devices 100, six bionic anti-high temperature protection devices 200, two vehicle-mounted computer workstations 300, and a base center Computer workstation 400. The internal structure and signal transmission method of an intelligent wireless data acquisition and transmission device 100, a bionic anti-high temperature protection device 200, an on-board computer workstation 300, and a base central computer workstation 400 are basically the same as those in the first embodiment. A bionic anti-high temperature protection device 200 contains one said intelligent wireless data acquisition and transmission device 100, and three said bionic anti-high temperature protection devices 200 are connected to one said vehicle-mounted computer workstation 300. In this way, six bionic anti-high temperature protection d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com